Patents

Literature

46results about How to "Stay plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

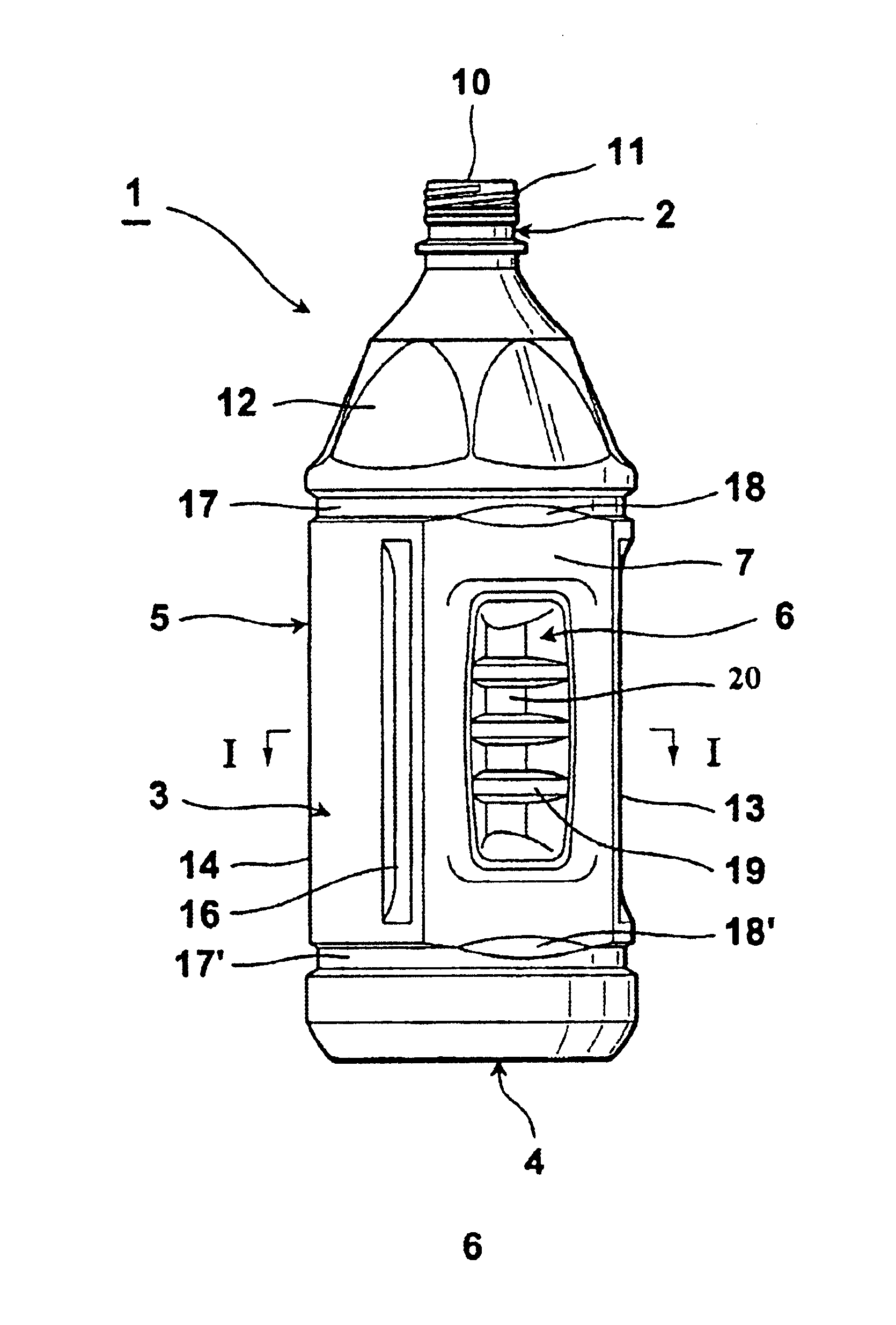

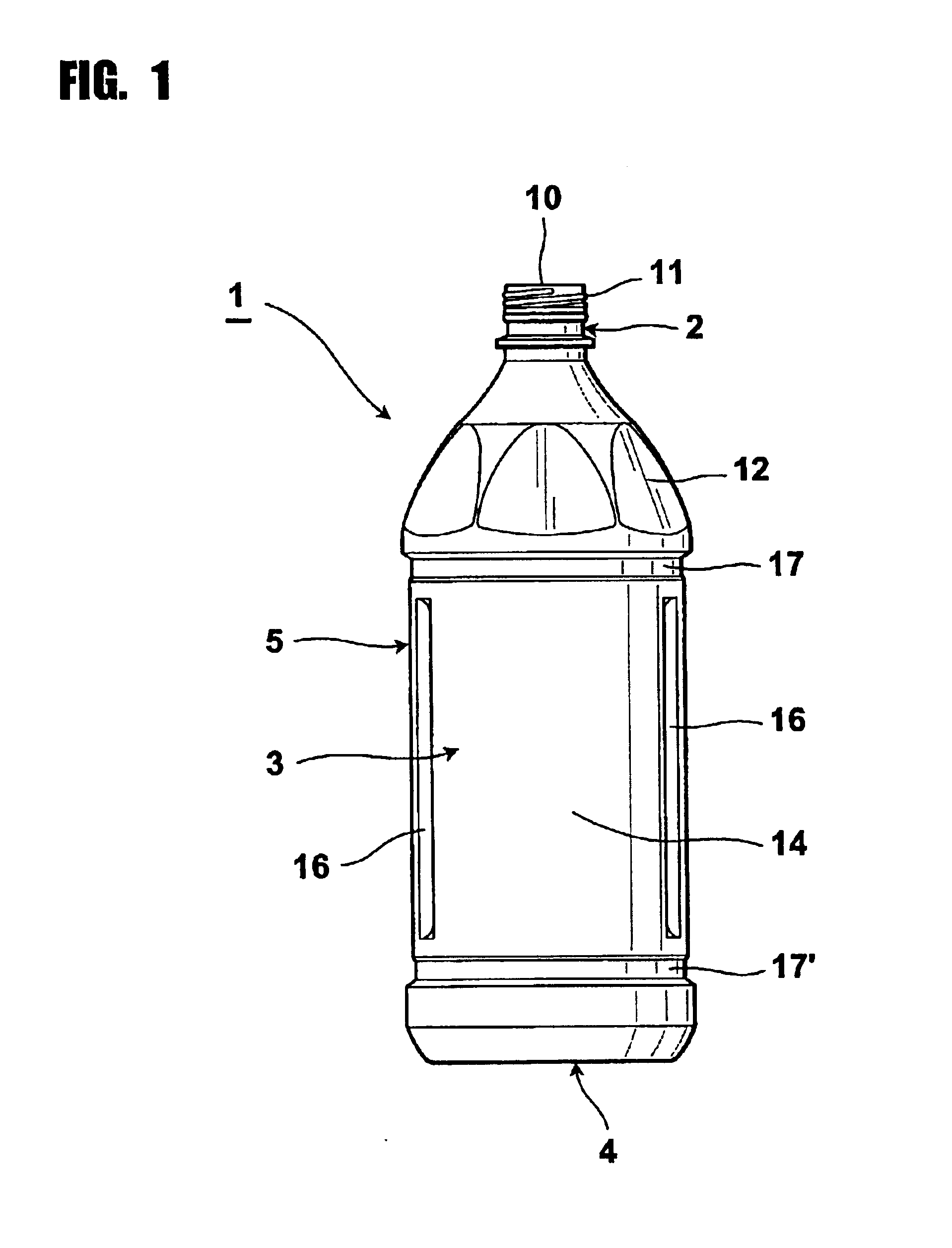

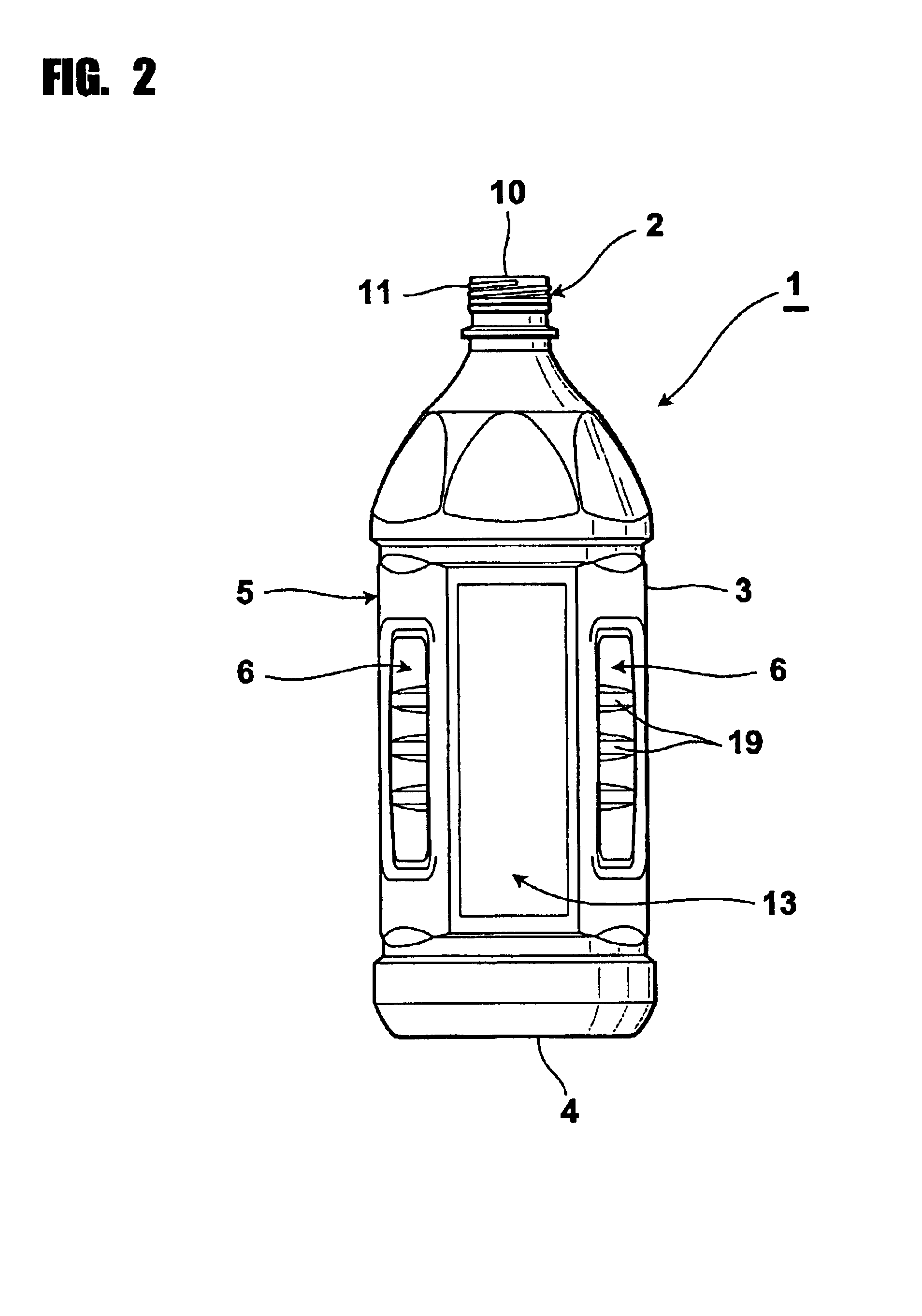

Handy bottle and process for manufacturing same

InactiveUS6964347B2Absorbs deformation strainMaintaining lightweight propertyBottlesLarge containersBlow moldingEngineering

A handy bottle is capable of absorbing deformation strain caused by variation of capacity, is easy to lift and carry because of its recessed portions for gripping and is excellent in dropping strength and capable of not buckling while maintaining moldability and lightweight property. Typically, the handy bottle has recessed portions for gripping on both sides of a body portion thereof and a shape in diametric cross section of the recessed portions is almost bilaterally symmetrical to a line connecting deepest portions of the recessed portions and a central axis of the body portion. The process for producing the handy bottle allows movable inserts capable of molding the recessed portions for gripping to be on standby in predetermined positions and allows the movable inserts to proceed toward the deepest portions of the recessed portions for gripping in the course of blow molding.

Owner:TOYO SEIKAN KAISHA LTD

Flame retardant polybutylene terephthalate resin composition

InactiveUS20090124733A1Improve performanceExcellent characteristicsOrganic dyesPolytetramethylene terephthalateGlass fiber

The invention provides a resin composition which gained flame-retardancy by a non-halogen based flame-retardant, having excellent small-warping performance without deteriorating excellent moldability and various characteristics (mechanical characteristics, electrical characteristics, and long-term environmental characteristics) which are inherent advantageous properties of polybutylene terephthalate resin. Specifically, to (A) 100 parts by weight of polybutylene terephthalate-based resin, there are mixed: (B) 10 to 100 parts by weight of a polymer of one or more types selected from the group consisting of modified polyester and styrene-based resin; (C) 10 to 100 parts by weight of specific phosphinic acid salt and / or diphosphinic acid salt and / or a polymer thereof; and (D) 20 to 200 parts by weight of glass fiber having an average cross-sectional area ranging from 100 to 300 square micrometers.

Owner:WIN TECH POLYMER LTD

Heat treatment process of high-carbon chromium bearing steel

The invention provides a heat treatment process of high-carbon chromium bearing steel and belongs to the technical field of steel materials and heat treatment. The heat treatment process comprises the steps of smelting, forging, incomplete annealing, normalizing, quenching and tempering, double-refining processing, carbonitriding and surface chromizing. According to the invention, repeated quenching, tempering and other heat treatment, surface carbonitriding and surface chromizing processes are mainly adopted to reinforce the hardness and strength and prolong the service life of a bearing, so that the finally produced bearing is higher in strength, stronger in hardness and longer in service life.

Owner:ANQING YINTAI BEARING

Microalloy strengthened hard pure gold and preparation method thereof

The invention provides a hard pure gold material for pure gold jewelry. The hard pure gold material is prepared from, by mass, 0.1-0.4% of calcium, 0.5-0.8% of titanium, 0.01-0.1% of rare earth elements and the balance gold, wherein the gold content is 99.0% or above. In the preparation process, by introducing the trace element calcium, a dispersed cluster structure is formed in a pure gold matrix, and the structure can effectively promote precipitation of a nano-scale gold titanic compound strengthening phase, so that the hardness and strength of the pure gold are greatly improved. The pure gold in the design is suitable for conventional jewelry processing processes and can be applied to various kinds of pure gold jewelry.

