Cu-TiN nano composite film based on magnetron sputtering codeposition technology

A nanocomposite and magnetron sputtering technology, applied in the field of composite materials, can solve the problems of decreased electrical conductivity, little increase in hardness, and insufficient increase in film hardness, etc., and achieves great application value, high production efficiency, and efficient preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the metal substrate is placed in the vacuum chamber of the double-target magnetron sputtering apparatus, and the gas in the vacuum chamber is taken out to reach 10 ‐4 After the pressure of Pa, fill the vacuum chamber with Ar gas and keep it at a pressure of 0.4-3Pa, use DC cathode sputtering metal Cu, radio frequency cathode sputtering TiN, the size of the sputtering target is Cu-TiN nanocomposite films were formed on the substrate by co-deposition of Cu and TiN sputtering materials, and composite films with different TiN contents were obtained by controlling the sputtering power of DC and RF cathodes.

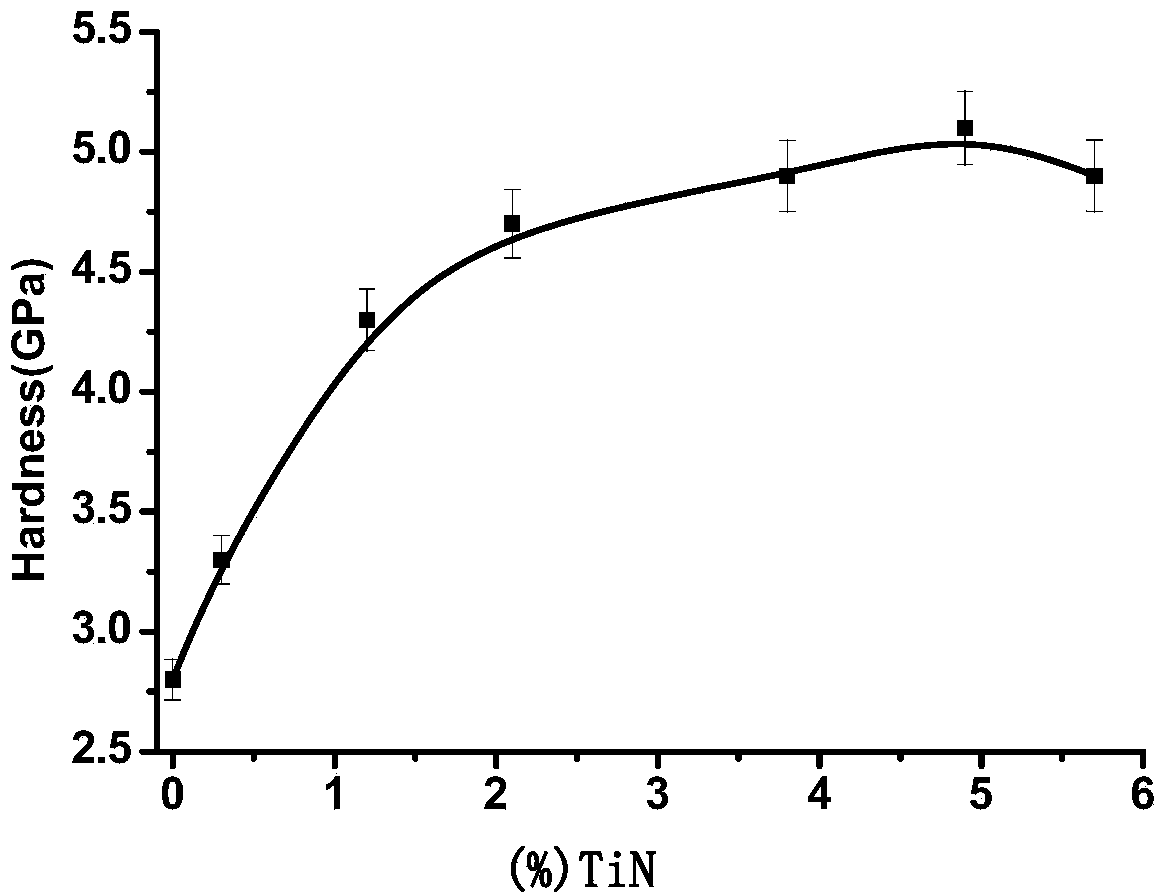

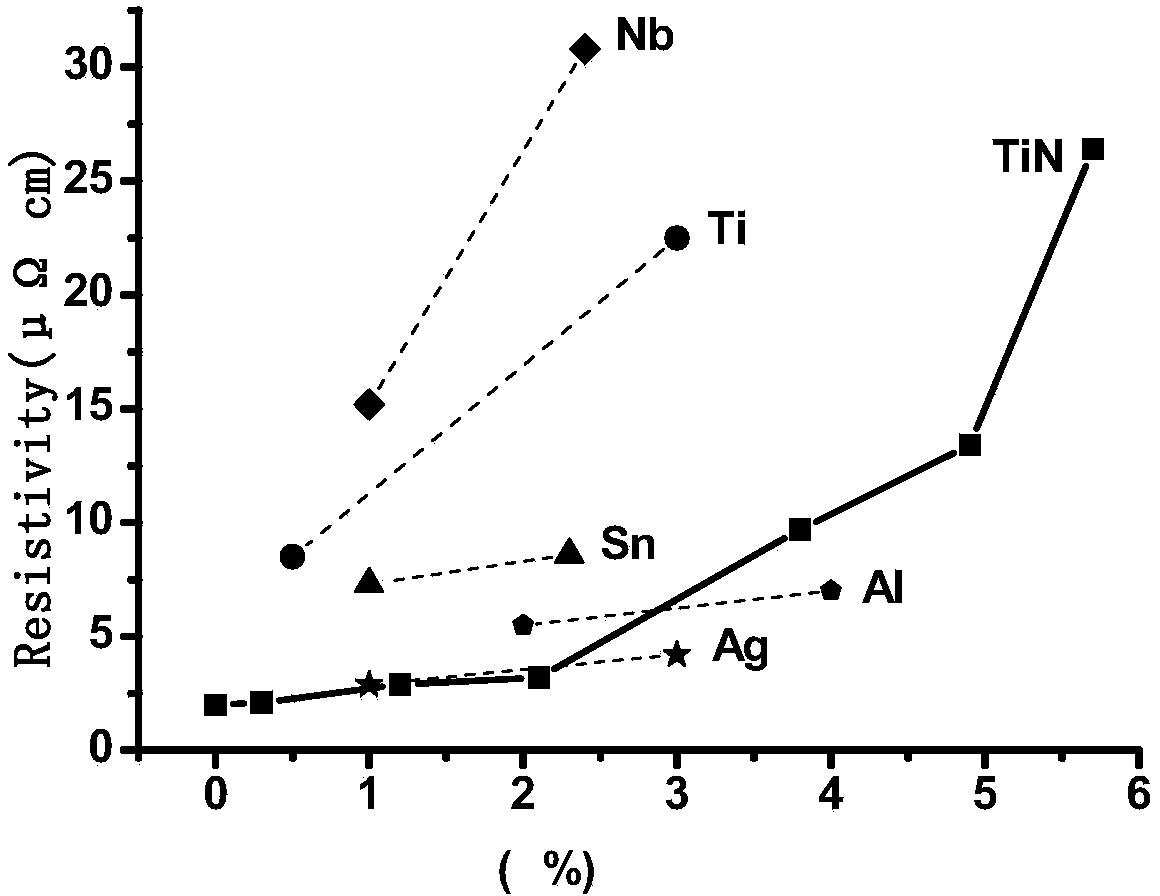

[0026] The content of TiN in the Cu‐TiN nanocomposite film is 1.0at.%, the rest is Cu, the hardness of the composite film is 4.1GPa, and the resistivity is 2.5μΩcm.

Embodiment 2

[0028] In this example, the operation similar to Example 1 is adopted. The content of TiN in the Cu-TiN nanocomposite film is 2.0 at.%, the remainder is Cu, the hardness of the composite film is 4.7 GPa, and the resistivity is 3.0 μΩcm.

Embodiment 3

[0030] In this example, the operation similar to that of Example 1 is adopted. The content of TiN in the Cu-TiN nanocomposite film is 5.0 at.%, the remainder is Cu, the hardness of the composite film is 5.1 GPa, and the resistivity is 15 μΩcm.

