Shaft coupling used between motor rotating shaft and spline connecting shaft

A technology of motor rotating shaft and connecting shaft, applied in rigid shaft couplings, couplings, electric components, etc., can solve the problems of easy sliding, small contact area, few fixed points, etc., to save production costs, expand The effect of versatility and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with specific embodiment:

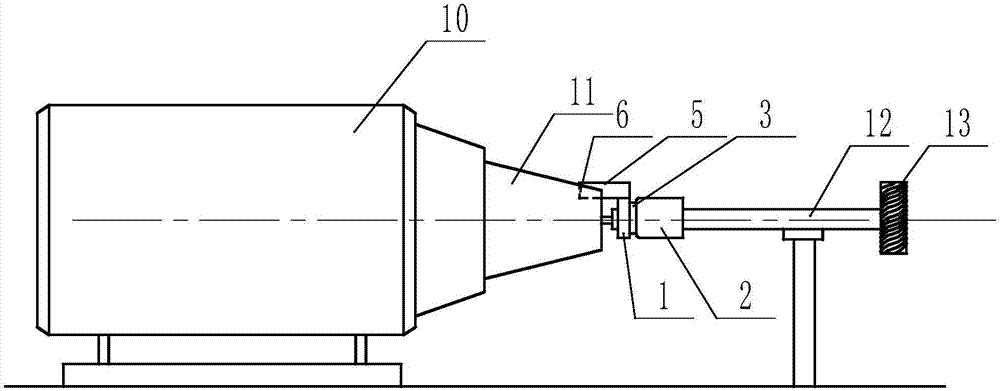

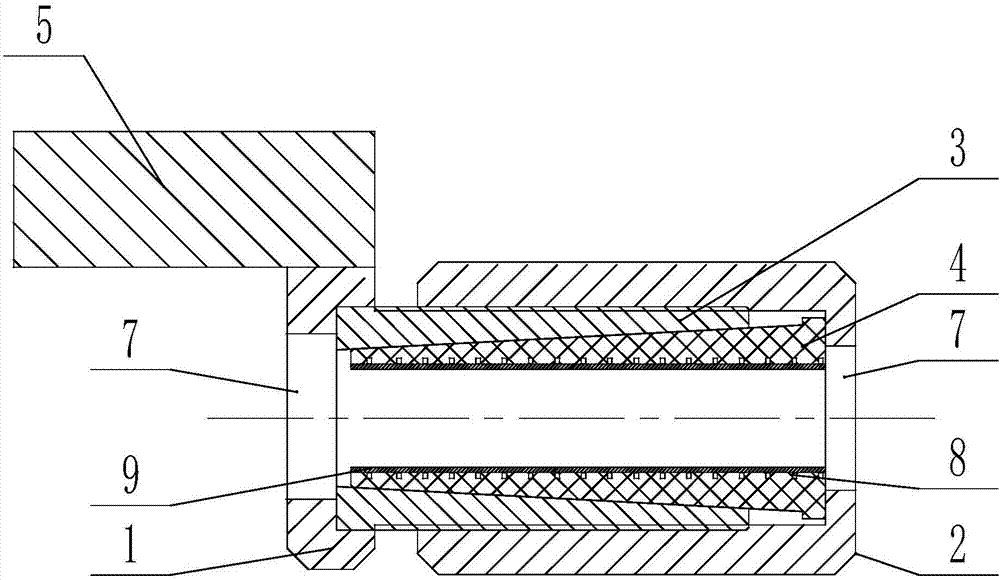

[0019] see figure 1 and figure 2 , a coupling used between the motor rotating shaft and the spline connection shaft, including a left sleeve 1, a right sleeve 2, a shaft sleeve 3 and a tapered sleeve 4, and the outer surface of the left sleeve 1 is welded with The positioning key 4 fixed along the axial direction, the positioning key 4 is clamped in the positioning groove 5 on the motor rotating shaft 11, the shaft sleeve 3 is connected with the left sleeve 1, and the inner side of the right sleeve 2 is provided with an internal thread, which is connected with the shaft sleeve 3 The external threads on the sleeve 3 are matched, the two ends of the shaft sleeve 3 are open, and the inner diameter of the opening at one end of the shaft sleeve 3 in contact with the left sleeve 1 is smaller than the inner diameter of the opening at the other end, forming a conical through hole. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com