Full-automatic underwater welding method

An underwater welding and automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high labor input cost, harsh working environment, less than 1 hour, etc., to improve drainage effect and ensure welding. quality, the effect of increasing the protective field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

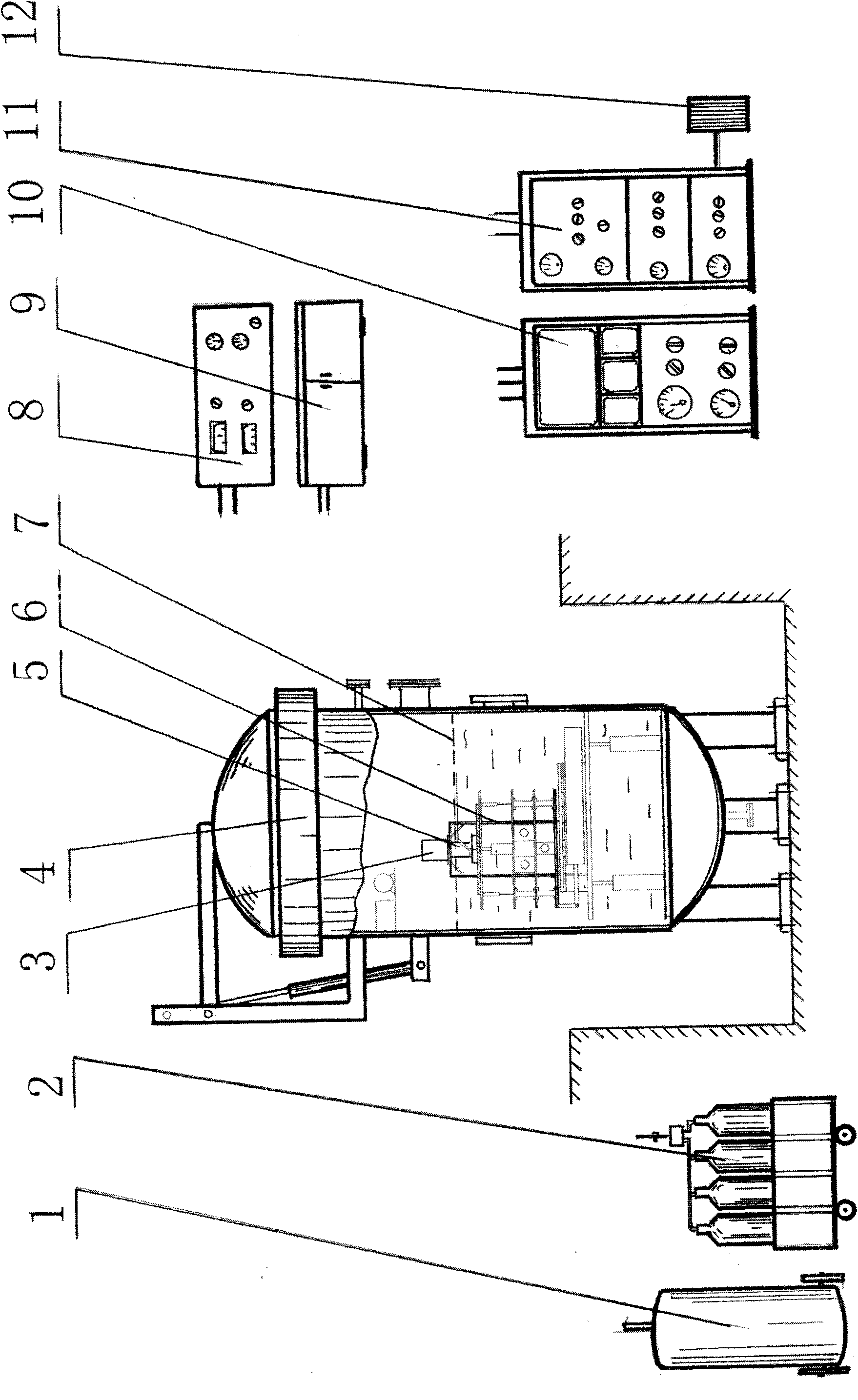

[0036] Depend on figure 1 It can be seen that the fully automatic underwater welding equipment mainly includes air compressor 1, gas cylinder 2, welding camera 3, welding test cabin 4, drainage device 5, hydraulically driven automatic welding platform 6, water surface 7, welding analyzer 8, and welding power supply 9 , monitoring TV cabinet 10, control system cabinet 11 and hand control box 12, wherein: the interior of the underwater welding test cabin 4 is filled with water to the water surface 7, the welding camera 3, the drainage device 5 and the hydraulically driven automatic welding platform 6 are installed in the underwater welding test In the cabin 4, the drainage device 5 is fixed in the middle of a shelf plate that is stationary relative to the welding test cabin 4. The welding torch is located in the center of the drainage device 5. The two sides of the shelf plate are bolted and quick-opening structures. The air compressor 1 and the gas cylinder 2. Welding analyzer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com