Crushing and excavation integral type backhoe loader

A backhoe loader and loader technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of difficult configuration of professional construction personnel, affecting the progress of the project, national losses, etc. , to achieve the effect of reducing the configuration of professionals, reducing one-time investment, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

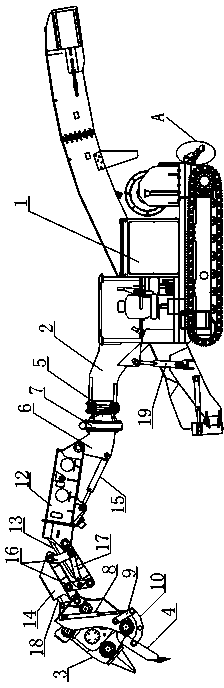

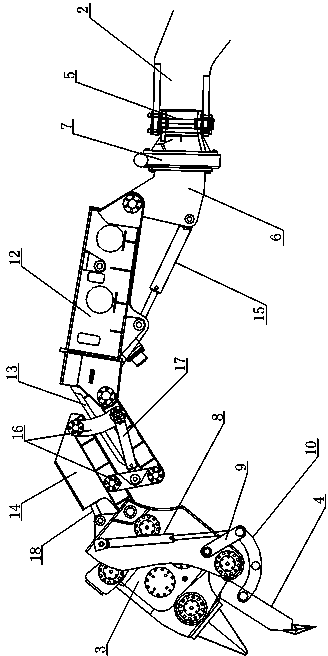

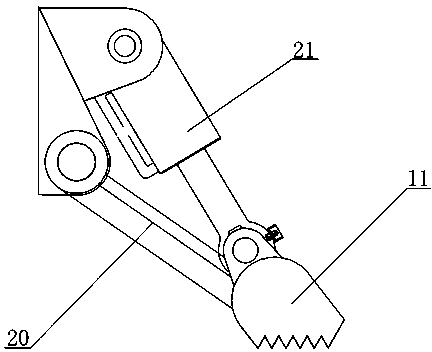

[0020] Such as Figure 1~4 As shown, the excavation-breaking integrated backhoe loader includes a backhoe loader host 1, and the backhoe loader host is provided with a slewing device connected to the backhoe loader host through a door frame 2, and the slewing device is far away from the backhoe loader. One end of the main engine is also connected with a telescopic device, and the end of the telescopic device away from the slewing device is also provided with a breaker 3; the breaker is also movably connected with a bucket 4; the slewing device includes a rotating arm connected with the mast 5. The boom seat 6 connected with the telescoping device, and the slewing support 7 connected with the boom seat and the rotating arm so that the boom seat can rotate 360° relative to the mast. Through the above settings, the present invention combines the mature backhoe loader technology and breaking hammer technology together. The backhoe loader has the advantages of high slag discharge e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com