Polishing device for inner wall of tubular workpiece

A technique for polishing devices and workpieces, which is applied to machine tools suitable for grinding the edge of workpieces, machine tools for surface polishing, grinding/polishing equipment, etc., which can solve the problems of high manufacturing costs, attenuation of grinding force along the process, and uneven grinding shapes. Rules and other issues, to achieve the effect of simple structure, uniform distribution of grinding force, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

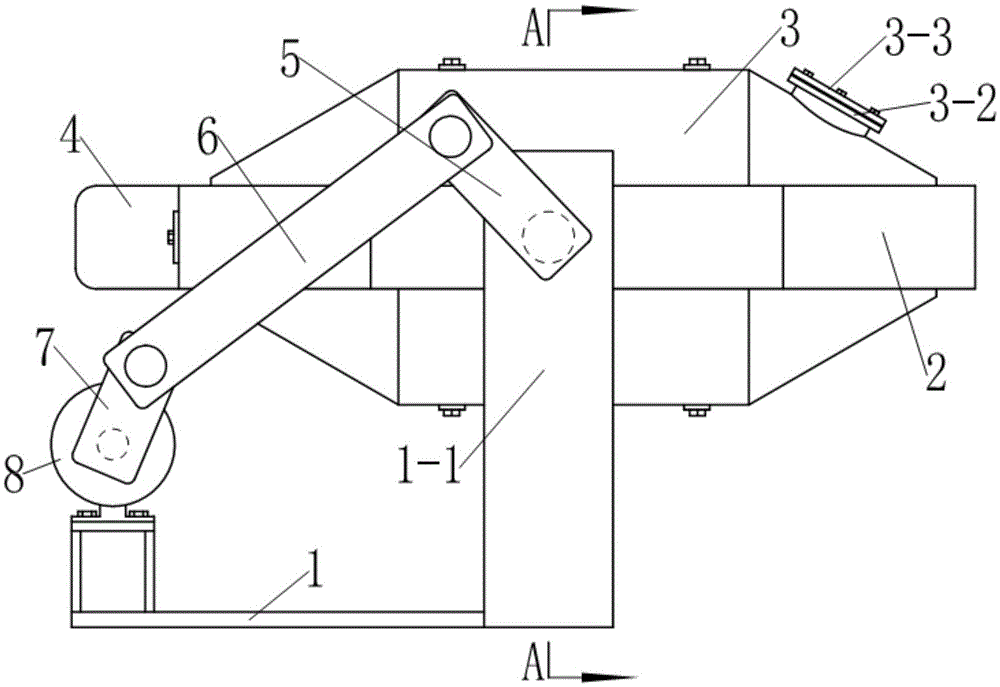

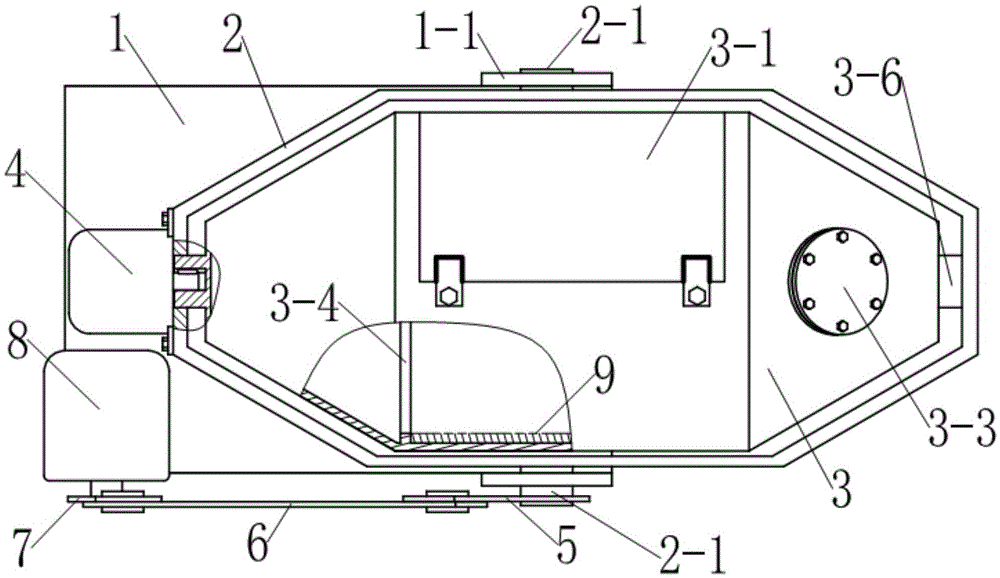

[0031] see figure 1 , the polishing device of the inner wall of the tubular workpiece includes a frame, a cylinder 3 and a crank rocker mechanism in this example;

