Arrangement and method for blanket gas supply control for an electrical welding apparatus

A technology of shielding gas and electric welding machine, which is used in arc welding equipment, manufacturing tools, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the invention will be explained in more detail by means of advantageous embodiments.

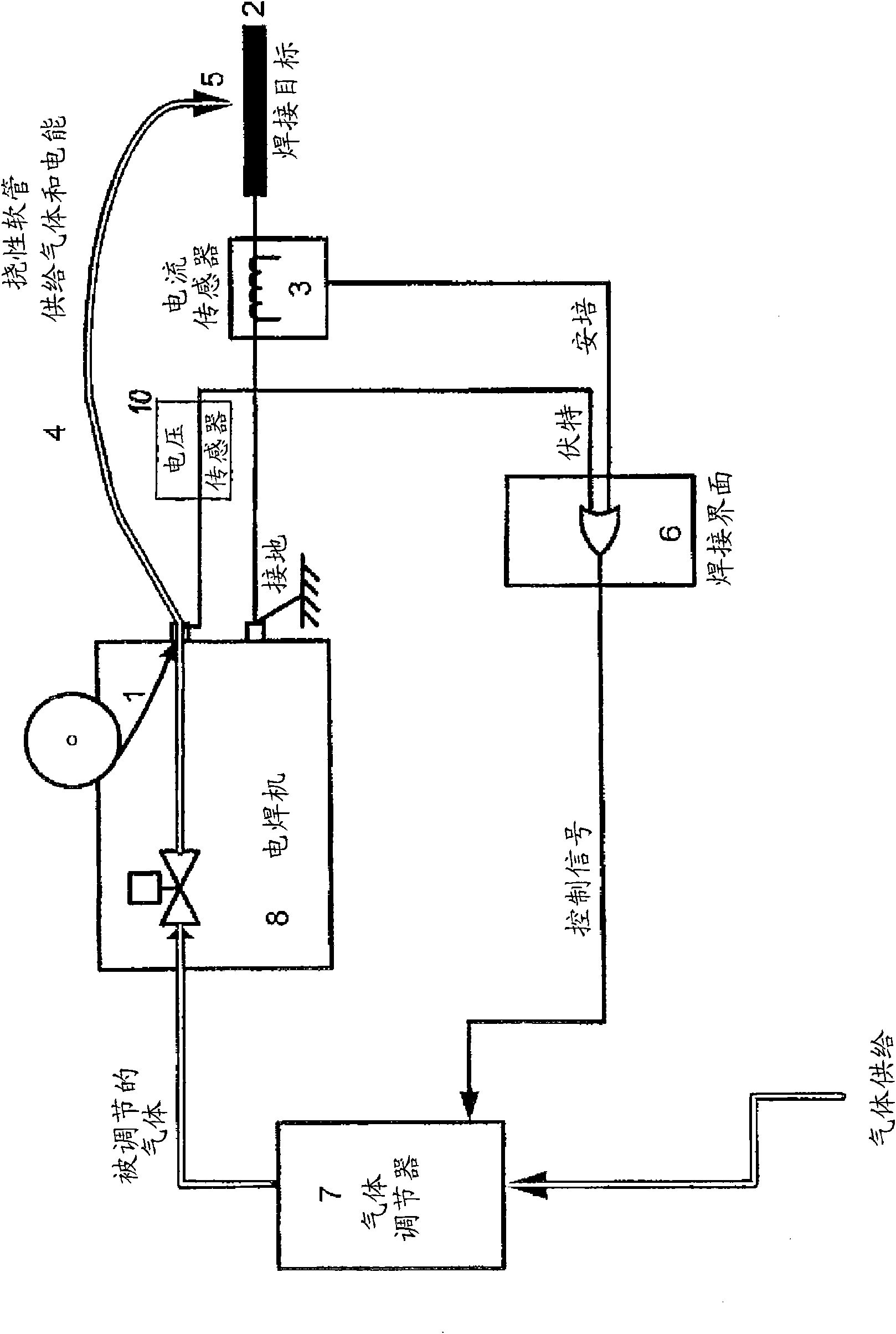

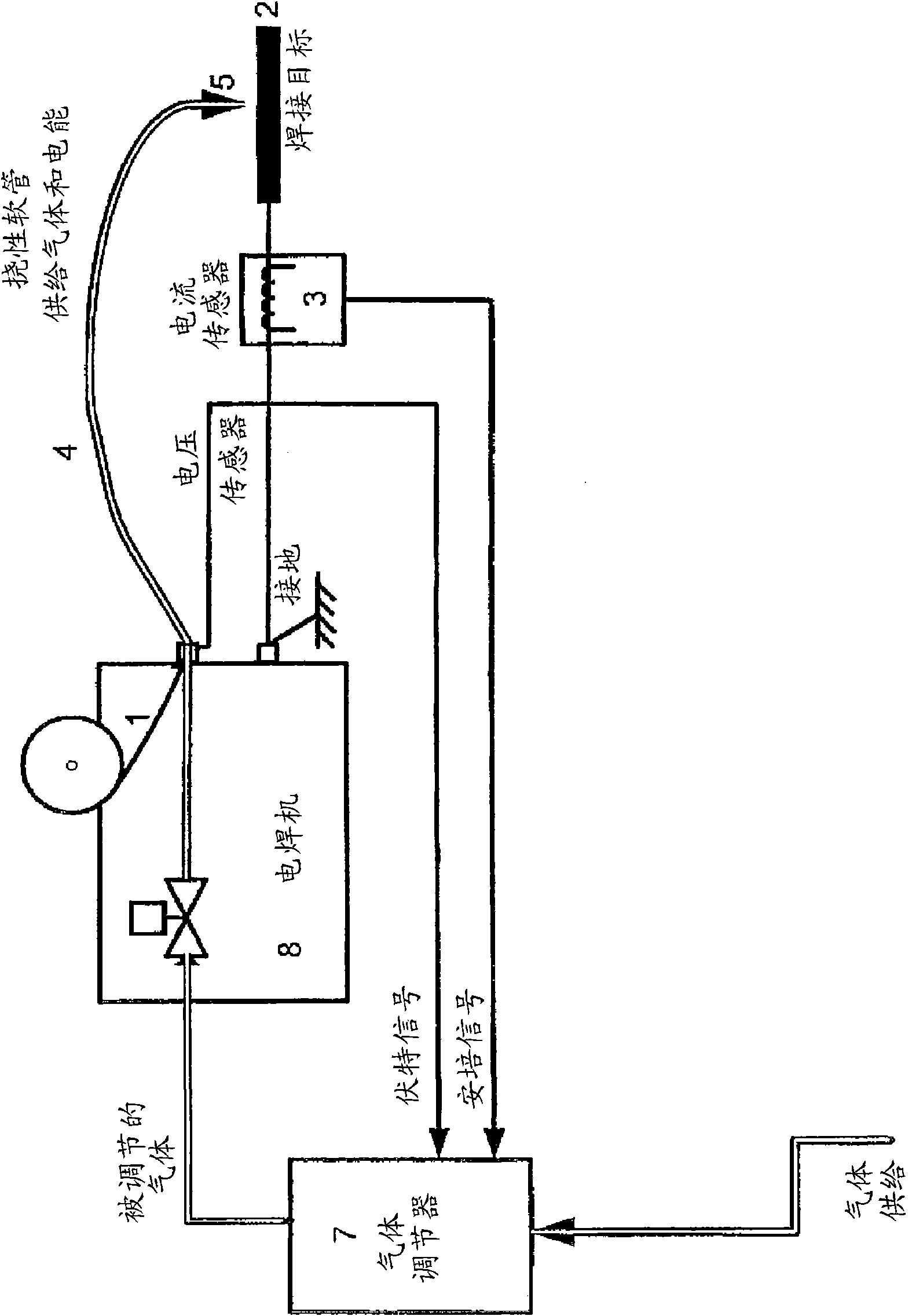

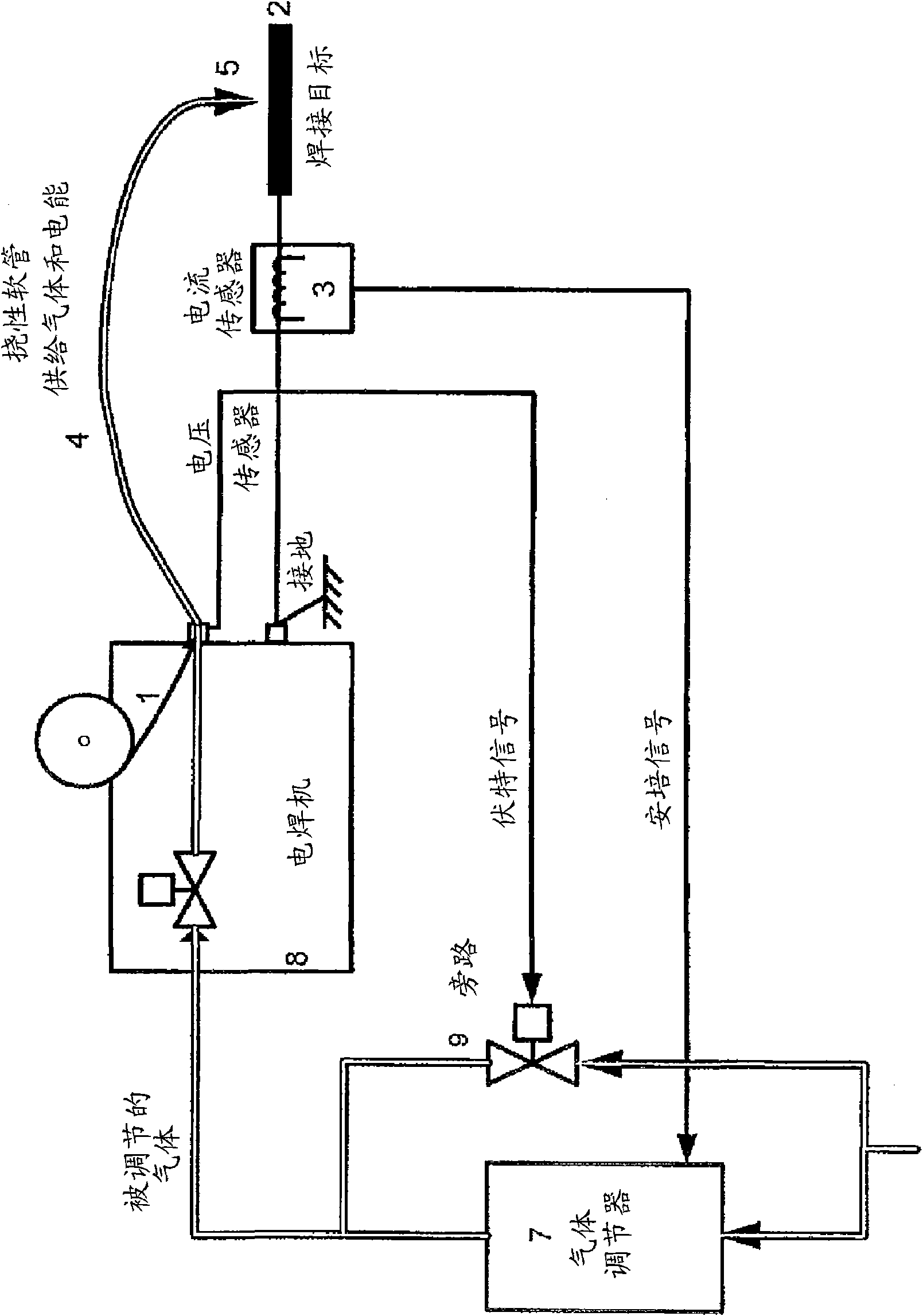

[0018] figure 1 A first embodiment of the invention is shown in which a gas regulator 7 incorporated into the shielding gas supply line of an electric welding machine 8 is adapted to regulate the output flow of shielding gas in response to the Control signal, the control signal comes from a voltage signal and a current signal, the voltage signal is provided by a voltage sensor arranged to detect the voltage supply from the welding machine 8 to the electrode 5, and the current signal (ampere) is arranged to be detected in the welding current path The current sensor 3 of the current supplies, for example, the current in the conducting circuit of the welding machine 8 to the welding power source of the welding rod 5 or, preferably, the current in the power supply connection between the object 2 to be welded and the welding machine 8 . The welding interface 6 receives v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com