Owner:SHANGHAI QIJIU NEW MATERIAL TECH CO LTD

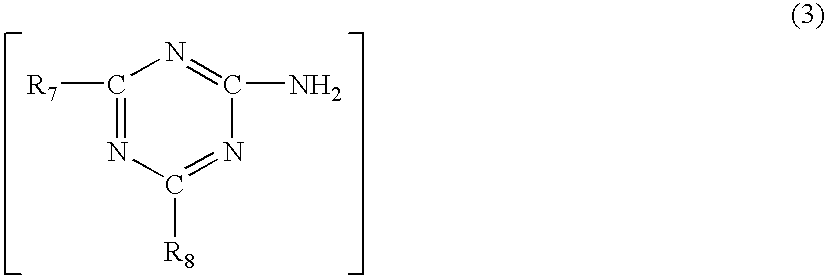

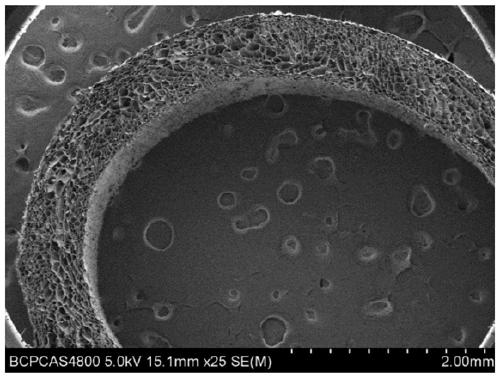

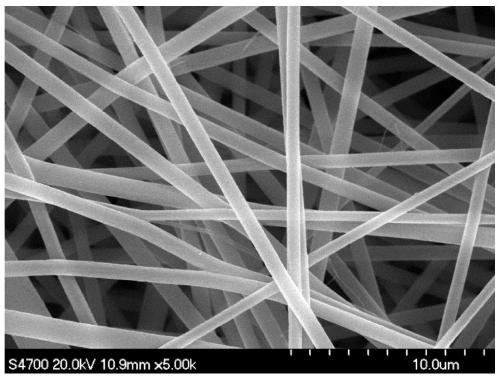

Composite nerve restoration catheter and preparation method thereof

InactiveCN110420355AHigh mechanical strengthPrevent collapseFilament/thread formingTissue regenerationElectrospinningSlurry

The invention provides a composite nerve restoration catheter and a preparation method thereof. The composite nerve restoration catheter comprises a hollow natural polymer catheter and an electrostatic spinning fiber layer coating the natural polymer catheter, wherein the natural polymer catheter is made of collagen slurry with the mass / volume concentration of 4%-7%, the electrostatic spinning fiber layer is made of a spinning solution containing polylactic acid and chitosan, and the mass ratio of the polylactic acid to the chitosan is (6-9.5):(0.5-4). The mechanical strength of the collagen catheter is obviously improved while the characteristics of the collagen catheter are kept, the good 3D structure is maintained in the nerve restoration process, and the catheter collapse is avoided. The production process is simple and prone to industrialization, and materials are widely sourced and cheap.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

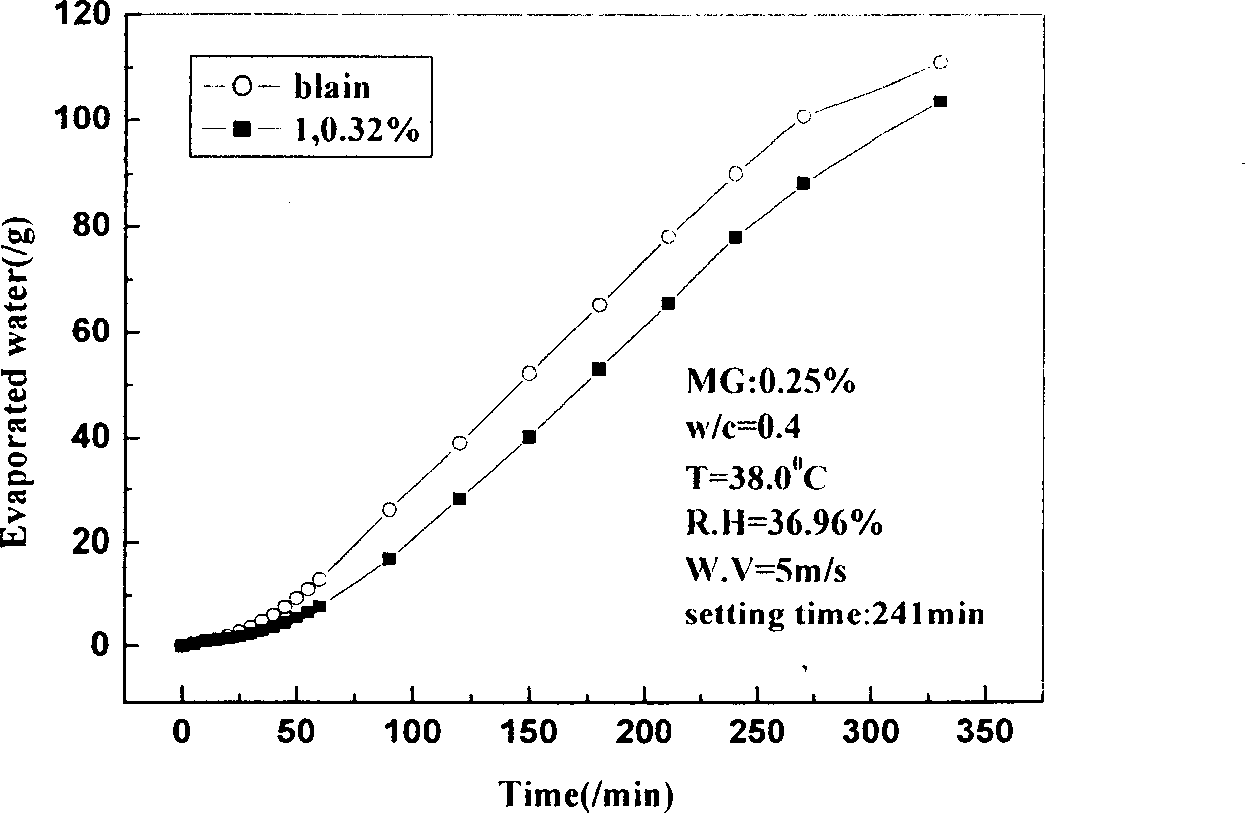

Moisture steaming blocking agent for plastic concrete

A water evaporating inhibitor for plastic concrete is prepared in the following proportion by weight by the following raw materials: 10-50% wax or the wax-mixture; 2-35% non-ionic and / or anionic emulsifier; 19.5-81% water and / or organic solvent made up of hydrocarbons or esters or ketenes with boiling point at 60-320 Deg C; 0-16% auxiliary agent. Spray said substance to the surface of plastic concrete without initial setting which could decreases the evaporation of water on the surface of said concrete. The application of said invention is not affected by construction yard, element shape and position with convenient construction, which could not only guarantee engineering quality, but also save labor force, water, improve construction conditions, accelerate job progress with no change to the strength, abradability and durability of concrete. The surface bonding property is not affected by re-handling on surface. It also deduces or eliminates plastic constriction cracking on the concrete surface and raised shell phenomenon caused by heavy wind.

Owner:JIANGSU SUBOTE MATERIAL

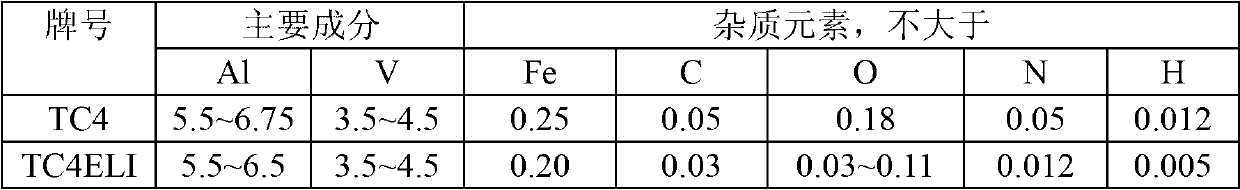

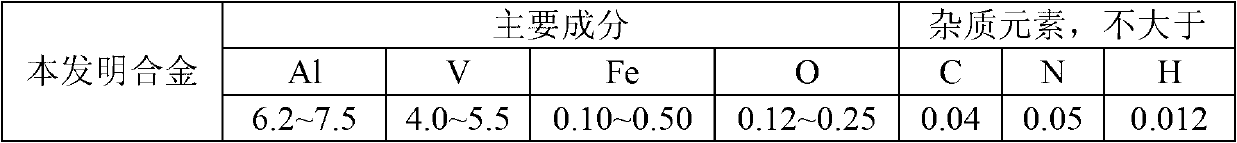

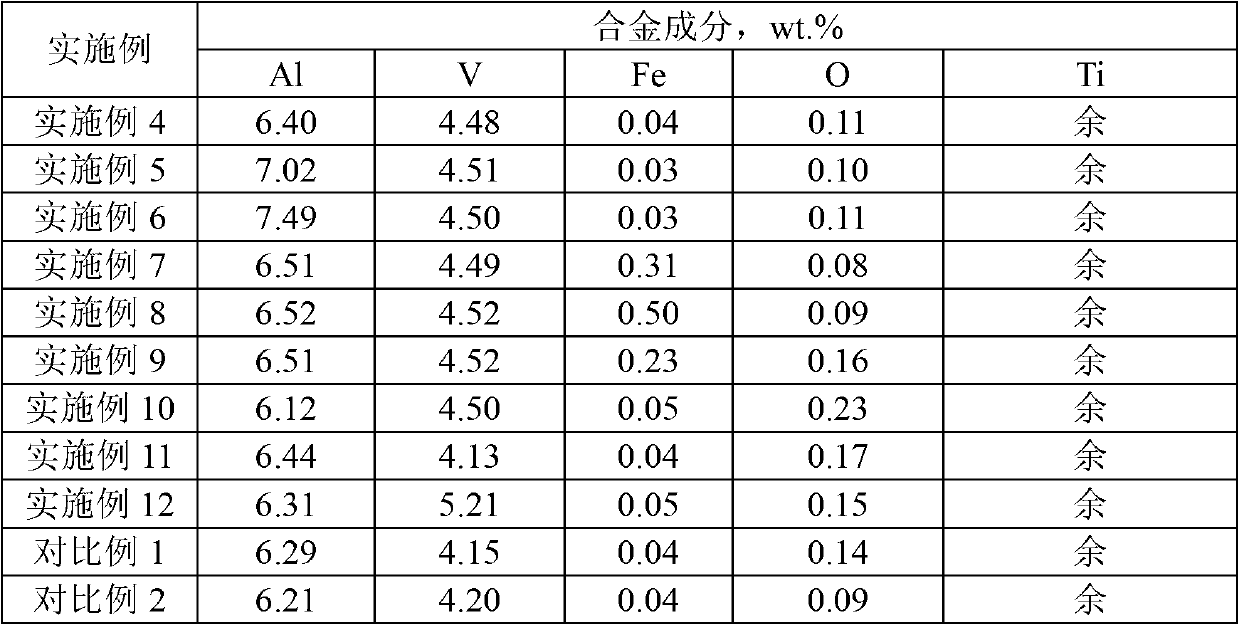

Alpha and beta combined titanium alloy wire for electron beam fused deposition rapid formed structural member with strength level of 920 MPa

The invention discloses an alpha and beta combined titanium alloy wire for an electron beam fused deposition rapid formed structural member with the strength level of 920 MPa. The alpha and beta combined titanium alloy wire is characterized in that an alpha phase is strengthened by an alloy element Al and an interstitial element O, and a beta phase is strengthened by an alloy element V and Fe, wherein the wire comprises the following components of: 6.2 to 7.5 weight percent of Al, 4.0 to 5.5 weight percent of V, 0.10 to 0.50 weight percent of Fe, 0.12 to 0.25 weight percent of O, the balance of Ti and inevitable impurity elements. The invention also provides the corresponding melting process, a thermal machining process and a thermal treatment process for the electron beam fused deposition rapid formed structural member. By the alloy wire, a requirement on the process for quickly forming by stacking the fuse wires of the electronic beams is met, and the titanium alloy structural member has relatively high mechanical performance. Great social benefits and economic benefits are created after the alloy wire is popularized and applied.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Platinum alloy material and preparation method

The invention provides a platinum alloy material which consists of the following components in percentage by mass: 0.3-1% of Ti, 0.02-0.15% of Zr and the balance of Pt. The preparation method of the alloy comprises the following steps of: smelting to prepare a Pt-Ti-Zr master alloy in a vacuum arc furnace, and smelting and casting in a vacuum induction furnace to prepare a Pt-Ti-Zr alloy ingot; performing solution heat treatment and low-temperature aging heat treatment of the alloy ingot in the vacuum arc furnace; performing plastic processing such as room-temperature forging, rolling (drawing) and the like to prepare a platinum alloy material sheet or wire of the proportion. The alloy provided by the invention maintains the corrosion resistance and plasticity of platinum while the hardness is over twice the hardness of platinum; the alloy is widely applied to electrode materials, jewelry and the like.

