Cylindrical workpiece processing multipurpose tool

A multi-purpose, workpiece technology, used in metal processing equipment, drill dies for workpieces, metal processing machinery parts, etc., can solve problems such as difficulty in ensuring workpiece positioning accuracy, and unsatisfactory machining accuracy of round holes or planes on workpieces. , to achieve the effect of high utilization rate of tooling equipment, simple structure and ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

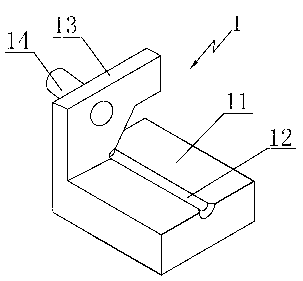

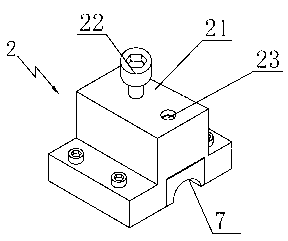

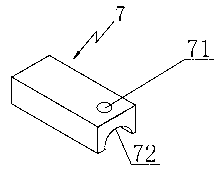

[0013] Such as figure 1 with Figure 4 As shown, the present invention comprises a base 1, a pressing block 2 and a drilling mold 3, the fixed plate 11 on the base 1 has a semicircular groove 12, and one end of the fixed plate 11 located at the semicircular groove 12 is provided with a positioning plate 13 , the positioning column 14 is vertically installed on the positioning plate 13, and the positioning column 14 is used to cooperate with the semicircular positioning groove on the workpiece 6 to prevent the workpiece 6 from rotating during processing; Boss 21 is provided with screw 22 and upper drill hole 23, and insert block 7 is arranged at the bottom of pressing block 2, and insert block 7 is provided with semicircular groove 72, and insert block 7 can be taken out, and workpiece can be carried out through upper drill hole 23. Drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com