Method for improving strength and flexibility of super strength steel laser-arc hybrid welded joint

A technology of ultra-high-strength steel and composite welding, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc. Solve problems such as large seam heat-affected zone, and achieve the effect of improving microstructure, capacity and service reliability, and stabilizing the composite welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

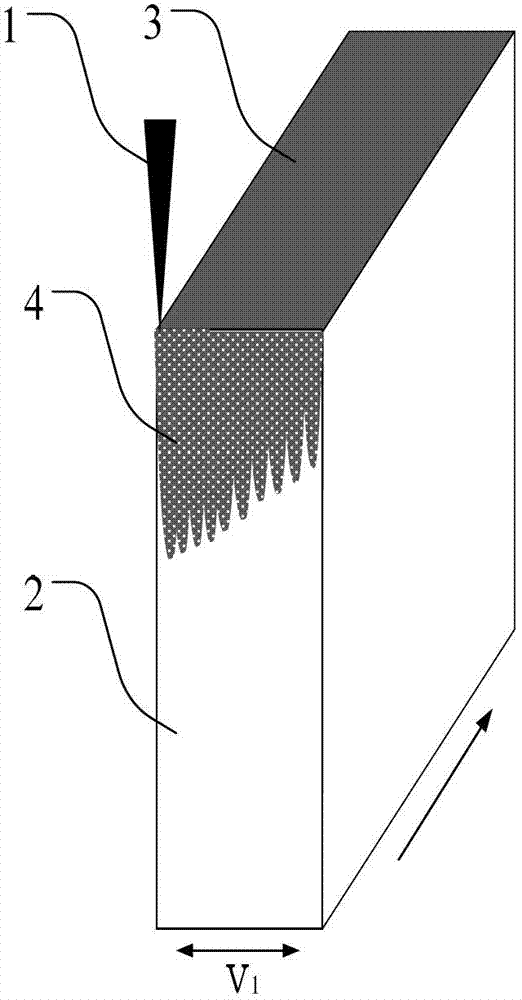

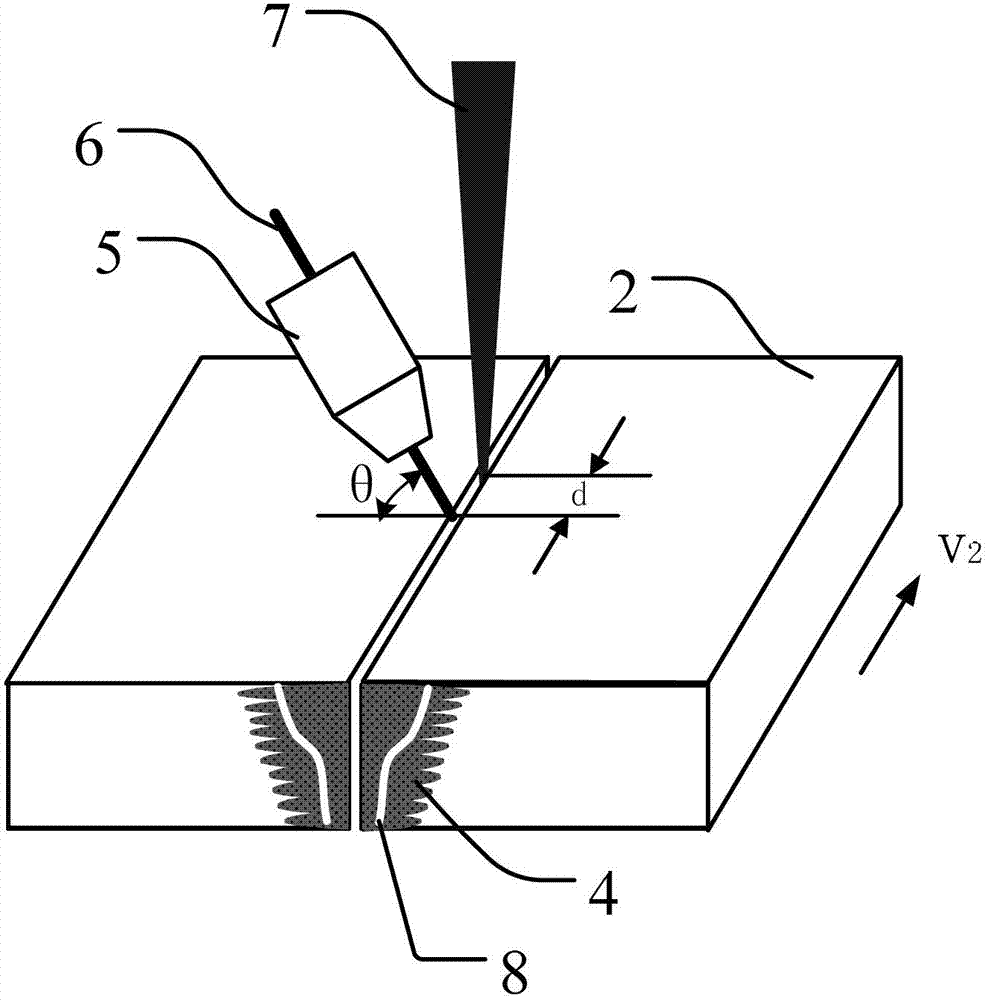

[0007] The specific implementation of the method for improving the strength and toughness of ultra-high strength steel laser-arc hybrid welding joints of the present invention is as follows. First, the pretreatment laser 1 is used to pretreat the joint surface 3 of the two workpieces 2 to be welded to form a laser fusion pretreatment area 4, such as figure 1 shown. The workpiece 2 to be welded is ultra-high strength steel with a thickness of 8 mm and a tensile strength of 600 MPa. The pretreatment laser 1 comes from a Nd:YAG laser with a maximum output power of 4kW and an output wavelength of 1.06μm. It outputs a continuous wave laser. It uses a focusing lens with a focal length of 175 and a defocus of -3 mm. Pretreatment laser 1 power 2~3 kW, scan rate v 1 The scanning overlap rate is 1.5~2.5 m / min, and the scanning overlap rate is 25~35%. 1 Reciprocating movement, the percentage of the overlapping path formed by the preprocessing laser 1 approaching and leaving the recipr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com