Owner:YUNNAN UNIV

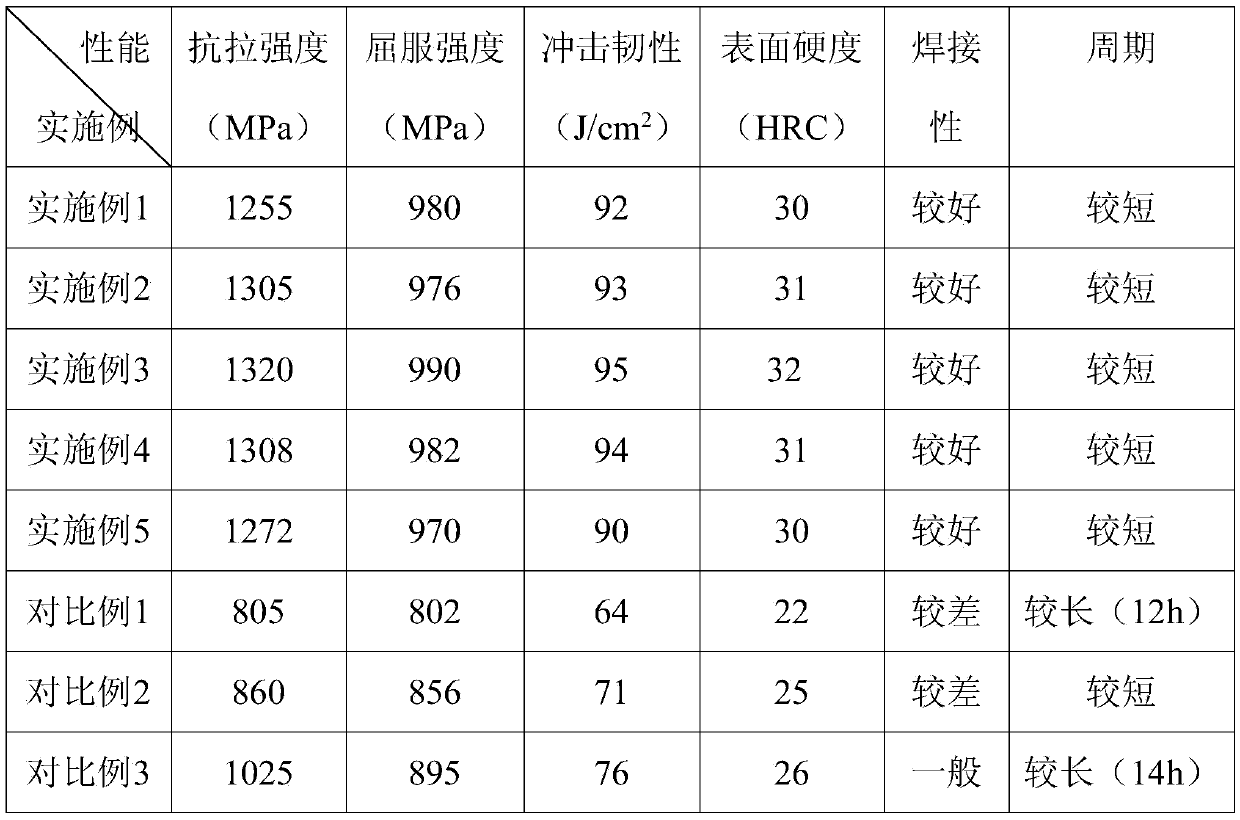

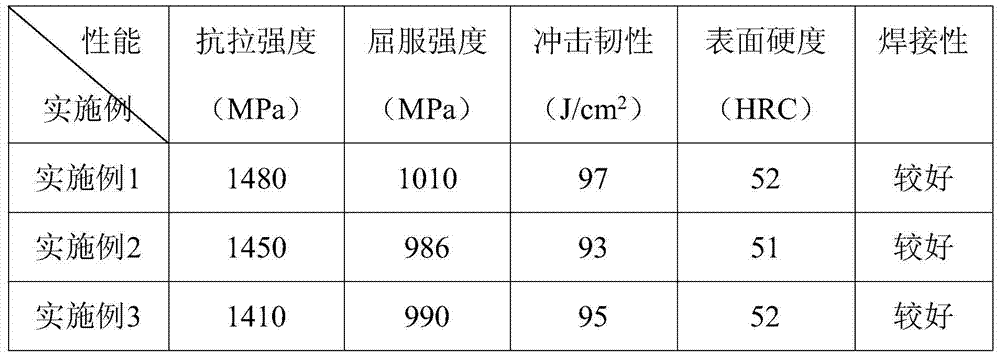

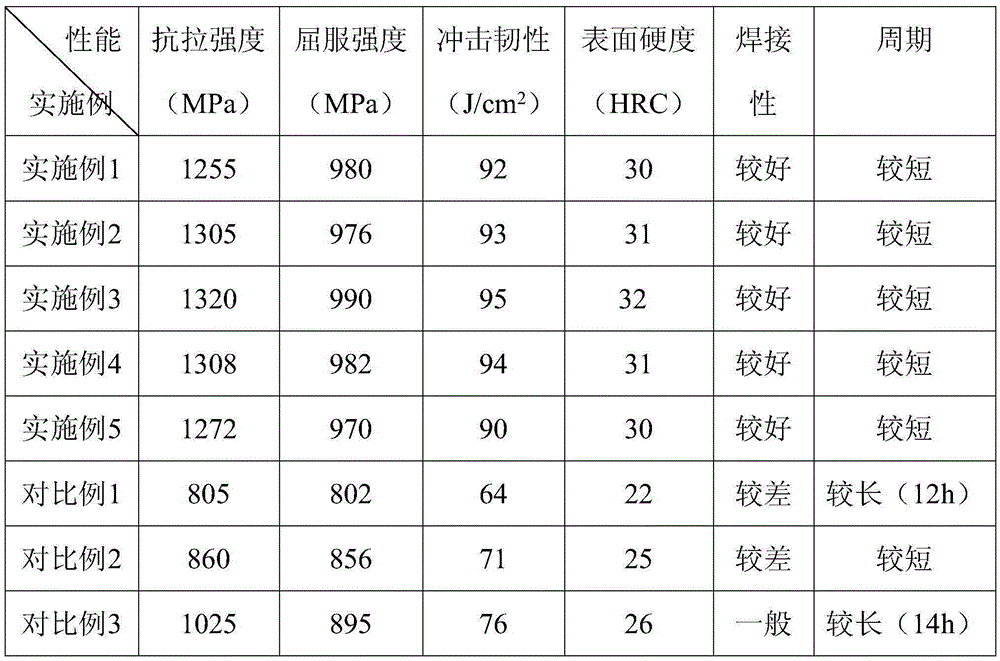

Machining method for nut plate

InactiveCN105369259AHigh tensile strengthImprove plasticityFurnace typesMetallic material coating processesRoom temperatureHardness

The invention relates to a machining method for a nut plate and belongs to the field of machining of alloy materials. The machining method includes the following steps that pretreatment is carried out, and quenching and tempering are carried out on high-strength alloy steel; heat treatment is carried out, the quenched and tempered high-strength alloy steel is forged and formed at the temperature of 1150-1220 DEG C, heat preservation is conducted for 0.3-0.6 h, quenching treatment is carried out by means of forging waste heat, the high-strength alloy steel is immediately water-cooled to the room temperature when cooled to 900 DEG C, the high-strength alloy steel is heated to 450-520 DEG C to be subjected to tempering for 2-3 h, finally the high-strength alloy steel is oil-cooled to the room temperature, and a semi-finished nut plate is obtained; and surface treatment is carried out, the semi-finished nut plate is sequentially subjected to oil and rust removal, activating treatment, blackening and passivation, and the nut plate is obtained. According to the nut plate, the high-strength alloy steel with components combined reasonably is selected to be subjected to quenching and tempering, forging, quenching, tempering and surface blackening, so that the machining cycle is greatly shortened, and the strength, hardness, toughness, corrosion resistance and abrasion resistance of the nut plate are greatly improved; meanwhile, the machining performance of the nut plate is improved, and the nut plate is easy to weld.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

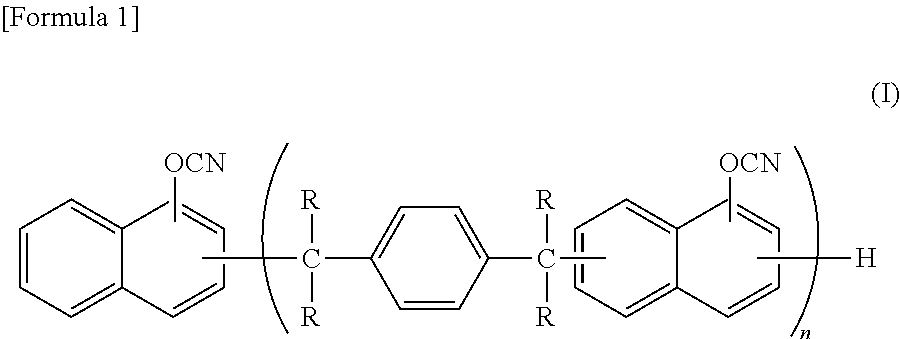

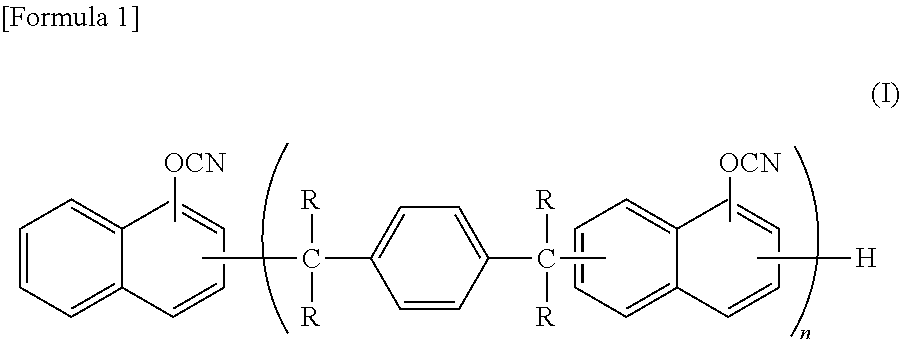

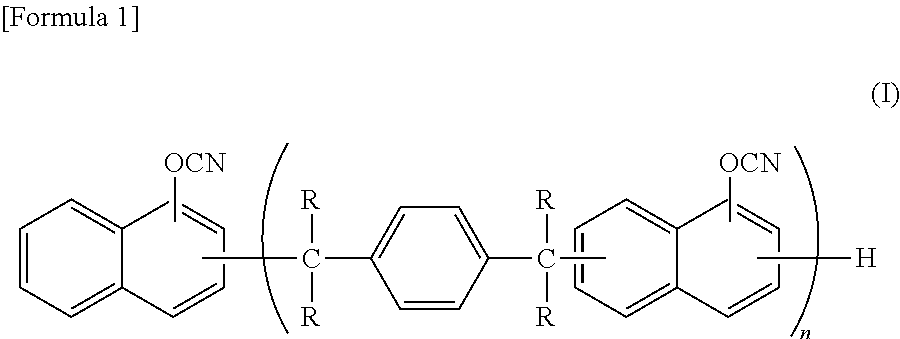

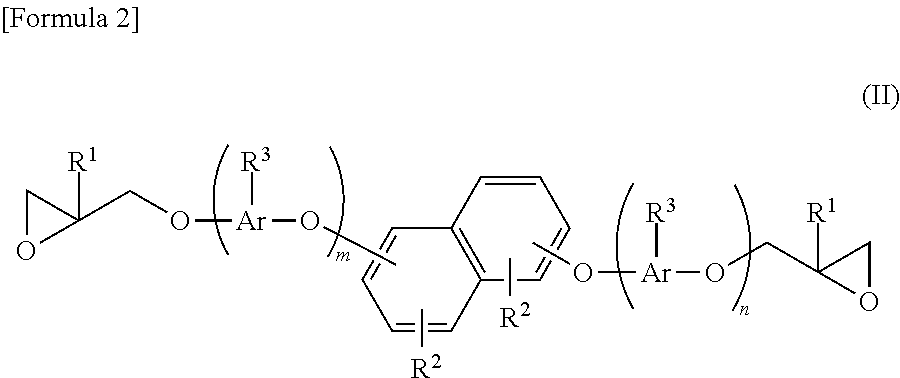

Resin composition, prepreg, and laminate

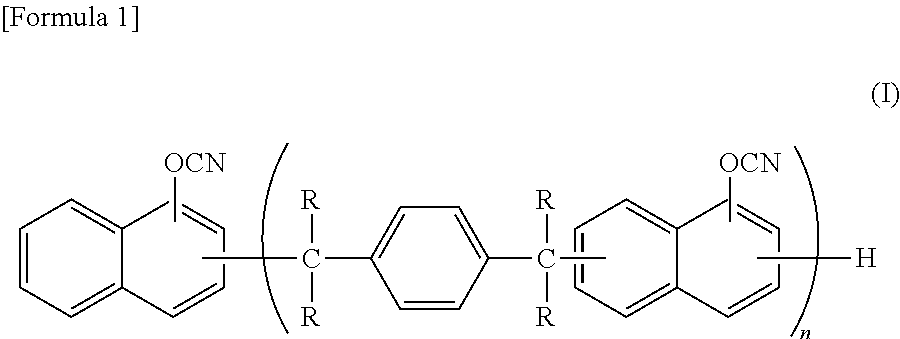

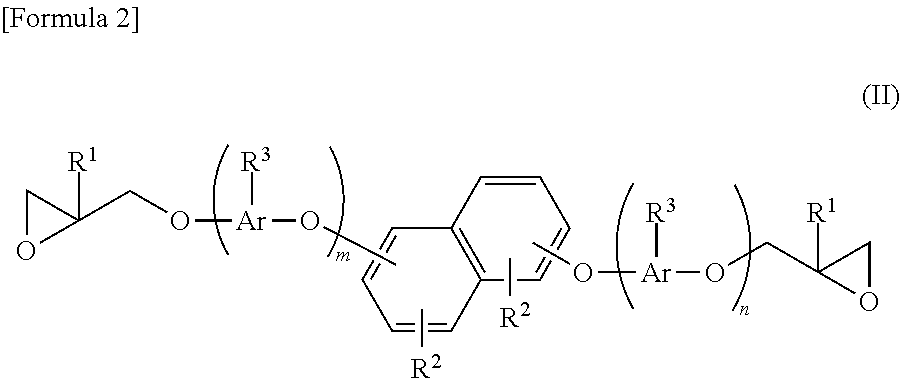

ActiveUS20140227924A1Improve heat resistanceExcellent flame retardanceSynthetic resin layered productsPrinted circuit aspectsCyanate compoundCyanate ester

A resin composition contains a cyanate ester compound, a maleimide compound, an epoxy resin, a silicone rubber powder, and an inorganic filler. The cyanate ester compound contains a compound represented by the following formula. The silicone rubber powder is contained in an amount of 40 to 150 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin. The inorganic filler is contained in an amount of 100 to 340 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin. A total content of the silicone rubber powder and the inorganic filler is 140 to 380 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin.

Owner:MITSUBISHI GAS CHEM CO INC

Dew point corrosion resisting paint and preparation method and use thereof

ActiveCN102675991AGuaranteed liquidityGood flexibilityAnti-corrosive paintsWater basedSodium Bentonite

The invention provides dew point corrosion resisting paint and a preparation method and use thereof. The dew point resisting paint can be used at the environment temperature of -25-24 DEG C, can keep flexibility and plasticity in the temperature range throughout, and can not crack or be liquefied. The dew point corrosion resisting paint comprises organic matters and inorganic matters. The organic matters comprise ethylene-propylene copolymer, 2-sulfhydryl benzothiazole and a water-based macromolecule elastic base material. The inorganic matters comprise bentonite, silica gel, corundum s fine powder and alumina. The preparation method includes mixing components according to the proportions, dispersing, polishing, soaking, warming reacting, stirring and filtering.

Owner:上海乐恒石油化工集团有限公司

Low-carbon steel and preparing method thereof

The invention relates to the technical field of material preparation, in particular to low-carbon steel and a preparing method thereof. The low-carbon steel includes a matrix, and the matrix is composed of the following chemical components including, by mass, 0.17%-0.22% of carbon, 0.19%-0.25% of silicon, 0.34%-0.45% of manganese, 0.03%-0.05% of phosphorus, 0.034%-0.045% of sulfur and the balanceiron; and the low-carbon steel is ferrite grains obtained from the matrix. The method includes the following steps of conducting preservation on a low-carbon steel rod-shaped sample at 650-750 DEG C for 1.5-2 h to obtain coarse-grain structure low-carbon steel with uniform compositions; using a torsion tester to conduct torsional deformation treatment on the obtained coarse-grain structure low-carbon steel; and placing the low-carbon steel obtained by indoor temperature torsional deformation into a vacuum thermal annealing furnace for annealing treatment. By means of the low-carbon steel and the preparing method, the strength of the obtained low-carbon steel is improved by 200 MPa, and meanwhile, the considerable failure elongation and static toughness are maintained.

