Hot galvanized high-strength steel with excellent Fe-Al alloy layer characteristics and manufacturing method thereof

A manufacturing method and hot-dip galvanizing technology, which are applied in the direction of superimposed layer coating, hot-dip coating process, metal material coating process, etc., can solve the problem of missing Fe-Al alloy layer, pitting, and different morphology of the alloy layer, etc. problem, to achieve the effect of uniform Fe-Al alloy layer, improved effective contact, and consistent morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0035] Table 1 is the composition of the hot-dip galvanized steel sheet of the present invention. Table 2 shows the annealing process of the hot-dip galvanized steel sheet and the properties of the hot-dip galvanized steel sheet according to the present invention.

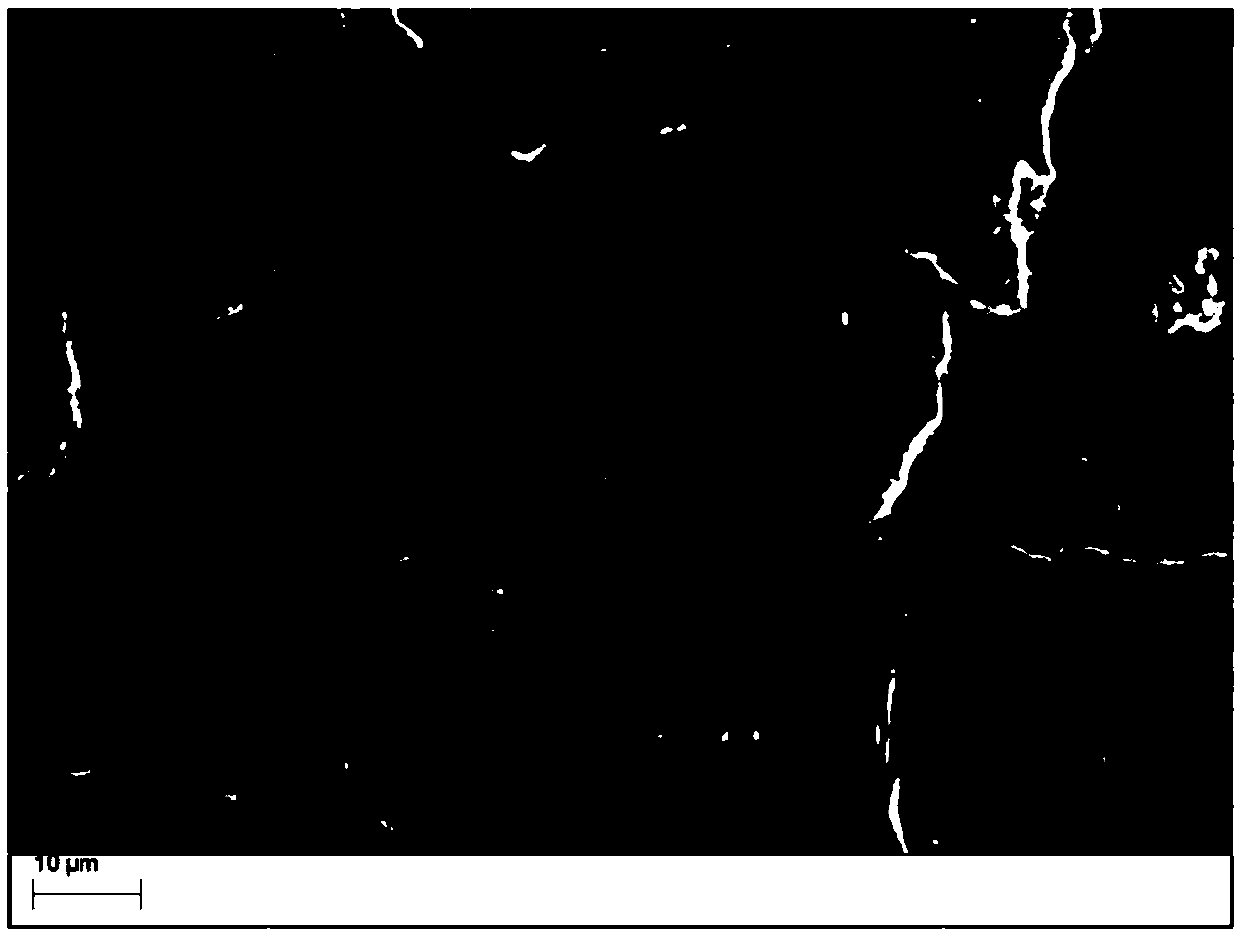

[0036] figure 1 It is a scanning electron microscope image of the surface of the Fe-Al alloy layer at the missing plating defect of direct annealing hot-dip galvanizing without pre-plating Fe treatment in Comparative Example 1. Depend on figure 1 It can be seen that the Fe-Al alloy layer is discontinuous and missing in large areas.

