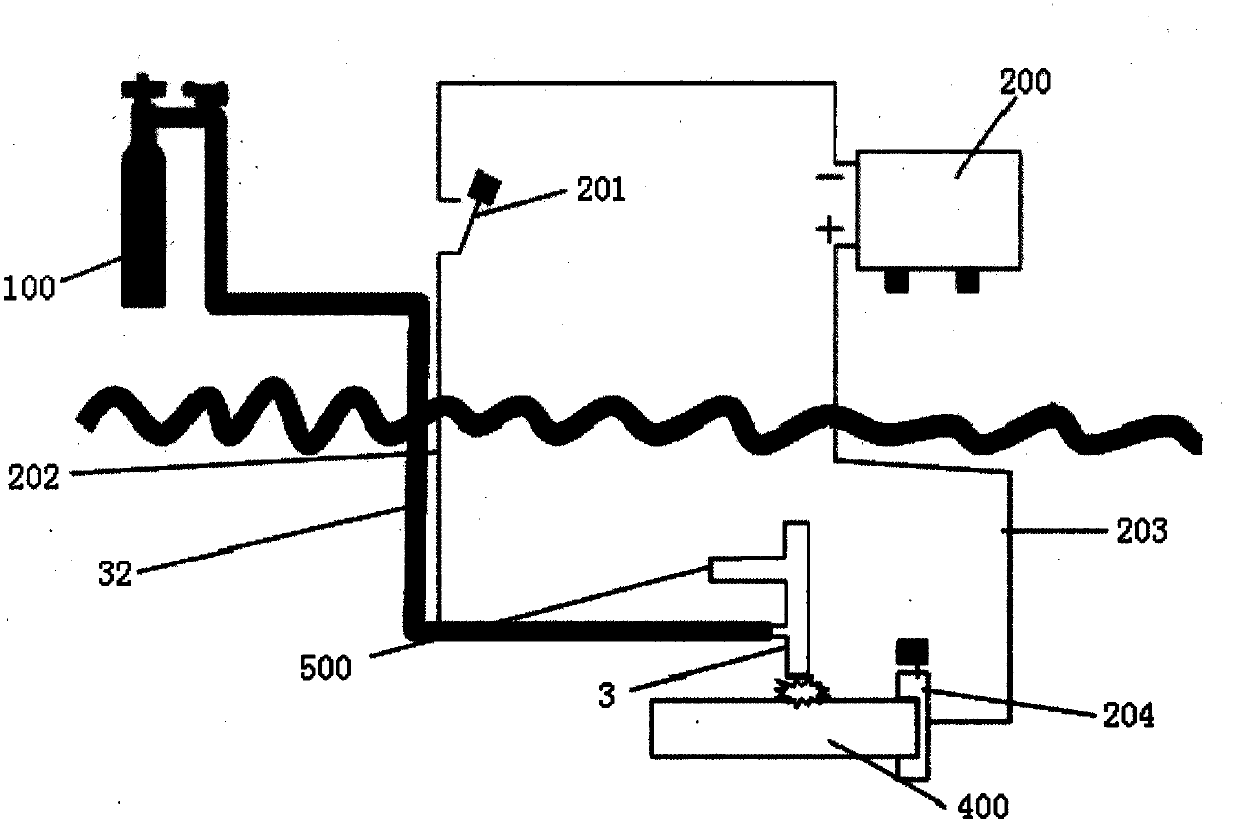

Underwater multifunctional stud welding device and welding method thereof

A welding device and multi-functional technology, applied in welding equipment, welding medium, welding equipment and other directions, can solve the problems that the repair quality cannot meet the strength requirements, the operation is difficult, the controllability is poor, etc. , the effect of short welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