Owner:TANGSHAN GANGLU IRON & STEEL

Method for producing hydrolyzable silicon group-containing oxyalkylene polymer and curing composition thereof

The problem of the invention is to efficiently produce a hydrolyzable silicon group-containing oxyalkylene polymer which has a low viscosity while maintaining a plasticity of a cured product and which does not contaminate an area around a sealing portion and / or has no adverse effect on an adhesion. The problem is solved by a process for producing a hydrolyzable silicon group-containing oxyalkylene polymer, which comprises using, as a starting material, an oxyalkylene polymer in which a first oxyalkylene polymer having at least two active hydrogen groups and a second oxyalkylene polymer having one active hydrogen group coexist, and converting the active hydrogen groups to hydrolyzable silicon groups.

Owner:KANEKA CORP

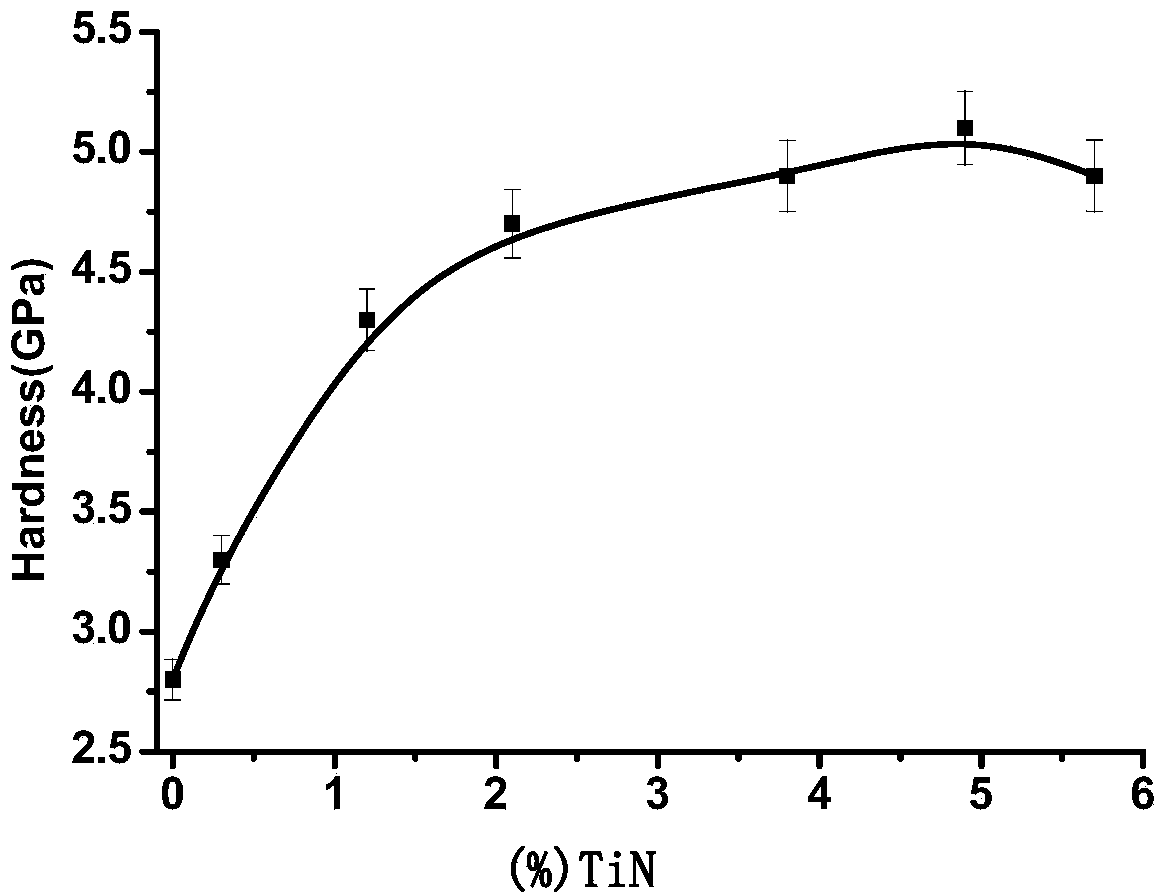

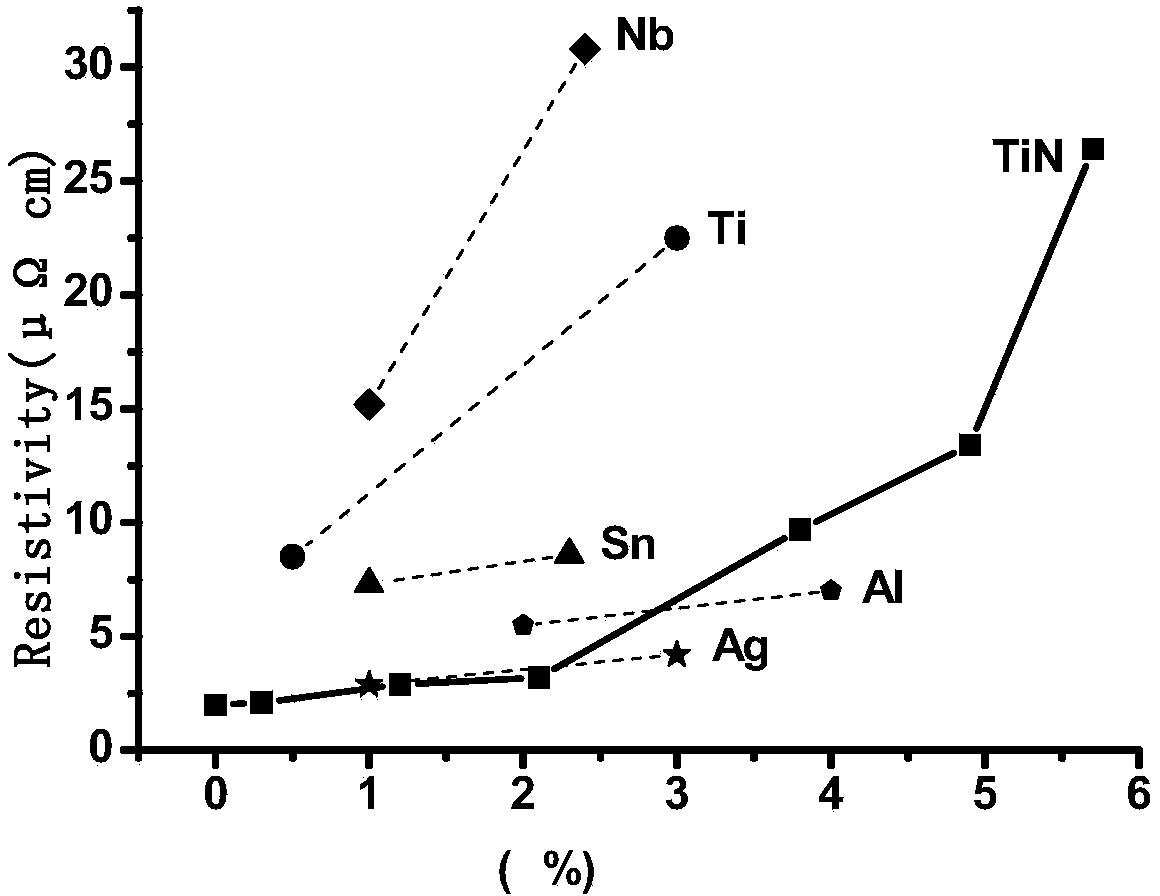

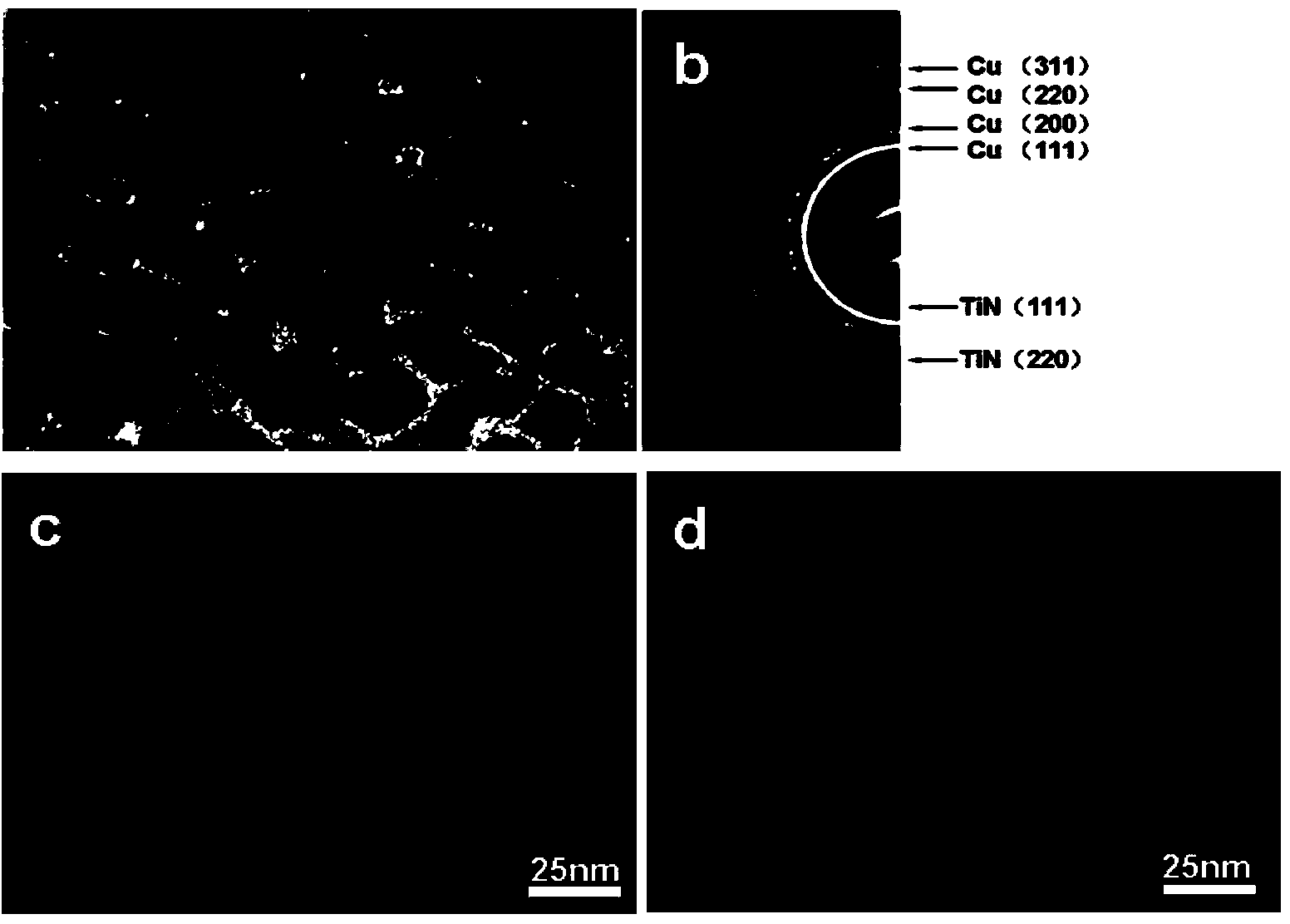

Cu-TiN nano composite film based on magnetron sputtering codeposition technology

InactiveCN104313543AStay plasticStay resilientVacuum evaporation coatingSputtering coatingComposite filmHardness

A Cu-TiN nano composite film based on a magnetron sputtering codeposition technology relates to the technical fields of micro-electrons and micromechanics, has a nanometer size, and has TiN additive particles and Cu crystal grains, which are uniformly mixed. The content of the TiN additive particles is 1.0-6.0 at.%. The composite film prepared by the invention is 4.1-5.1GPa in thickness and 3-25 micro-omega cm at electrical resistivity. When the additive contents (referred to alloy element content as for a Cu-based alloy film and referred to the content of added compounds as for a Cu-based composite film) are equal, the hardness of the composite film is obviously higher than that of the Cu-based alloy film adopted in industrial production at present, and the electrical conductivity is not lower than but much higher than that of the alloy film in most cases. The film can meet the high-hardness requirements of modern industry, in particular the technical fields of micro-electrons and micromechanics, on the conductive film.

Owner:上海工具厂有限公司 +1

Process for producing aging-resistant rubber material

InactiveUS20060035028A1Improve heat resistanceStay plasticPretreated surfacesCoatingsRubber materialCross-link

An aging-resistant rubber material with an improved heat resistance without deteriorating the moldability even if a rubber layer is formed from an aqueous latex of rubber and without any cost increase, even if a surface tack prevention treatment by an antitack agent is carried out, can be produced by applying a coating liquid containing an amine-based antioxidant in solution or dispersion to the surface of a cross-linked rubber material, followed by heating to a temperature of 80° C. or higher, thereby diffusing the amine-based antioxidant into the rubber material. When a coating solution containing an antitack agent together with the amine-based antioxidant in solution or dispersion is used, the surface tack prevention treatment of the cross-linked material as a product can be made at the same time.

Owner:NOK CORP +1

Resin composition, prepreg, and laminate

ActiveUS9512329B2Reduction factorExcellent heat resistance and flame retardanceSynthetic resin layered productsPrinted circuit aspectsCyanate compoundCyanate ester

A resin composition contains a cyanate ester compound, a maleimide compound, an epoxy resin, a silicone rubber powder, and an inorganic filler. The cyanate ester compound contains a compound represented by the following formula. The silicone rubber powder is contained in an amount of 40 to 150 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin. The inorganic filler is contained in an amount of 100 to 340 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin. A total content of the silicone rubber powder and the inorganic filler is 140 to 380 parts by mass based on 100 parts by mass in total of the cyanate ester compound, the maleimide compound, and the epoxy resin.

