Dust suppression system

A pipeline and softening device technology, applied in water/sludge/sewage treatment, use of liquid separation agent, descaling and water softening, etc., can solve the problems of secondary pollution of dust collectors, heavy maintenance workload, and large initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

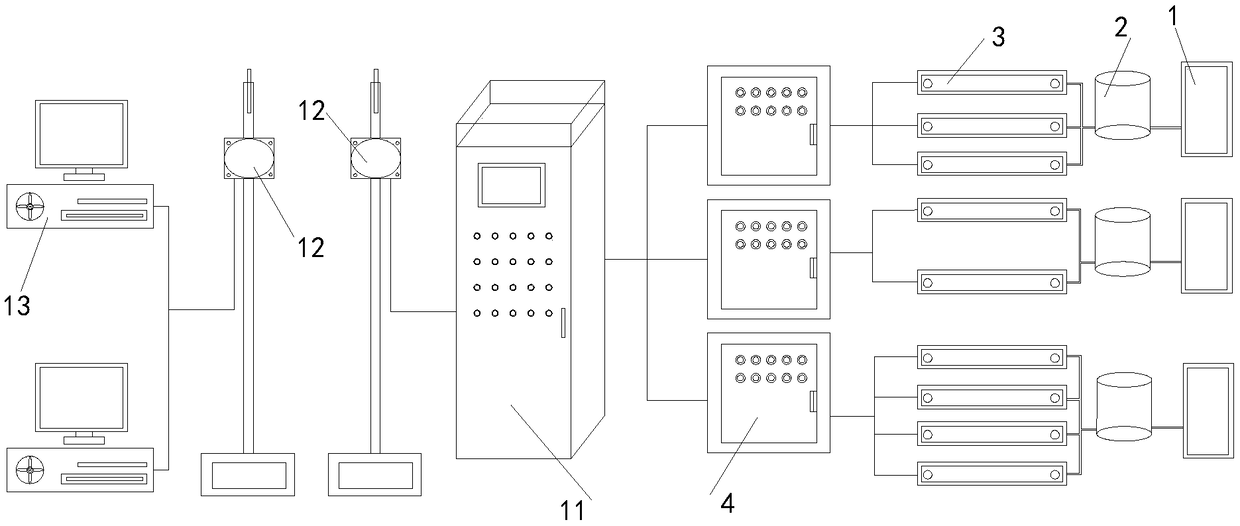

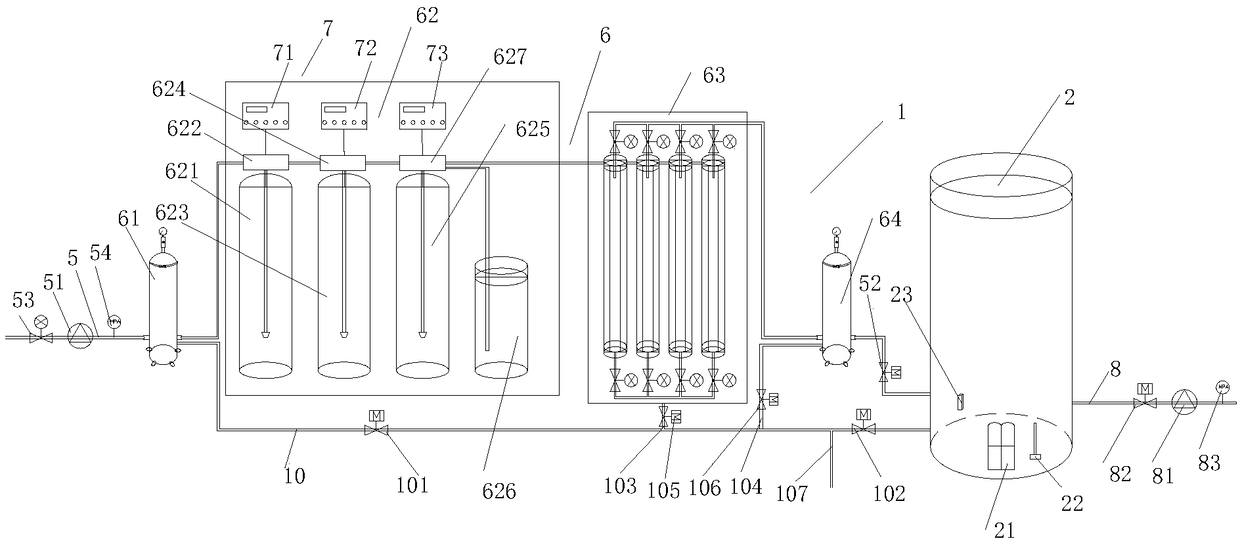

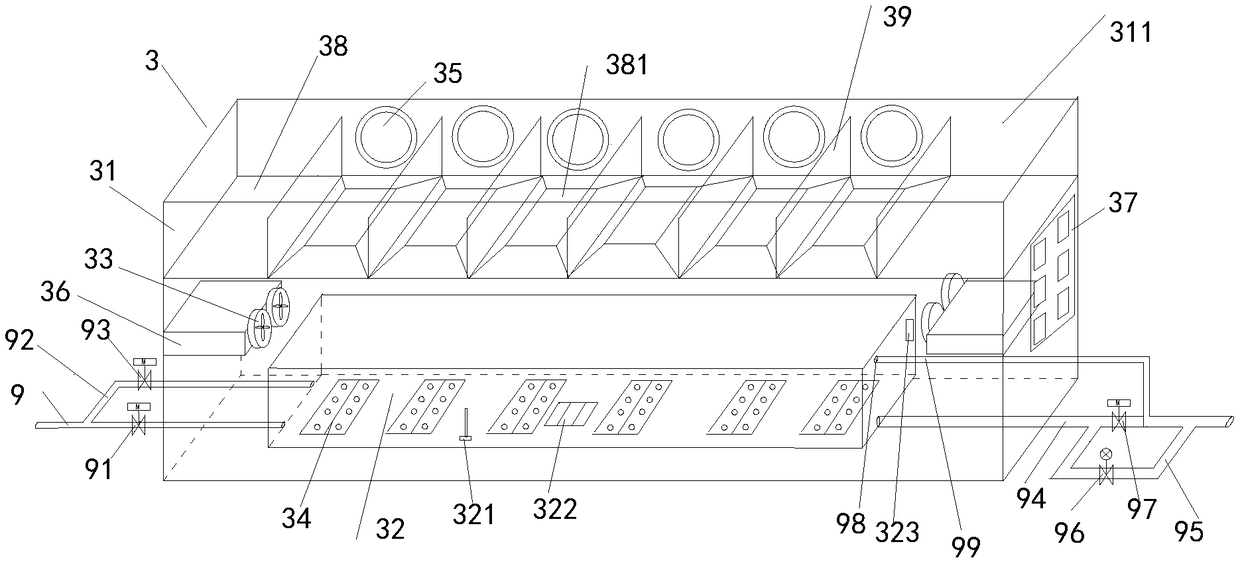

[0045] Embodiment 1. A dust suppression system. Combine below Figure 1 to Figure 3 The system provided in this embodiment will be described in detail.

[0046] see Figure 1 to Figure 3 , a dust suppression system provided in this embodiment, including a water filtering and softening device 1, a water storage tank 2, at least one dry fog dust suppression device 3 and a local controller 4; the water filtering and softening device 1 includes a tap water inlet pipe 5 , filtering and softening device 6 and filtering and softening device controller 7, the tap water inlet pipe 5 communicates with the side of the lower end of the water storage tank 2 through the filtering and softening device 6, the water inlet of the tap water inlet pipe 5 A tap water booster pump 51 is provided, a filtered water inlet solenoid valve 52 is provided on one end communicating with the water storage tank 2 , and a constant temperature water outlet pipe 8 communicates with the other side of the lower ...

Embodiment 2

[0072] Embodiment 2, a kind of dust suppressing method. Combine below Figure 1 to Figure 3 The method provided in this embodiment will be described in detail.

[0073] see Figure 1 to Figure 3 , a kind of dust suppression method that the present embodiment provides, described method comprises the following steps:

[0074] S1. When the water storage level gauge 23 detects that the height of the water in the water storage tank 2 is lower than the set lower limit value of the water storage tank water level, it sends a signal to the local controller 4, and the local control The device 4 controls the opening of the filtered water inlet solenoid valve 52, and at the same time controls the filter softening device controller 7 to start working, tap water enters the tap water inlet pipeline 5 passing through the filter softening device 6, and the filter softening device The device 6 filters and softens the tap water in the tap water inlet pipe 5 , and then automatically transports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com