Ferritic martensitic iron based alloy, a component and a process

a technology of ferric martensitic iron and iron based alloy, which is applied in the field to a component and a process, can solve the problems of lower strength and toughness of ferric martensitic alloy compared to nickel-based superalloy, and achieve the effects of reducing the number of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The prior art is formed by iron-based alloys, known from EP 0 867 523, in which use is made of tungsten.

[0012]With preference, the new ferritic-martensitic alloy dispenses with the addition of tungsten (W) except for the customary impurities, which lie considerably below 0.1% by weight, in particular below 0.01% by weight.

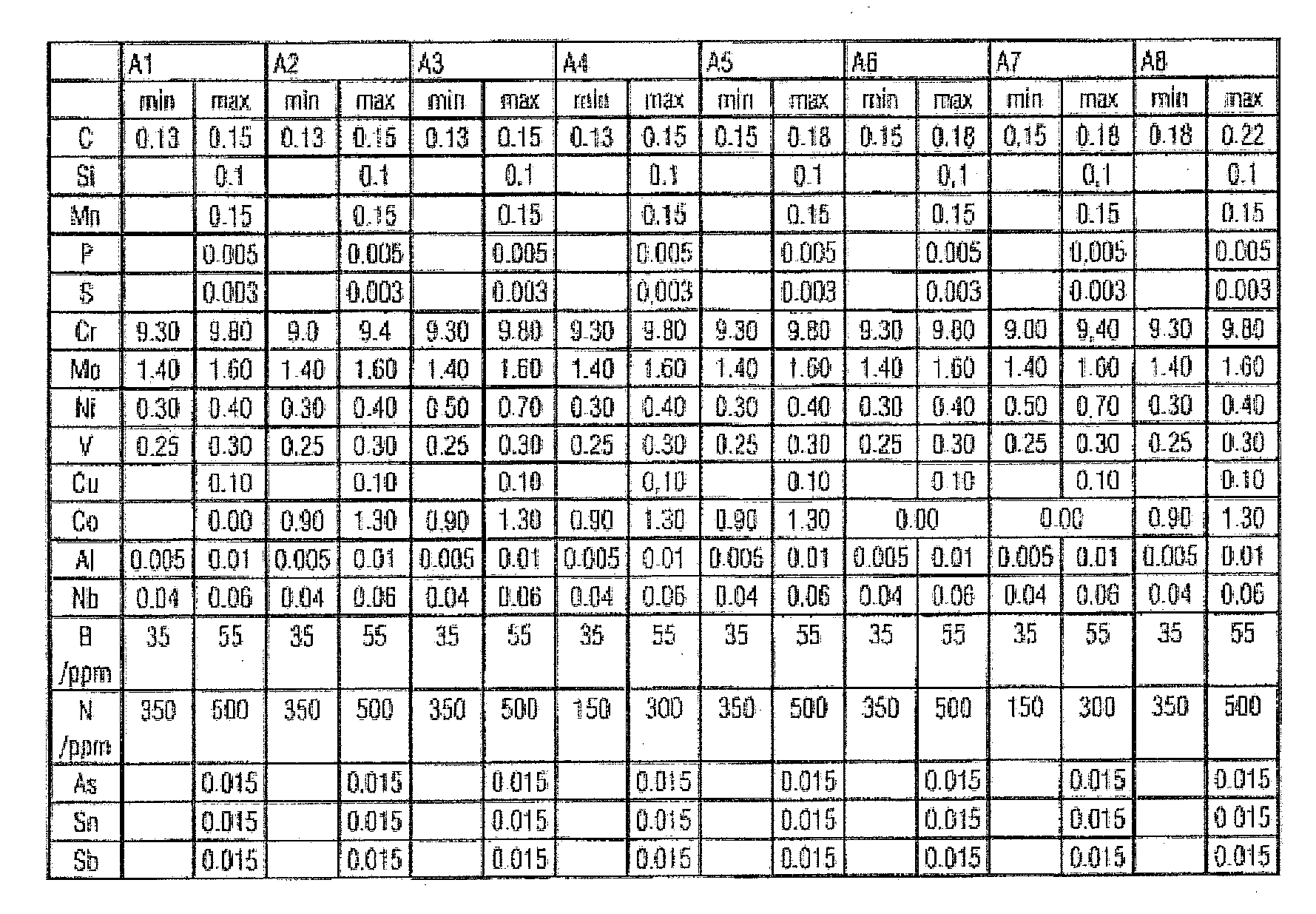

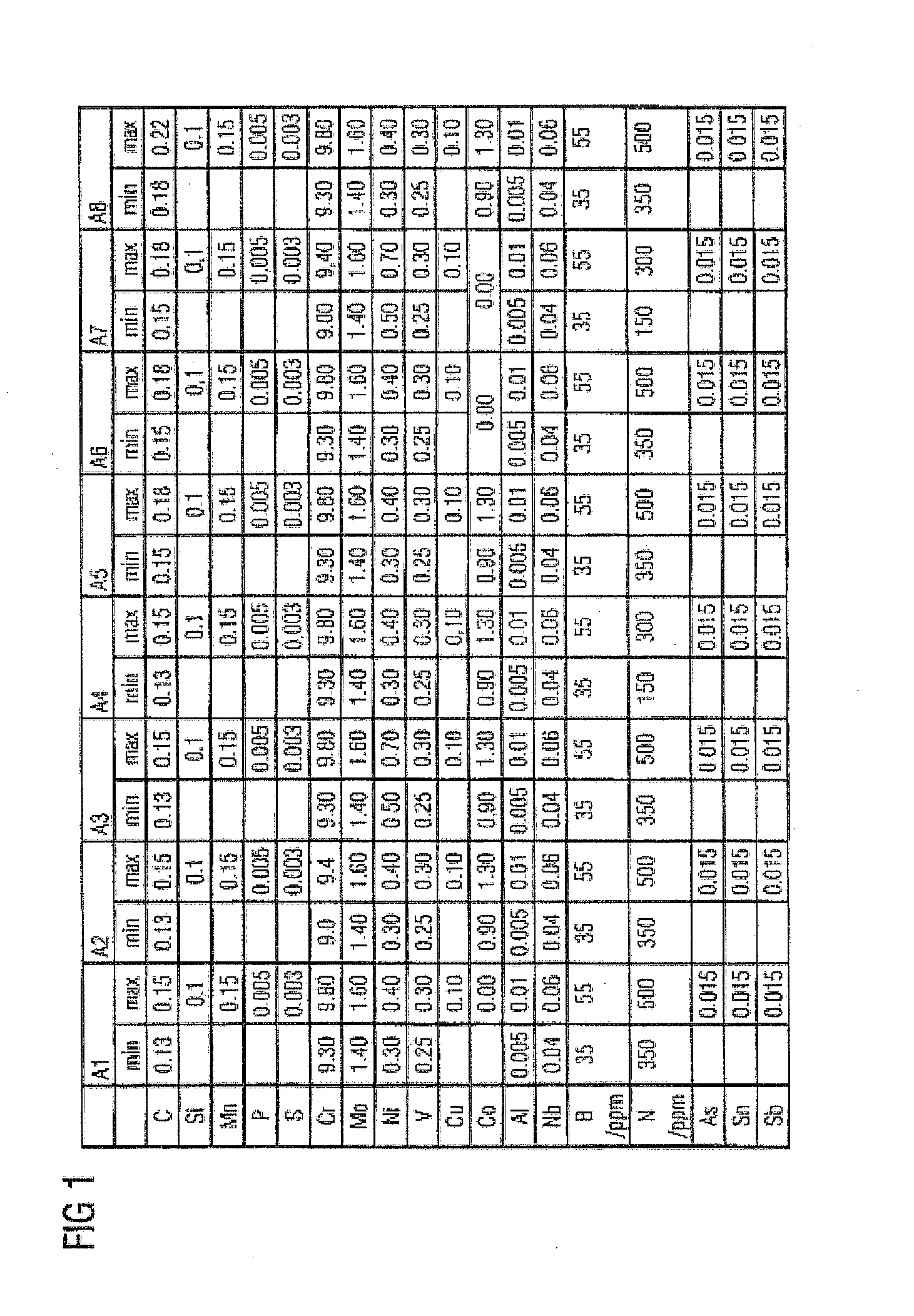

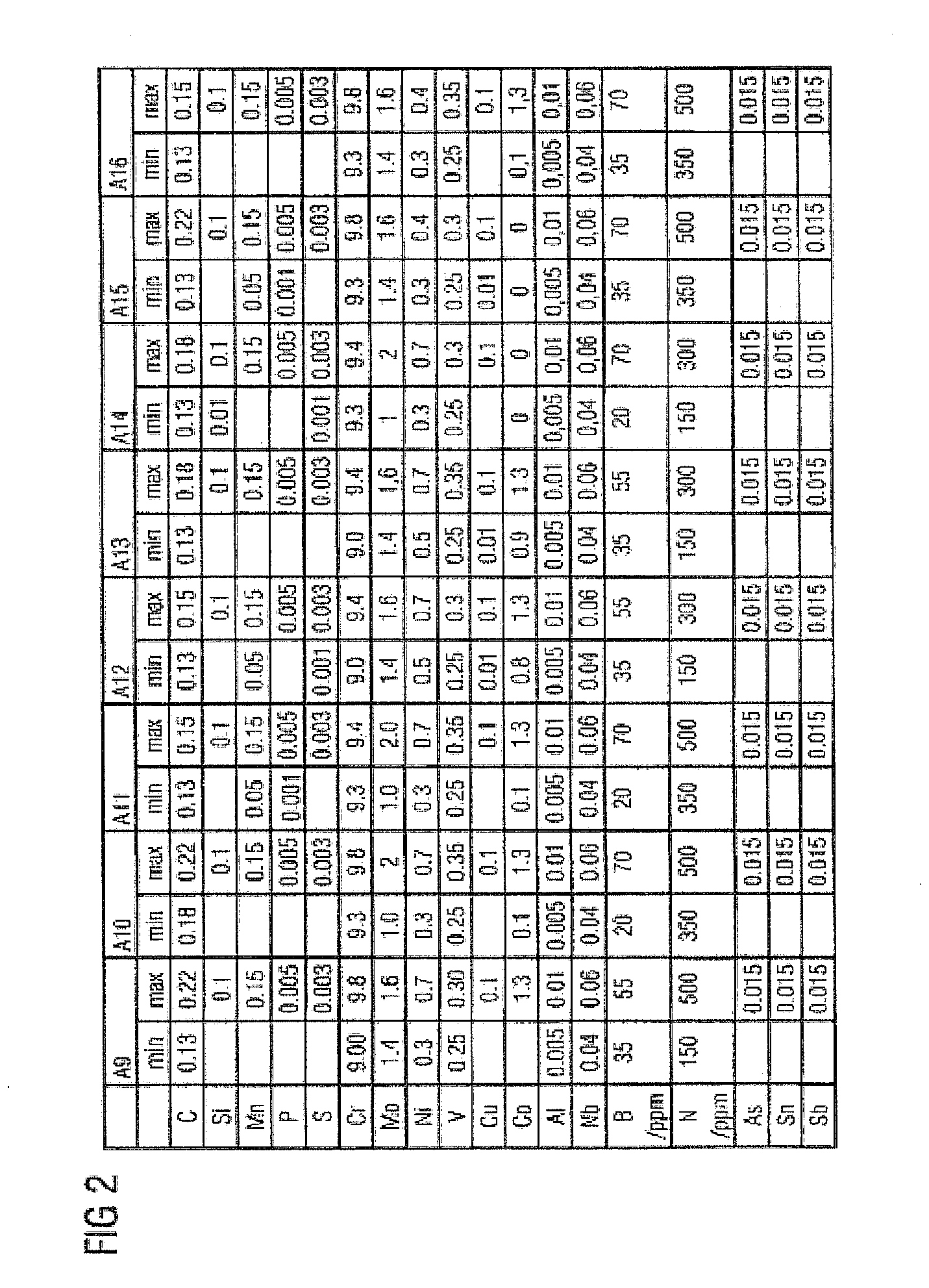

[0013]The tables in FIGS. 1 to 3 show some exemplary embodiments of the invention.

[0014]The iron-based alloy comprises, in an inconclusive list (in % by weight):[0015]carbon (C): 0.13-0.22,[0016]chromium (Cr): 9.0-9.8,[0017]molybdenum (Mo): 1.0-2.0, in particular 1.4-1.6,[0018]nickel (Ni): 0.3-0.8, in particular 0.3-0.7,[0019]vanadium (V): 0.25-0.35, in particular 0.25-0.3,[0020]aluminum (Al): 0.005-0.01,[0021]niobium (Nb): 0.04-0.06,[0022]boron (B): 20 ppm-70 ppm, in particular 35 ppm-55 ppm,[0023]nitrogen (N): 150 ppm-500 ppm,[0024]cobalt (Co): 0-1.5, in particular up to 1.3,[0025]manganese (Mn): 0-0.15,[0026]silicon (Si): 0-0.1,[0027]phosphorus (P): 0-0.00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| strengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com