Owner:MITSUBISHI GAS CHEM CO INC

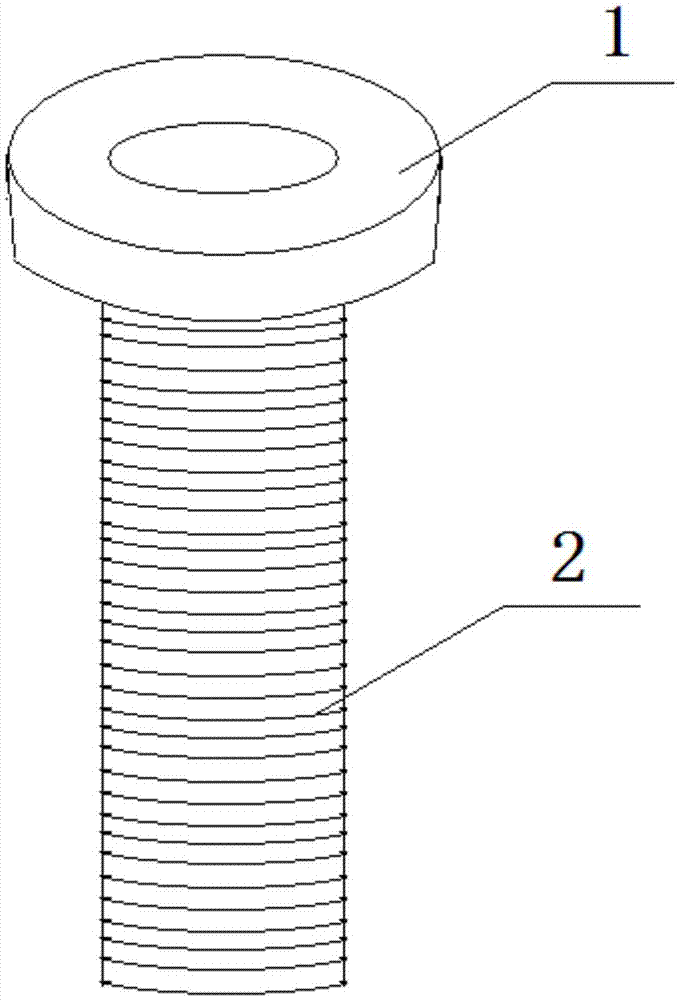

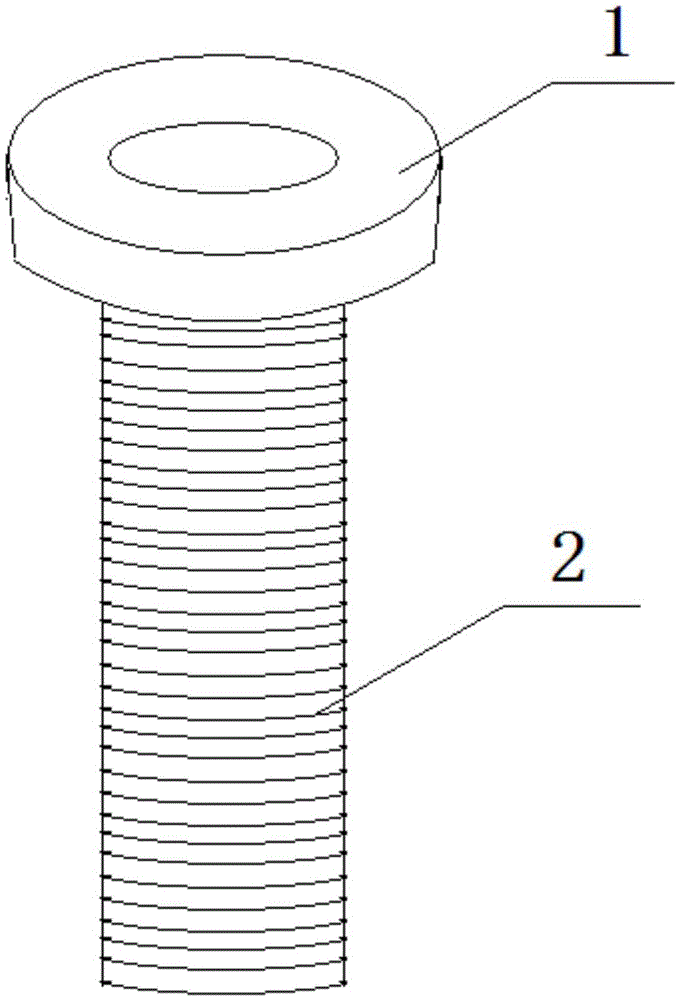

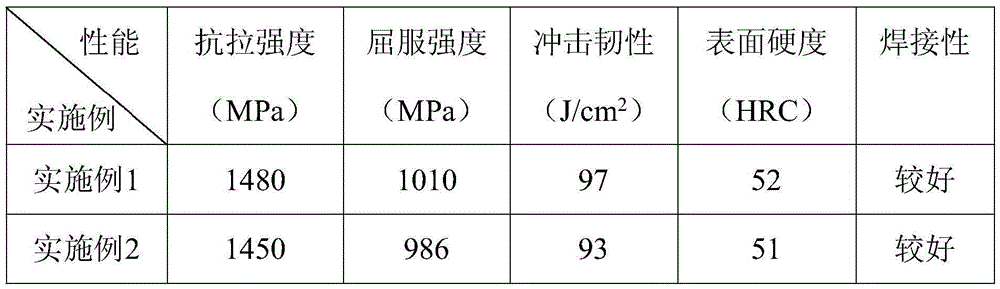

Long nut

InactiveCN105443545AImprove high temperature stabilityImprove wear resistanceScrewsEngineeringNitride

The invention belongs to the technical field of long nut machining, relates to a fastening piece, and particularly to a long nut. The long nut is composed of a screw cap and a screw rod; the screw cap is in a disc shape, and the outer diameter of the screw cap is greater than that of the screw rod; a circular concave hole arranged coaxially with the screw rod is formed in the middle of the screw cap and extends deeply to the screw rod, and the outer wall of the screw rod is provided with an external thread. The long nut is made of a three-dimensional network silicon nitride ceramic / alloy steel composite material. The three-layer layer-shaped porous silicon nitride ceramic / alloy steel composite material comprises, by volume, 30-50% of three-layer layer-shaped porous silicon nitride ceramic and 50-70% of alloy steel. The long nut is made of the three-layer layer-shaped porous silicon nitride ceramic / alloy steel composite material, and the three-layer layer-shaped porous SiC ceramic and the alloy steel are supporting frameworks to each other; the advantages of the SiC ceramic and the alloy steel are fully brought out, the high-temperature stability, abrasion resistance, corrosion resistance and the like of the long nut are improved effectively, and moreover the weight of the long nut is decreased.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

