Spinning purging device for inner wall of steel pipe

The utility model relates to a technology for the inner wall of a steel pipe and a spin-type technology, which is applied in the field of a spin-type purging device for the inner wall of a steel pipe, which can solve the problems of wasting energy, poor adaptability, and inability to achieve full inner pipe wall purging, and achieves a simple overall structure and a purging area. The effect of large and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

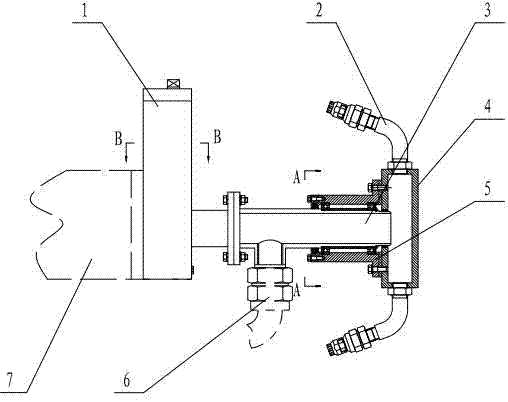

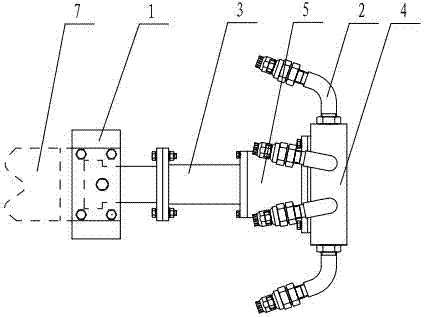

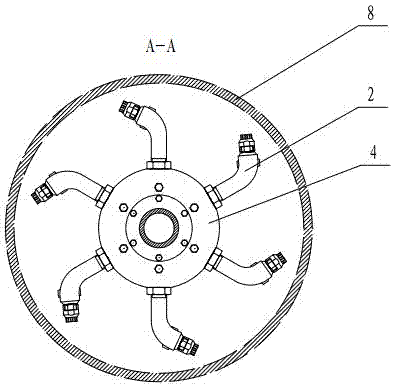

[0025] According to attached figure 1 , attached figure 2 And attached Figure 5 It can be seen that the present invention specifically relates to a spin-type purging device for the inner wall of a steel pipe, which includes a screw lifting device 1, a three-way air chamber 3 and a self-rotating nozzle device. The chute 1-1 of the track, the screw nut 1-3 that is slidingly matched with the "T" shaped slideway, and the screw 1-2 that is threaded with the screw nut 1-3, the screw 1- 2. Placed in parallel with the "T"-shaped slideway; the three-way air chamber 3 is a "T"-shaped hollow tube, the left port is fixed to one end of the screw nut 1-3 of the screw lifting device 1 through a flange, and the lower port It communicates with the compressed air pipeline 6, and the right port is connected with the self-rotation device; the self-rotation nozzle device includes a rotation sleeve 5, a turntable 4 and a nozzle 2, and the turntable 4 is a hollow circular shell, and the turntabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com