Patents

Literature

34results about How to "Will not affect the formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-acting air-suspending friction-free air cylinder

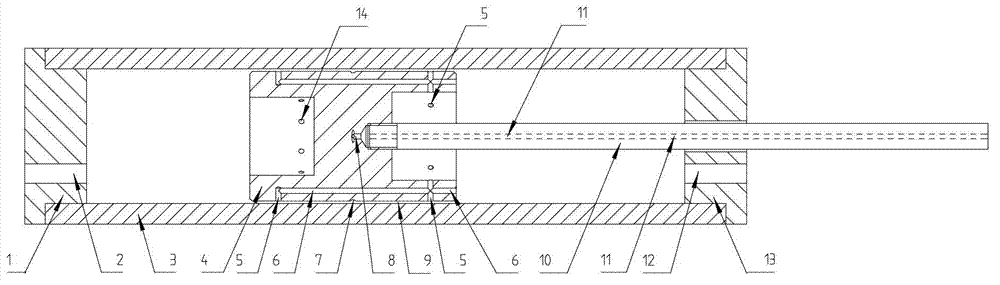

A double-acting air-suspending friction-free air cylinder comprises a cylinder barrel, a piston, a piston rod, a front end cover and a rear end cover, first blind holes axially punched from one end face of the piston form first air inlet holes, second blind holes radially punched from the piston wall are communicated with the first air inlet holes so as to form first throttling holes, third blind holes axially punched from the other end face of the piston form second air inlet holes, the second air inlet holes and the first air inlet holes on the other end face of the piston form included angles but are not communicated, fourth blind holes radially punched from the piston wall are communicated with the second air inlet holes to form second throttling holes, a circumferential groove is arranged on the middle circumferential surface of the piston and is internally punched along the radial direction of the piston to be led to the circle center so that pressure relief grooves are formed, the pressure relief grooves are uniformly distributed along the circumference direction and are communicated with the first air inlet holes, the second air inlet holes, the first throttling holes and the second throttling holes, and one end, connected with the piston rod, of the piston is punched along the axial center so to be communicated with the pressure relief grooves. The air cylinder achieves air supply by a high-pressure chamber thereof, and an air film is unaffected by high pressure.

Owner:CHONGQING SHUANGSHI MOTORCYCLE MFG

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

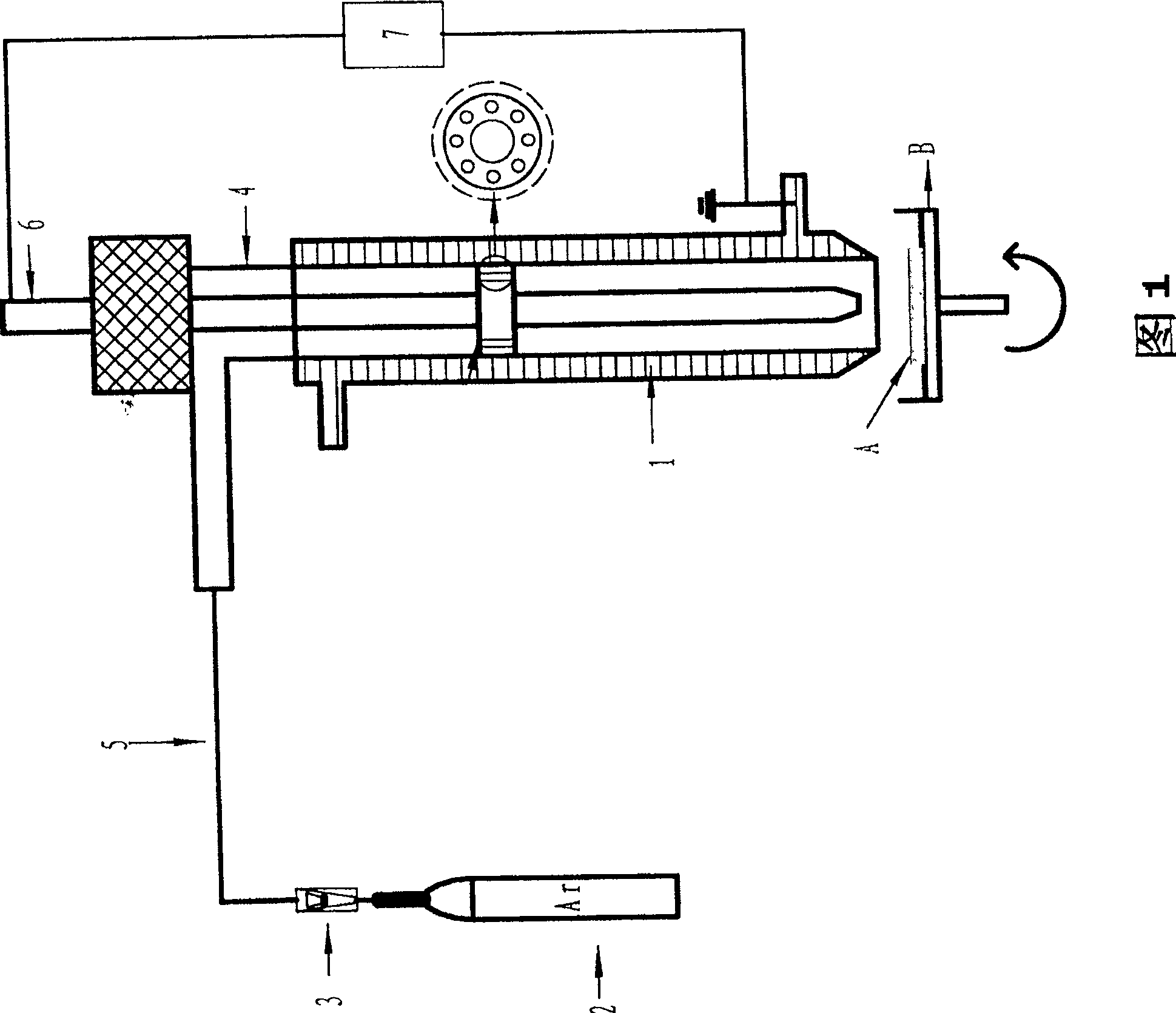

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

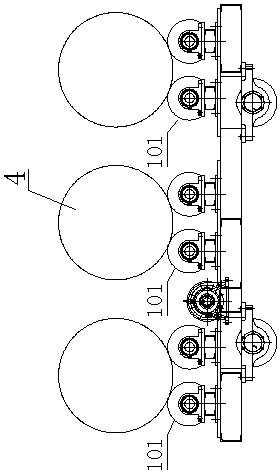

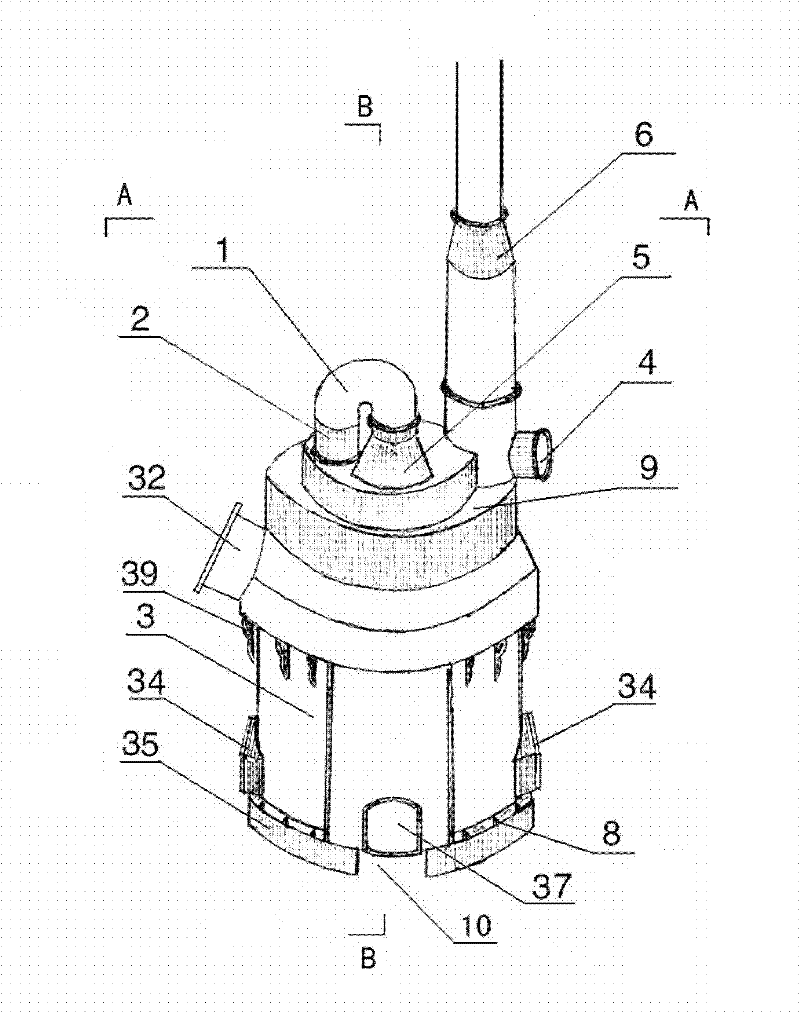

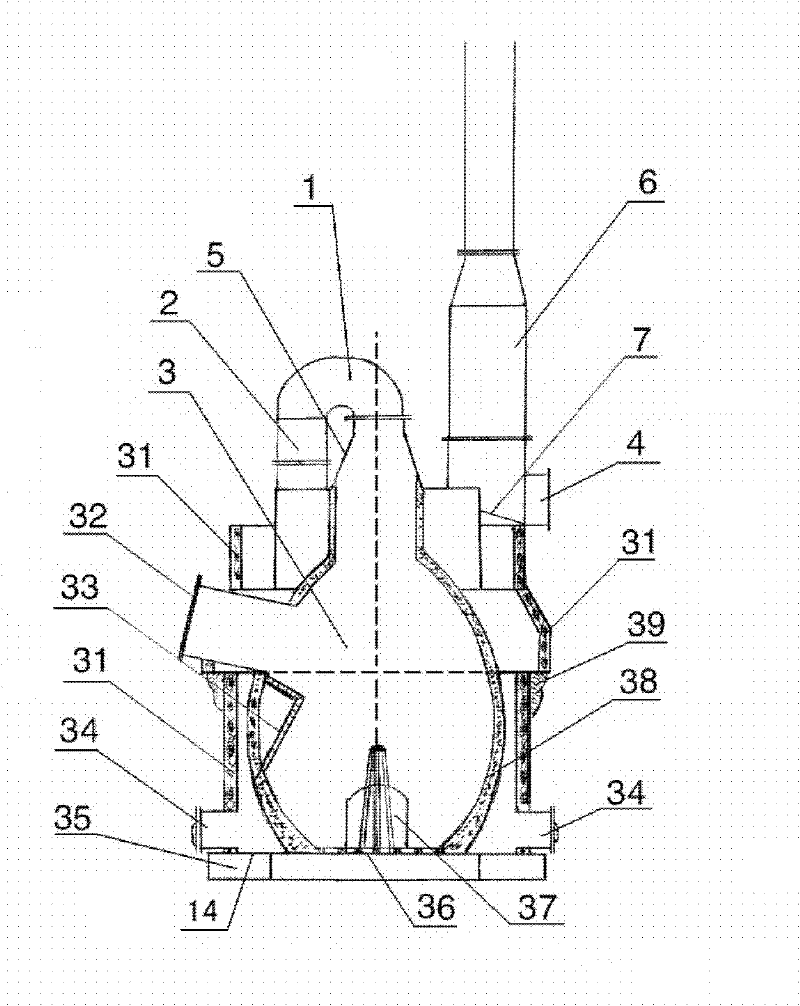

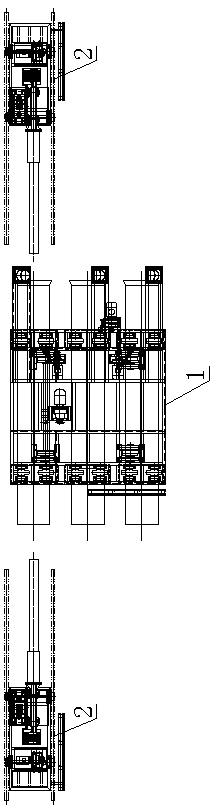

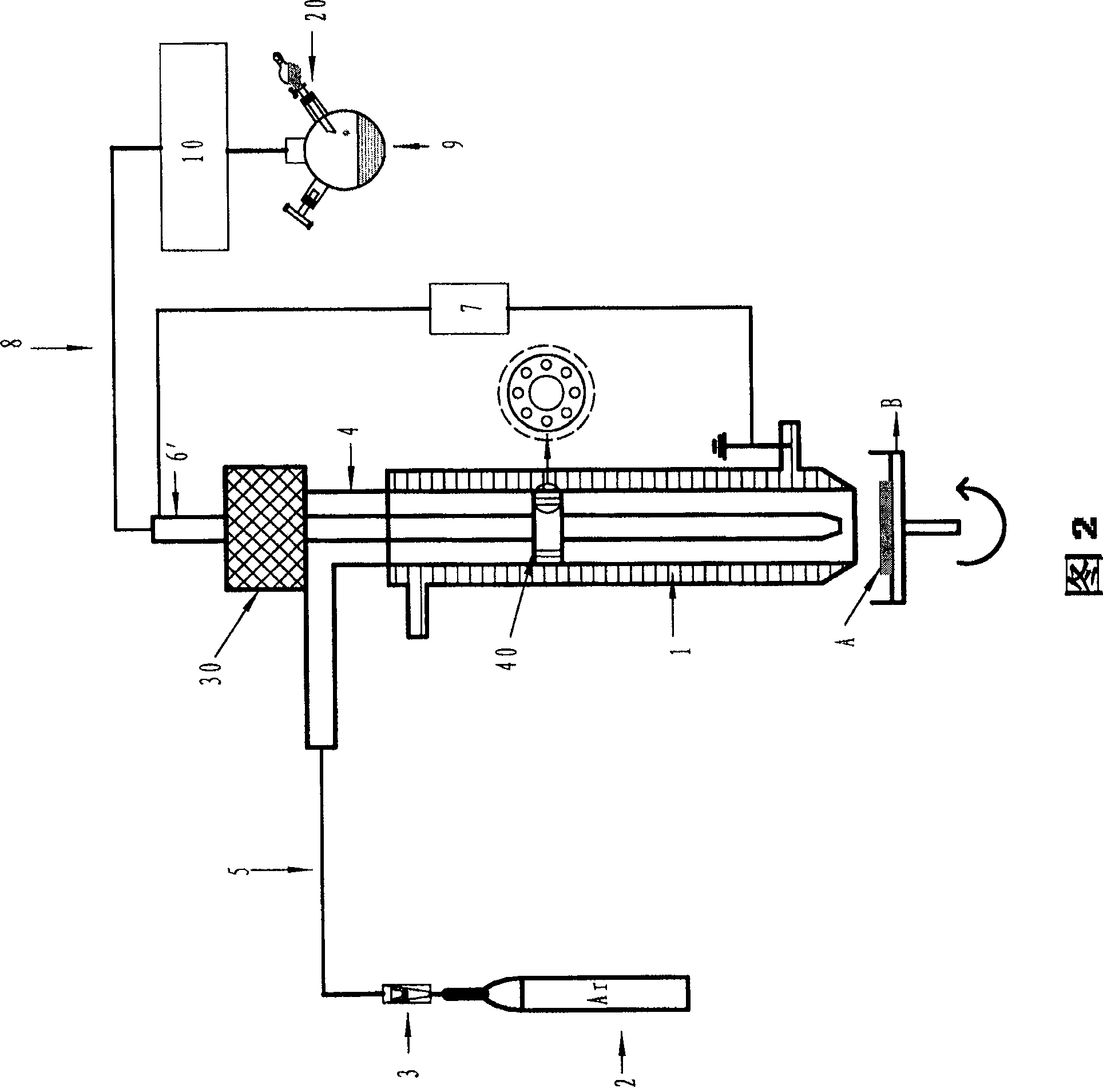

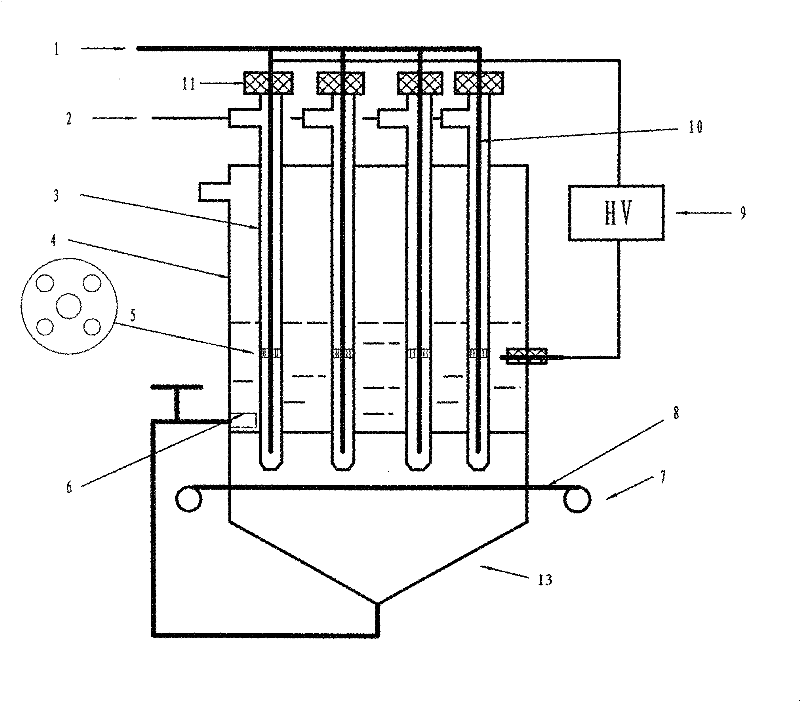

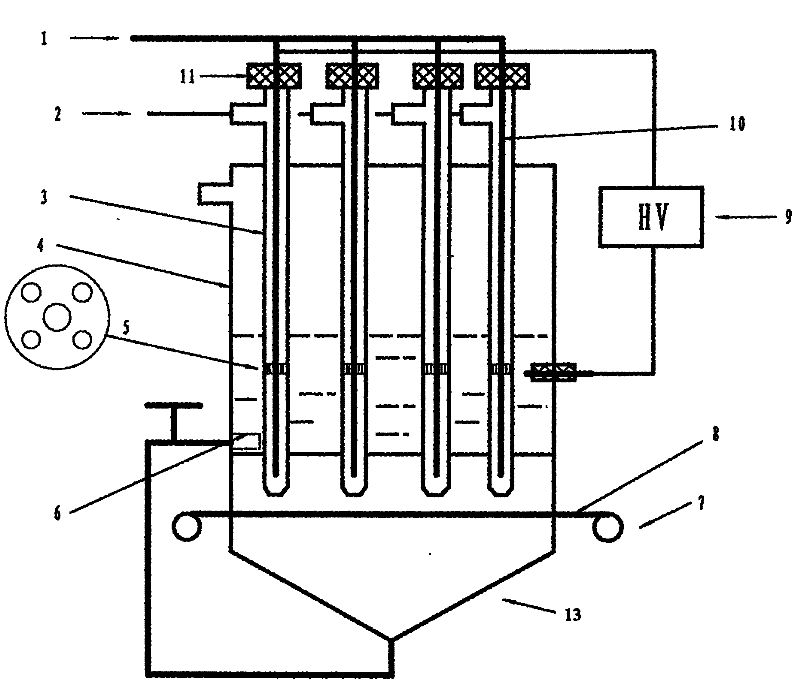

Room-temperature plasma torch array device simultaneously carrying out fiber yarn modification and sewage treatment

InactiveCN101538792AFast degradationTo achieve the effect of surface modificationWater/sewage treatment by irradiationPhysical treatmentFiberYarn

The invention discloses a room-temperature plasma torch array device simultaneously carrying out fiber yarn modification and sewage treatment. A plurality of rows of silica tubes internally provided with tubular metal electrodes are inserted into the electrodes of a conductive aqueous solution, one end of the silica tube penetrates the bottom of an organic-glass water tank and enters a modification room, the other end thereof is exposed out of the organic-glass water tank and sealed by a polyfluortetraethylene sleeve, the tubular metal electrodes penetrate the polyfluortetraethylene sleeve and are communicated with an active gas source, the exterior of the silica tube is communicated with an inert gas source, the bottom of the silica tube end is provided with through holes, the modification room is internally provided with fiber yarns vertical to the holes at the bottom of each row of the silica tubes and having the number corresponding to that of the silica tubes, the tubular metal electrodes are connected with a high-voltage end after being parallelly connected, and the low-voltage end is connected with the electrodes of the conductive aqueous solution. The conductive liquid is taken as an external electrode, has a cooling discharge system, reduces energy consumption, and avoids the generation of arc discharge due to the short circuit of the two electrodes caused by reflecting the plasma; simultaneously, the liquid electrode avoids the generation of medium fracture caused by different expansion coefficients of the metal electrodes and the medium.