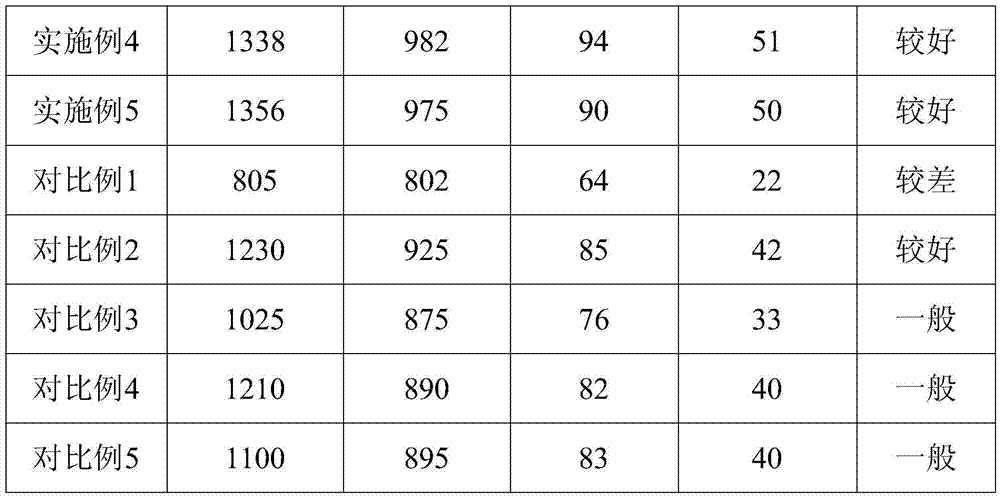

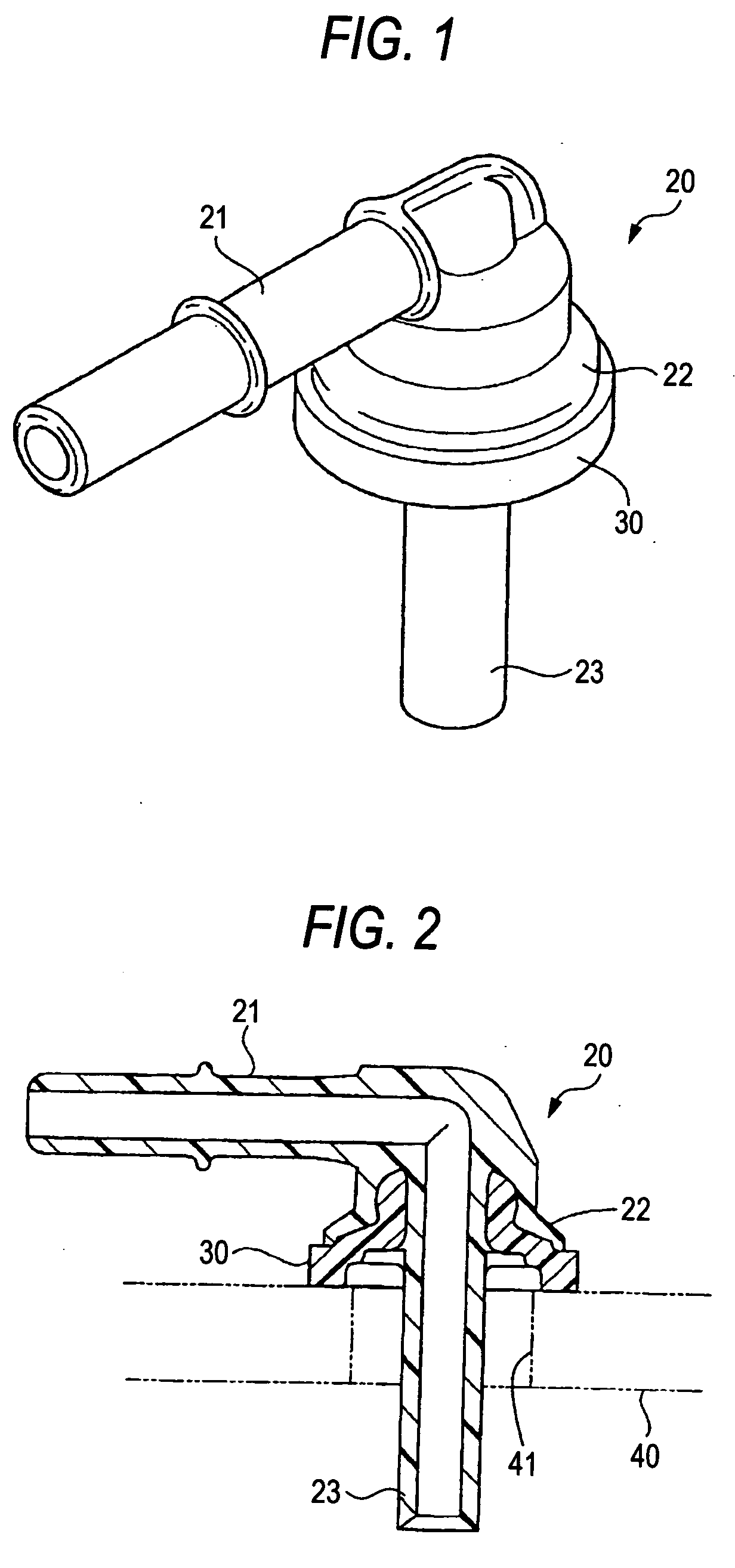

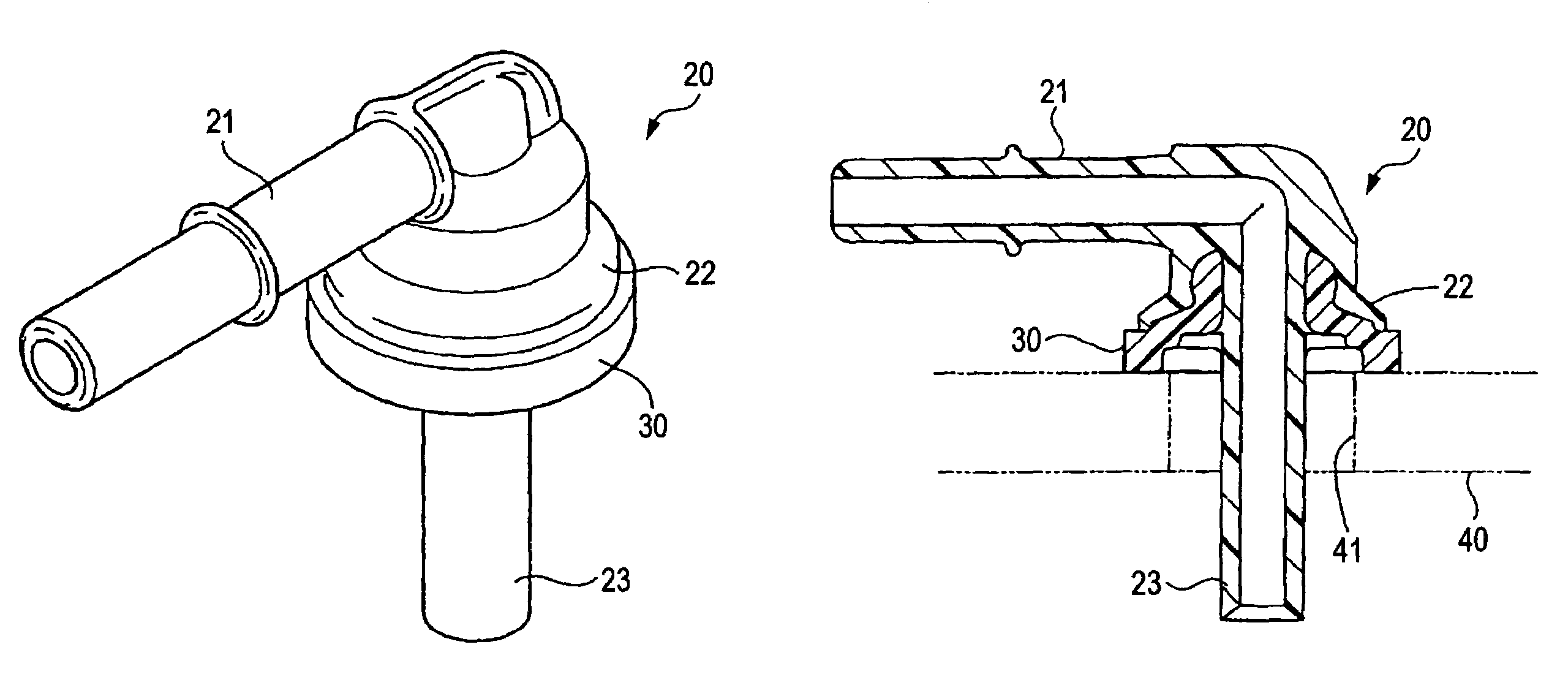

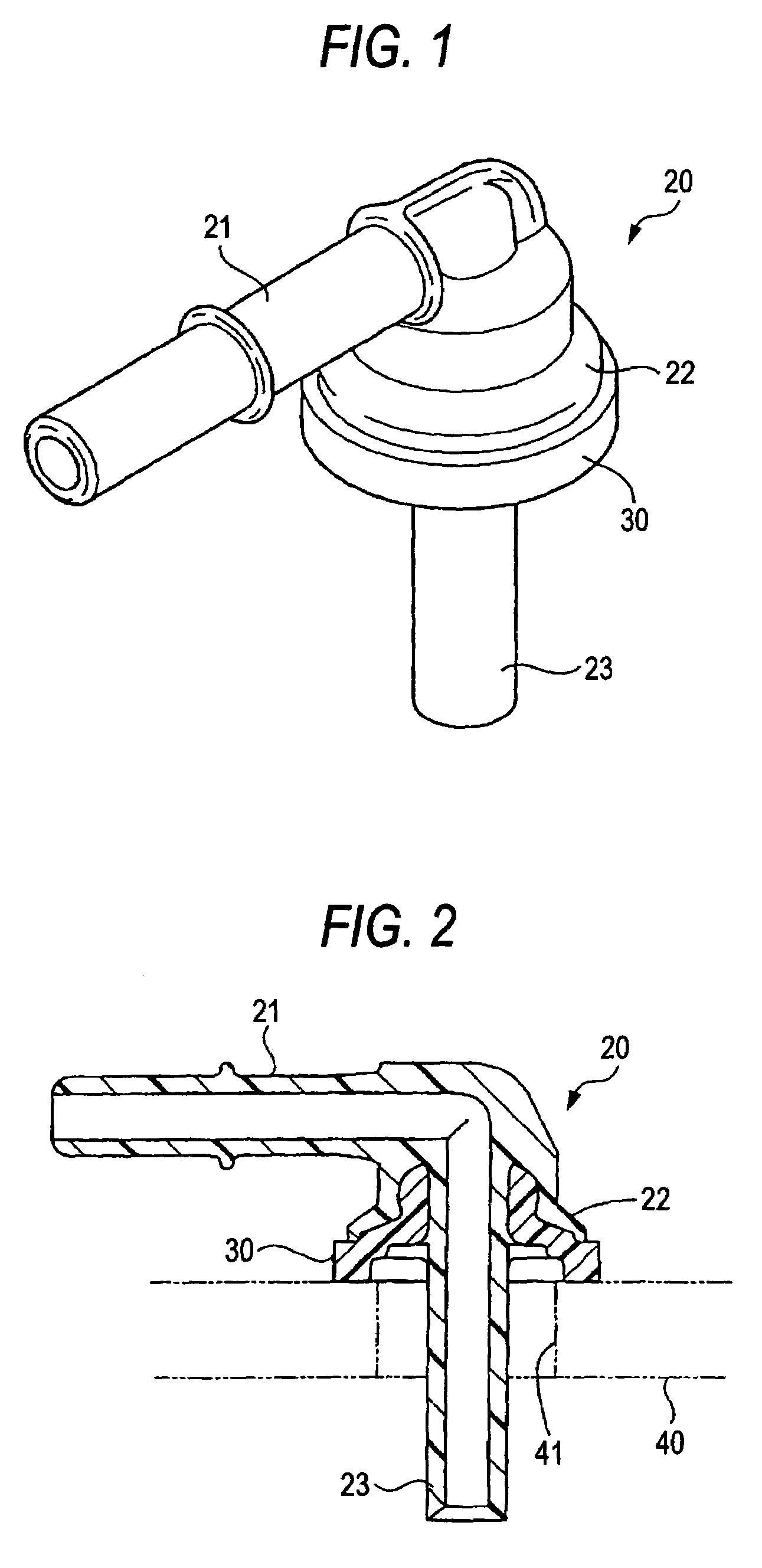

Joint for fuel tank and method for manufacturing the same

ActiveUS20050133509A1Good moldabilityImprove joint strengthThin material handlingFuel supplyPolyolefinFuel tank

A joint for fuel tank is attached to an opening of a resin fuel tank. The joint includes a joint main body and a flanged junction. The flanged junction is connected to the joint main body and is weldable to a periphery of the opening of the fuel tank. The joint main body includes a semi-aromatic polyamide obtained by polymerization of source monomers containing an aromatic monomer component and an aliphatic monomer component. An amount of a terminal amino group of the semi-aromatic polyamide is greater than or equal to 40 μeq / g. The junction includes a modified polyolefin having: a density in a range of 0.930 to 0.950; and a melt flow rate as measured in accordance with JIS-K7210 in a range of 0.06 to 3.0 g / 10 minutes.

Owner:PIOLAX CO LTD

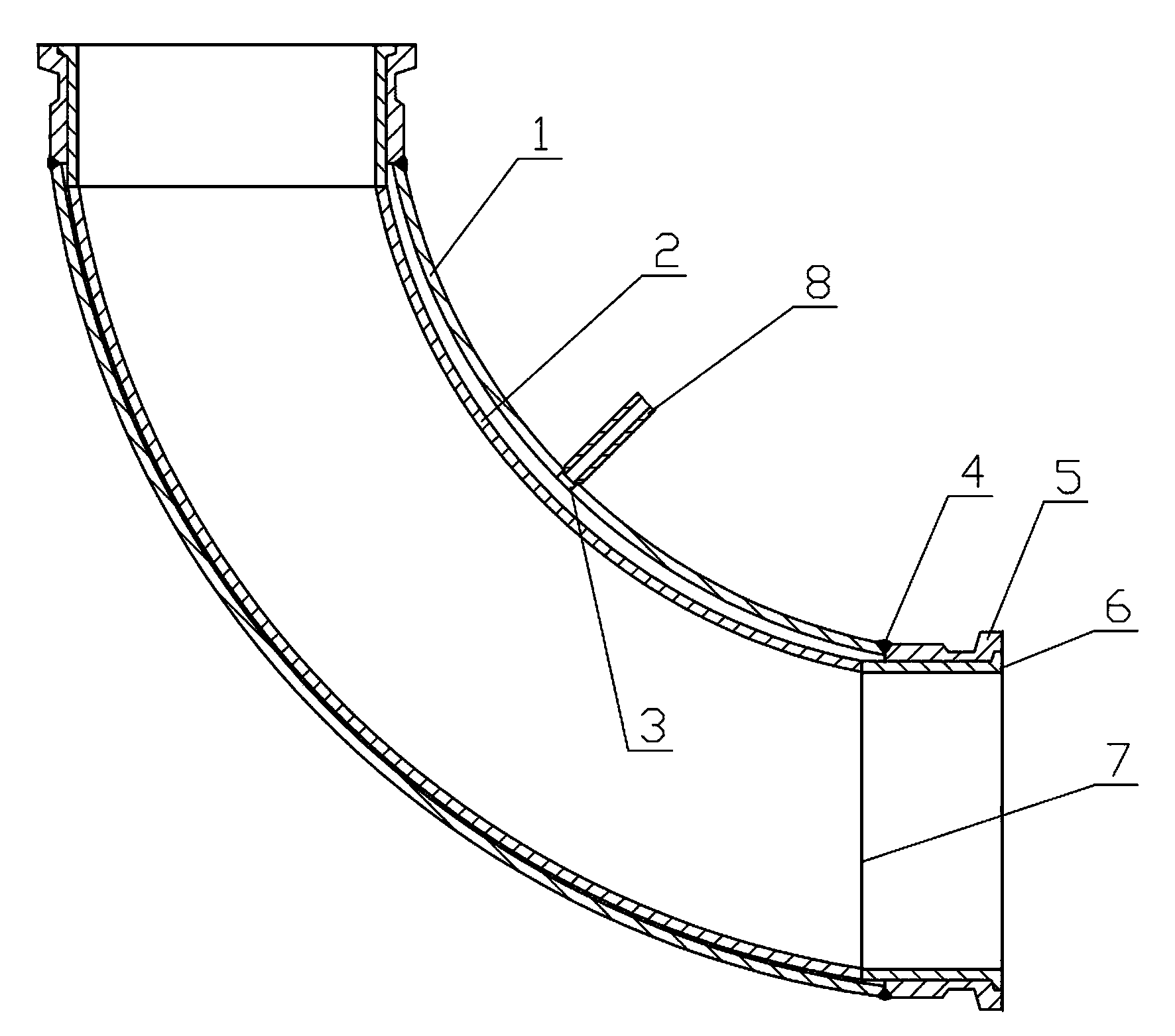

Crack filling method of compound bent pipe and abrasion-resistant compound bent pipe

The invention relates to a crack filling method of a compound bent pipe and the abrasion-resistant compound bent pipe, and belongs to the technical field of machining. The crack filling method of the compound bent pipe and the abrasion-resistant compound bent pipe resolve the problems that an interval exists between a lining and an outer shell in an existing abrasion-resistant compound bent pipe, so that in the use process, more than 90 percent of compound bent pipes will crack and can not be used any longer. The crack filling method is characterized in that (1) the lining and the outer shell are combined in a sleeved mode, and an injection hole is drilled in the outer shell; (2) two flanges are adopted and respectively comprise a flange inner ring and a flange outer ring, and after each flange inner ring and the corresponding flange outer ring are combined in a sleeved mode, the outer ends are welded into a whole; (3) the outer shell is welded to the flange outer rings, the lining and the flange inner rings are in clearance fit to form an assembly interval crack; (4) paste is injected from the injection hole through an injection gun to fill the interval between the lining and the outer shell; (5) after the paste is cured, plug welding is carried out on the injection hole. The crack filling method of the compound bent pipe has the advantage that the high chromium cast iron compound bent pipe is not prone to cracking when subjected to an impact load, and is mainly used for manufacturing the abrasion-resistant compound bent pipe.

Owner:XIANGYANG TO WIN MACHINERY

Joint for fuel tank and method for manufacturing the same

ActiveUS7490863B2Excellent in fuel non-permeabilityGood chemical resistanceThin material handlingSiphonsPolyolefinFuel tank

A joint for fuel tank is attached to an opening of a resin fuel tank. The joint includes a joint main body and a flanged junction. The flanged junction is connected to the joint main body and is weldable to a periphery of the opening of the fuel tank. The joint main body includes a semi-aromatic polyamide obtained by polymerization of source monomers containing an aromatic monomer component and an aliphatic monomer component. An amount of a terminal amino group of the semi-aromatic polyamide is greater than or equal to 40 μeq / g. The junction includes a modified polyolefin having: a density in a range of 0.930 to 0.950; and a melt flow rate as measured in accordance with JIS-K7210 in a range of 0.06 to 3.0 g / 10 minutes.

Owner:PIOLAX CO LTD

70-DEG C protective-layer soft polyvinyl chloride plastic

InactiveCN105860350AHigh strengthEnlarging pores and pore structurePlastic/resin/waxes insulatorsCoumaronesToluene

The invention discloses 70-DEG C protective-layer soft polyvinyl chloride plastic. The plastic is prepared from, by weight, 45-50 parts of polyvinyl chloride, 22-25 parts of polystyrene, 15-18 parts of butadiene-acrylonitrile rubber, 6-9 parts of acrylic rubber, 3.2-3.6 parts of toluene diisocynate, 2.2-2.5 parts of stearic acid, 14-17 parts of super-dispersive graphene-reinforced filler, 1.4-1.7 parts of accelerant CZ, 2-2.3 parts of accelerant TMTD, 1.3-1.6 parts of coumarone, 0.8-1.2 parts of antioxidant TNP and 1.2-1.5 parts of antioxidant DLTP.

