Backfill mining method with stope rooms being arranged in centering and staggered mode

A staggered arrangement, filling mining technology, applied in filling, ground mining, mining equipment and other directions, can solve the problems of economic loss, no interconnection, hidden safety hazards in the production process, etc., to ensure normal operation, improve air quality, avoid excessive effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

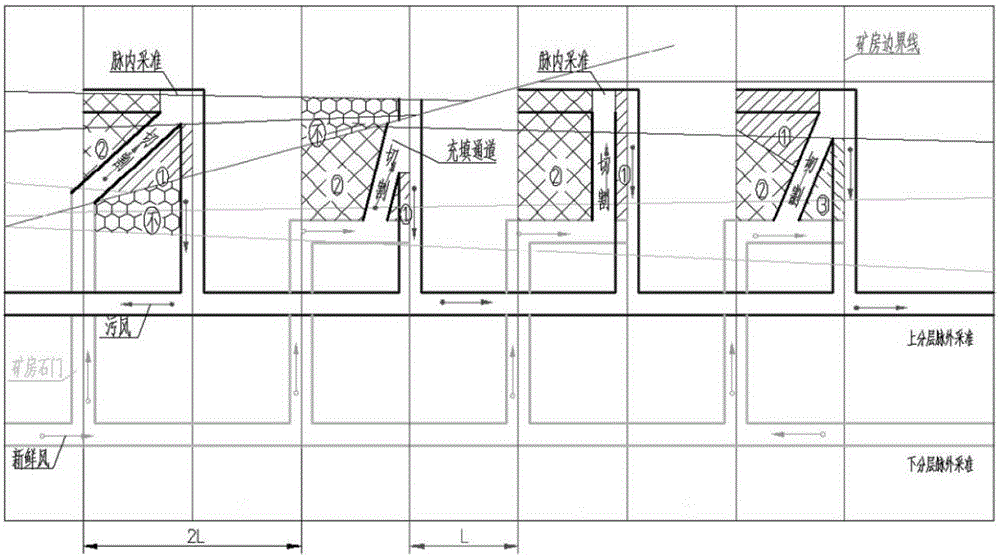

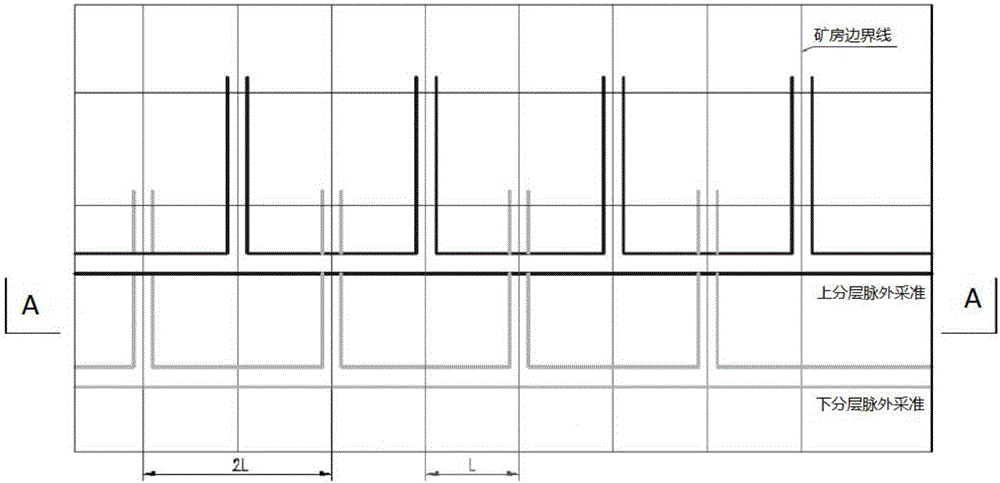

[0031] Such as Figure 1-9 As shown, a filling mining method in which the center of the mine room is arranged in a staggered manner comprises the following steps:

[0032] Step 1: Arrange development system, panel system and stratified entry road outside the vein in the vein mining area;

[0033] Here, the arrangement of the development system includes a ventilation system, a transportation system, and a drainage system, and the panel system is a panel slide shaft, a ramp, and a panel return air shaft.

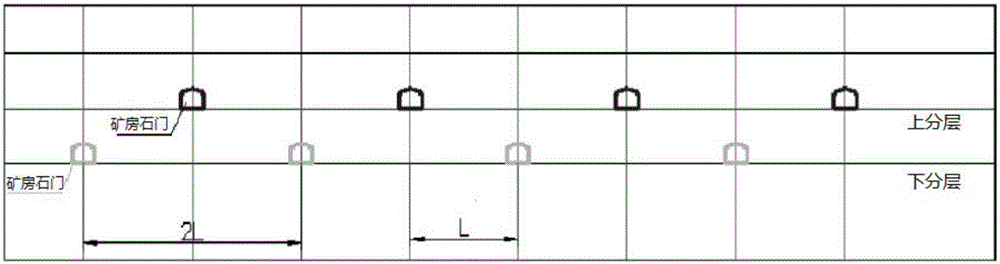

[0034] Step 2: Set the strike length of the mining house, delineate the boundary line of the mine house, set a mine stone gate at every interval twice the strike length of the mine house on the same layer, and set a mine gate between two adjacent mining layers. The stagger distance of the center line of Fangshimen is the strike l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com