Owner:ZHEJIANG SCI-TECH UNIV

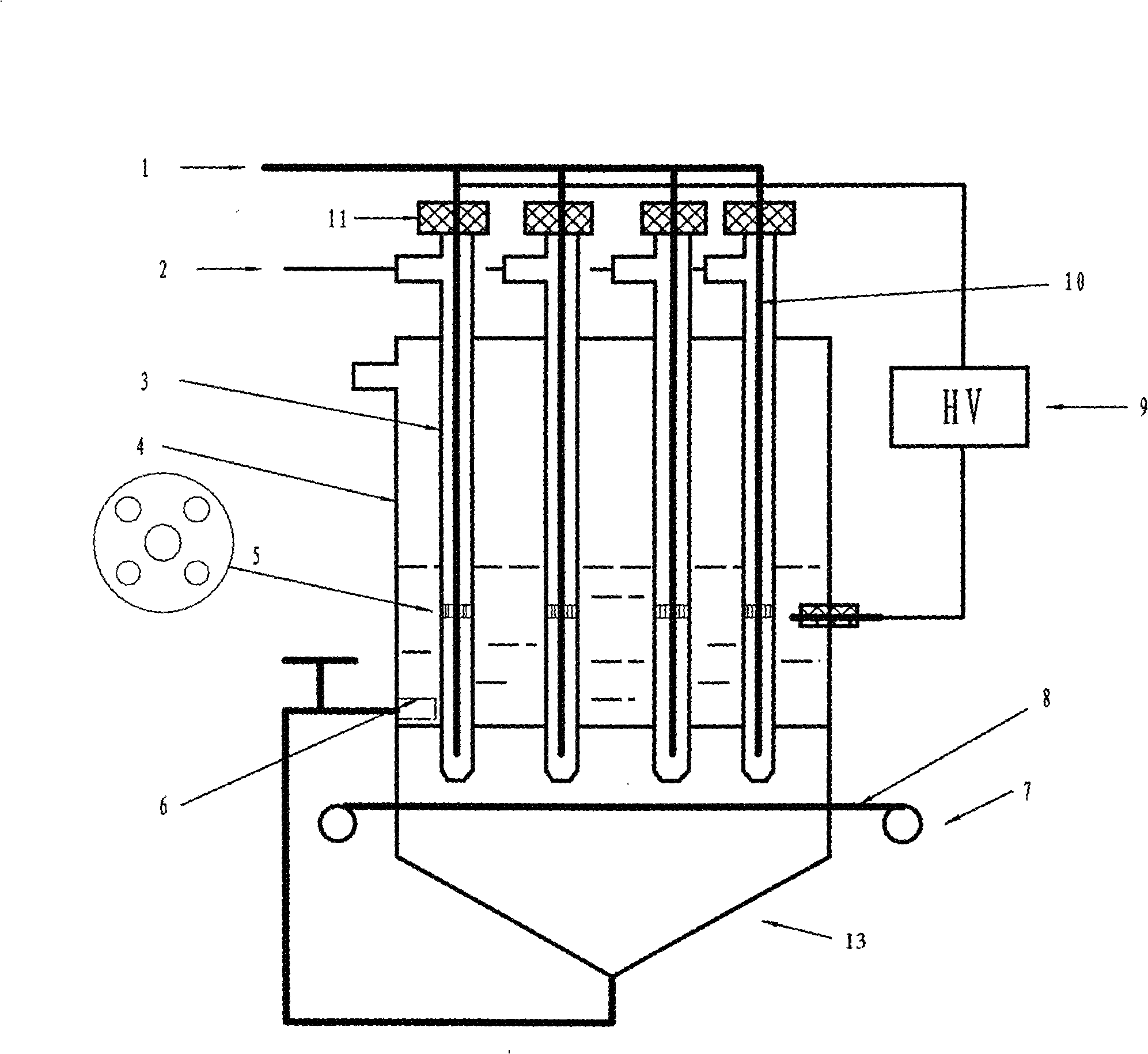

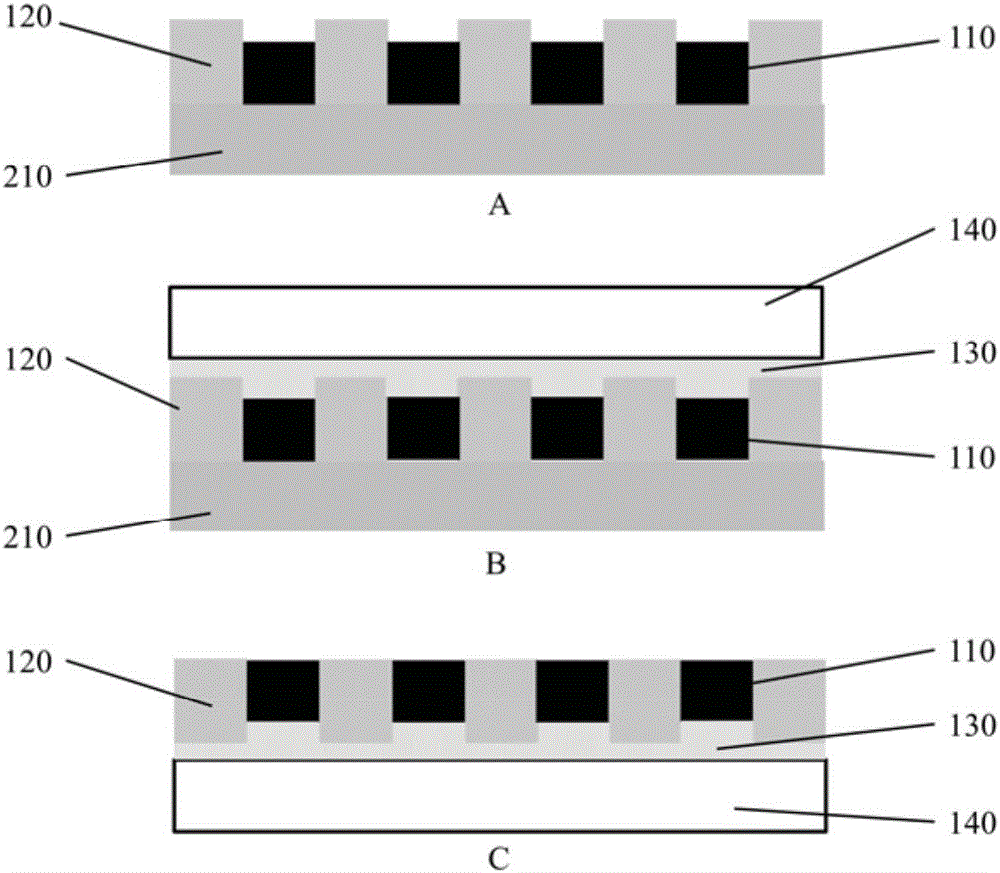

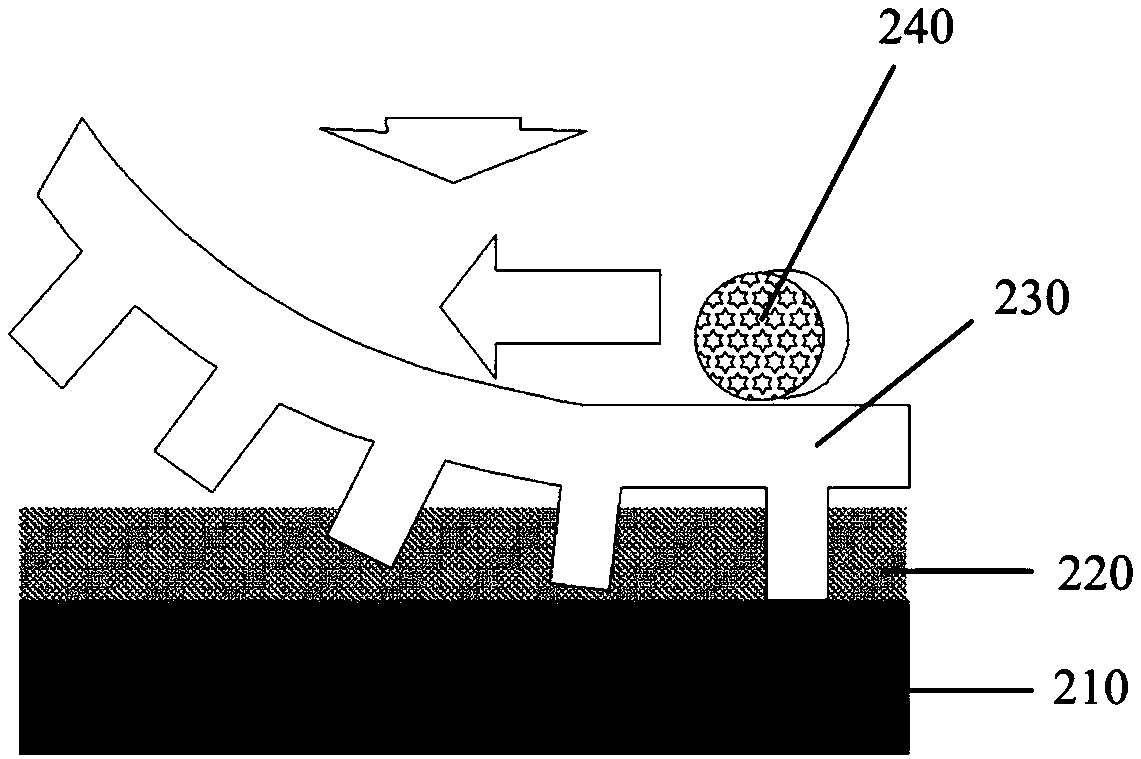

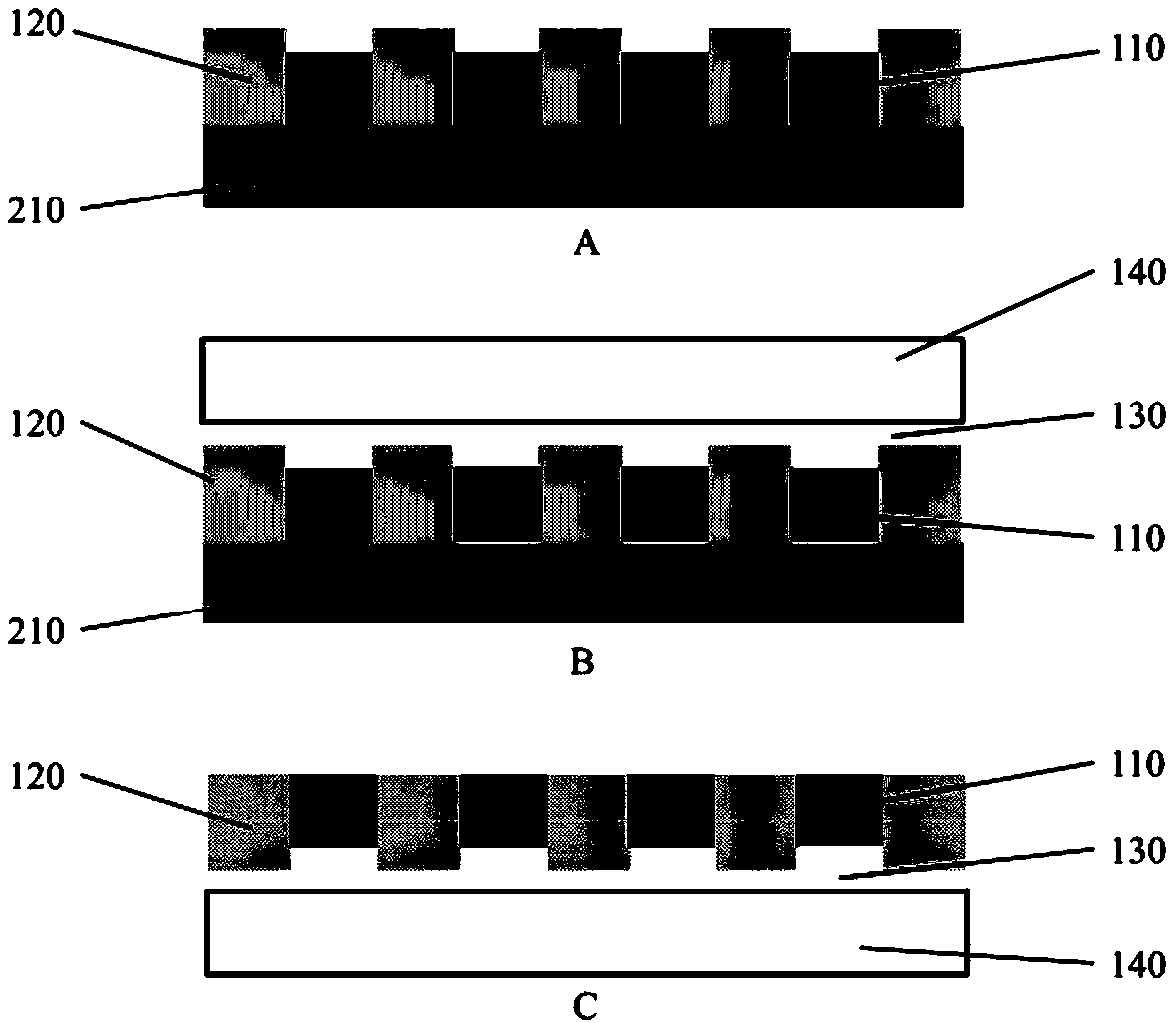

Graphical fine electroconductive film and production method thereof

ActiveCN106448825AIncrease resistanceWill not affect the formationConductive layers on insulating-supportsMicrometerSurface roughness

The invention discloses a graphical fine electroconductive film. The graphical fine electroconductive film comprises a base and a graphical fine electrode. The graphical fine electrode is arranged on the base or embedded in the base. The width of the graphical fine electrode is 50 nanometers to 10 micrometers, the height thereof is 10 nanometers to 10 micrometers, and surface roughness thereof is 0.1 nanometer to 100 nanometers. The invention further discloses a production method of the graphical fine electroconductive film. The graphical fine electrode which has high transmittance, low square resistance and high flexural performance is realized; an etching process is avoided, environment friendliness is achieved, and electrode resolution ratio can reach 100 nanometers; the graphical fine electroconductive film is simple to operate and suitable for large-scale and low-cost production, and can be applied to application fields such as touch panels, solar cells, LED (light-emitting diode) display, OLED (organic light-emitting diode) display and QLED (quantum dot light-emitting diode) display.

Owner:SVG TECH GRP CO LTD +1

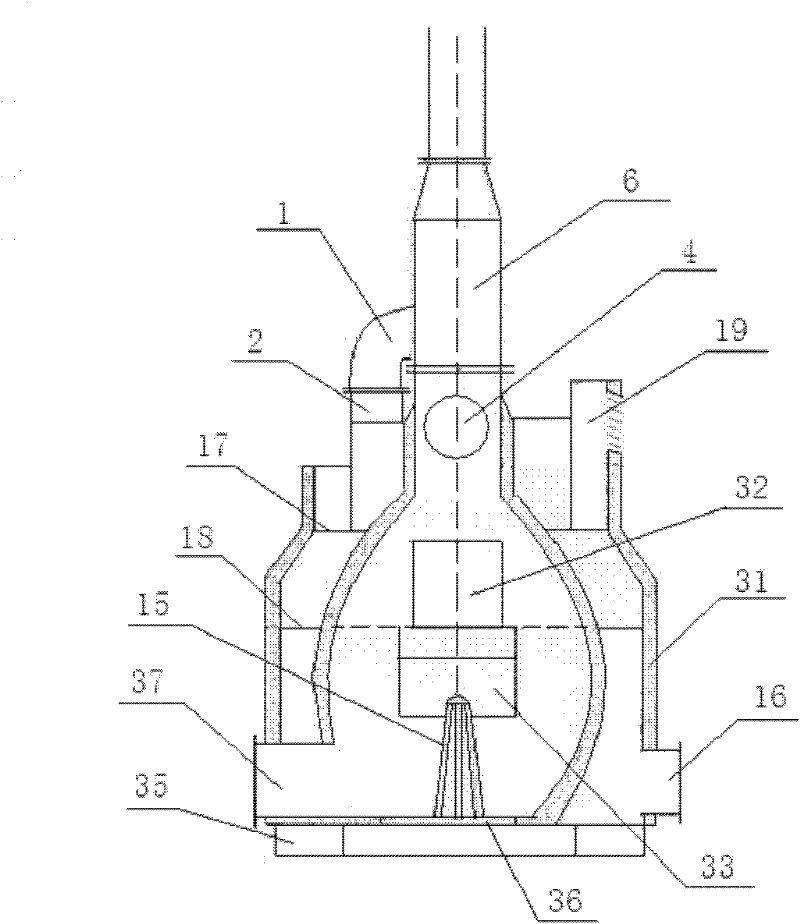

Small refuse incinerator

The invention provides a refuse incinerator which comprises a fume spiral channel device, an incinerator body, a hot air gathering slot, a fume exhaust tube and a chimney, wherein the hot air gathering slot is arranged at the bottom of the incinerator body and is fixedly connected with the bottom surface of the incinerator body; the incinerator body comprises an insulating layer and an inner core layer; a space is reserved between the insulating layer and the inner core layer, thus forming a cold air preheating duct; the side wall at the top of the inner core layer is provided with an air hole; the side wall of the upper part of the incinerator body is provided with a feed port; fire bars are arranged on a bottom plate of the incinerator body; the fume spiral channel device is arranged at the top of the incinerator body; a fume spiral channel outer plate and the incinerator body define a fume spiral channel; the chimney is communicated with the fume spiral channel; and the fume exhaust tube is arranged on the side wall of a bottom end. The refuse incinerator has the advantages that the failure rate is low; the service life is long; the problem of influence of coking on fume flow path and oxygen supply in a hearth can be avoided; the refuse incinerating capacity is increased; and the incineration effect is good.