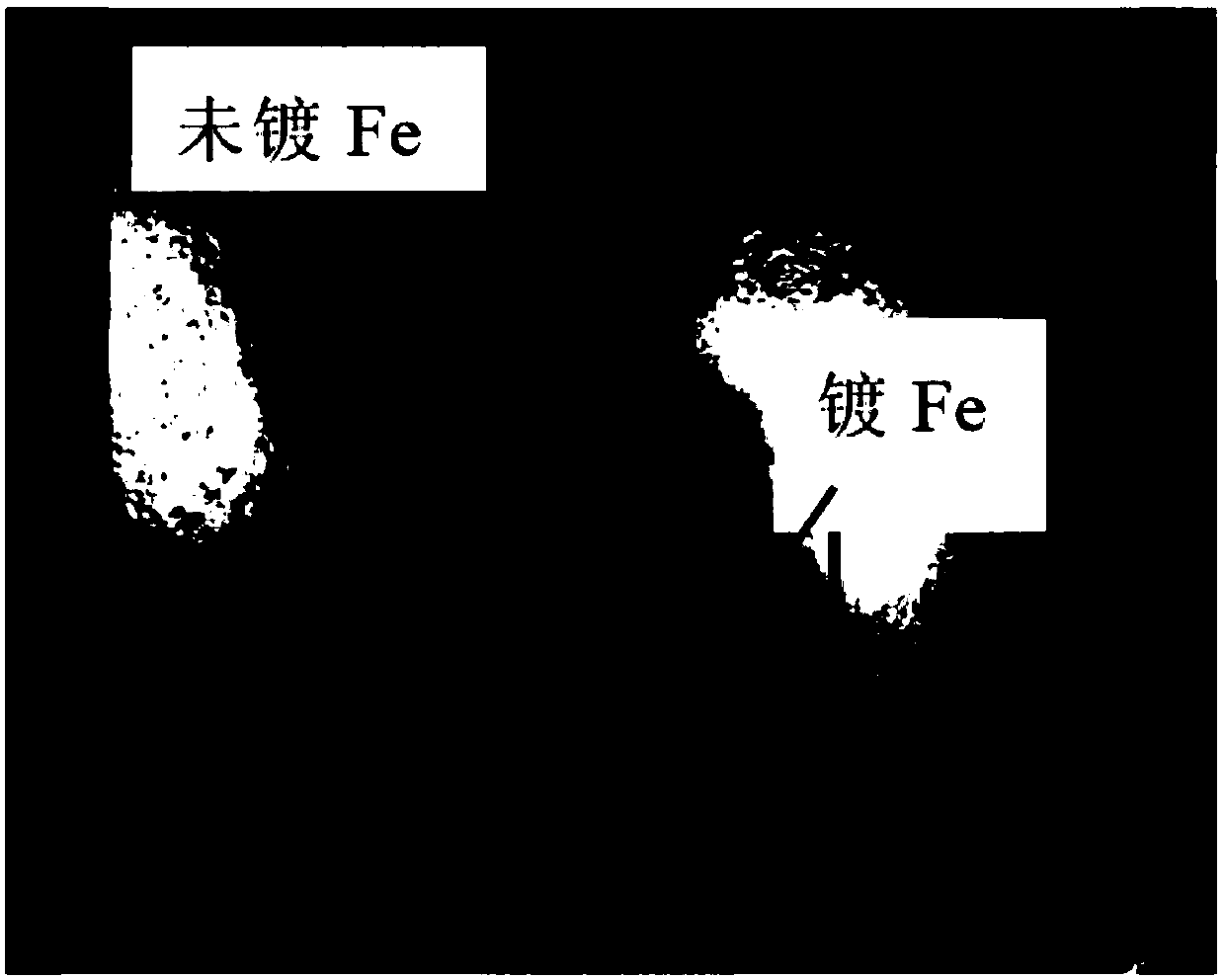

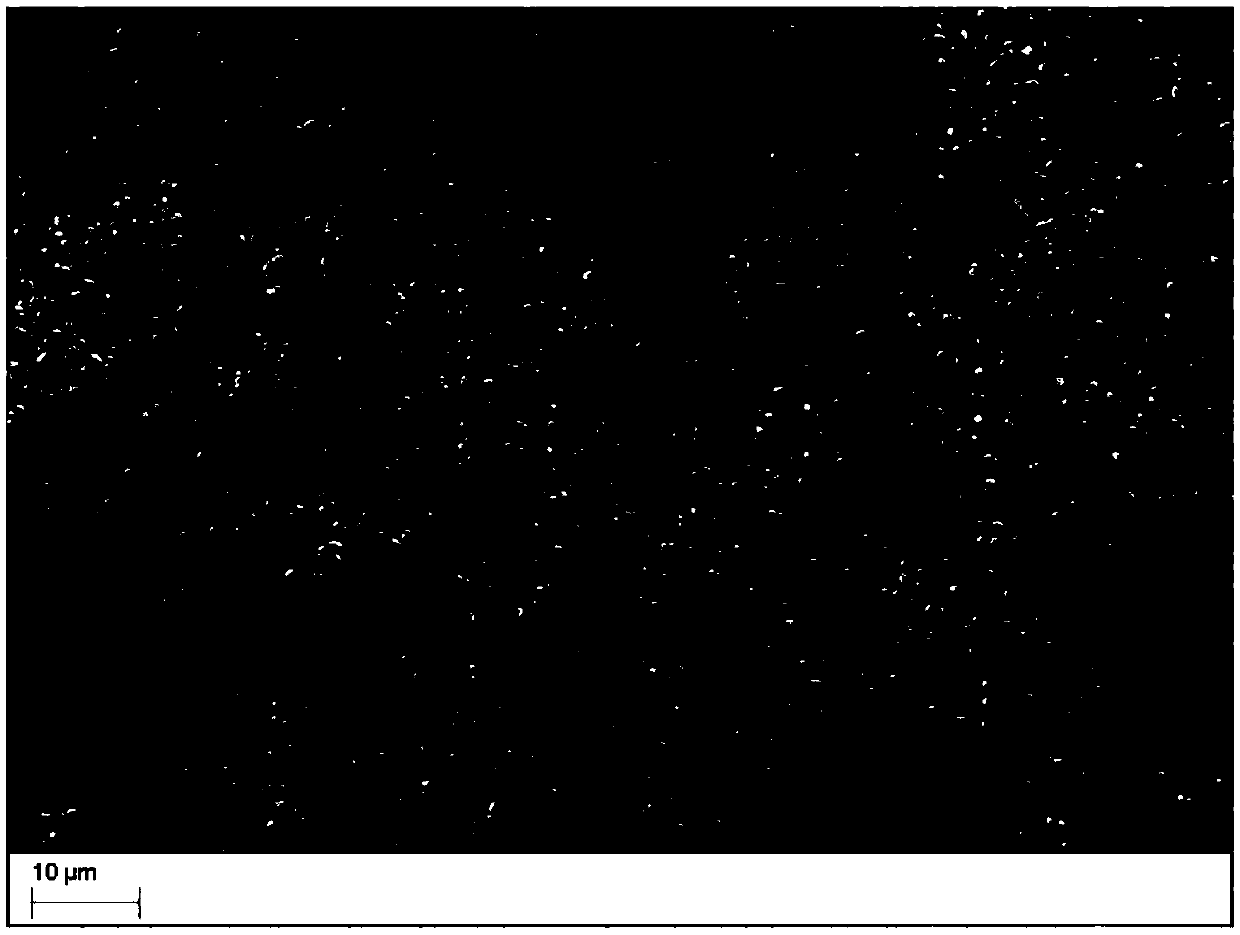

[0037] figure 2It is the appearance of the galvanized sheet after the pre-coating Fe treatment in Example 2. Compared with the non-pre-plating Fe treatment part, it can be found that the surface quality of hot-dip galvanizing after the Fe coating is better,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com