Cutter fixing structure and cutter and cutter handle suitable for same

A fixed structure and cutting tool technology, applied in the field of machining cutting tools, can solve the problems of scrapped parts and affecting the machining accuracy of cutting tools, and achieve the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

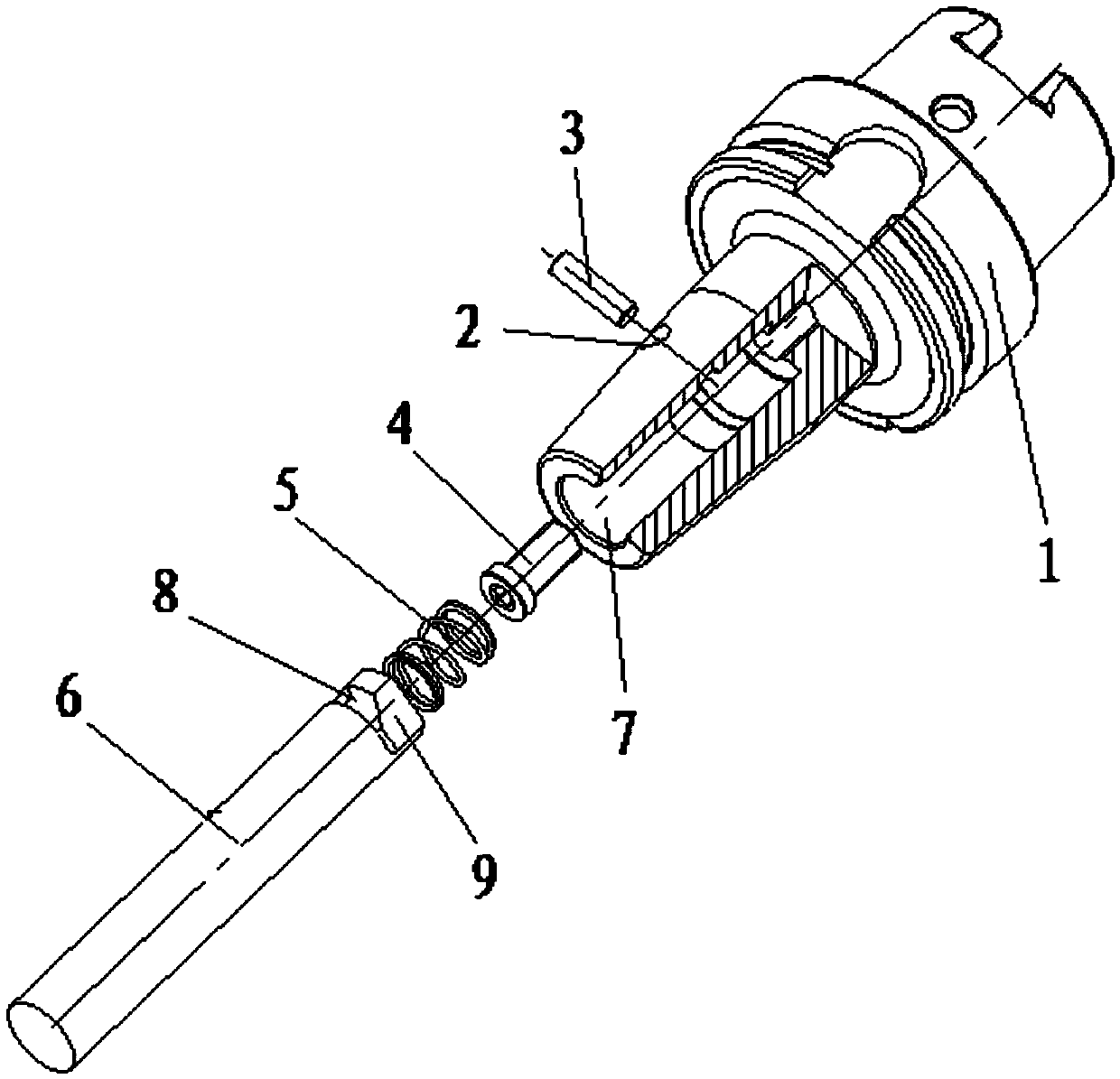

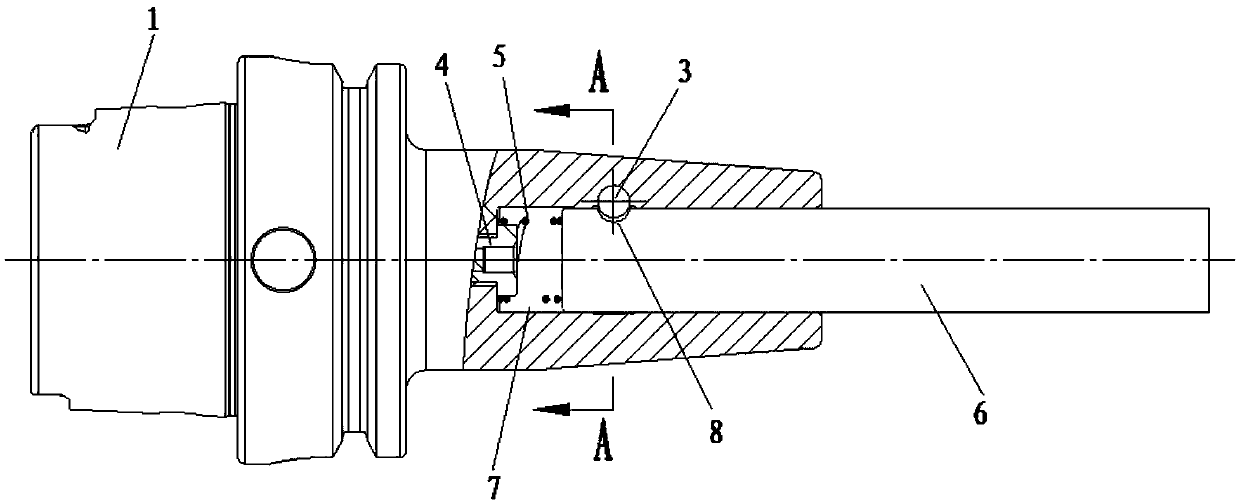

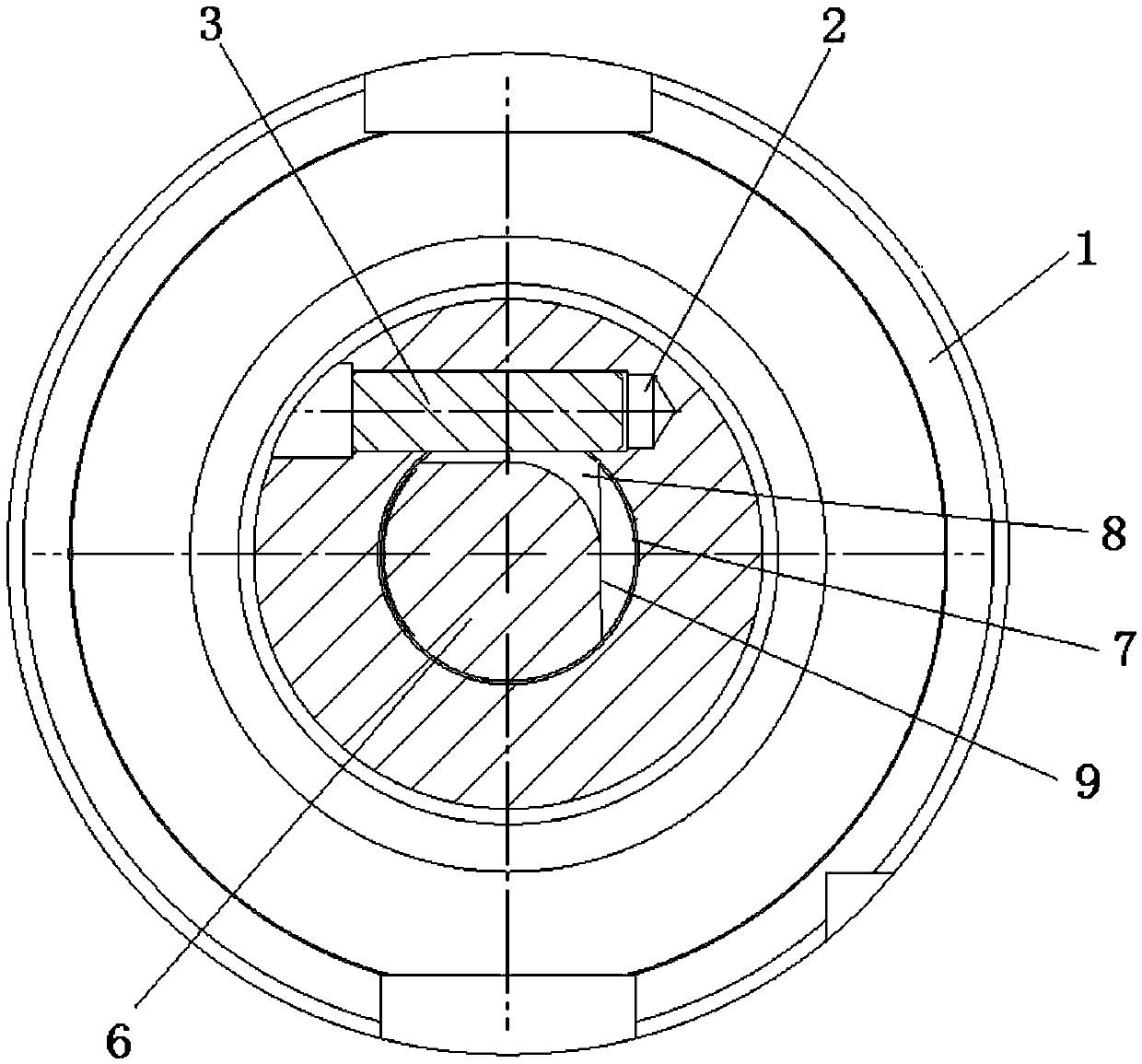

[0021] The knife fixing structure includes a knife handle 1 and a knife 6. The knife handle 1 is provided with a knife hole 7 extending inward from the end of the knife handle 1, the knife 6 is inserted into the knife hole 7, and the knife handle 1 holds the knife 6; it also includes a safety lock Pin 3; the handle 1 is provided with a lock pin hole 2 extending inward from the side of the handle 1; the cutter 6 is provided with a lock pin passage groove 8 and a knife retraction concave platform 9, and the knife retraction concave platform 9 is formed by the end surface of the cutter 6 Extend to the lock pin through the slot 8; the safety lock pin 3 is loaded into the lock pin hole 2 and inserted into the lock pin through the slot 8, the safety lock pin 3 restricts the axial movement of the tool 6; the handle 1 releases the clamping of the tool 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com