Owner:和田县绿海环保设备有限公司

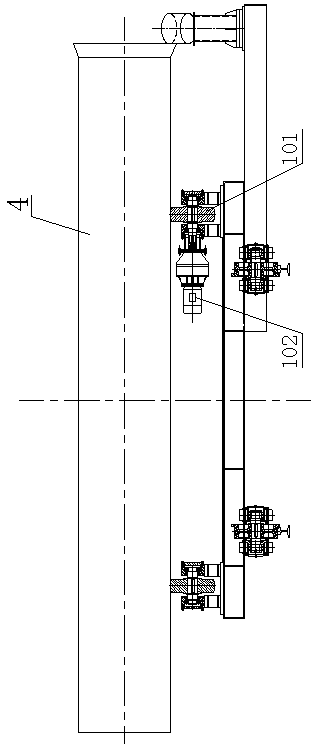

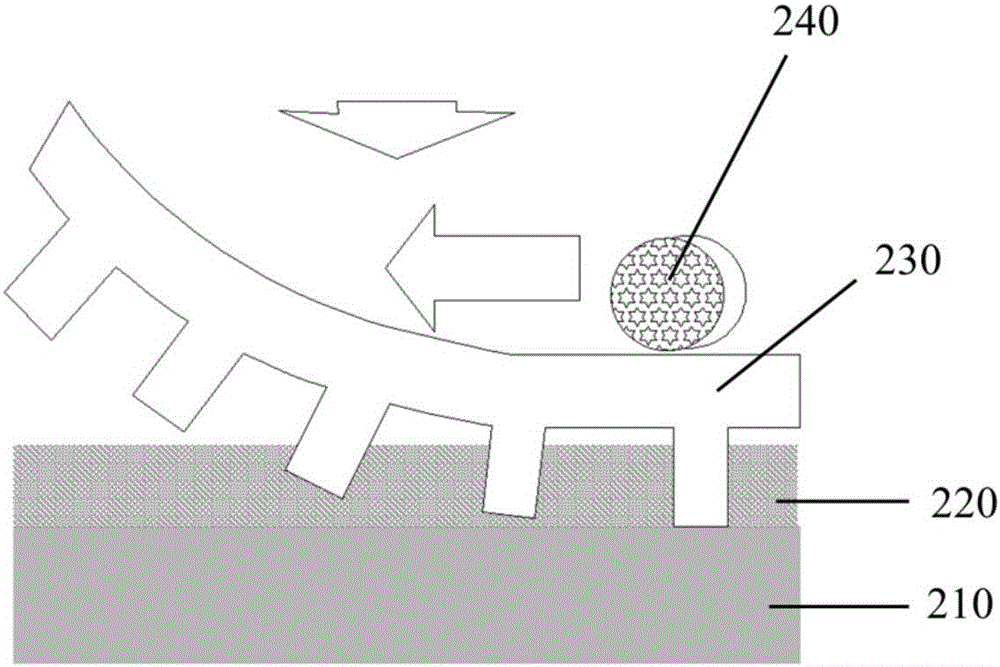

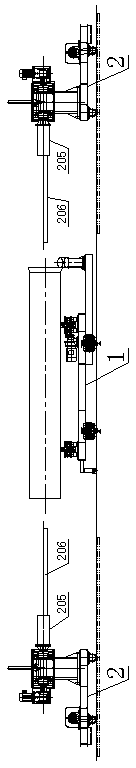

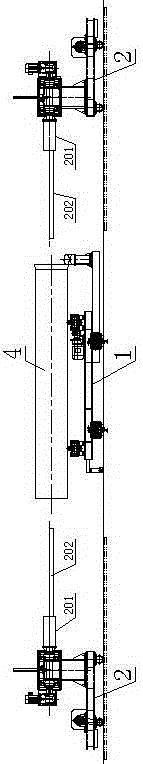

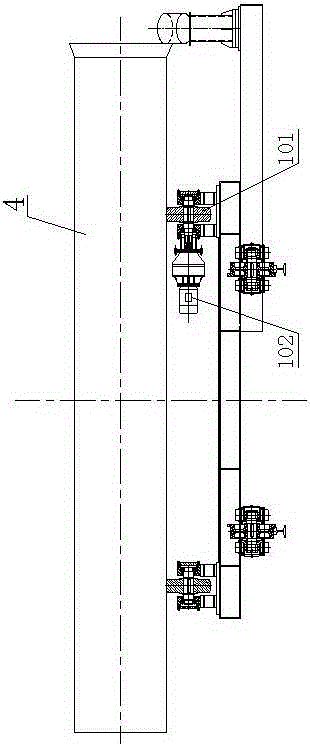

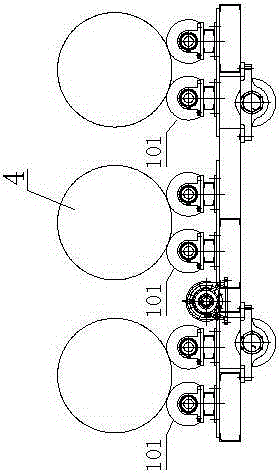

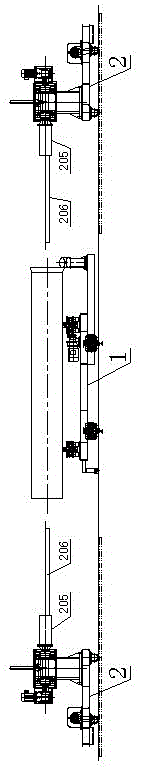

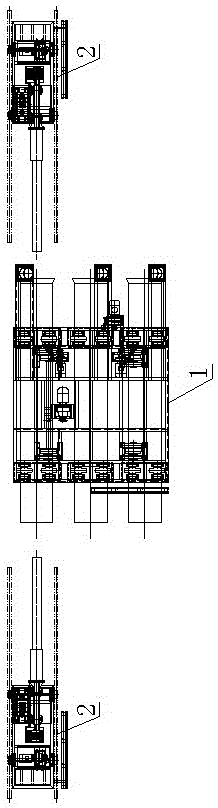

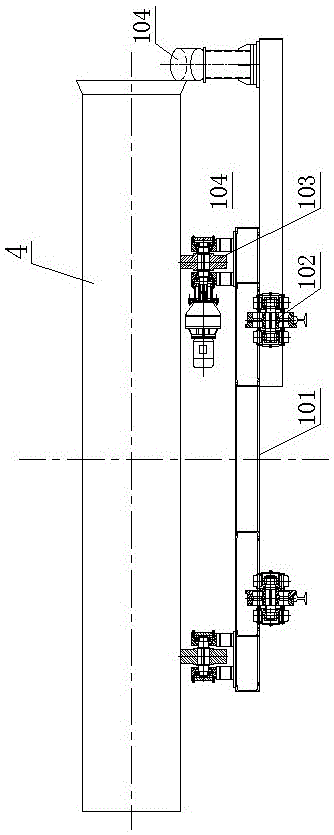

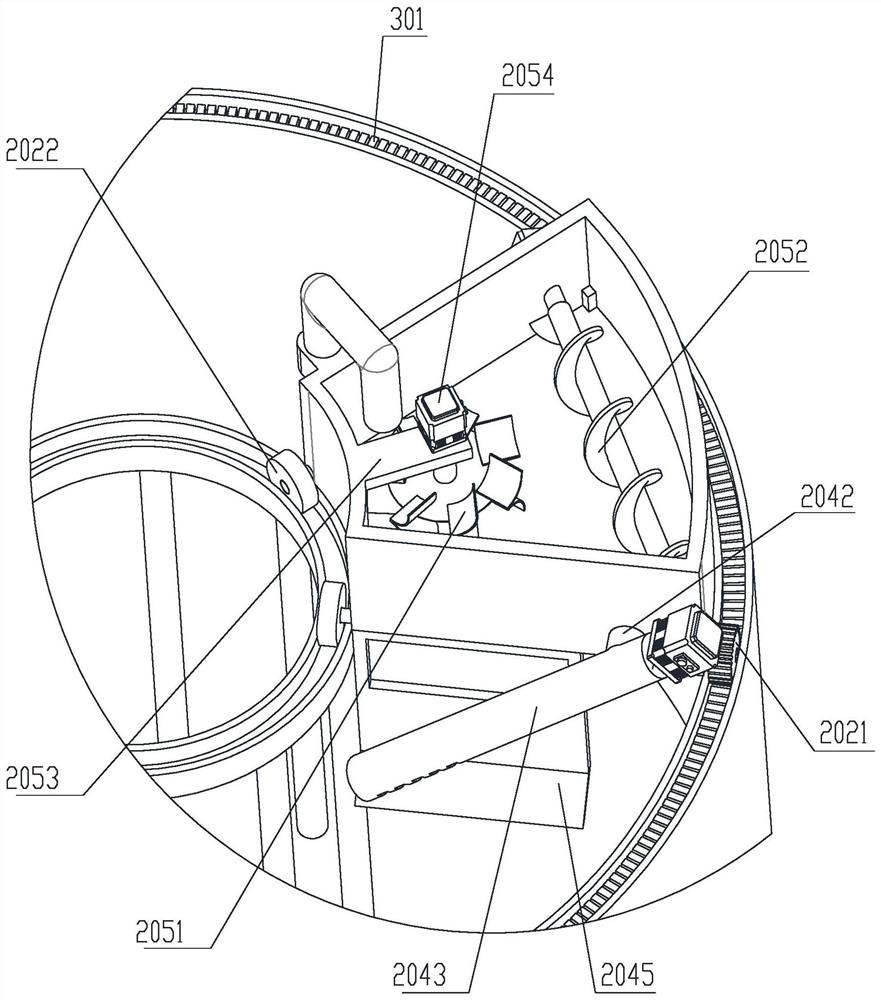

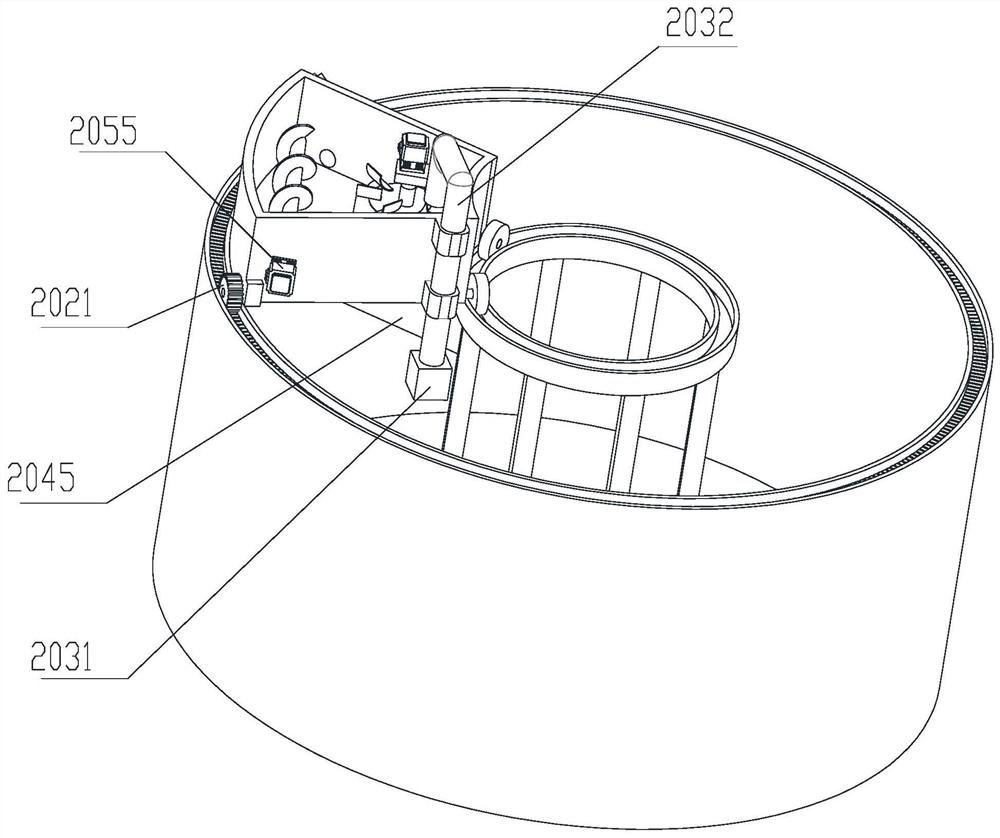

Lining coating equipment for ductile cast iron pipe

ActiveCN103707411AShorten processing timeIncrease productivityFeeding arrangmentsSurface layering apparatusVehicle frameCast iron pipe

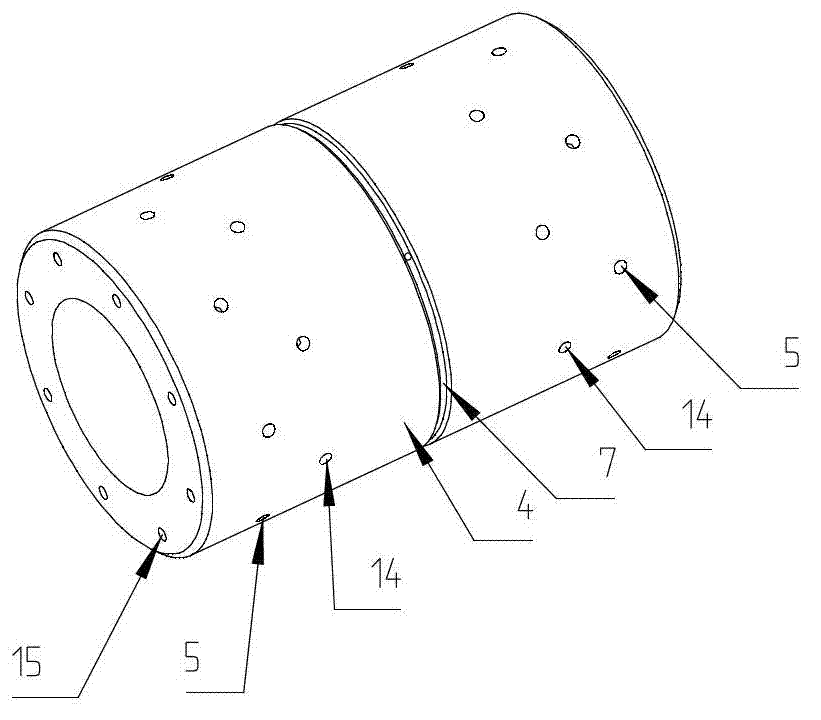

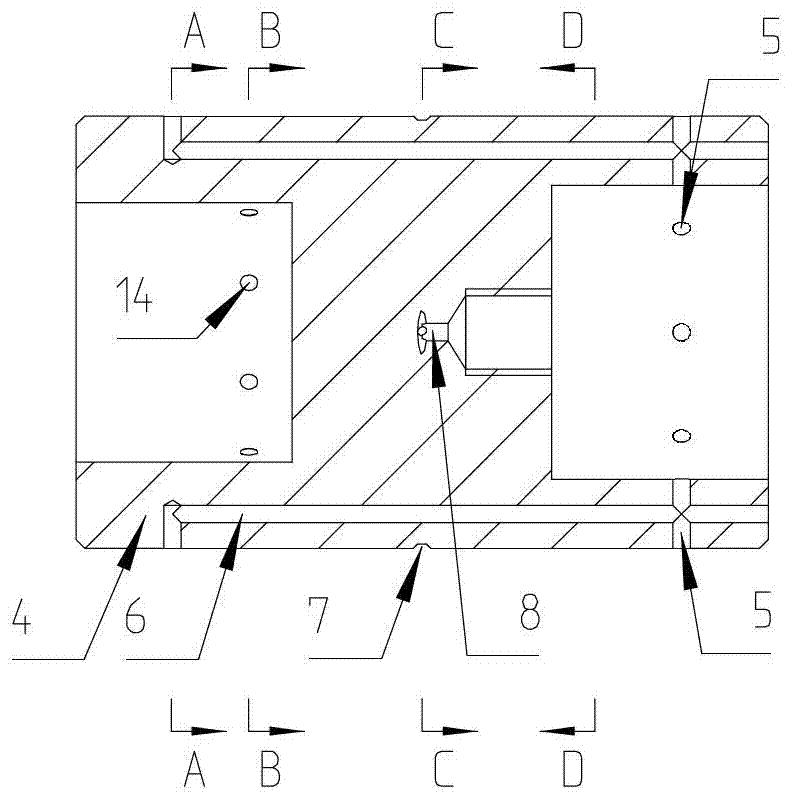

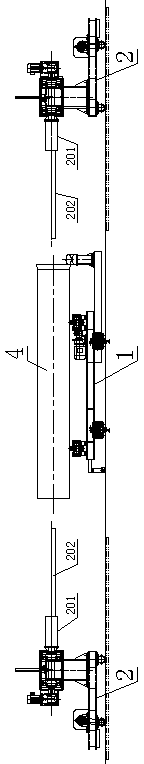

The invention relates to lining coating equipment for a ductile cast iron pipe. The lining coating equipment comprises a rotary platform trolley and is characterized in that the rotary platform trolley is composed of a frame, a walking wheel set arranged below the frame and multiple riding wheel sets arranged above the frame, a heating fire gun used for preheating the ductile cast iron pipe is arranged at the position, corresponding to the riding wheel sets, below the frame, and material distributing trolleys are arranged on the two sides of the frame respectively. The lining coating equipment for the ductile cast iron pipe solves the problem that existing lining coating equipment has the defects that a lining is prone to disengagement, production efficiency is low, and the applicability is low; meanwhile, the machining forming time of the lining is shortened, and production efficiency is improved.

Owner:广西安钢永通铸管管业有限公司

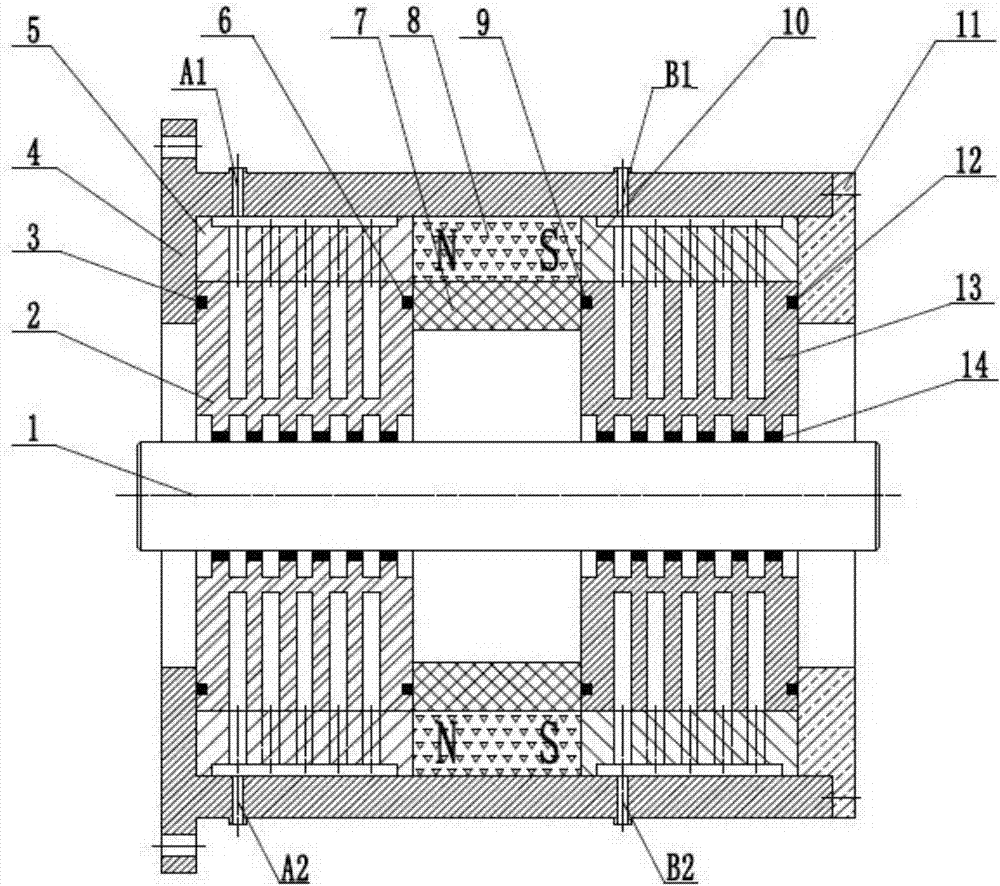

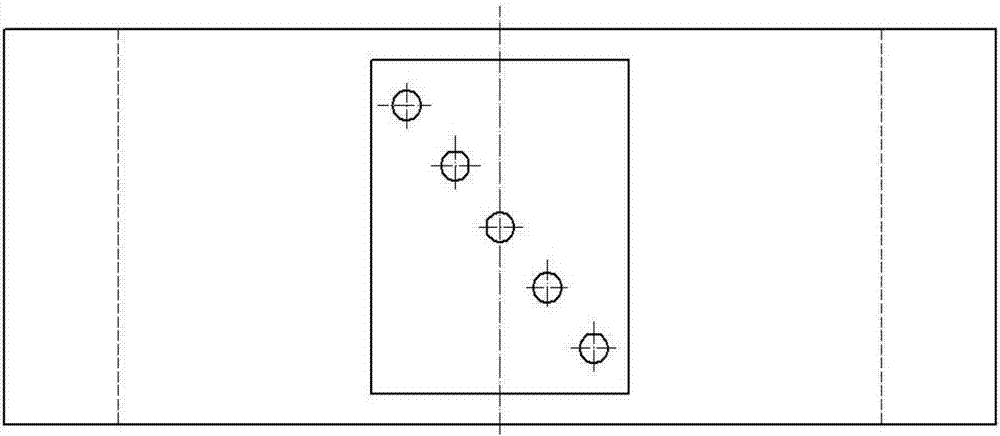

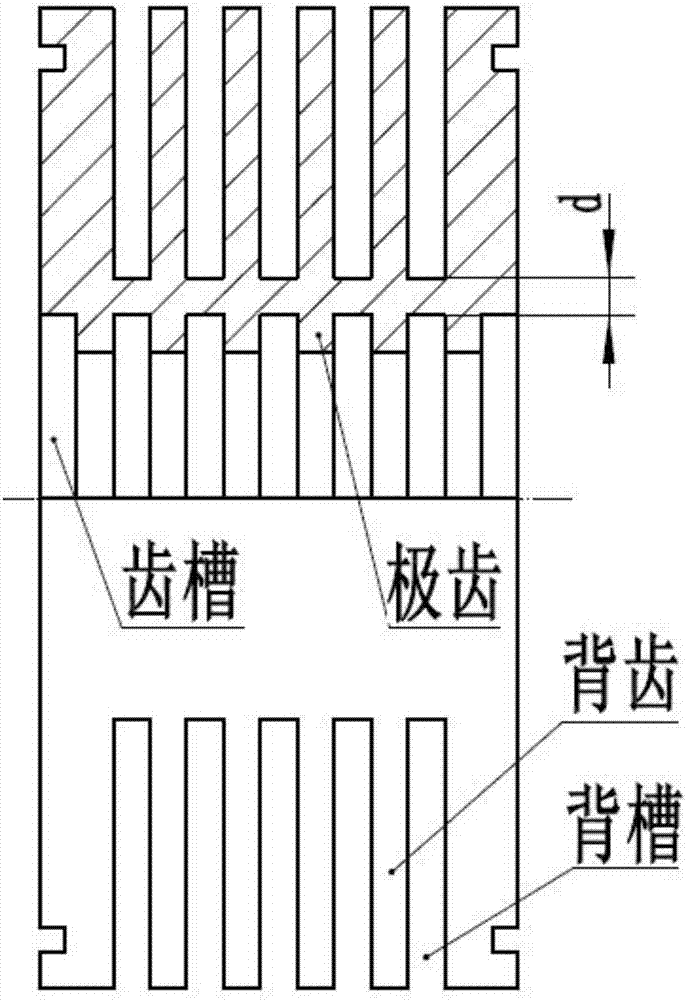

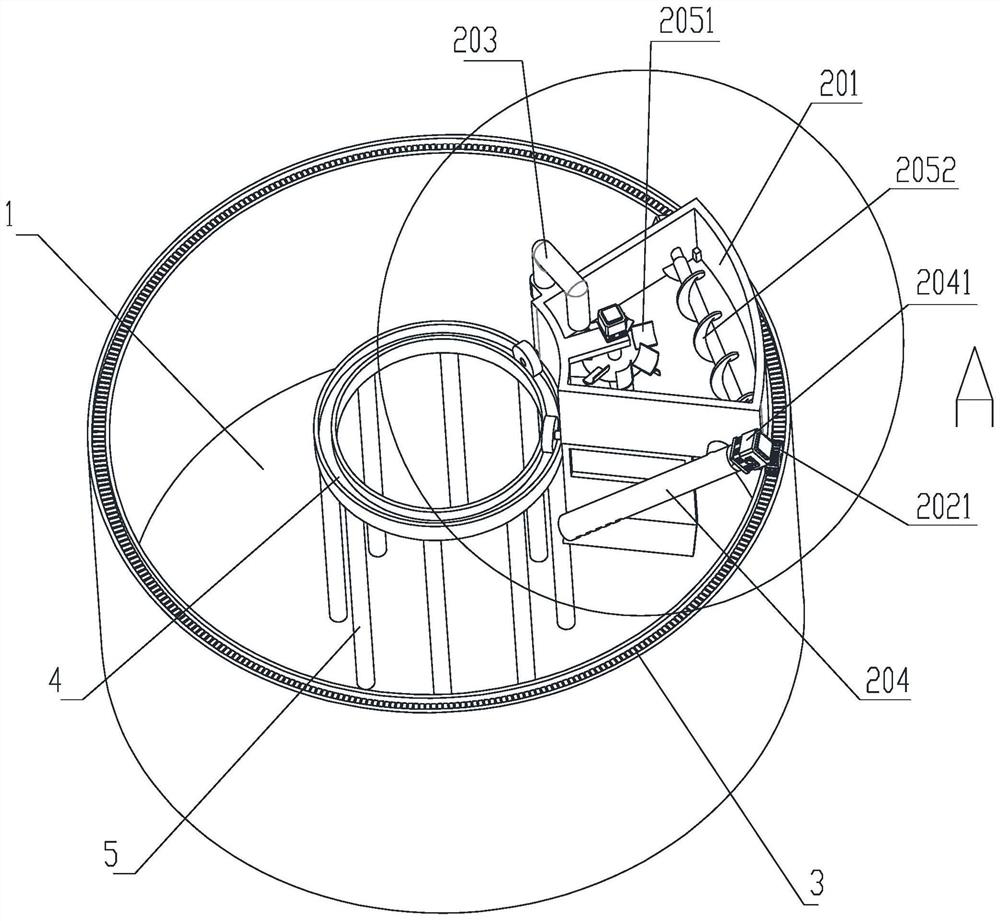

Pole shoe back-trough circulating cooling magnetic liquid sealing device

InactiveCN106969150AIncrease contact areaWill not affect the formationEngine sealsCoolant flowPole piece

The utility model relates to a pole piece back groove type circulating cooling magnetic liquid sealing device, which belongs to the field of mechanical engineering sealing. The problems of short service life and reduced sealing performance of the existing magnetic liquid sealing device under the conditions of large diameter, high rotational speed and high ambient temperature are solved. In the device, the outer surface of the pole shoe is provided with back grooves for circulating cooling liquid, which are alternately arranged with the back teeth, which can increase the contact area between the pole shoe and the cooling liquid and improve the cooling efficiency; the back teeth are opposite to the pole teeth, and the back grooves and The tooth slots are opposite to each other, which does not affect the formation of the magnetic circuit and ensures the pressure resistance of the sealing device; the radial distance d between the back slot and the tooth slot is 0.5-1mm, and the cooling efficiency is high; It is opposite to the back slot on the pole piece; the round holes are distributed diagonally in the rectangular slot on the surface of the magnetic guide sleeve, and the number is equal to the number of the back slot on the pole piece. This design does not affect the formation of the magnetic circuit, and can ensure that every There is fluid coolant in each pole shoe back groove, and the cooling efficiency is high.

