Moisture steaming blocking agent for plastic concrete

A technology of plastic concrete and evaporation inhibitor, which is applied in the field of concrete to achieve the effects of ensuring project quality, saving labor, and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

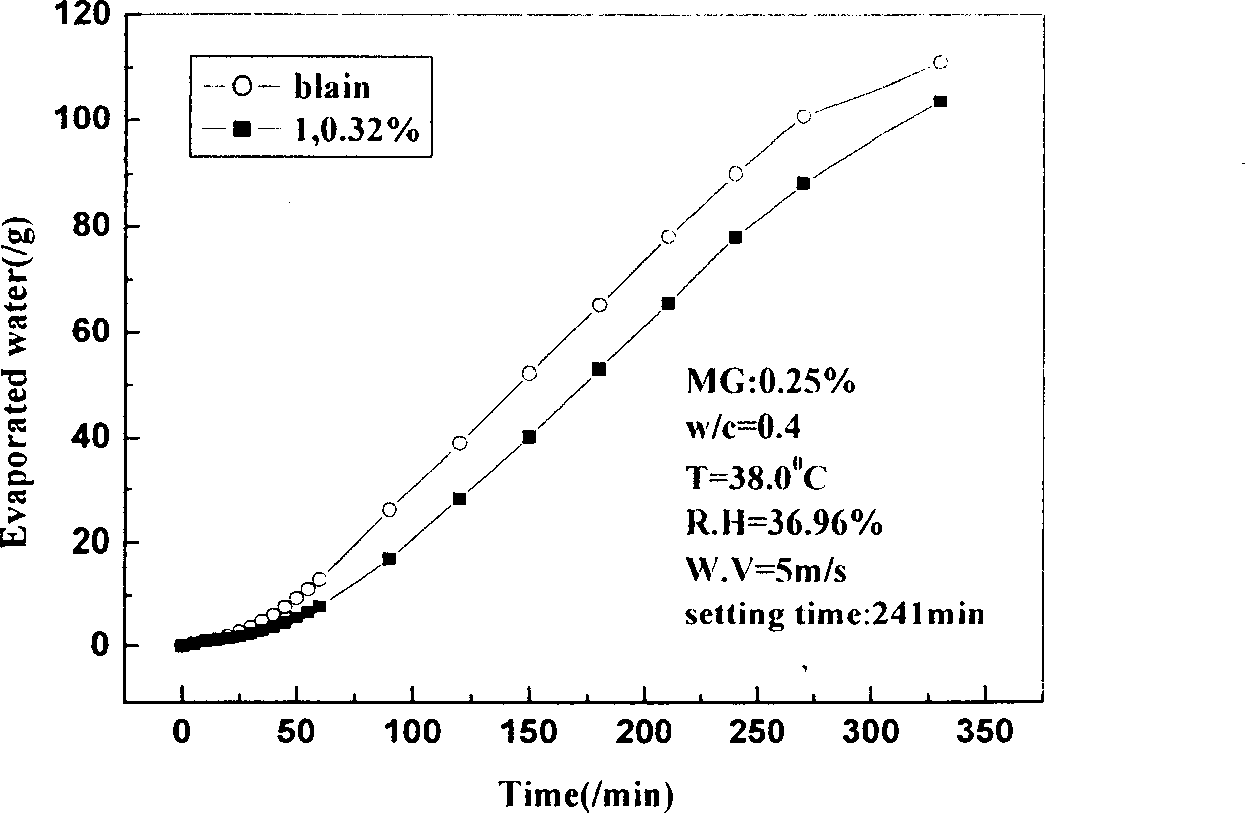

Image

Examples

Embodiment 1

[0032] A translucent water-emulsion type plastic concrete water evaporation inhibitor, the formula of the inhibitor is:

[0033] Water 60.8%

[0034] Paraffin, melting point: 56°C (GB / T2539) 25%

[0035] 2mol ethylene oxide added aliphatic alcohol C 12 -C 18 2.5%

[0036] 15mol ethylene oxide added stearyl alcohol 3%

[0037] Petroleum sulfonate, sodium salt 2.7%

[0038] Fluorocarbon surfactant (1% by weight) (Zonyl Fsp, manufactured by DuPont) 1.0%

[0039] Ethylene glycol phenyl ether 3.5%

[0040] Tributoxyethyl Phosphate 1.5%

Embodiment 2

[0042] A translucent water-emulsion type plastic concrete water evaporation inhibitor, the formula of the inhibitor is:

[0043] Water 52.5%

[0044] Paraffin, melting point: 50-52°C (GB / T2539) 15%

[0045] Microcrystalline paraffin, melting point: 67-72°C (GB / T8026) 15%

[0046] 20mol ethylene oxide added oleyl / cetyl alcohol 6%

[0047] 15mol ethylene oxide added stearyl alcohol 3%

[0048] Sodium dodecylbenzenesulfonate 1.5%

[0049] Fluorocarbon surfactant (1% by weight) (Zonyl Fsp, manufactured by DuPont) 1.0%

[0050] Diethylene glycol monomethyl ether 4.5%

[0051] Tributoxyethyl Phosphate 1.5%

Embodiment 3

[0053] A translucent water-emulsion type plastic concrete water evaporation inhibitor, the formula of the inhibitor is:

[0054] Water 54.5%

[0055] Paraffin, melting point: 30-35°C 15%

[0056] Oxidized polyethylene wax, melting point: 100-105°C, acid value: 23-28 10%

[0057] 12mol ethylene oxide added aliphatic alcohol C 12 -C 18 10%

[0058] Sodium Cumene Sulfonate 2.0%

[0059] Octyl Sulfate 2.5%

[0060] Diethylene glycol monomethyl ether 2.5%

[0061] Propylene glycol phenyl ether 3.5%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com