Sliding bearing with micro holes on inner wall thereof

A sliding bearing and microporous technology, used in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of insufficient strength, high cost, and difficult manufacturing, and achieve obvious lubrication effect, simple processing, and reduce friction and wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

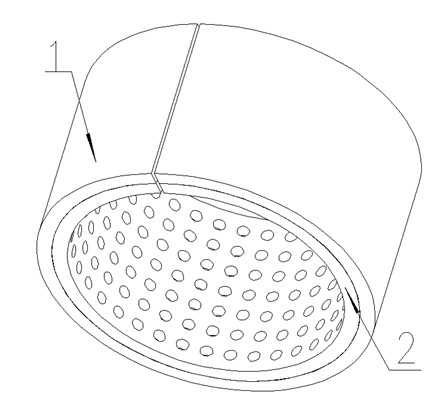

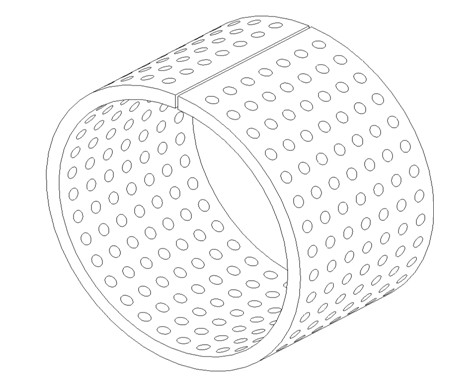

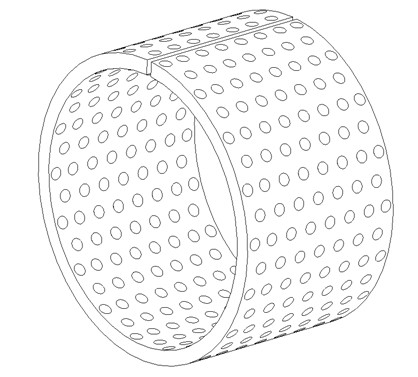

[0018] Such as figure 1 As shown, a sliding bearing with micropores on the inner wall is rolled into a sliding bearing after welding the bearing pad 1 and the bearing lining 2 with uniform micro-through holes on the surface, and the bearing lining 2 with uniform micro-through holes on the surface Inside the bearing. The micro-holes on the surface of the bearing lining 2 are distributed in parallel and equidistant arrangement to the bearing axis, or in two adjacent columns parallel to the bearing axis, equidistant and misplaced arrangement, such as figure 2 , image 3 shown. In the figure, the total area of the micro-holes on the surface of the bearing lining 2 is 19% of the surface area of the inner wall of the bearing lining 2, the depth-to-diameter ratio range of the micro-holes on the surface of the bearing lining 2 is 0.1, the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com