Owner:BEIJING JIAOTONG UNIV

Adhesive

InactiveCN1727427AImprove adhesionImprove flatnessEster polymer adhesivesAdhesiveButyl cyanoacrylate

An adhesive for the wound of the pearl-culturing clam is proportionally prepared from alpha-butyl cyanoacrylate, alpha-isobutyl cyanoacrylate, hydroxymethyl cellulose, phenyldiphenol, and toluenesulfonic acid. Its advantages are short setting time, high water-proofing nature, and low dead rate of clam.

Owner:商菁华

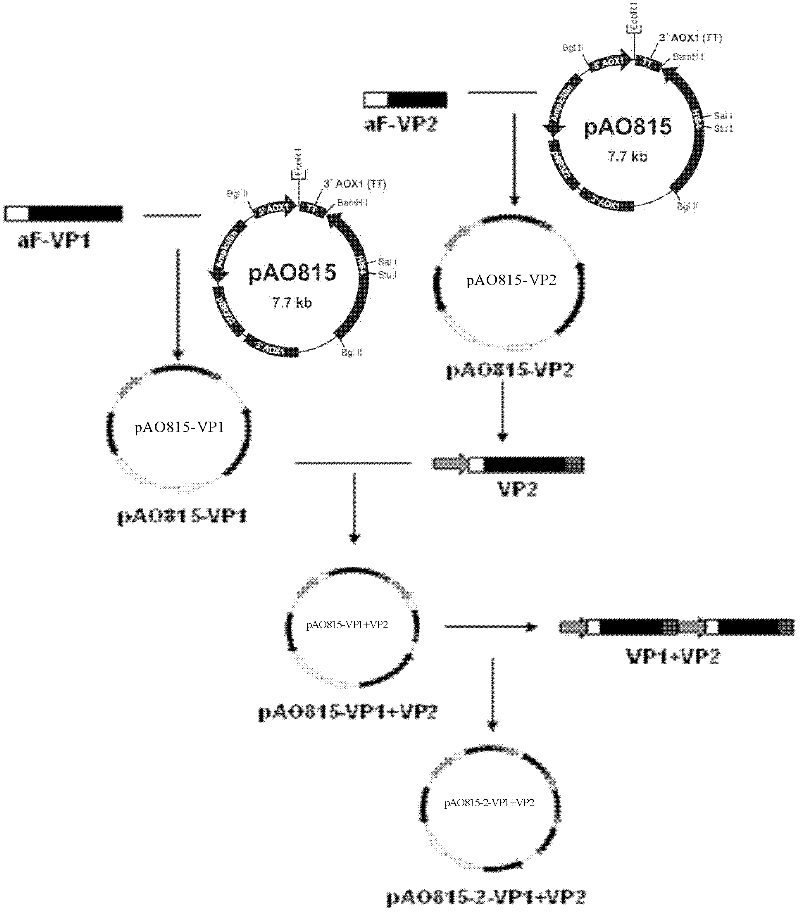

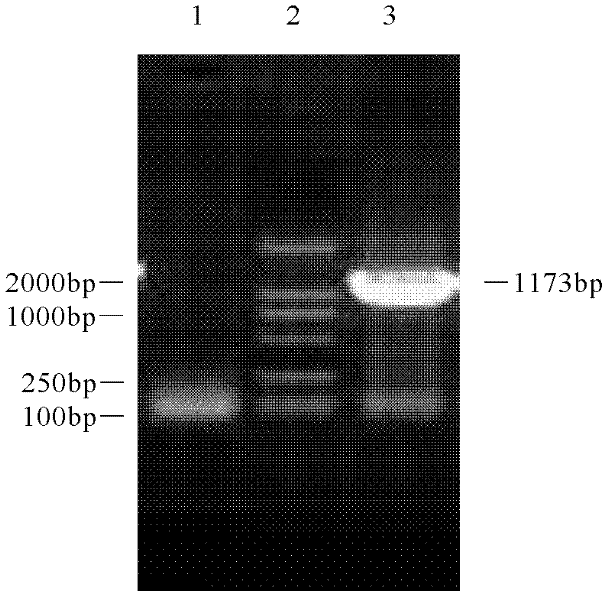

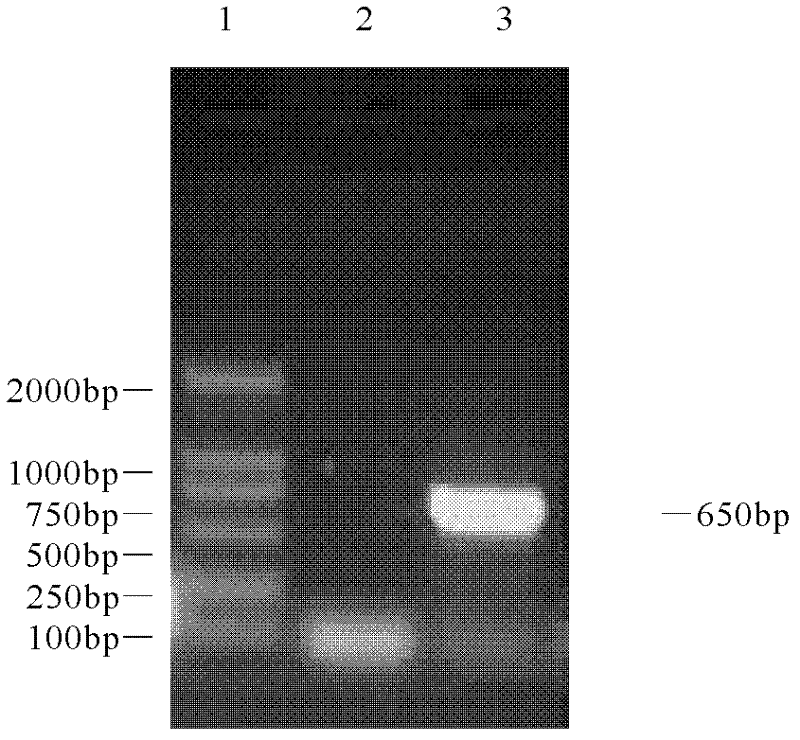

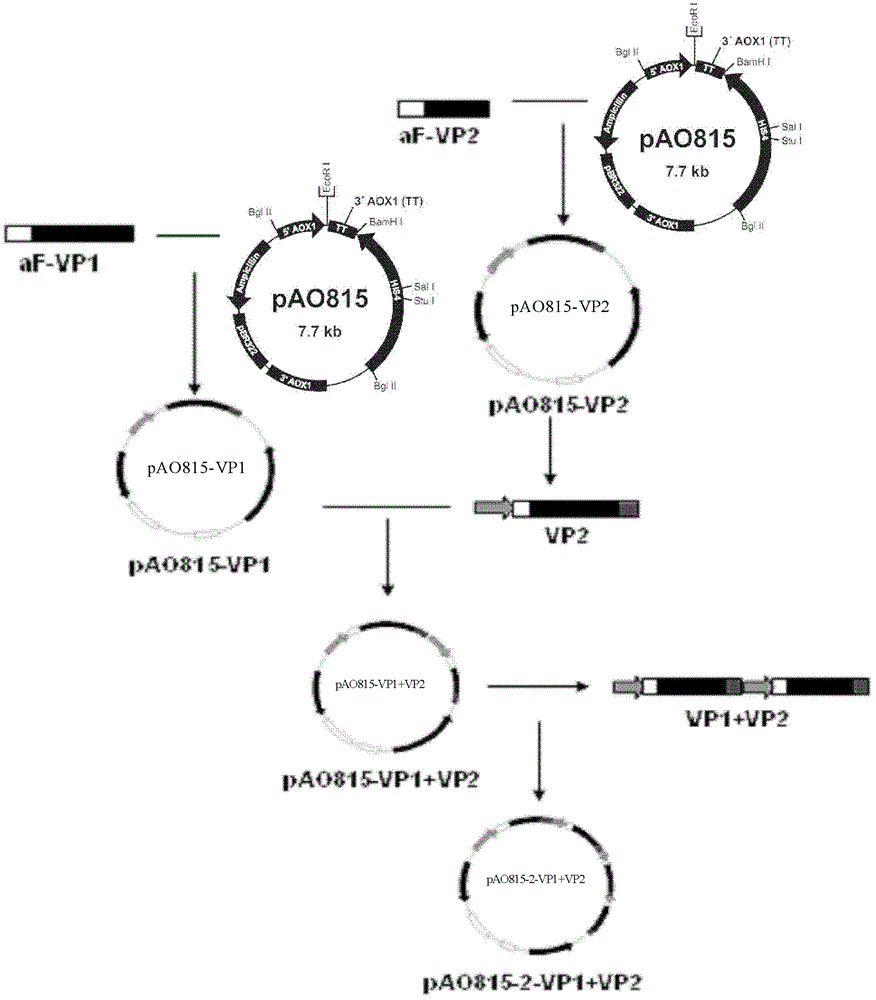

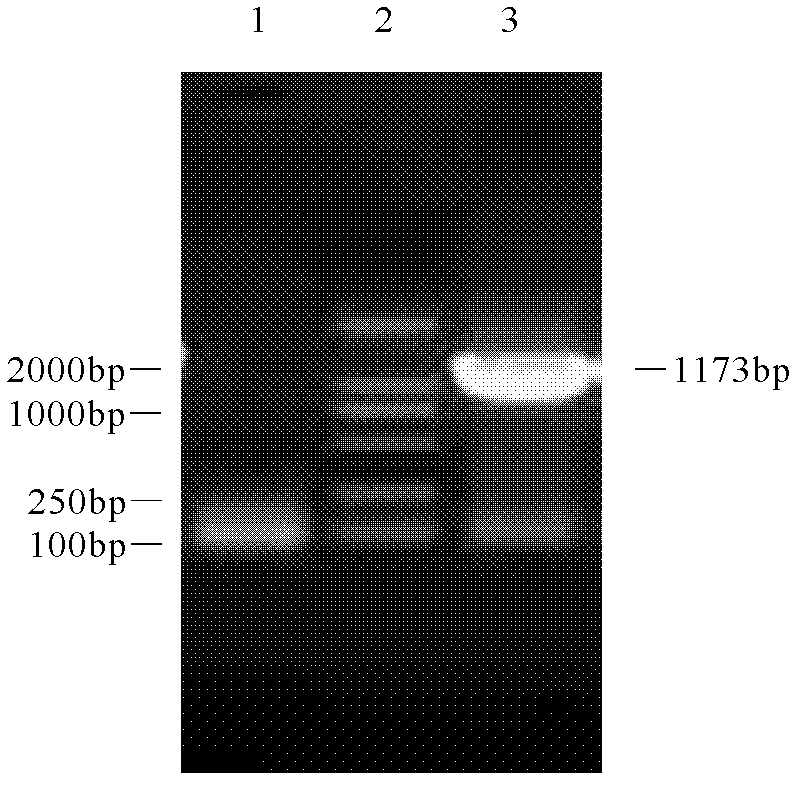

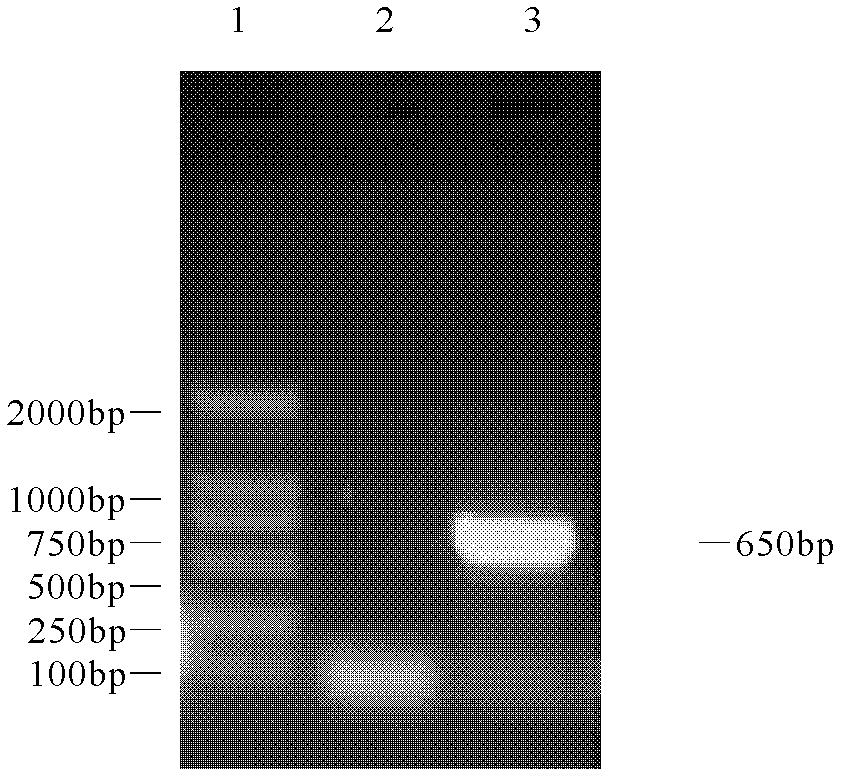

Recombinant yeast engineering strain coexpressed by proteins of chicken anaemia viruses VP1 and VP2, construction method thereof and application thereof

ActiveCN102311928AThe expression product has high activityEasy to scale up productionFungiViral antigen ingredientsBiotechnologyWestern blot

The invention discloses a recombinant yeast engineering strain coexpressed by proteins of chicken anaemia viruses VP1 and VP2, a construction method thereof and an application thereof. The preservation number of the recombinant yeast engineering strain is CGMCC 5045. A large scale induction is carried out on the engineering strain, and the expression level of the VP1 reaches 12g / L. The detection of SDS-PAGE and Western-blot proves that the recombinant coexpressing proteins have the biological activity and the antigenicity of the natural proteins of the chicken anaemia viruses. Results of experiments that a recombinant antigen vaccine which is prepared from the recombinant proteins is use to immunize SPF chickens show that: the chicken infective anaemia recombinant antigen vaccine can effectively induce a body to generate a specific humoral immune response and the immune chicken to obtain the protect of anti-CAV attack, and can effectively prevent the propagation of the viruses in bodies.

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

Lining Process of Ductile Iron Pipe

ActiveCN103691625BWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

Ductile iron pipe lining equipment

ActiveCN103707411BWill not affect the formationNo shedding phenomenonFeeding arrangmentsSurface layering apparatusVehicle frameEngineering

The invention relates to lining coating equipment for a ductile cast iron pipe. The lining coating equipment comprises a rotary platform trolley and is characterized in that the rotary platform trolley is composed of a frame, a walking wheel set arranged below the frame and multiple riding wheel sets arranged above the frame, a heating fire gun used for preheating the ductile cast iron pipe is arranged at the position, corresponding to the riding wheel sets, below the frame, and material distributing trolleys are arranged on the two sides of the frame respectively. The lining coating equipment for the ductile cast iron pipe solves the problem that existing lining coating equipment has the defects that a lining is prone to disengagement, production efficiency is low, and the applicability is low; meanwhile, the machining forming time of the lining is shortened, and production efficiency is improved.

Owner:广西安钢永通铸管管业有限公司

Blood-replenishing and calcium-replenishing cake and preparation method thereof

InactiveCN104351299AExtended storage timeImprove storabilityDough treatmentBakery productsChemistryAnimal science

The invention relates to a blood-replenishing and calcium-replenishing cake. The blood-replenishing and calcium-replenishing cake comprises the following raw materials in parts by weight: 50-80 parts of milk, 20-40 parts of tamarind pulp, 1-4 parts of bean flour, 90-95 parts of wheat flour, 5-10 parts of brown sugar, 60-100 parts of red dates and 100-200 parts of water. The invention further relates to a preparation method of the blood-replenishing and calcium-replenishing cake. The blood-replenishing and calcium-replenishing cake tastes delicious, is long in shelf life, and plays a role in both blood replenishing and calcium replenishing.