Owner:ANHUI YANGTIAN PLASTIC IND TECH

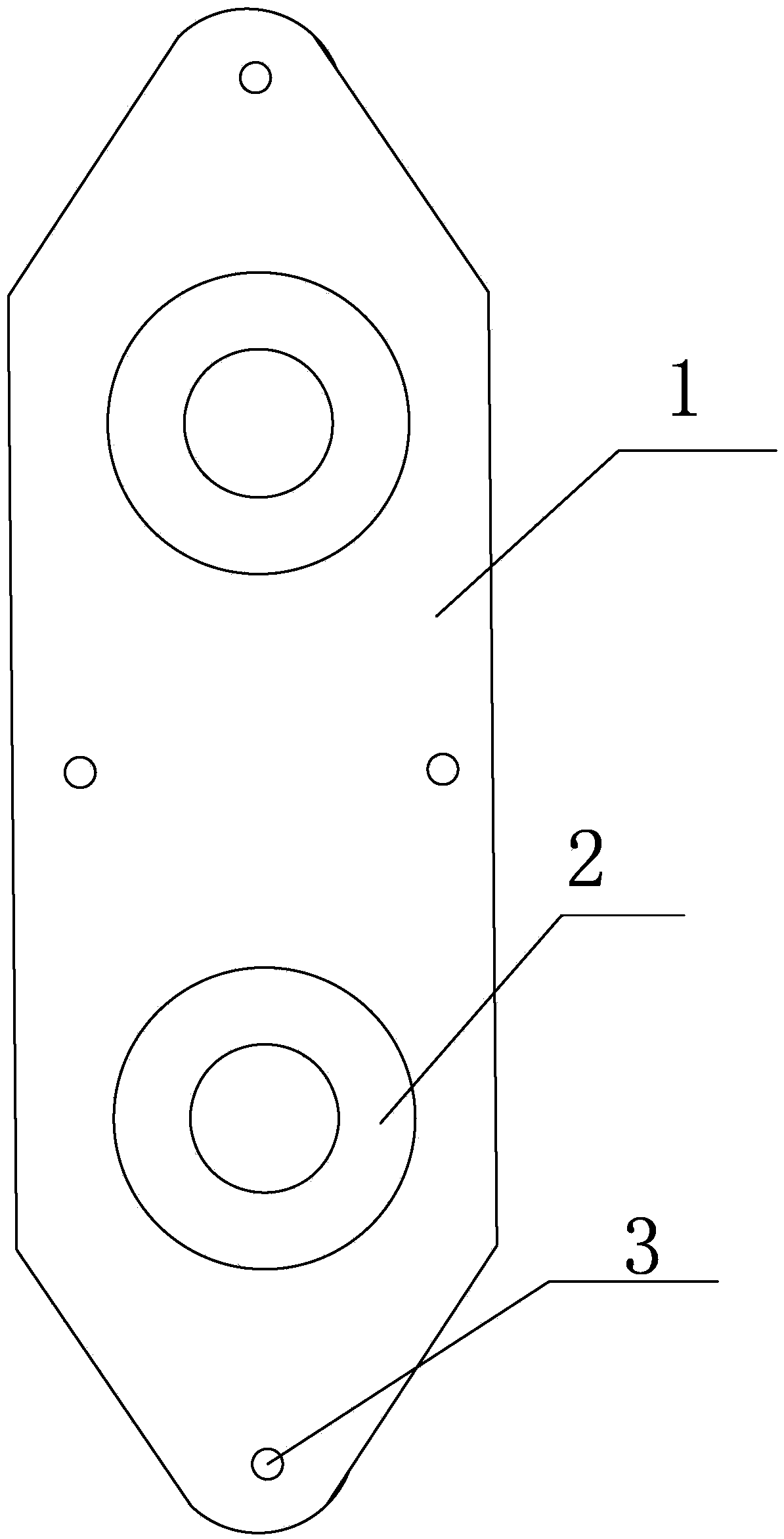

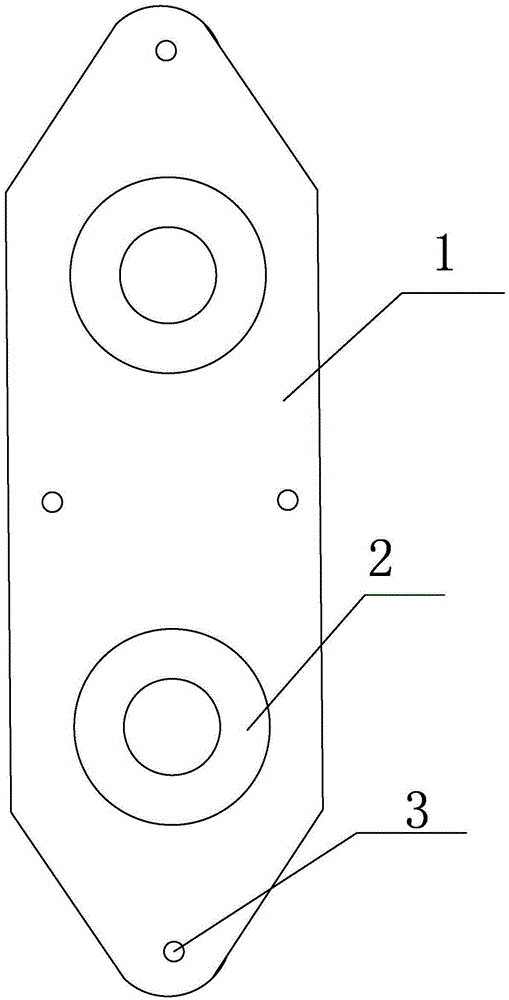

Nut plate

InactiveCN105422590ALong process cycleImprove plasticityNutsMetallic material coating processesFastenerAlloy steel

The invention relates to a fastener, in particular to a nut plate and belongs to the technical field of alloy materials. The nut plate comprises a body, bosses and positioning holes, wherein the bosses are symmetrically arranged in the positions, near the end portions, of the two ends of the body; the number of the positioning holes is an even number; the positioning holes are symmetrically formed in the surface of the body; the middle axis position of the body is hollow; the nut plate is formed by machining high-strength alloy steel. The high-strength alloy steel of the nut plate comprises, by mass, 0.02-0.10% of C, 0.05-0.30% of Si, 0.20-0.50% of Mn, 0.15-1.20% of Al, 0.50-1.2% of Cr, 0.003-0.01% of V, 0.08-0.20% of B, 0.01-0.03% of Ti, 0-0.035% of S, 0-0.035% of P, and the balance Fe. The constituents and mass percentage of the nut plate are reasonable in compatibility, higher strength and hardness are achieved, higher plasticity and toughness are also achieved, the machining performance of the nut plate is improved remarkably, and the nut plate is easy to weld.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

High-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and preparation method thereof

InactiveCN111850361AStay plasticMaintain corrosion resistanceFurnace typesHeat treatment furnacesThin slabManganese

The invention relates to a high-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and a preparation method thereof, and aims to solve the problems of low strength and low post-welding strength of the existing high-performance aluminum alloy sheet in China. The method comprises the following steps of: smelting a pure aluminum ingot, a pure magnesium ingot, an aluminum-manganese intermediate alloy, an aluminum-erbium intermediate alloy, an aluminum-zirconium intermediate alloy, an aluminum-titanium intermediate alloy and an aluminum-beryllium intermediatealloy to obtain an aluminum alloy solution; and sequentially carrying out casting, homogenizing annealing, hot rolling cogging wide rolling, hot continuous rolling, uncoiling slicing, sheet annealing, tension leveling and finished product sawing on the aluminum alloy solution to obtain the aluminum-magnesium-erbium-zirconium alloy wide sheet. The invention can obtain the high-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and the preparation method thereof.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Lily polysaccharide edible film

The invention provides lily polysaccharide edible film which is prepared by heating, moulding and film forming of lily polysaccharide molecule with molecular weight of 301-500Kda and comprising glucose, galactose, mannose, arabinose and galacturonic acid. The obtained lily polysaccharide edible film has advantages of moisture resistance, antibacterial performance, reduced moldy and high toughness, and is good substitute of traditional edible moisture-proof film.

Owner:上海汉素信生化科技发展有限公司

Machining method for long nut

InactiveCN105420474AImprove high temperature stabilityImprove wear resistanceNutsSolid state diffusion coatingHardnessUltimate tensile strength

The invention relates to a machining method for fasteners, in particular to a machining method for a long nut, and belongs to the technical field of long nut machining. The machining method comprises the steps that three-layer layered porous silicon carbide ceramics / alloy steel combined materials are subjected to normalization firstly and then are machined to be a long nut blank, and finally the long nut blank is subjected to heat treatment to form the long nut. The heat treatment comprises carburizing treatment and tempering treatment. The three-layer layered porous silicon carbide ceramics / alloy steel combined materials comprise 30-50% of three-layer layered porous silicon carbide ceramics and 50-70% of alloy steel by volume percent. The long nut is prepared from the three-layer layered porous silicon carbide ceramics / alloy steel combined materials, the three-layer layered porous silicon carbide ceramics and the alloy steel are supporting frameworks for each other, the strength, hardness, toughness, corrosion resistance and abrasion resistance of the long nut are improved through annealing treatment and carburizing treatment, the machining performance of the long nut is improved, and the long nut is easy to weld.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

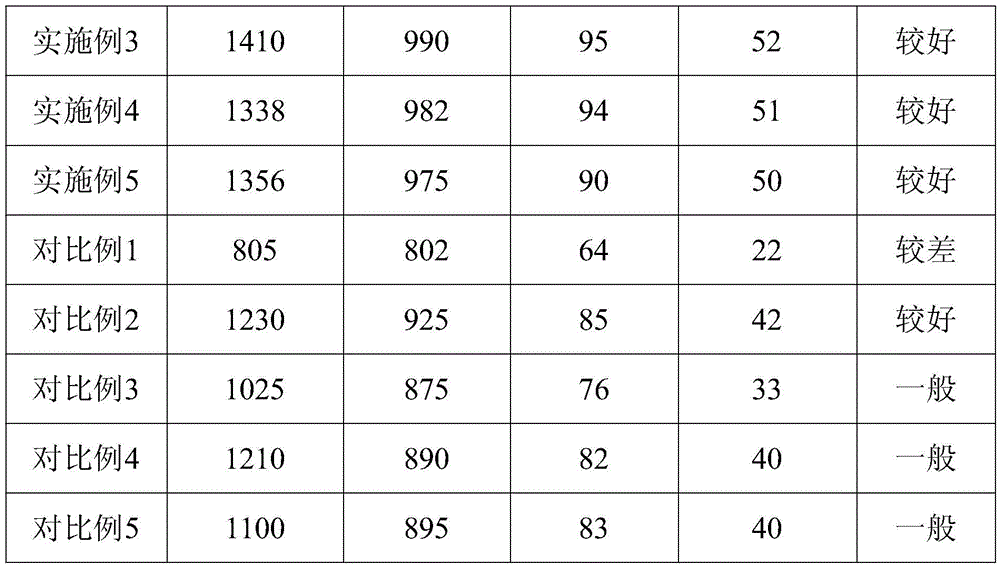

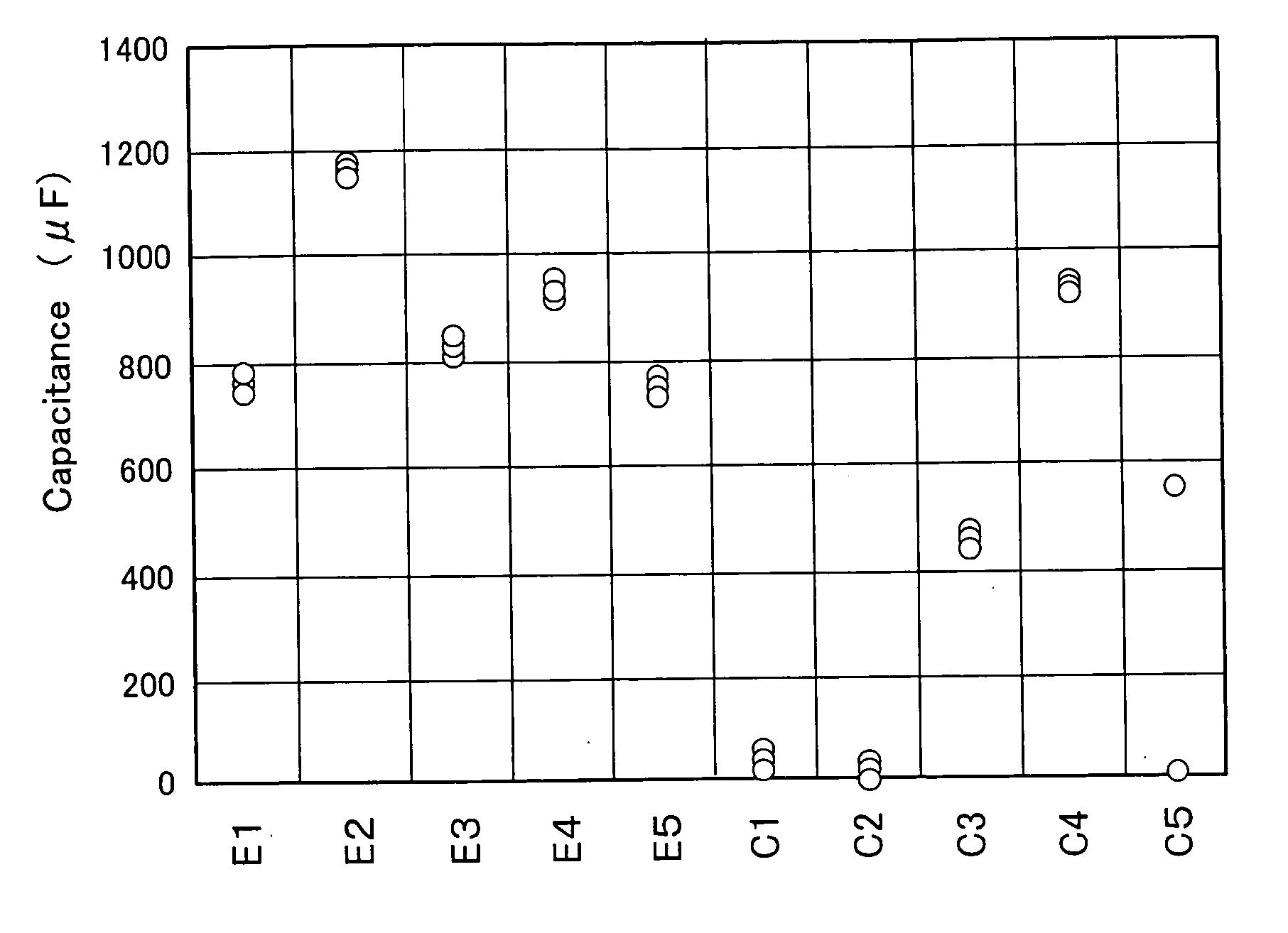

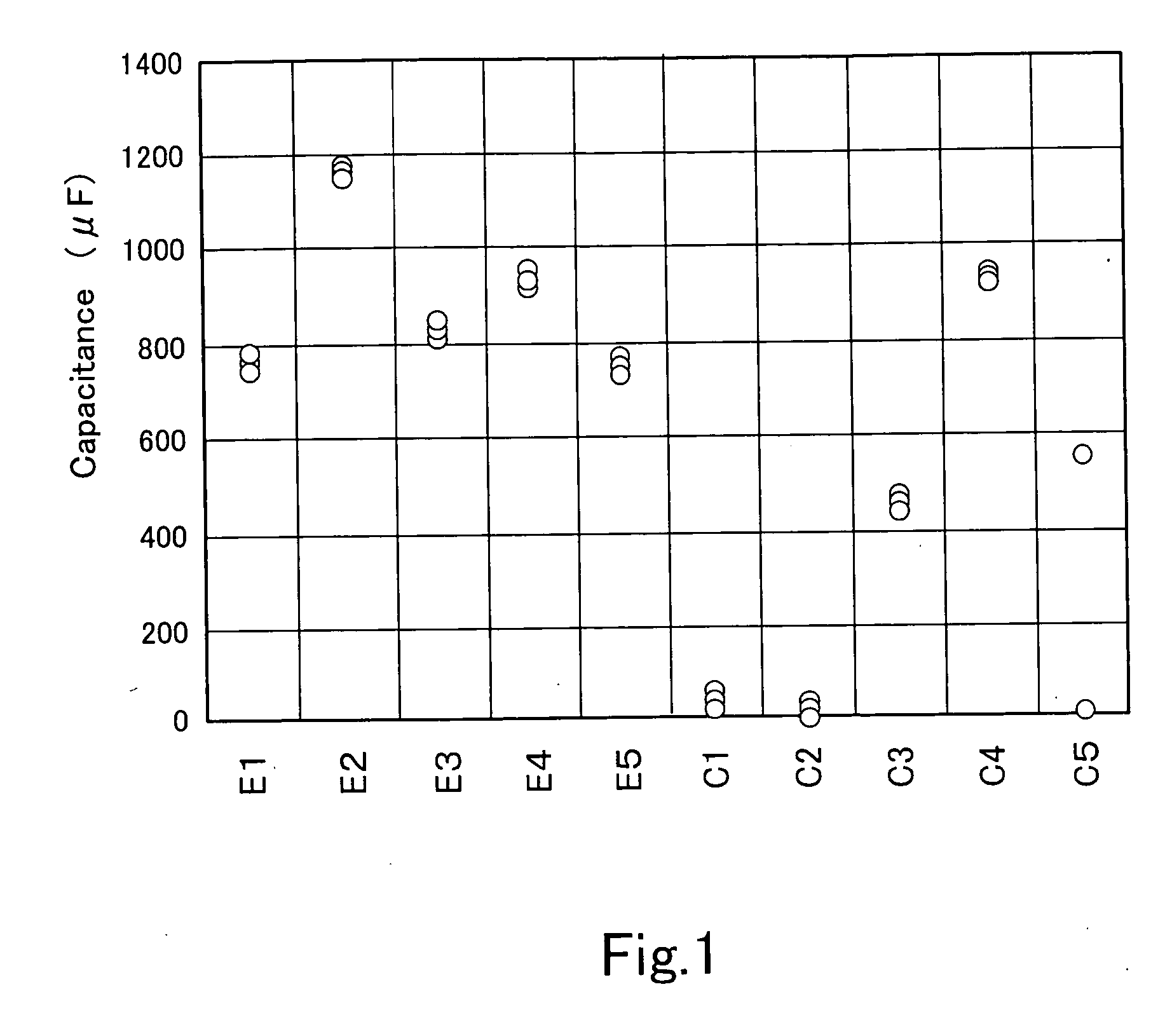

Niobium alloy powder, anode for solid electrolytic capacitor and solid electrolytic capacitor

