Machine tool with a workpiece table

A technology of workpiece table and machine tool, which is applied in the direction of metal processing machinery parts, manufacturing tools, metal processing equipment, etc., and can solve the problems of limited application possibilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

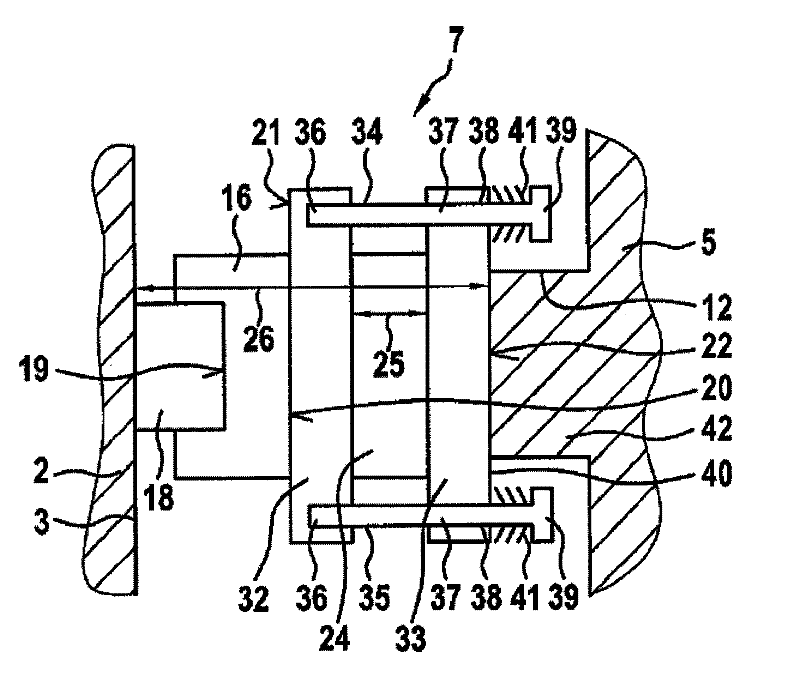

[0026] figure 1 Shows—in schematic form—the parts of a machine tool 1 with a machine frame 2. The frame 2 has a vertical wall 3, and the workpiece table 5 is set on the vertical wall by means of a holding device 4. The holding device 4 has holding elements 6, 7 which are placed at a distance from each other and which—with respect to the vertical direction of the vertical wall 3 (arrow 8)—are positioned at positions 9, 10 of different heights. The workpiece table 5 is held on the machine frame 2 by means of two holding elements 6 and 7.

[0027] in figure 1 In an exemplary embodiment, the workpiece table 5 is realized as a rigid table 11. It has a vertically extending rear side wall 12, and has a table surface 13 extending transversely with respect to the rear side wall 12, especially at a right angle, and the table surface is used to receive an unshown workpiece or an unshown workpiece tray. As you can from figure 1 It can be seen that the workpiece table 5 is held on the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com