Owner:ANHUI YANZHIFANG FOOD

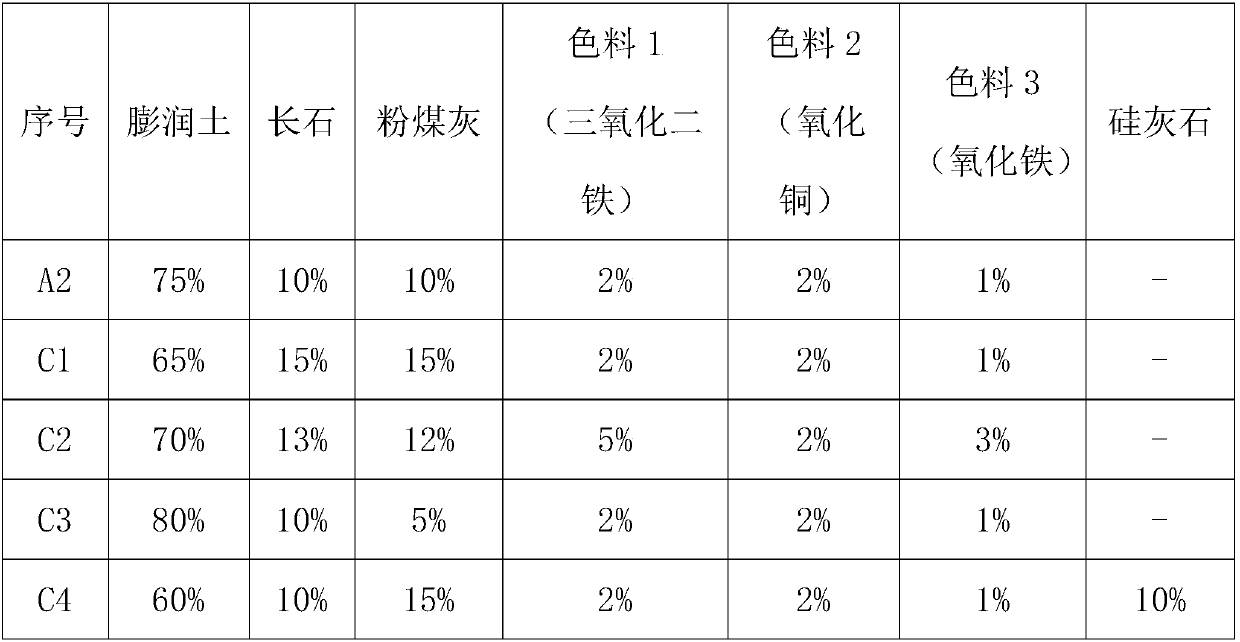

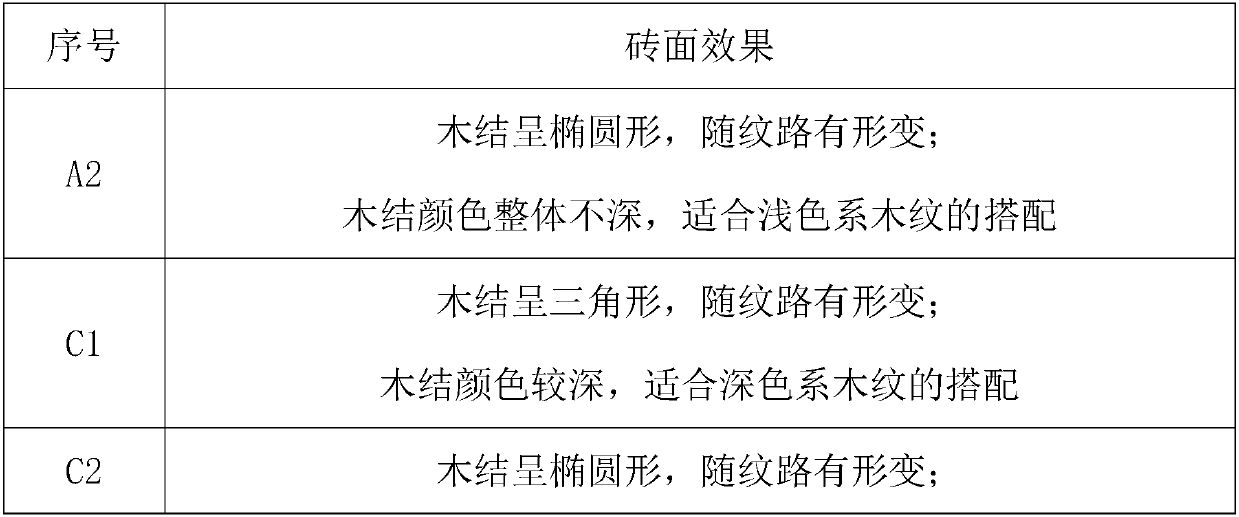

Preparation method of wood-grain brick with wood-knot effect

ActiveCN107793129ASolve the technical problem that cannot have the effect of wood knot simulationHigh simulationCeramic materials productionClaywaresBrickShrinkage rate

The invention discloses a preparation method of a wood-grain brick with a wood-knot effect. The preparation method comprises the following steps: A, preparing materials: a1, preparing two or more clays which are consistent in drying rate and shrinkage rate, have a contrast effect in color after baked, and are 10 to 20 percent in water content; a2, preparing particle clusters containing non-uniformly-mixed pigments; B, feeding materials: putting raw materials, in proportion, into an extruder provided with spiral blades according to the required color contrast degree, putting the clay serving asbottom color first, putting the particle clusters intermittently after the clay is put into the extruder fully, putting the clay serving as grain, putting the particle clusters intermittently, then putting the clay serving as the bottom color, putting the particle clusters intermittently, putting the clay serving as grain, repeating the steps above and repeatedly, continuously and alternatively feeding; C, extruding and molding; D, performing drying and baking to obtain wood-grain bricks with wood-knot effect. By adopting the preparation method of the wood-grain brick with the wood-knot effect, the technical problem that an existing conventional extruding-molding wood-grain brick cannot have a wood-knot simulation effect is solved.

Owner:FOSHAN HENGTAI HONGSHI CERAMIC CO LTD

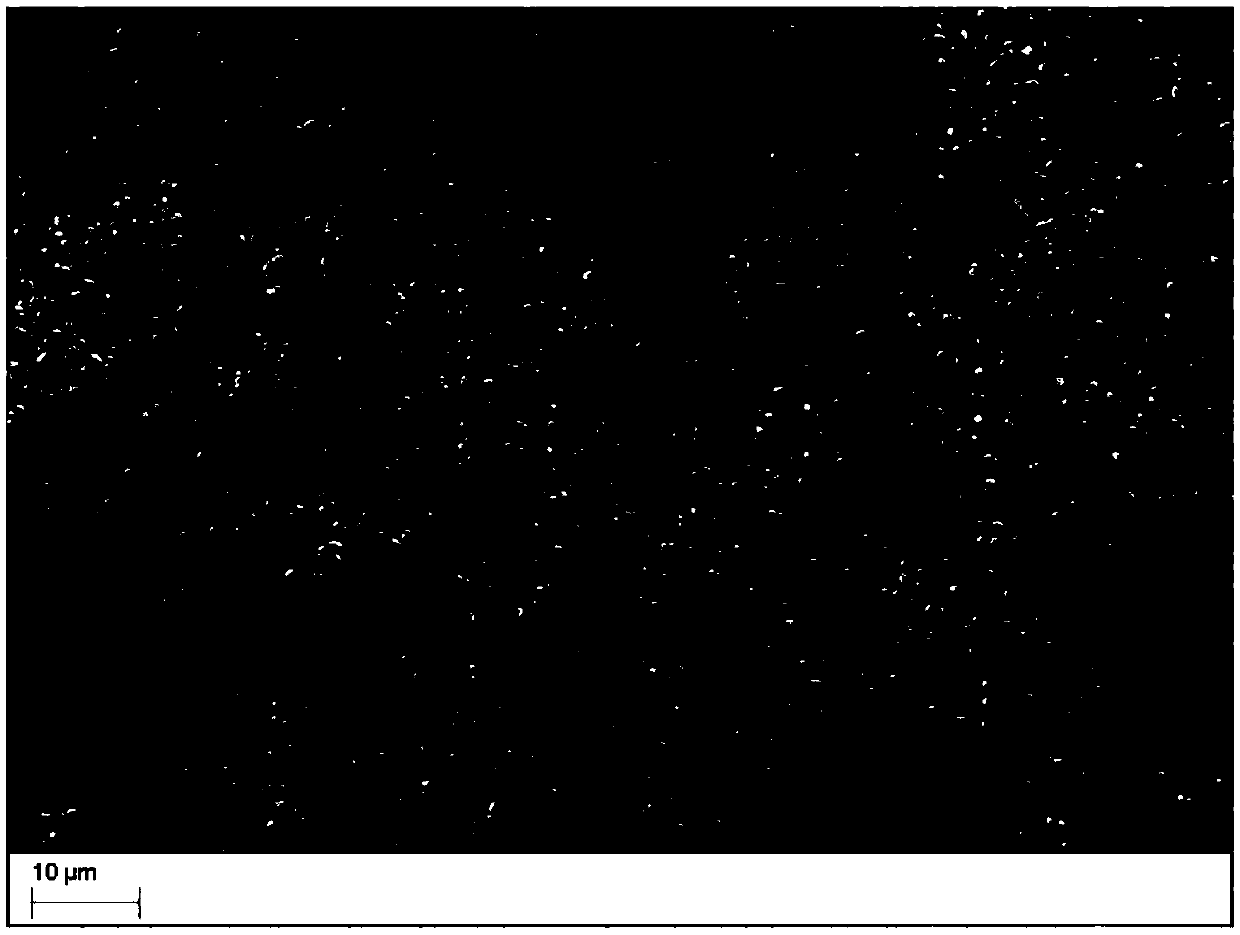

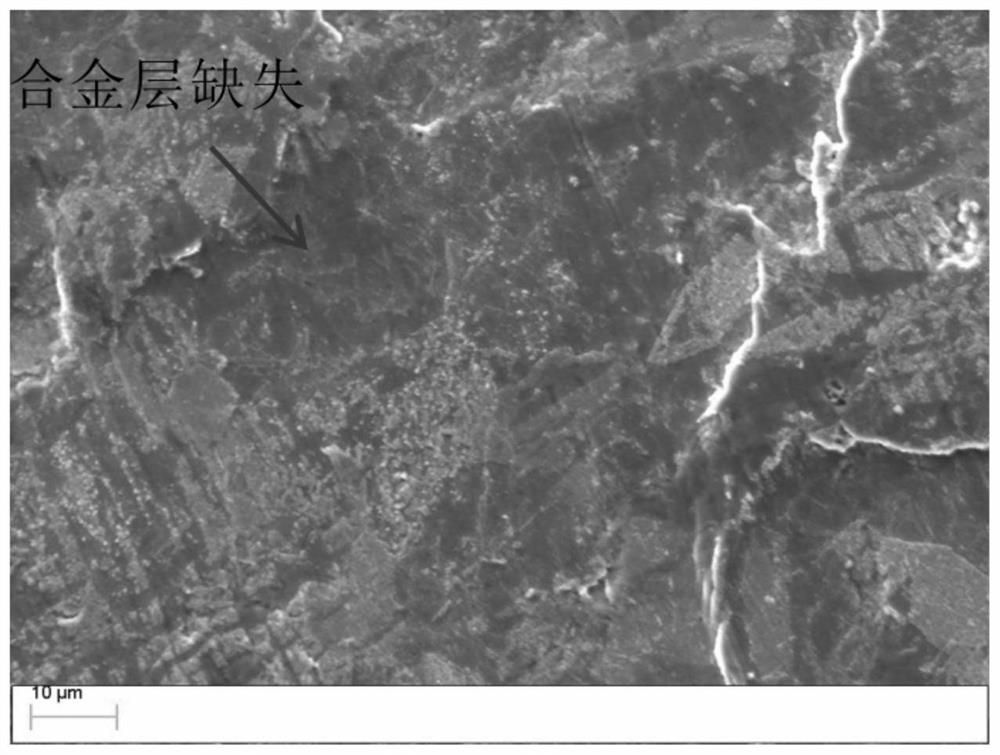

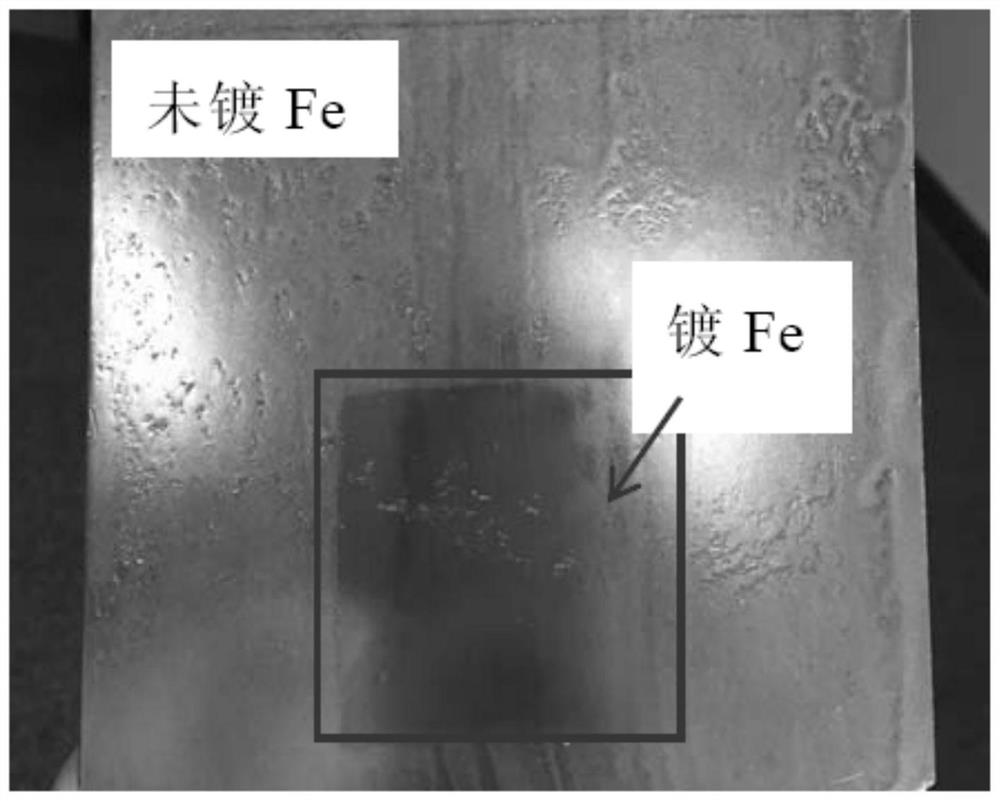

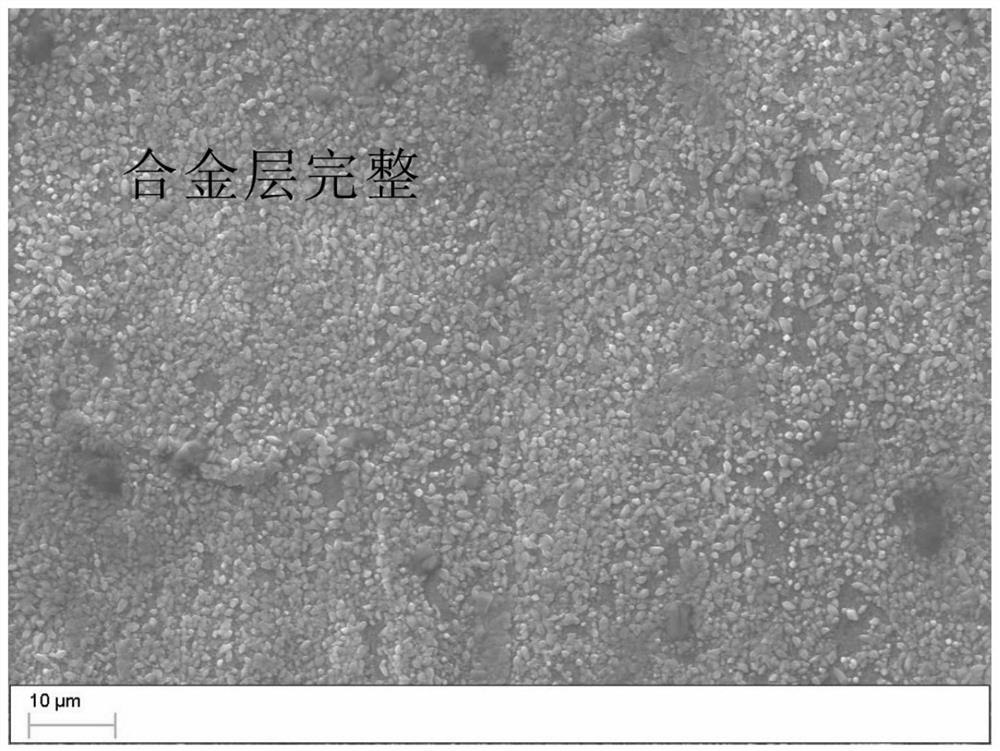

Hot galvanized high-strength steel with excellent Fe-Al alloy layer characteristics and manufacturing method thereof

ActiveCN110760771AReduce contentIncrease contentHot-dipping/immersion processesSuperimposed coating processChemical compositionAlloy

The invention relates to a hot galvanized high-strength steel with excellent Fe-Al alloy layer characteristics and a manufacturing method thereof. The hot galvanized high-strength steel comprises a substrate, a Fe-Al alloy layer and a galvanized layer in sequence, the substrate comprises the following chemical components of, in percentage by weight, 0.15-0.25 wt% of C, 1.00-2.00 wt% of Si, 1.50-3.00 wt% of Mn, less than or equal to 0.015 wt% of P, less than or equal to 0.012 wt% of S, 0.03-0.06 wt% of Al and the balance Fe and inevitable impurities. The loss area of the Fe-Al alloy layer is less than 5%, the Fe-Al alloy layer is uniform, complete and uniform in appearance, the hot galvanized steel plate obtained after hot galvanizing is good in appearance quality, the defects such as leakage plating, hemp spots, chromatic aberration and the like are avoided, and the hot galvanized high-strength steel is suitable for automobile structural parts and outer plates with higher requirementson surface quality and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

Barrier glow discharging plasma generator and generation with atmosphere medium

A atmospheric pressure medium bar glowing discharge plasma generating equipment and the method, the equipment including the electric liquid electrode and the inert gases source, the electric liquid electrode setting in the outer layer of the double-decked medium material tube, the inner layer of the double-decked medium material tube connect with the inert gases source and has electrode stick that discharge with the electric liquid electrode by the voltage action, the electrode stick, the high voltage electrical source and the electric liquid electrode form a loop. The invention avoid reflecting the plasma to lead the pulling arc phenomenon by use the new atmospheric pressure medium bar discharge equipment that the electric liquid is the outer electrode, also the water liquor can cooling the system and reduce the energy consumption; the liquid electrode avoid the medium break that cause by the difference of the expanding quotiety between the medium and the heated metal electrode, extend the using longevity.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

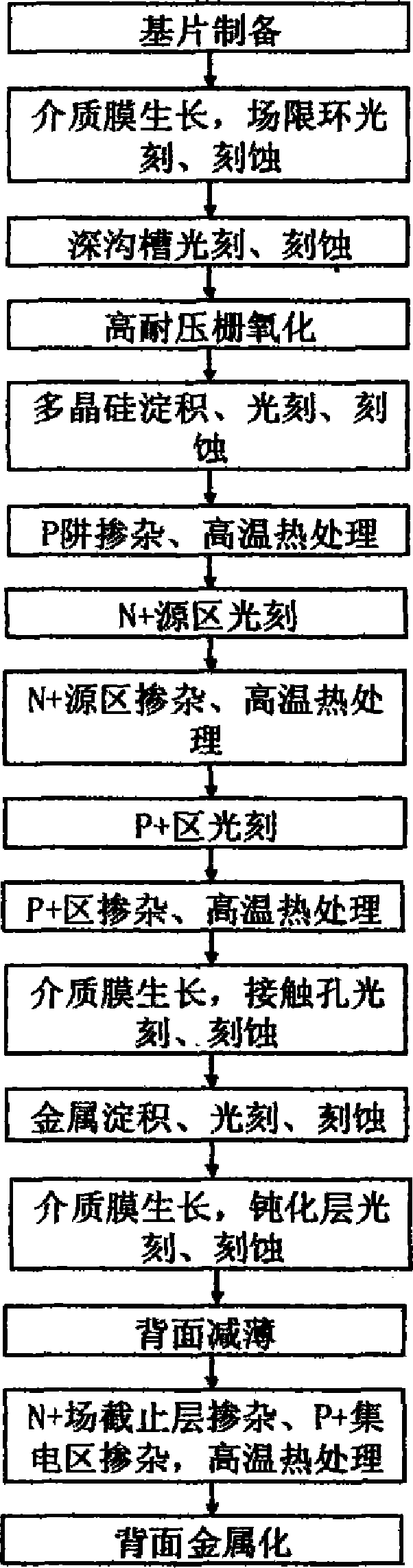

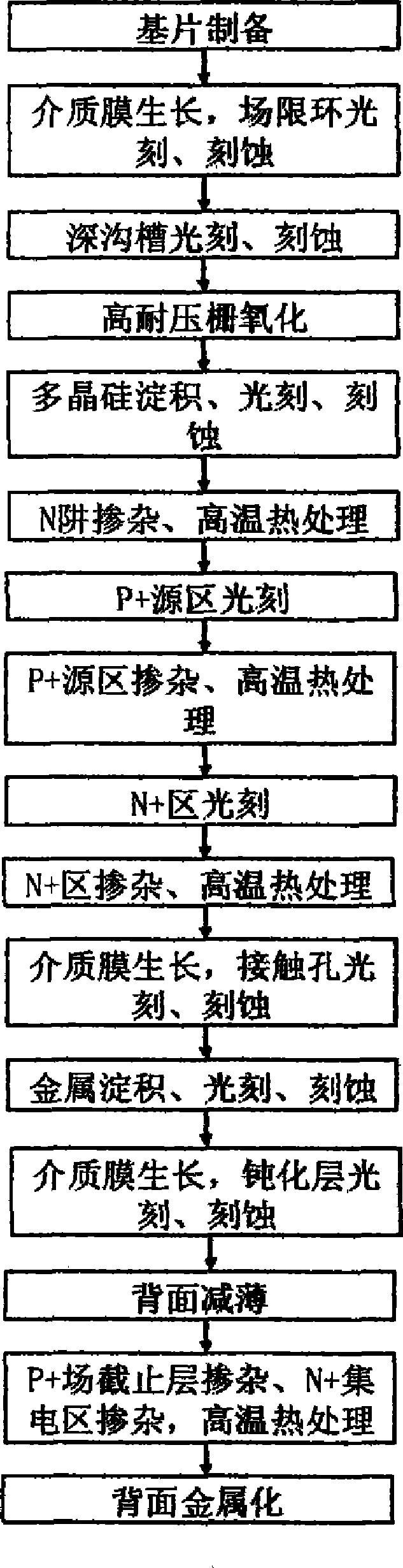

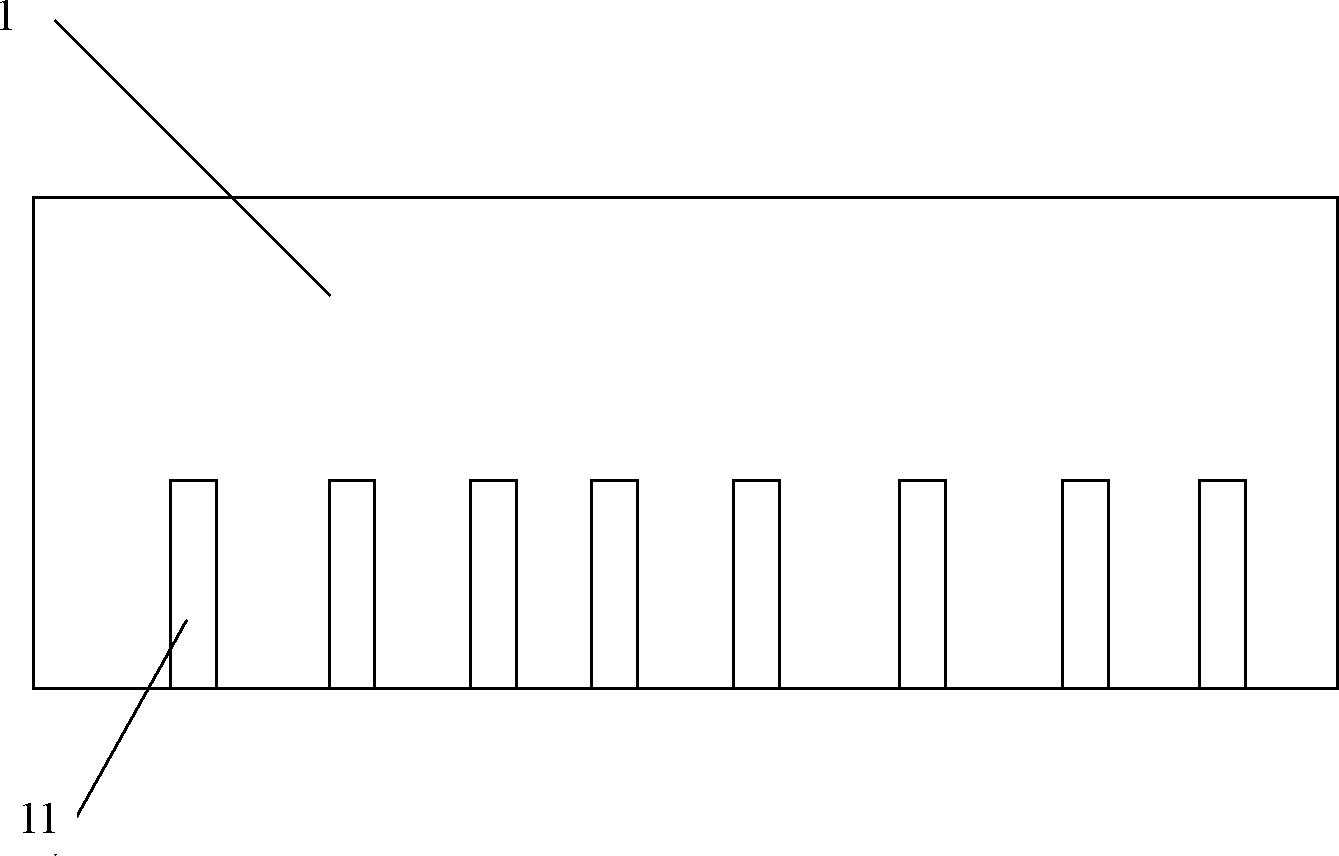

Manufacturing method for semiconductor device with field barrier layer

ActiveCN102931081BAddresses limitations in thin sheet capacityLow costSemiconductor/solid-state device manufacturingSilicon chipLarge size