InactiveUS20050280977A1Long-term stabilityImprove heat resistanceLiquid electrolytic capacitorsWound capacitorsHydrogenElectrolytic capacitor

There is provided a niobium alloy powder suitable for manufacturing solid electrolytic capacitors having small leakage currents and high capacitances, where the powder is obtained by enhancing the thermal stability of the niobium oxide coating film while improving the temperature dependence of the sintering behavior of the powder. The niobium alloy powder includes one or more of molybdenum, chromium, and tungsten each with a content of 0.002 to 20% by mass, and phosphorus and boron each with a content of 0.002 to 5% by mass, and moreover, includes hydrogen with a content of 0.005 to 0.10% by mass, the balance being substantially niobium; the specific surface area of the powder is from 1 to 20 m2 / g; the powder has a cumulative pore volume of 0.2 ml / g or more; and the cumulative volume of the pores each having a diameter of 1 μm or less makes up 10% or more and the cumulative volume of the pores each having a diameter of 10 μm or less makes up 40% or more in relation to the total cumulative pore volume.

Owner:KAWATETABU MINING

70 degrees centigrade insulation grade flexible polyethylene plastic

The invention discloses a 70 degrees centigrade insulation grade flexible polyethylene plastic, comprising the following raw materials by weight: 37-40 parts of low-density polyethylene, 23-26 parts of PVC resin, 12-15 parts of polyvinyl chloride, 1.1-1.4 parts of stearic acid, 15-18 parts of ultra-dispersed graphene reinforcement filler, 0.5-0.8 part of paraffin, 1-3 parts of polyethylene wax, 2.6-2.9 parts of calcium stearate, 0.9-1.2 parts of butyl benzyl phthalate, 1.4-1.7 parts of epoxidized butyl oleate, 0.4-0.6 part of anti-aging agent, and 1.4-1.7 parts of diisooctyl phenyl phosphite.

Owner:ANHUI YANGTIAN PLASTIC IND TECH

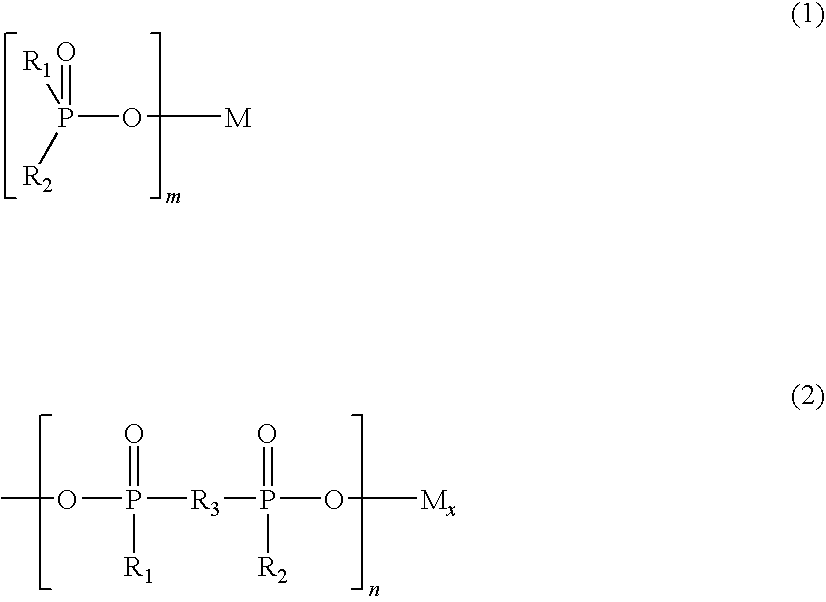

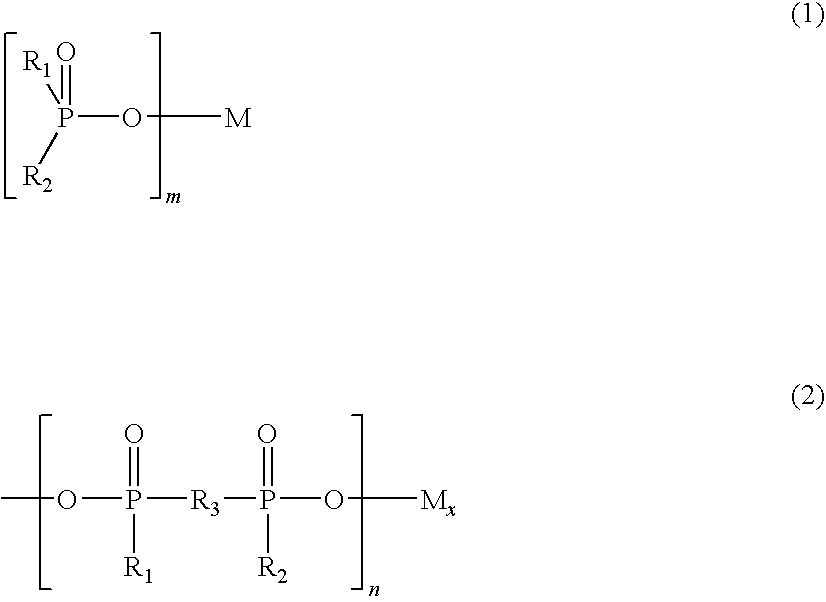

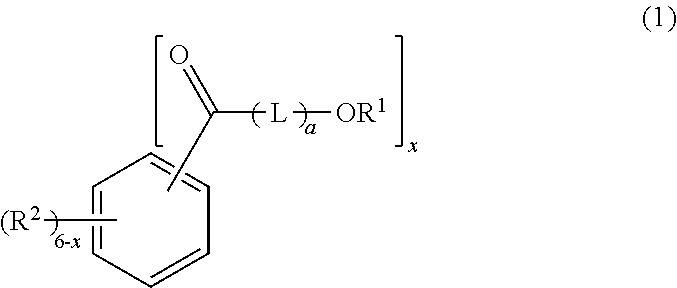

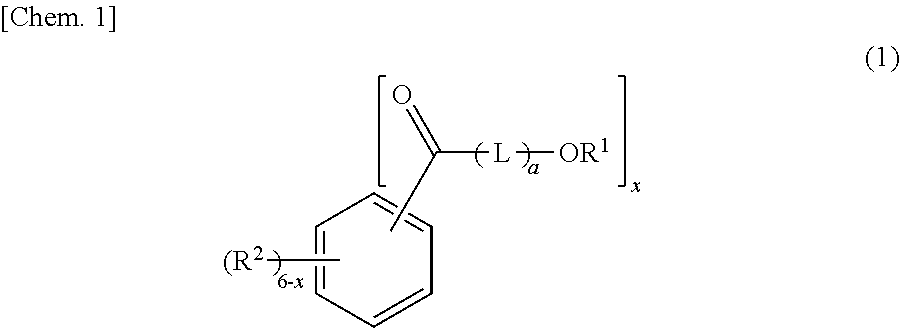

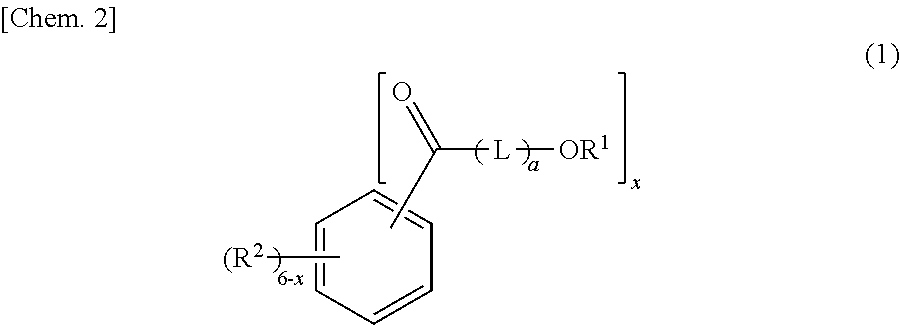

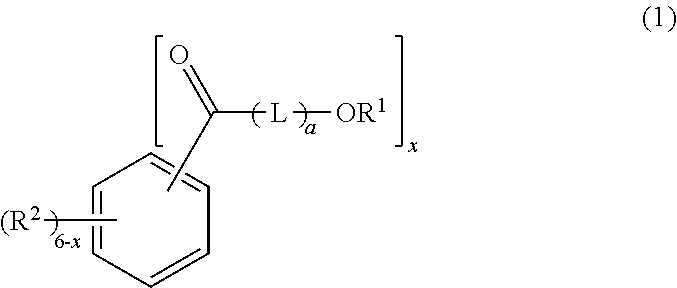

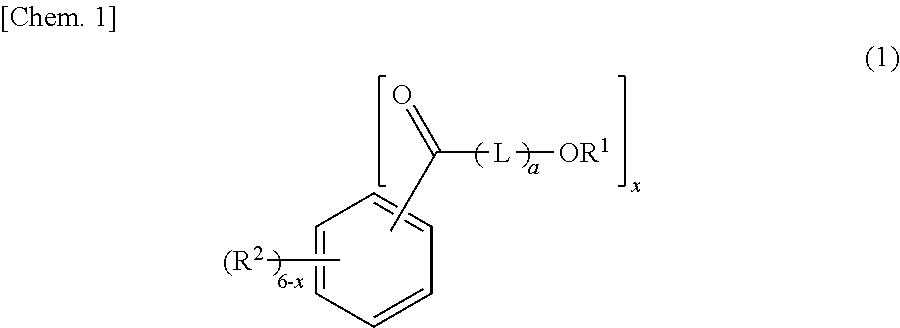

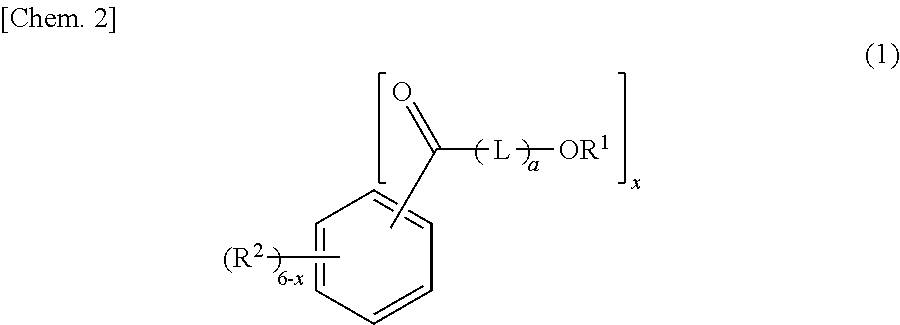

Plasticizer for vinyl chloride resin, vinyl chloride resin composition, wire harness, and dashboard

ActiveUS20180244894A1Improve compatibilityStay plasticOrganic compound preparationCarboxylic acid esters preparationHydrogen atomHeat resistance

The present invention provides a plasticizer for a vinyl chloride resin including an ester compound (A1) represented by General Formula (1):(in the formula, L's each represent an aliphatic oxycarboxylic acid residue having 3 to 18 carbon atoms or a cyclic ester residue having 3 to 18 carbon atoms, R1's each represent an alkyl group having 6 to 18 carbon atoms, R2's each represent a hydrogen atom or an alkyl group having 1 to 6 carbon atoms, a represents a repeating number of the L, provided that the total of the plural a's is from 1 to 10, and x is an integer of 2 to 4), in order to provide a plasticizer for a vinyl chloride which has excellent compatibility with vinyl chloride resins and with which a vinyl chloride resin composition capable of providing a molded article having excellent freeze resistance and heat resistance can be obtained.

Owner:DAINIPPON INK & CHEM INC

Medium-carbon high-chromium crack-resistant abrasion-proof steel ball and preparation method thereof

The invention discloses a medium-carbon high-chromium crack-resistant abrasion-proof steel ball. The medium-carbon high-chromium crack-resistant abrasion-proof steel ball has the following components in percentage by weight of: 0.25-0.35% of C, 0.5-0.7% of Si, 1.2-1.3% of Mn, 0.02-0.04% of Ni,13-15% of Cr, 0.2-0.3% of Mo, 0.1-0.2% of Al, 0.02-0.04% of B, 0.02-0.04% of Ti, 0.04-0.06% of V, 0.01-0.03% of W, 0.01-0.02% of La, and the balance of Fe and inevitable impurities, wherein an expression that 0.5Cr-11.4Ni-8.5W-1.3Mn is greater than 4.2% and lower than 5.5% is met. The invention also discloses a preparation method of the medium-carbon high-chromium crack-resistant abrasion-proof steel ball. The medium-carbon high-chromium crack-resistant abrasion-proof steel ball disclosed by the invention is high in abrasion resistance and good in crack resistance.

Owner:芜湖市永帆精密模具科技有限公司

Plasticizer for vinyl chloride resin, vinyl chloride resin composition, wire harness, and dashboard

ActiveUS10703880B2Improve compatibilityStay plasticOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePlasticizer

The present invention provides a plasticizer for a vinyl chloride resin including an ester compound (A1) represented by General Formula (1):(in the formula, L's each represent an aliphatic oxycarboxylic acid residue having 3 to 18 carbon atoms or a cyclic ester residue having 3 to 18 carbon atoms, R1's each represent an alkyl group having 6 to 18 carbon atoms, R2's each represent a hydrogen atom or an alkyl group having 1 to 6 carbon atoms, a represents a repeating number of the L, provided that the total of the plural a's is from 1 to 10, and x is an integer of 2 to 4), in order to provide a plasticizer for a vinyl chloride which has excellent compatibility with vinyl chloride resins and with which a vinyl chloride resin composition capable of providing a molded article having excellent freeze resistance and heat resistance can be obtained.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com