Comprehensive mechanical rock drift excavating process

A comprehensive mechanization and rock roadway technology, applied in the direction of cutting machinery, slitting machinery, mining equipment, etc., can solve the problems of slow rock roadway excavation progress, construction workers' lung diseases, complex process and other problems, and achieve the goal of improving unit Improve the level, improve the development efficiency, and ensure the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Carry out the specific embodiment of the present invention in detail below in conjunction with accompanying drawing:

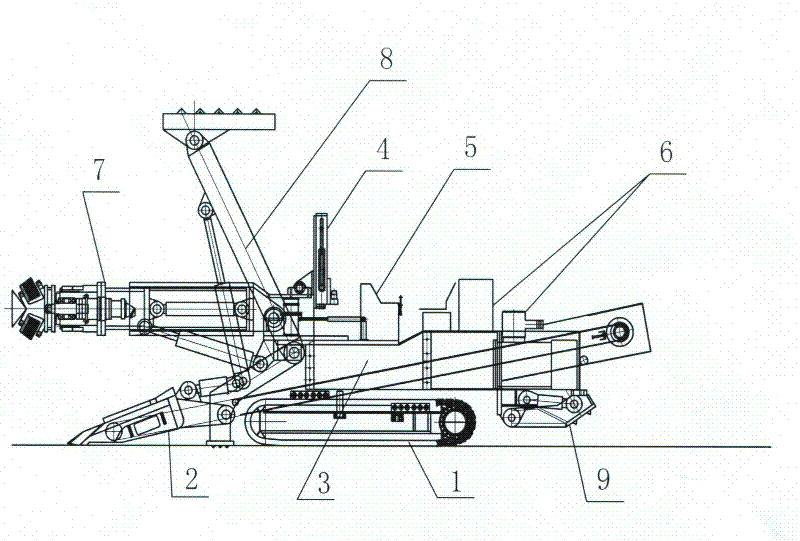

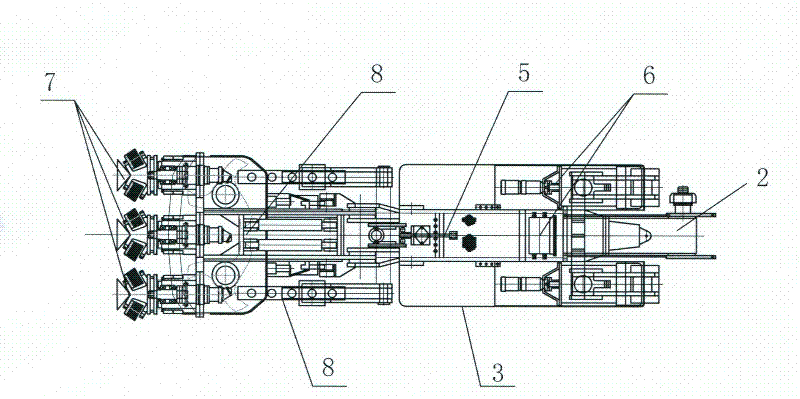

[0048] The comprehensive mechanized rock roadway excavation process of the present invention adopts the comprehensive mechanized rock roadway operation line, which is composed of a comprehensive mechanized rock roadway boring machine, a crawler-type movable belt conveyor and a crawler-type movable wet spraying machine; The mechanized rock roadway boring machine is used for excavation and support operations, and the crawler-type movable belt conveyor is used to transport rocks from the working face; the wet shotcrete machine is used to wet the roadway to seal the roadway.

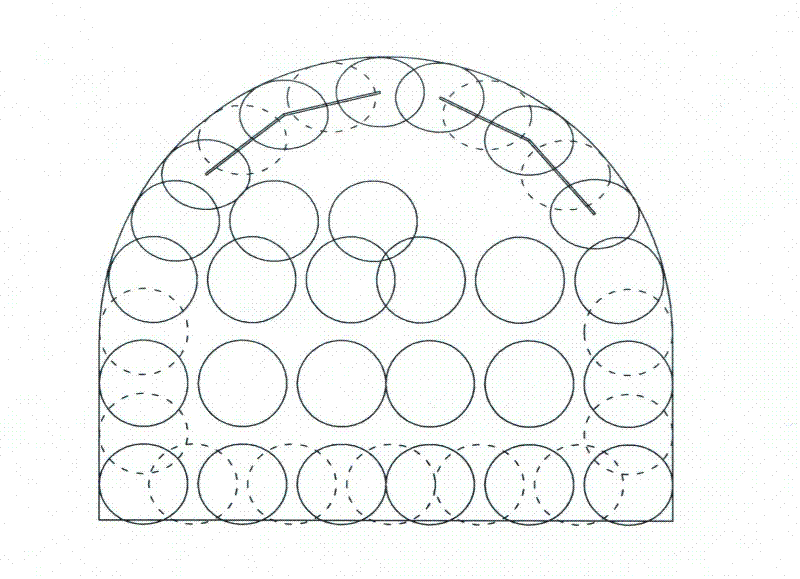

[0049] Such as figure 1 with figure 2 Shown, the comprehensive mechanization rock roadway boring machine that the present invention uses, the model that front part adorns three cutting cutter heads and swings up and down propelling device is the model of the embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com