The invention discloses a manufacturing method for a semiconductor device with a field barrier layer. The manufacturing method comprises the following steps of etching a slot or a hole with required depth on the back of a silicon chip; growing highly doped polysilicon in the slot or the hole; diffusing at high temperature for a long time in the slot or the hole; performing the conventional positive process on the semiconductor device; and reducing the thickness of the back of the silicon chip, and leaving the required field barrier layer. According to the manufacturing method for the semiconductor device with the field barrier layer, the step of manufacturing the field barrier layer required to be subjected to high-temperature diffusion is adjusted to the front stage of a processing process of the device, a high-temperature diffusion process is not required in the silicon chip positive process, new field barrier layer structures which can confirm to different demands are easy to obtain, the problem of the limitation of the capability of a machine for processing slices is solved, the machine can finish the positive process under the condition of keeping the thickness of the silicon chip, the field barrier layer can be manufactured at deep places away from the upper surfaces of the large-size wafers, and the cost is lower.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Adhesive

An adhesive for the wound of the pearl-culturing clam is proportionally prepared from alpha-butyl cyanoacrylate, alpha-isobutyl cyanoacrylate, hydroxymethyl cellulose, phenyldiphenol, and toluenesulfonic acid. Its advantages are short setting time, high water-proofing nature, and low dead rate of clam.

Owner:商菁华

Stone sewage precipitation system

PendingCN112479419AWill not affect the formationCircumstances that do not lead to derailmentMultistage water/sewage treatmentTreatment involving sedimentationSewageMechanical engineering

The invention discloses a stone sewage sedimentation system, and relates to the technical field of stone processing. According to a technical scheme, the stone sewage sedimentation system comprises asedimentation tank, a track is arranged at the top of the sedimentation tank, a walking stirring box is arranged on the track, and the stirring box comprises a stirring box body, a walking mechanism is arranged at the bottom of the stirring box body, and a water inlet mechanism is arranged on one side of the stirring box body, a feeding mechanism is arranged on the other side of the stirring box body, and a stirring mechanism is arranged in the stirring box body. The invention has the beneficial effects that: the stirring box rotationally walking above the sedimentation tank is arranged, waterabsorption and stirring can be conducted while feeding is conducted, formation of sediments in the sedimentation tank cannot be affected in the full stirring process, and standing after stirring is completed is not needed; two kinds of stirring blades are arranged in the stirring box, one kind of stirring blades help full stirring, and the other kind of stirring blades prevent part of floccules formed in the stirring process from blocking a pipeline and discharging the floccules.

Owner:SHANDONG CAIYUANHEXIN ENERGY EFFICIENCY PROJECT

A kind of hot-dip galvanized high-strength steel with excellent fe-al alloy layer characteristics and its manufacturing method

ActiveCN110760771BReduce contentIncrease contentHot-dipping/immersion processesSuperimposed coating processChemical compositionAlloy

A hot-dip galvanized high-strength steel having the characteristics of an excellent Fe-Al alloy layer and a manufacturing method thereof, the hot-dip galvanized high-strength steel sequentially comprises a substrate, an Fe-Al alloy layer and a galvanized layer, and the chemical composition of the substrate is weight percent are: C: 0.15-0.25wt%, Si: 1.00-2.00wt%, Mn: 1.50-3.00wt%, P≤0.015wt%, S≤0.012wt%, Al: 0.03-0.06wt%, the rest are Fe and Impurities are unavoidable; the missing area of the Fe-Al alloy layer is less than 5%, the Fe-Al alloy layer is uniform, complete, and has consistent appearance characteristics, and the hot-dip galvanized steel sheet obtained after hot-dip galvanizing has good appearance quality, no leakage plating, Defects such as pitting and chromatic aberration are suitable for automotive structural parts and outer panels that have high requirements on surface quality and formability.

Owner:BAOSHAN IRON & STEEL CO LTD

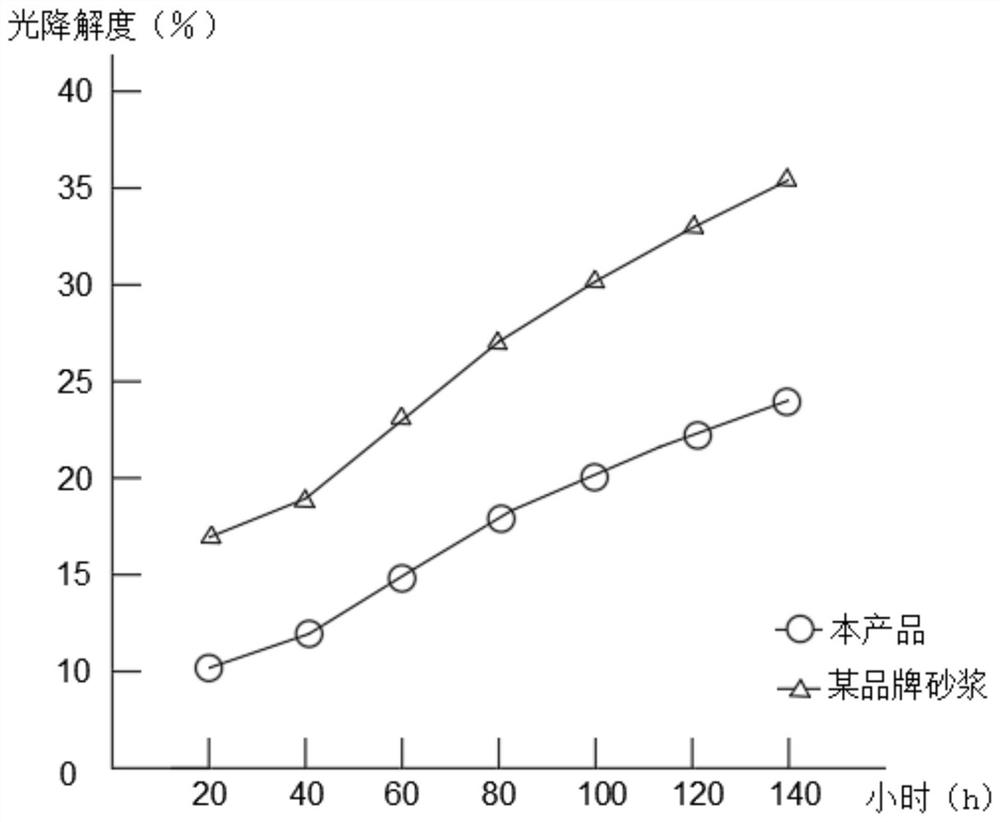

Polymer mortar

The invention discloses high-molecular mortar, relates to the technical field of high-molecular mortar, and aims to solve the problems that when the existing high-molecular mortar is used in an outdoor environment for a long time, the high-molecular polymer of the existing high-molecular mortar is poor in ageing resistance, so that the existing high-molecular mortar is aged under the irradiation of external ultraviolet rays and infrared rays, and the durability of cement mortar is reduced. And the safety of the mortar building is influenced. Comprising the following components in percentage by weight: 30-35% of cement; 40%-45% of quartz sand; 5%-7% of a thickening agent; 1%-3% of polyoxyethylene; 5%-8% of an anti-aging auxiliary agent; 0.5%-1% of polypropylene fiber; 5%-10% of surface modified nano zinc oxide; a binder; the surface-modified nano-zinc oxide is prepared from surface-modified nano-zinc oxide and an anti-aging aid, the surface-modified nano-zinc oxide is prepared from surface modified nano-zinc oxide, the anti-aging aid is prepared from an ultraviolet light absorber, a light stabilizer and an antioxidant in a combined and matched manner, and the adhesive is internally prepared from nigrosine cured particles and a binding agent component, the surface-modified nano-zinc oxide is subjected to surface modification by virtue of a coupling agent gamma-aminopropyltriethoxysilane.

Owner:福建智汇畅城科技有限公司

A kind of preparation method of patterned fine conductive film

ActiveCN106448825BIncrease resistanceWill not affect the formationConductive layers on insulating-supportsMicrometerSurface roughness

The invention discloses a graphical fine electroconductive film. The graphical fine electroconductive film comprises a base and a graphical fine electrode. The graphical fine electrode is arranged on the base or embedded in the base. The width of the graphical fine electrode is 50 nanometers to 10 micrometers, the height thereof is 10 nanometers to 10 micrometers, and surface roughness thereof is 0.1 nanometer to 100 nanometers. The invention further discloses a production method of the graphical fine electroconductive film. The graphical fine electrode which has high transmittance, low square resistance and high flexural performance is realized; an etching process is avoided, environment friendliness is achieved, and electrode resolution ratio can reach 100 nanometers; the graphical fine electroconductive film is simple to operate and suitable for large-scale and low-cost production, and can be applied to application fields such as touch panels, solar cells, LED (light-emitting diode) display, OLED (organic light-emitting diode) display and QLED (quantum dot light-emitting diode) display.

Owner:SVG TECH GRP CO LTD +1

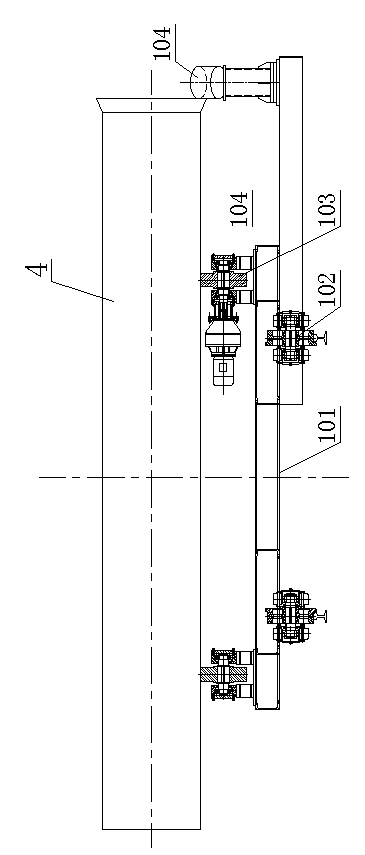

Lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings

InactiveCN110605225AWill not affect the formationNo shedding phenomenonChemical industryPretreated surfacesEpoxyMetallurgy

The invention discloses a lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings. The technology comprises the following steps of carrying out shot blasting treatment on a spiral steel pipe product to be subjected to lining coating formation to make the inner wall and the outer wall of the spiral steel pipe product clean and expose theground color of the inner wall and the ground color of the outer wall of the pipe product; placing the pipe product subjected to shot blasting onto a riding wheel of a lining coating forming device,starting up a variable-frequency motor connected with the riding wheel to drive the pipe product to rotate, controlling the rotating speed of the pipe product to range from 30 revolutions per minute to 60 revolutions per minute, igniting a heating fire gun below the pipe product to preheat the pipe product, heating the pipe product to 50 DEG C to 70 DEG C, and shutting off the fire gun after heating; arranging one spraying trolley at one end of the inner wall of the pipe product and one spraying trolley at one end of the outer wall of the pipe product, using the spraying trolleys to spray solvent-free epoxy ceramic paint onto the inner wall and the outer wall of the pipe product at the same time, controlling the advancing frequency of the spraying trolleys to be within the range from 15 HZto 30 HZ, and forming the solvent-free epoxy ceramic linings on the inner wall and the outer wall of the pipe product; and placing the pipe product onto the riding wheel for rotation again till the pipe product cools and solidifies. With the lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings, the manufacturing cost of inner linings and outer linings can be reduced, and the service life of spiral steel pipes can be prolonged.

Owner:广西安钢永通铸管管业有限公司

Room temperature plasma torch array device for simultaneous fiber modification and sewage treatment

InactiveCN101538792BIncrease temperatureFast degradationWater/sewage treatment by irradiationPhysical treatmentDielectricFiber

The invention discloses a room temperature plasma torch array device for simultaneously modifying fiber filaments and treating sewage. Multiple rows of quartz tubes with built-in tubular metal electrodes are inserted into the conductive sewage solution electrodes. One end of the quartz tubes passes through the bottom of the plexiglass tank and enters the modification chamber, and the other end exposes the plexiglass tank and is sealed with a Teflon sleeve outside the tube-shaped metal electrodes. It passes through the polytetrafluoroethylene sleeve to communicate with the active gas source, and the outside of the quartz tube communicates with the inert gas source. There are holes at the bottom of the end of the quartz tube. In the modification chamber, there are rows of fibers perpendicular to the bottom holes of each row of quartz tubes. The wire and tubular metal electrodes are connected in parallel to the high-voltage end, and the low-voltage end is connected to the conductive sewage solution electrode. The conductive liquid of the present invention is used as an external electrode, has a cooling discharge system, reduces energy consumption, and avoids the phenomenon of arcing caused by the short circuit of the two electrodes caused by the reflected plasma; at the same time, the liquid electrode avoids the use of a metal electrode that is different from the expansion coefficient of the medium. The phenomenon of medium rupture occurs.

Owner:ZHEJIANG SCI-TECH UNIV

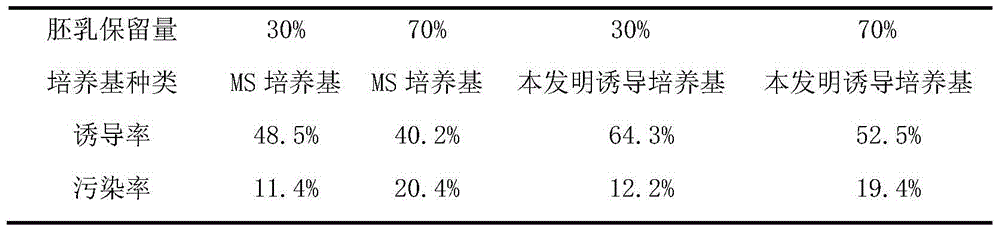

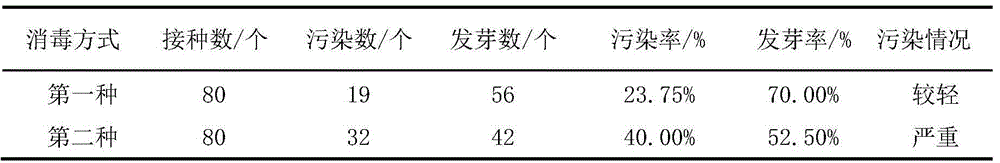

Method for Inducing Callus Formation from Phyllostachys pubescens Seed Embryo

ActiveCN104920213BLow pollution rateWill not affect the formationHorticulture methodsPlant tissue cultureCallus formationVitality

A phyllostachys pubescens embryo induced callus formation method comprises the following steps: (1) screening out phyllostachys pubescens seeds with the vitality higher than 75%; (2) taking out embryos of the screened phyllostachys pubescens seeds, cutting to remove 50% or more than 50% of endosperm, conducting treatment by use of running water, ethanol, bacteria-free water, a sodium hypochlorite solution, bacteria-free water, mercury bichloride added with Tween-80 in sequence, and then removing surface moisture for later use; (3) inoculating disinfected embryos onto an induction medium, conducting dark culture for 7-10 days to form calluses, then separating the calluses out, inoculating the separated calluses onto a propagation medium for propagation culture for 20-30 days. According to the phyllostachys pubescens embryo induced callus formation method, as the embryos of the phyllostachys pubescens seeds are selected as explants, dirt, clay, bacteria and other pollutants, hidden in gaps between the testa and internal embryos of the phyllostachys pubescens seeds can be directly removed, and accordingly, the pollution rate is effectively reduced. The phyllostachys pubescens embryo induced callus formation method has the advantages that the callus inductivity can reach 64.3%, the pollution rate can be controlled at 20% or below, and the calluses are favorable in condition and excellent in growth situation.