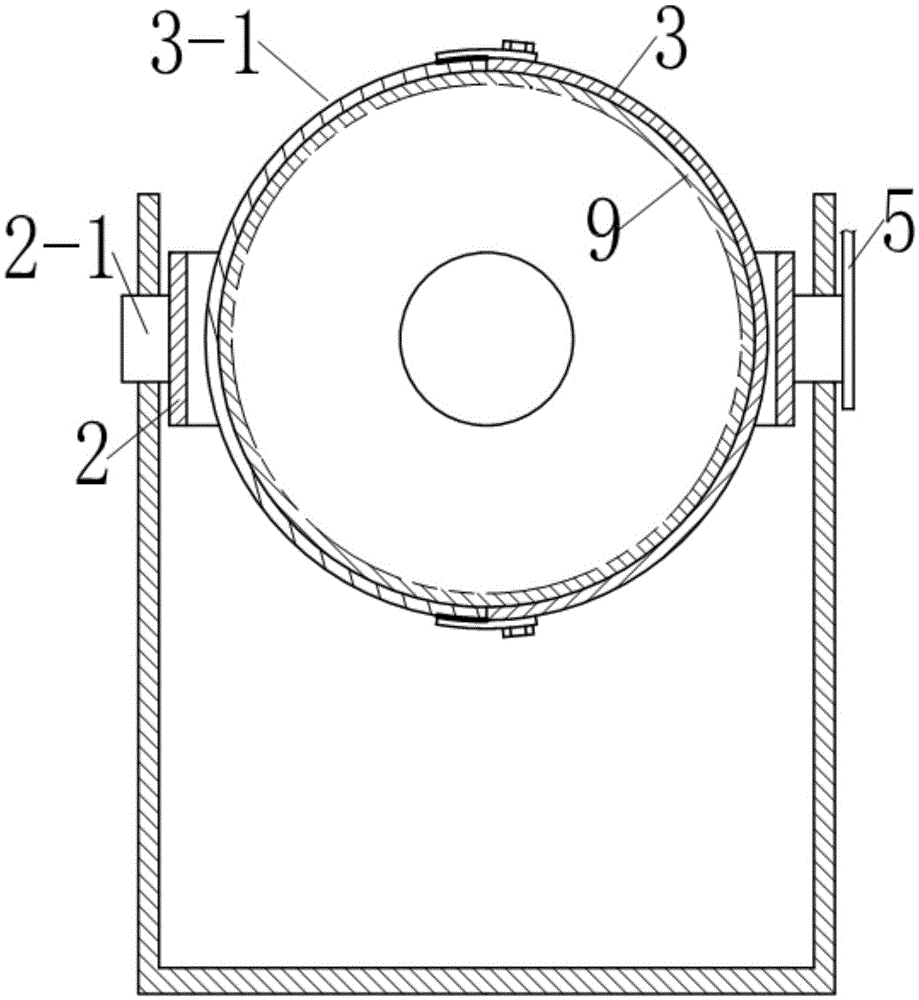

[0032] see Figure 1~3 , the frame is composed of a rectangular base 1 and a swing frame 2 arranged on the base 1, and a pillar 1-1 perpendicular to the upper surface of the base 1 is respectively provided on both sides of the base 1. The swing frame 2 is polygonal, and the middle part of the two sides of the polygon is vertically provided with a trunnion 2-1. 1 to form a hole shaft fit, the rotation center line of the trunnion 2-1 is parallel to the horizontal plane.

[0033] see Figure 4 , the middle part of the drum 3 is cylindrical, and the two ends are radially contracted to form a truncated cone with pointed ends facing outwards. The cylindrical middle part of the cylinder 3 is used for coaxial clamping of the tubular workpiece 9 to be processed. A clamping opening 3-5 for clamping workpieces is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com