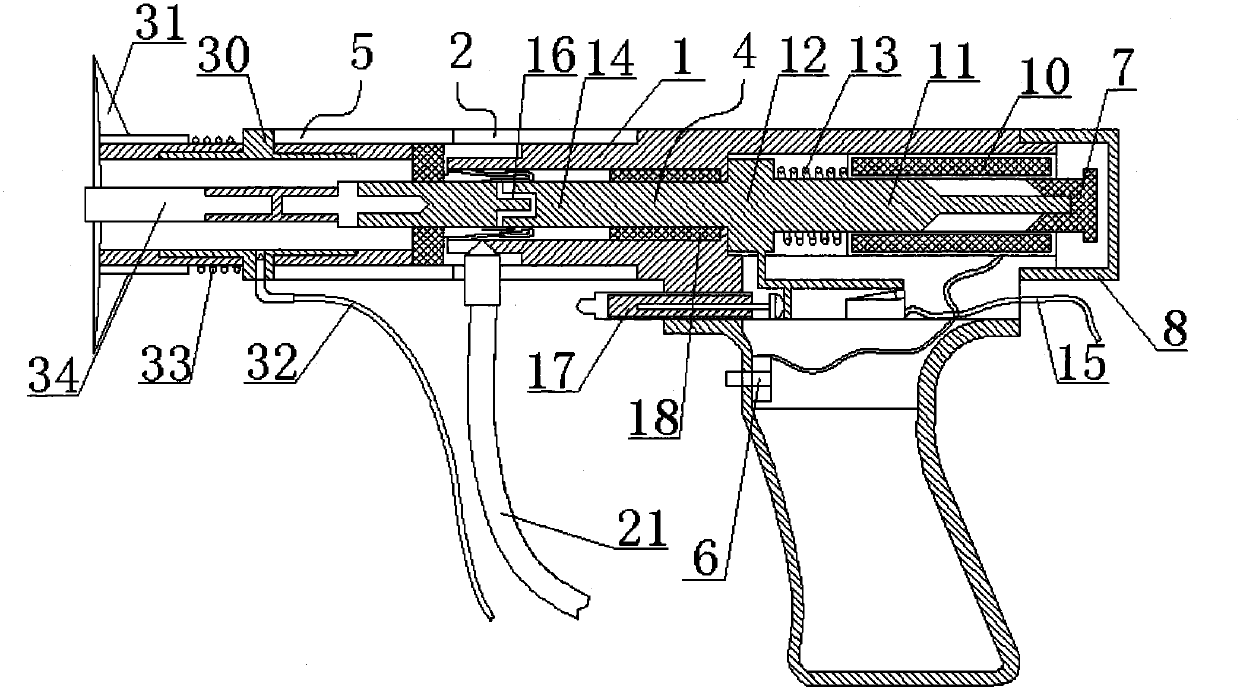

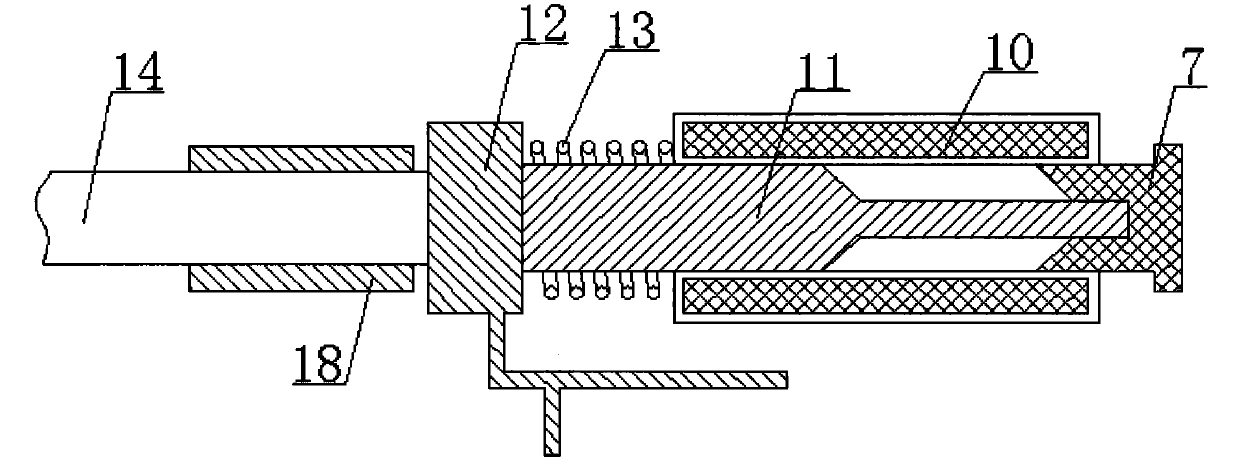

[0061] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0062] What needs to be explained here is that the orientation words left and right mentioned in the text are based on figure 2 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

[0063] Stud welding is a stud welding method in which the welding arc is used as the heat source, and it welds the stud to the workpiece, rather than arc welding with a covered electrode or other filler metal. Studs and similar fasteners themselves are both weldments and electrodes. The arc is ignited and burned between the end of the stud and the plate (metal plate, pipe), and the stud falls into the molten pool to pressurize. Forming welded joints is a high-speed arc joining method.

[0064] Different from land welding, underwater stud welding is difficult, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com