Owner:ANHUI AGRICULTURAL UNIVERSITY

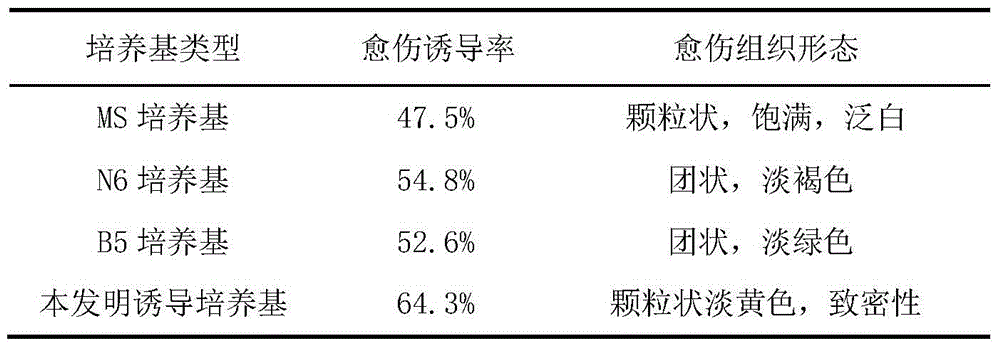

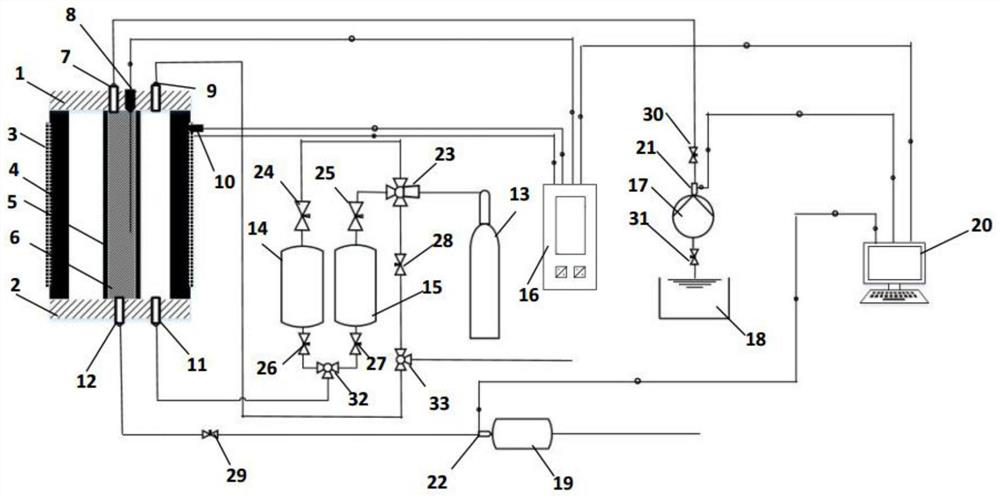

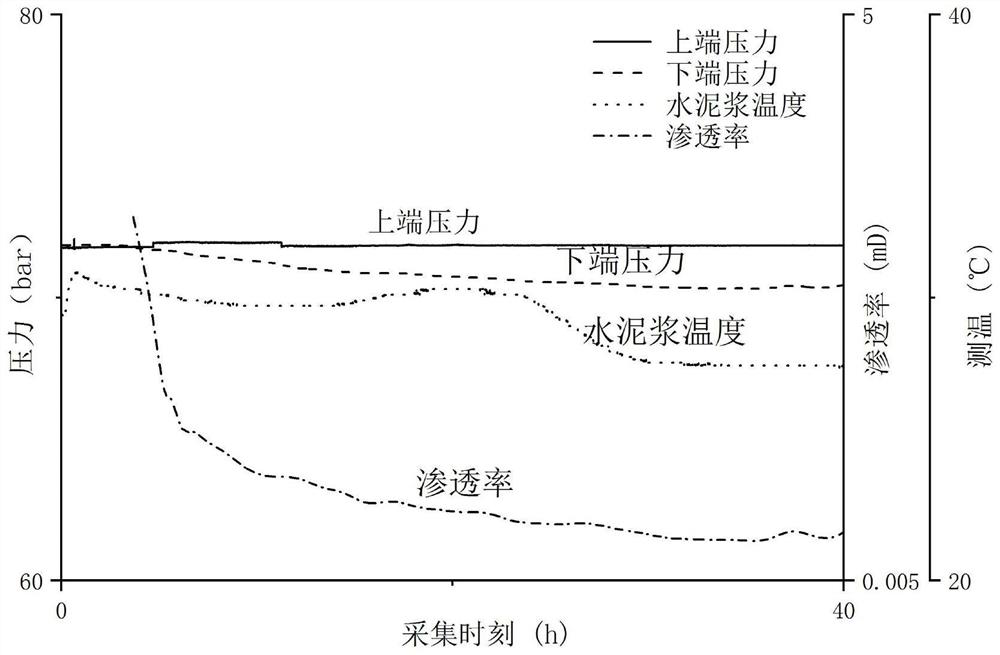

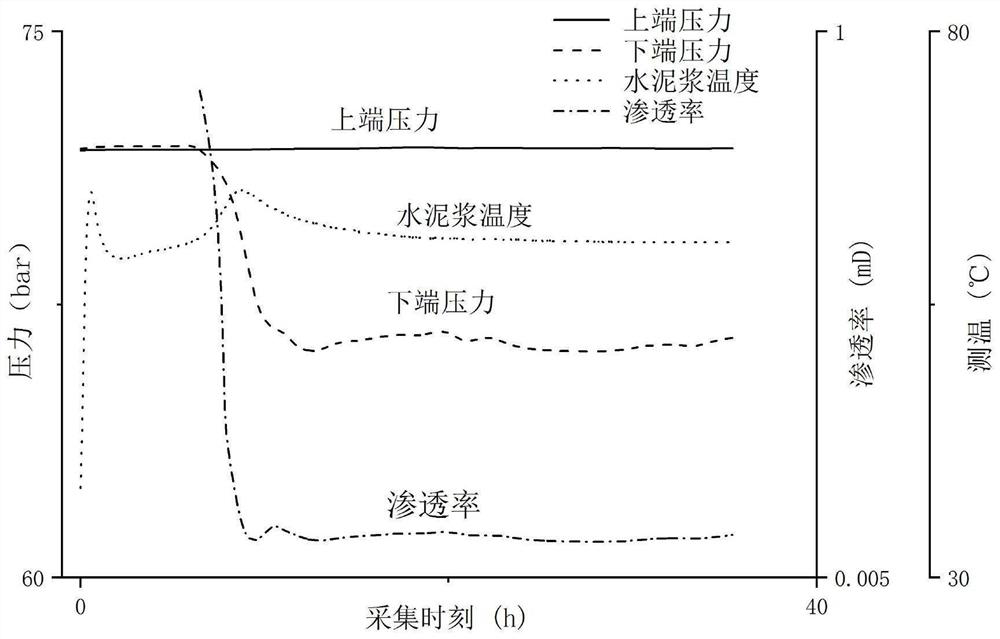

Dynamic permeability testing device and method in oil-gas well cement paste solidification process

ActiveCN114279936AWill not affect the formationValid testMaterial heat developmentPermeability/surface area analysisTemperature controlControl system

The invention discloses a dynamic permeability testing device and method in the solidification process of oil and gas well cement slurry. The device comprises a sealing slurry cup, an upper end pressure control system, a lower end micro-flow control system, a temperature control system, an annular injection and drainage system and a computer control acquisition system. Wherein the sealing slurry cup is used for containing cement slurry to be detected; the upper end pressure control system is used for applying pressure to the upper end of the cement paste to be detected; the lower-end micro-flow control system is used for controlling micro-seepage of the test medium in the to-be-tested cement paste; the temperature control system is used for heating and measuring the temperature of to-be-measured cement And the annular injection and drainage system is used for injecting and draining a heating medium into the sealed slurry cup. The permeability development process in the cement paste solidification process is monitored in a micro-seepage mode, a test medium seeps through the cement paste at a weak flow, and formation of a cement paste hydration and gelling structure is not affected; the slurry preparation water is used as a test medium, cement slurry hydration is not affected, and hydration and solidification of cement slurry in a shaft under temperature and pressure can be simulated.

Owner:SOUTHWEST PETROLEUM UNIV

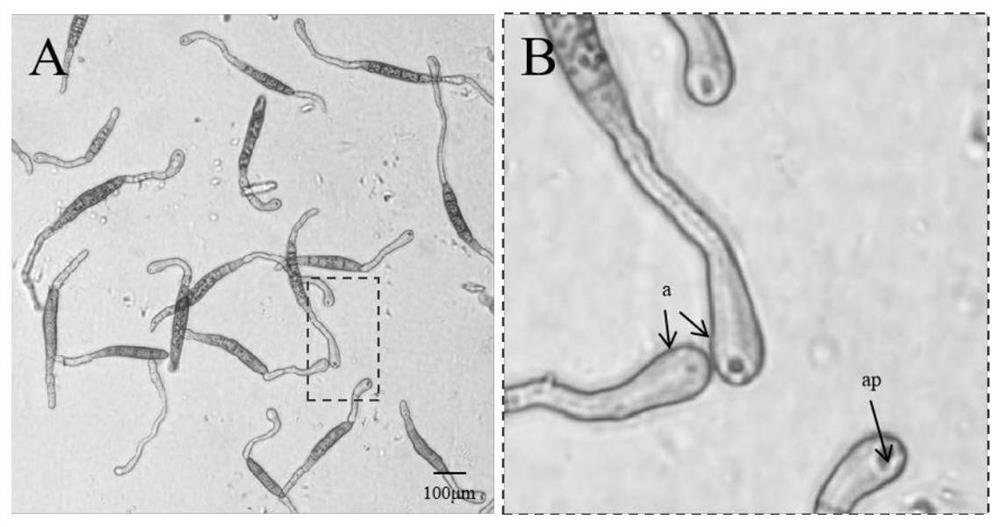

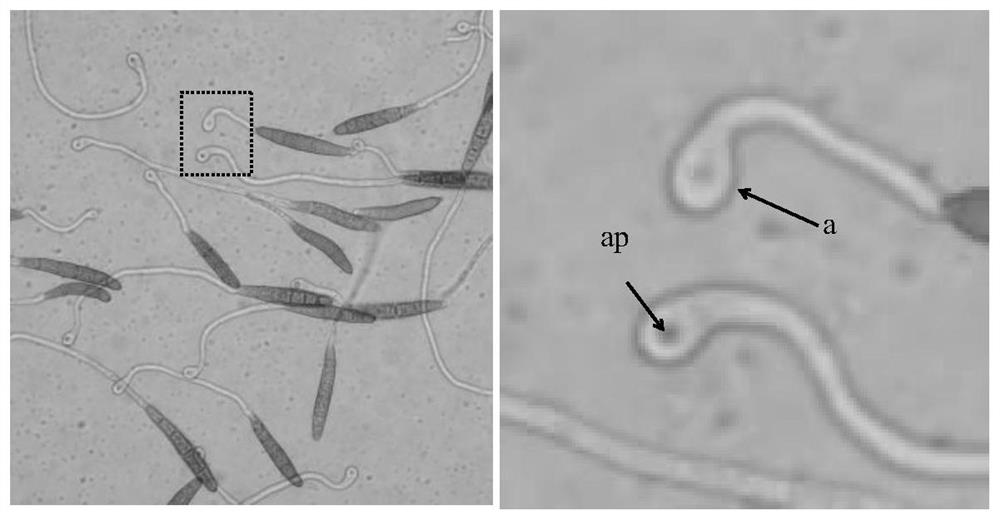

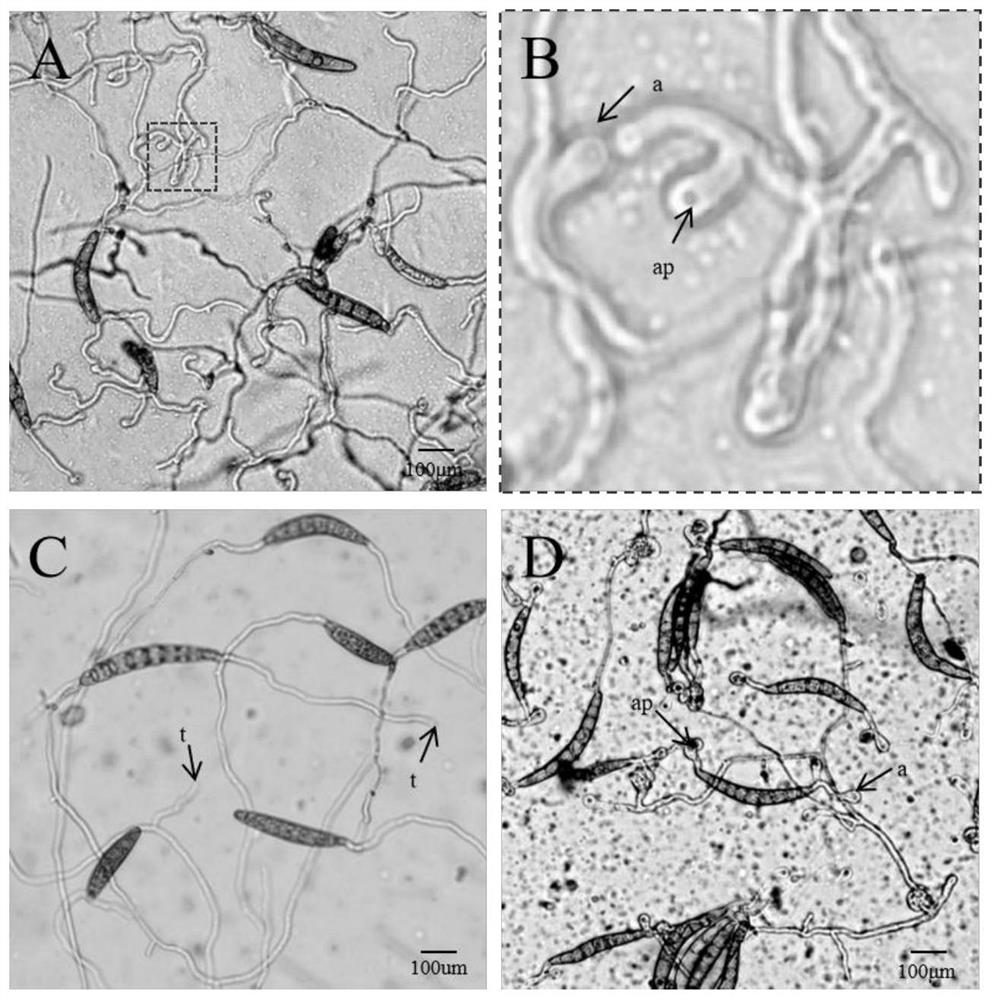

A material for inducing appresses of corn leaf spot fungus and its preparation method and application

The invention discloses a material for inducing appresses of corn leaf spot fungus and its preparation method and application, and belongs to the technical field of research on the infection mechanism of plant pathogenic fungi. The material is made of the following raw materials by volume: 4-6 parts of Si-PUD resin copolymerized with silicone diol and aliphatic isocyanate, and 4-6 parts of self-curing liquid polytetrafluoroethylene resin. The materials for inducing appresses of corn leaf spot fungus of the present invention have safe raw materials, simple preparation, and convenient use, are suitable for high-throughput systems, are used for inducing appresses of corn leaf spot fungi, have high induction efficiency, and are suitable for the infection mechanism of corn leaf spot fungus. Research.

Owner:河北福赛农业科技有限公司

Recombinant yeast engineering strain coexpressed by proteins of chicken anaemia viruses VP1 and VP2, construction method thereof and application thereof

ActiveCN102311928BThe expression product has high activityEasy to scale up productionFungiViral antigen ingredientsYeastChicken anaemia virus