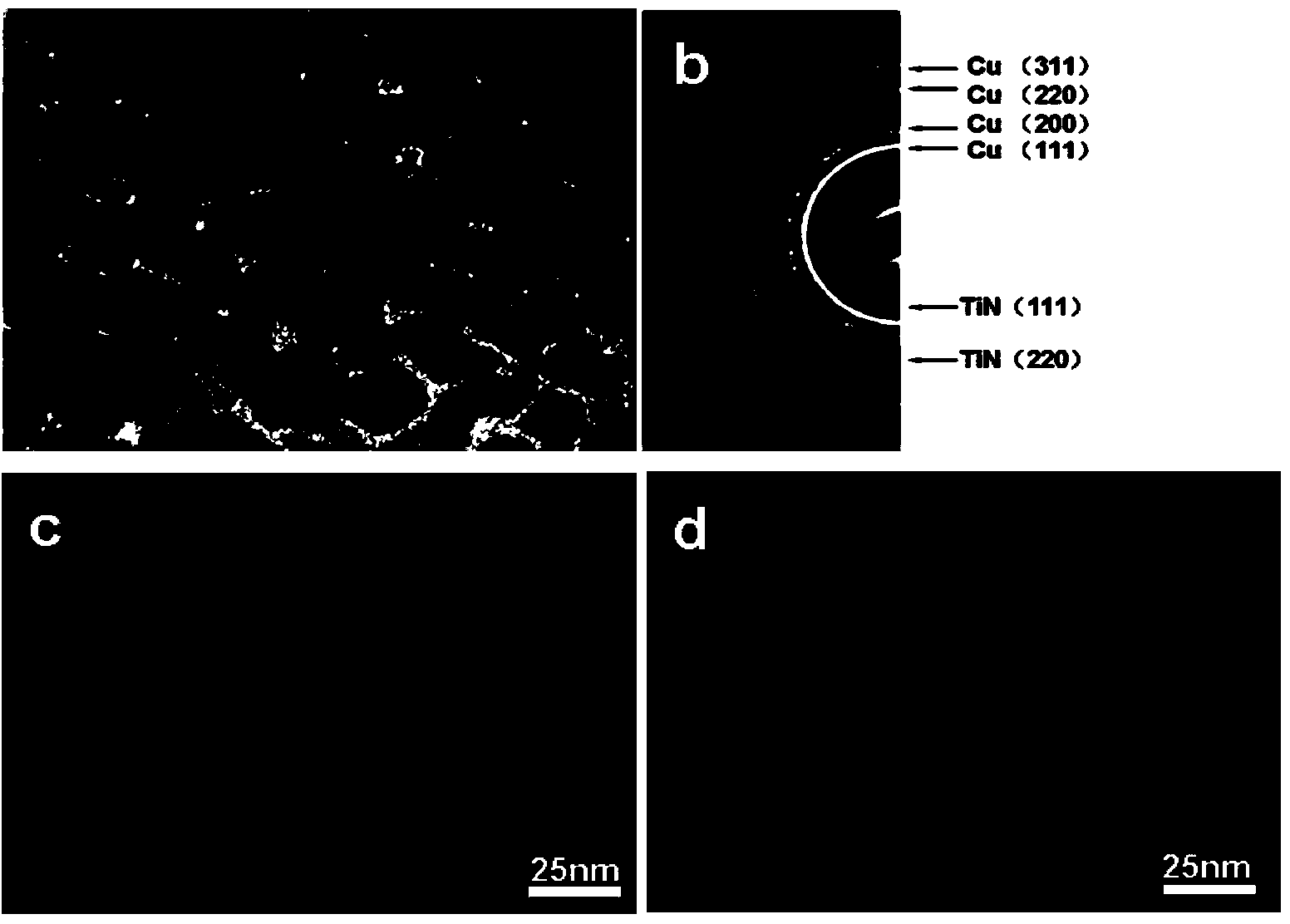

[0031] Implementation effect: such as Figure 1 ~ Figure 3 As shown, the hardness of the Cu-TiN nanocomposite film prepared by the above-mentioned embodiment is obviously improved when the content of TiN is lower; Cu grains smaller than 50nm and TiN particles smaller than 10nm form a uniformly distributed mixed structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com