Fixture for performing excircle finish turning on starter armature

A fixture and electromechanical technology, which is used in the field of fixtures for the outer circle finishing of the starter armature, can solve the problems of unguaranteed coaxiality of the secondary clamping, uncontrollable clamping by manual operation, and affecting the qualification rate of the armature. , to solve the magnetic pole interference in the armature and stator, prevent axial movement and rotation, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

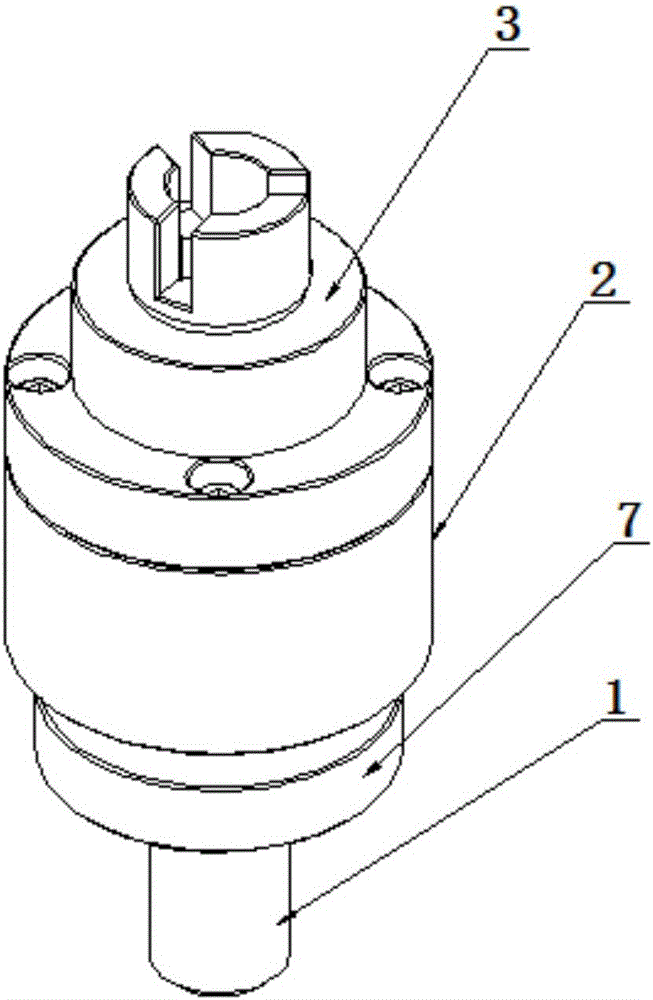

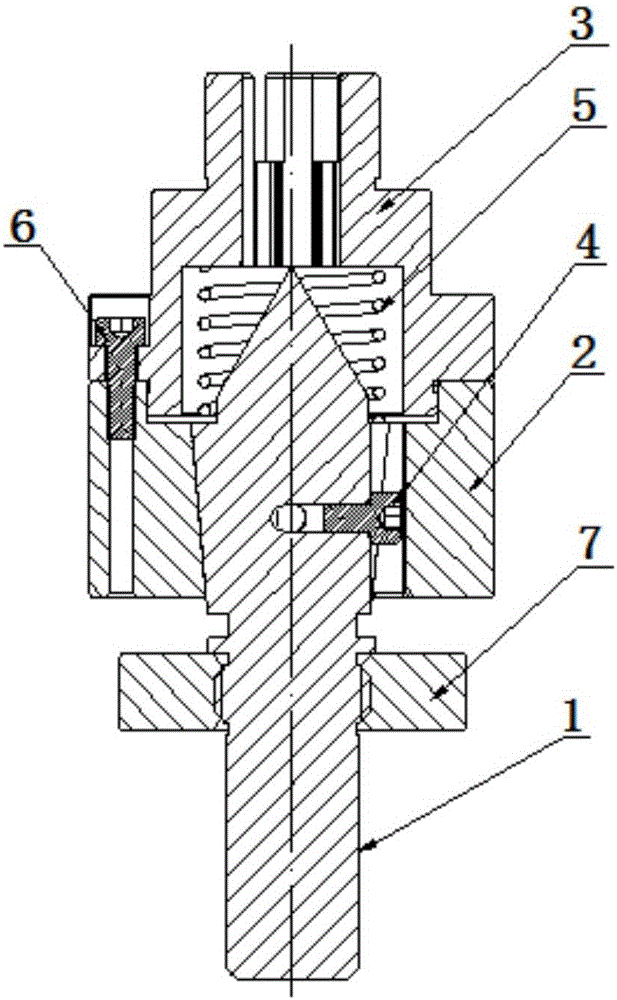

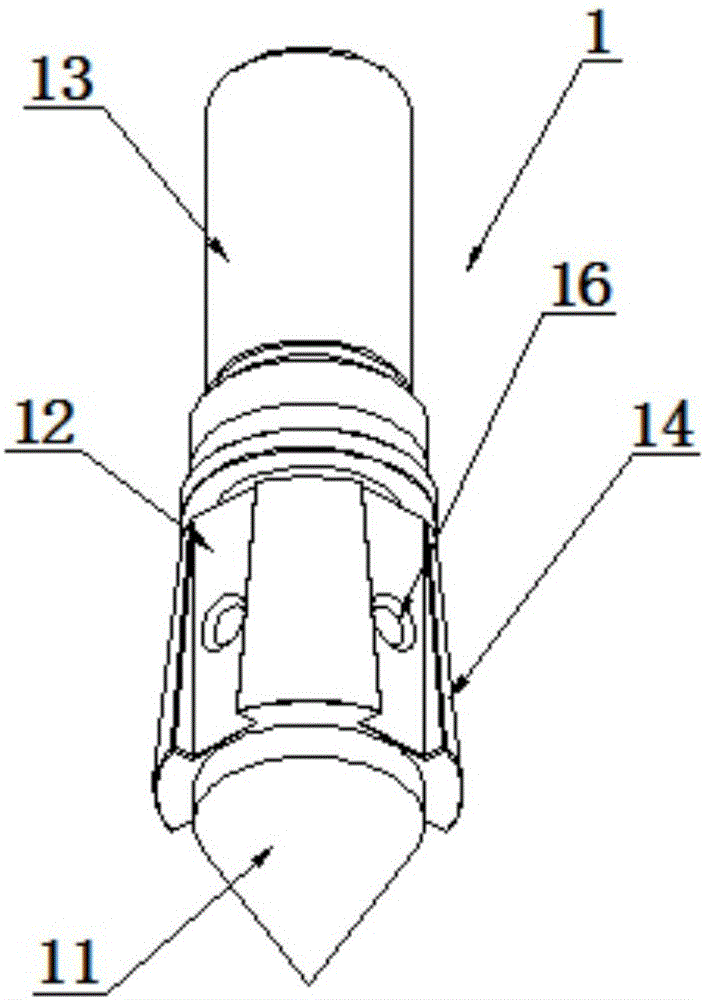

[0024] refer to Figure 1-8 , a jig for starter armature outer circle finish turning according to the present invention includes a top 1, which in turn includes a tip 11 at the top, an adjustment part 12 at the middle and a rod 13 at the tail, and the jig It also includes a central hole adjustment sleeve 2 sleeved on the adjustment part 12 and a hollow structure coarse positioning sleeve 3 installed coaxially with the central hole adjustment sleeve 2 and sleeved on the tip 11 of the tip 1. The inner cavity of the coarse positioning sleeve 3 There are clamping teeth 31 adapted to the starter armature, and the structure of the clamping teeth 31 is used to connect the armature and the fixture, which increases the contact area between the fixture and the armature, and prevents the armature from loosening during processing, which affects the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com