Owner:HARBIN VETERINARY RES INST CHINESE ACADEMY OF AGRI SCI

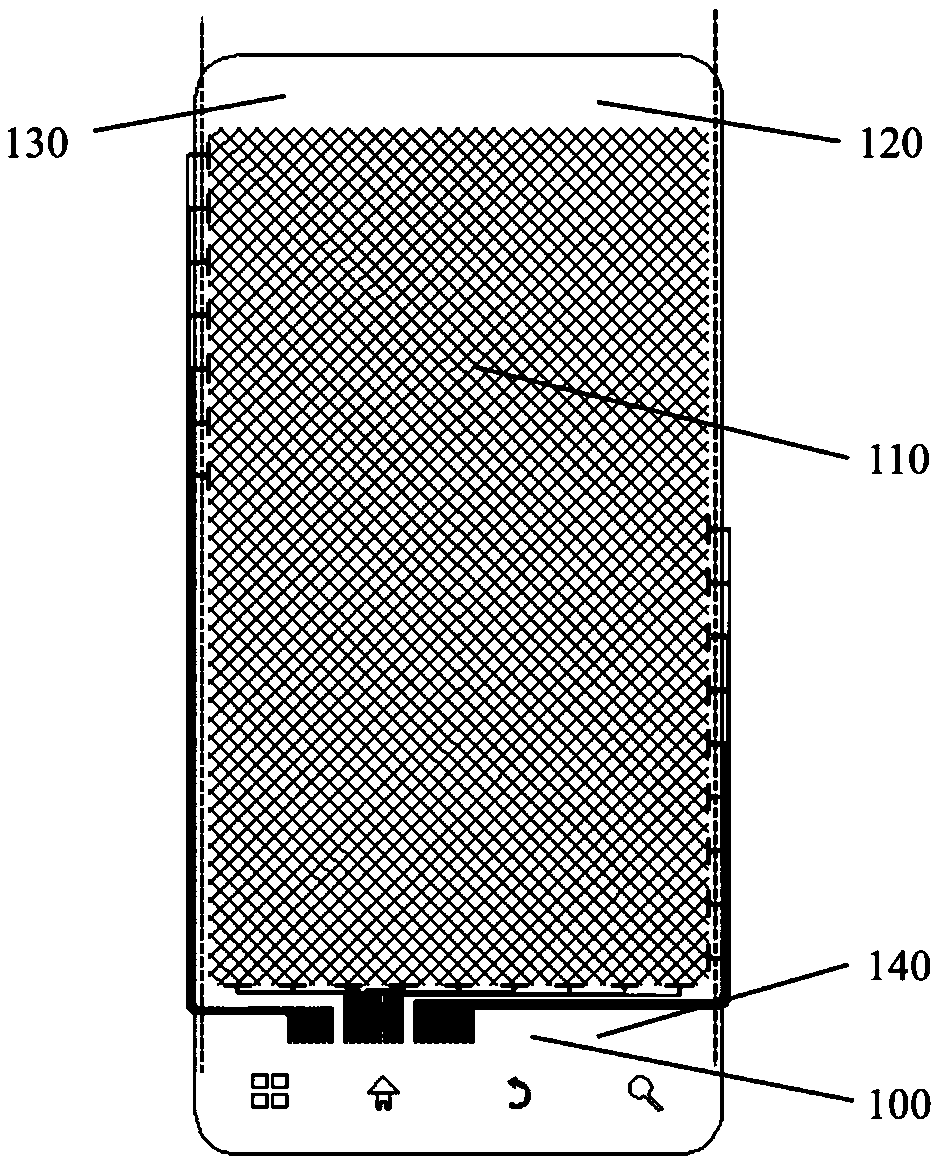

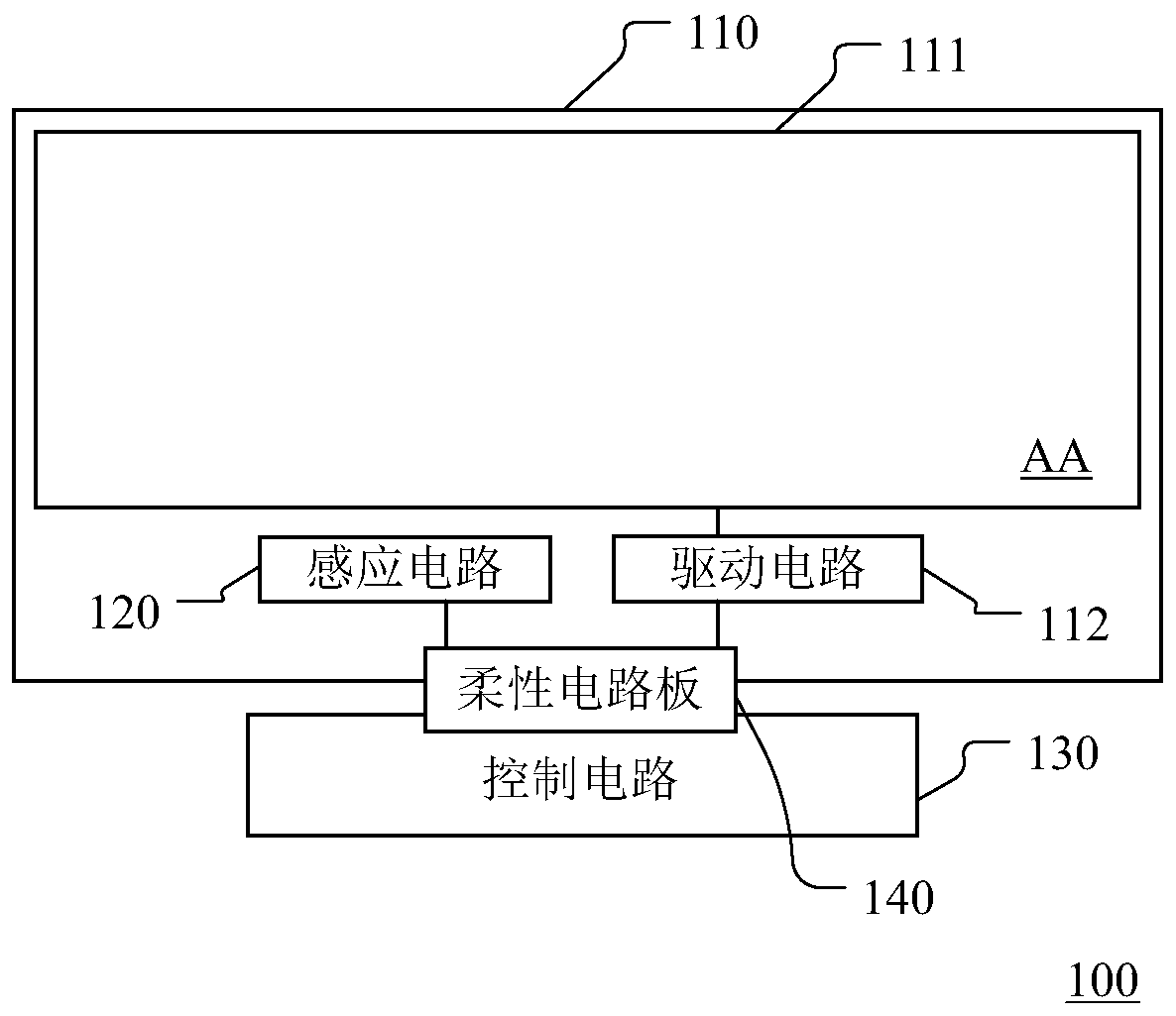

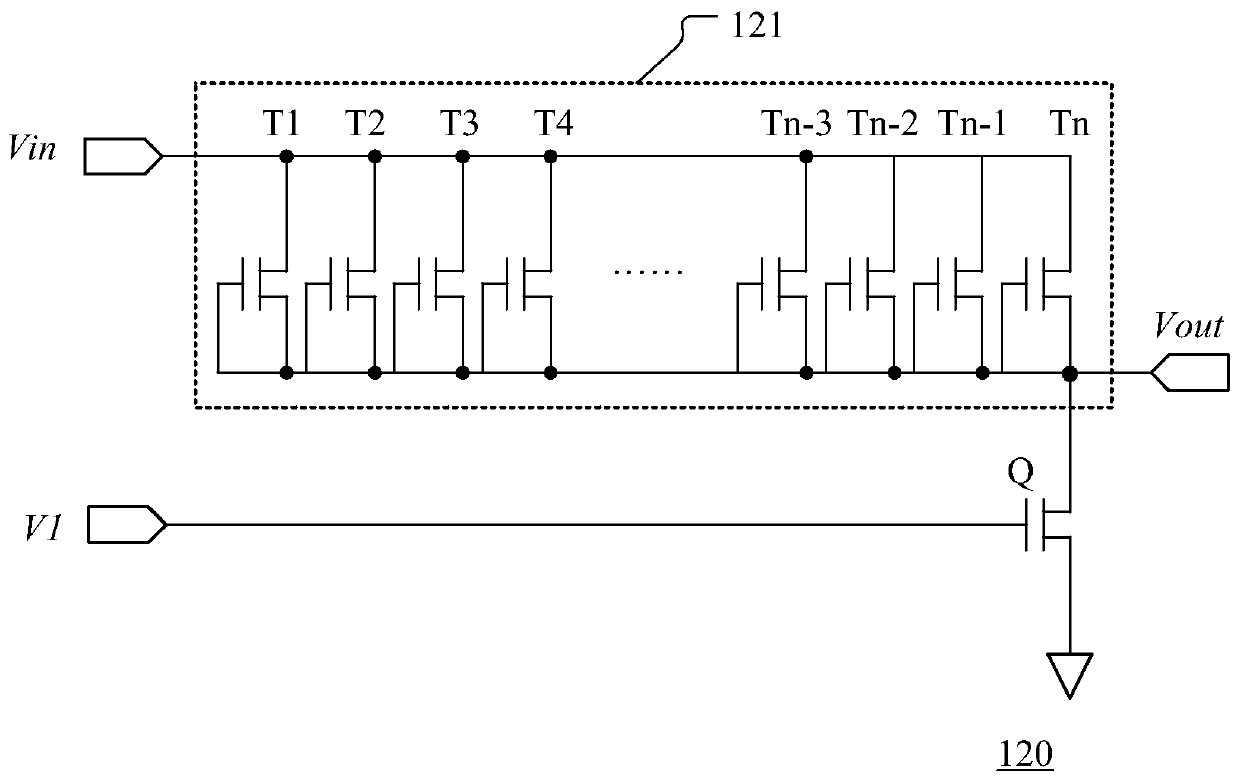

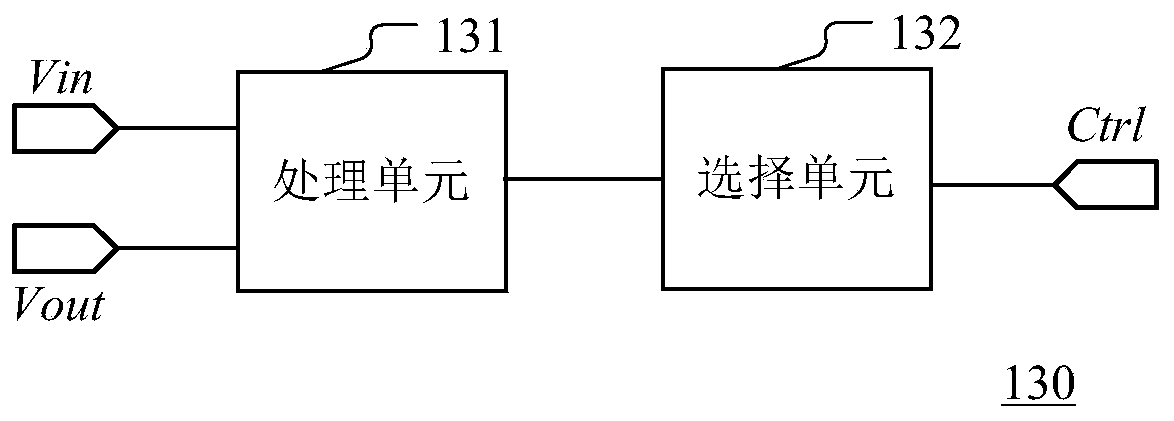

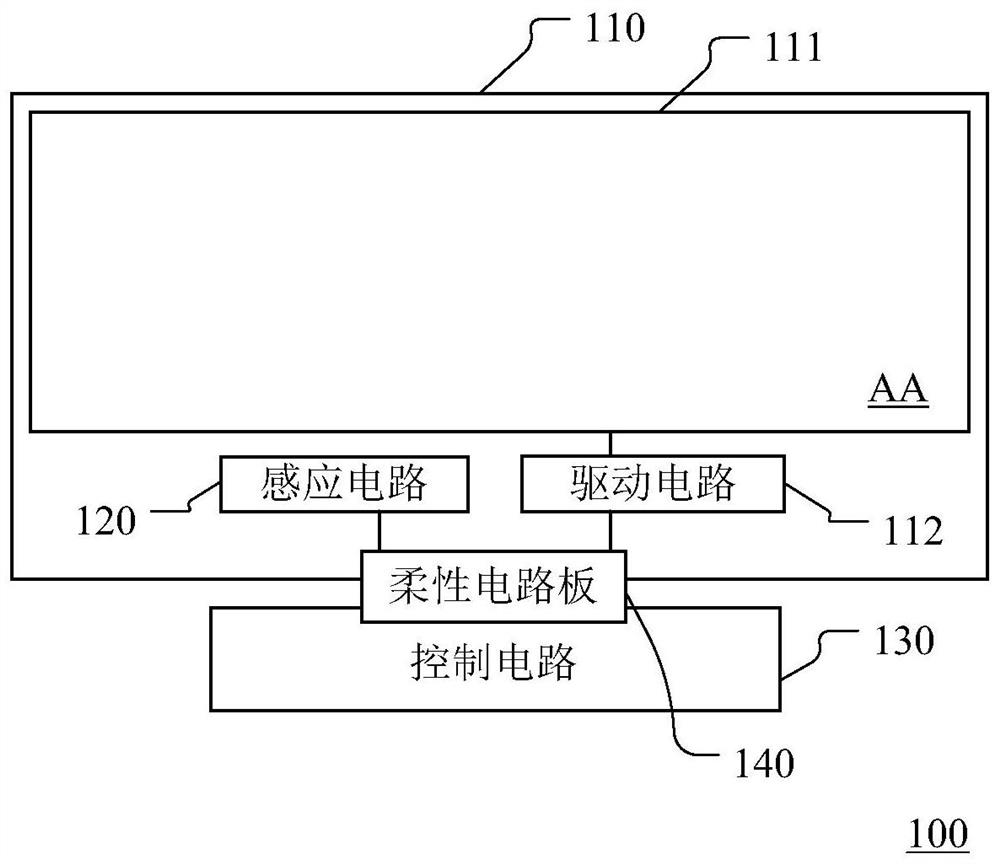

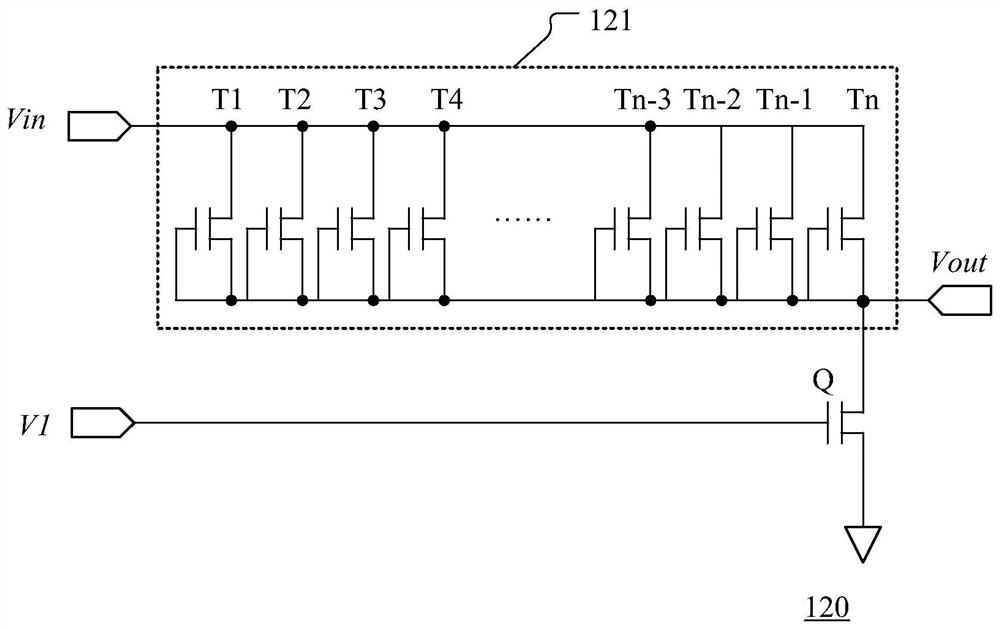

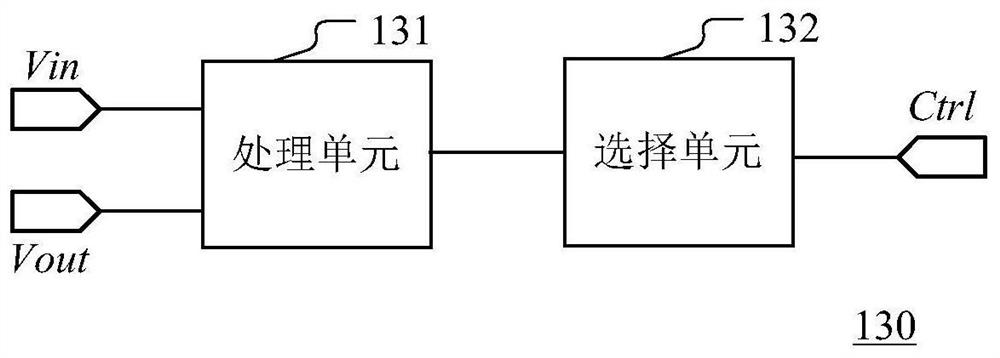

Display device and driving compensation method thereof

ActiveCN110660358AHigh precisionWill not affect the formationStatic indicating devicesPixel arrayHemt circuits

The invention discloses a display device and a driving compensation method thereof. The display device comprises a display panel; a driving circuit used for providing a driving signal to drive a pixel array in the display panel; an induction circuit sensitive to temperature and / or illumination intensity and comprises an input end; an output end; at least one sensing element connected between the input end and the output end, wherein the equivalent resistance of the at least one sensing element is changed along with the change of temperature and / or illumination intensity; a bias element connected with the output end, and the equivalent resistance of at least one sensing element and the equivalent resistance of the bias element divide the input voltage to obtain a detection voltage; and a control circuit connected with the induction circuit so as to receive the detection voltage and adjust the driving signal according to the detection voltage. The induction circuit is arranged inthe display panel, the temperature and / or the illumination intensity of the display panel are / is detected, the control circuit is arranged to adjust and obtain the driving signal corresponding to thetemperature or the illumination intensity, and the display quality of the display device is guaranteed.

Owner:KUSN INFOVISION OPTOELECTRONICS

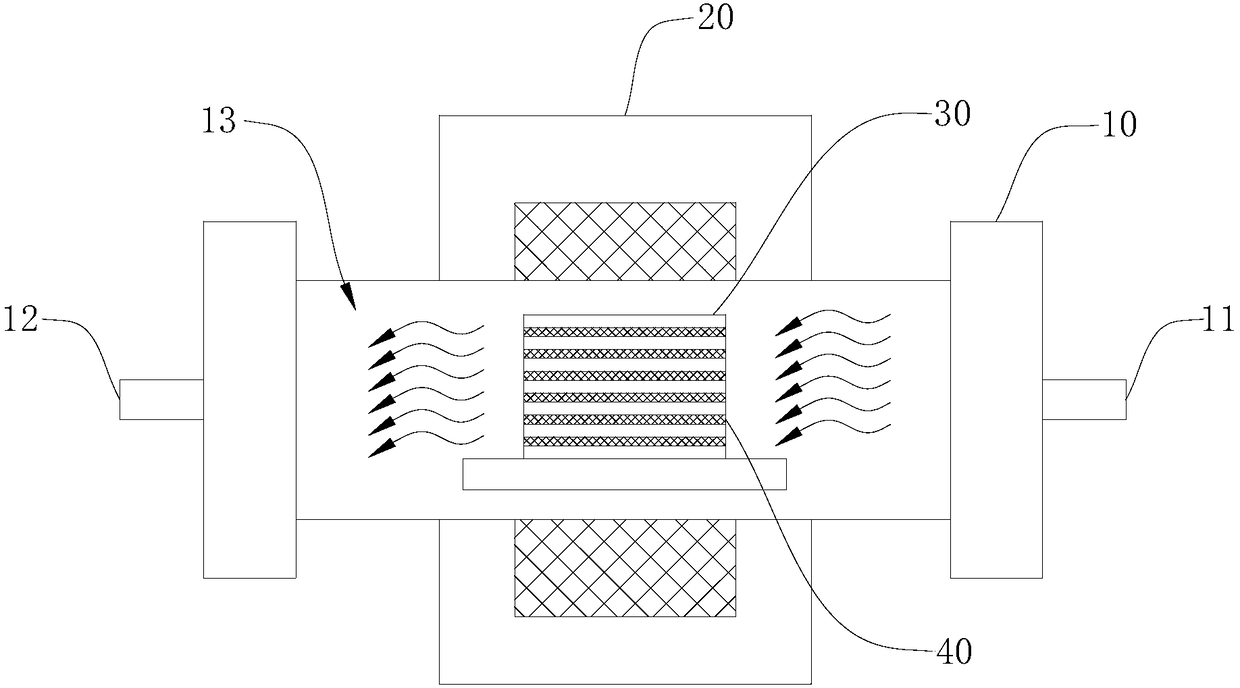

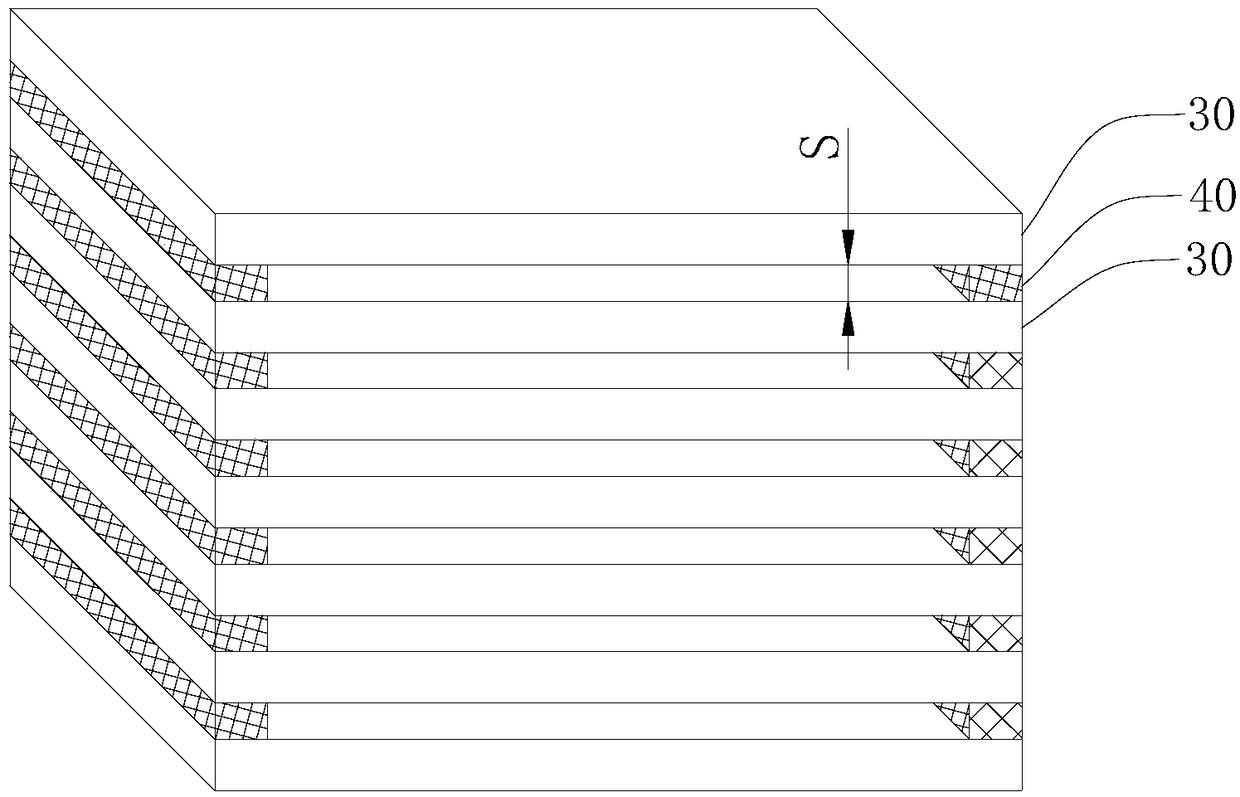

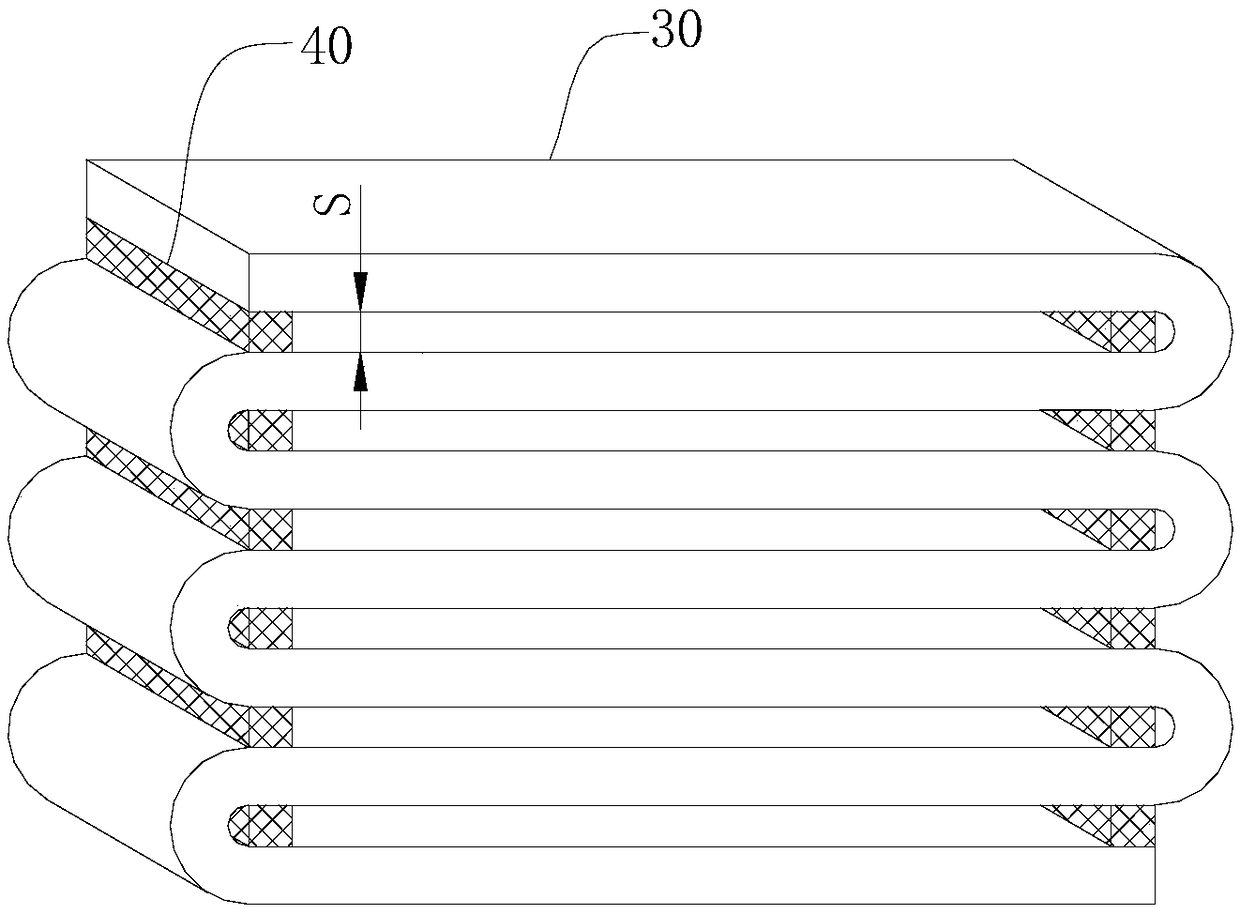

Chemical vapor deposition method device

InactiveCN109371382APrevent sinteringAvoid stickingChemical vapor deposition coatingChemical vapor depositionMetal substrate

The invention discloses a chemical vapor deposition method device, and belongs to the technical field of preparation of two-dimensional materials. The chemical vapor deposition method device comprisesa reaction furnace and a heating device, wherein the heating device is arranged around the reaction furnace, the two ends of the reaction furnace are correspondingly provided with an air inlet and anair outlet, a reaction chamber is arranged inside the reaction furnace, a plurality of layers of metal substrates are arranged in the reaction chamber, and a porous separation strip is arranged between the edges of every two adjacent metal substrates, so that a gap S is formed between every two adjacent layers of metal substrates. According to the chemical vapor deposition method device, under the conditions that a precursor which is not blocked and in a gas state is circulated, and meanwhile high-temperature sintering or adhesion of the metal substrates is avoided, the space of the reactionchamber is fully utilized, the area used for allowing the metal substrates to be placed is increased, then the area of a two-dimensional material thin film which can be formed is increased, and the device is suitable for industrial production and preparation; and in addition, the two-dimensional material thin film prepared through the device has continuity, can have a large macroscopic area and issuitable for application in the aspects of industry, research and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Display device and driving compensation method thereof

ActiveCN110660358BHigh precisionWill not affect the formationStatic indicating devicesDisplay deviceHemt circuits

Owner:KUSN INFOVISION OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com