Chemical vapor deposition method device

A chemical vapor deposition, heating device technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as small area, and achieve the effect of increasing area, increasing fluidity, and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

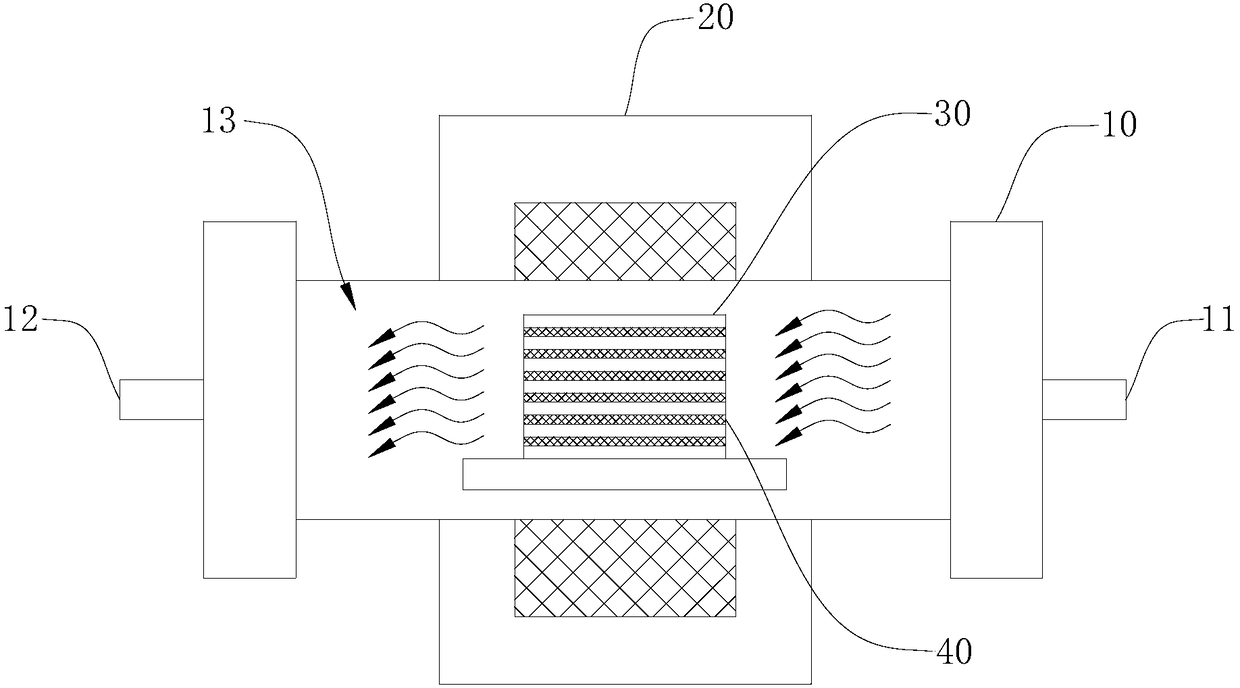

[0037] Please refer to figure 1 , a chemical vapor deposition method device, comprising: a reaction furnace 10 and a heating device 20 . The reaction furnace 10 is a horizontal tube furnace with a reaction chamber 13 inside and an air inlet 11 and an air outlet 12 at both ends for the circulation of gases such as protective gas and gaseous precursors. The heating device 20 is arranged around the reaction furnace 10 for raising the temperature of the reaction furnace 10 . The reaction chamber 13 is provided with a support platform on which a multi-layer metal substrate 30 is placed. In this embodiment, the metal base 30 is copper foil with a thickness of 100 μm. In other embodiments of the present invention, the reaction furnace 10 can also be a vertical tube furnace, etc., and the heating device 20 can be matched with the corresponding reaction furnace 10; the metal base 30 can also be made of materials such as nickel, iron, cobalt, gold, silver, Metals such as platinum and...

Embodiment 2

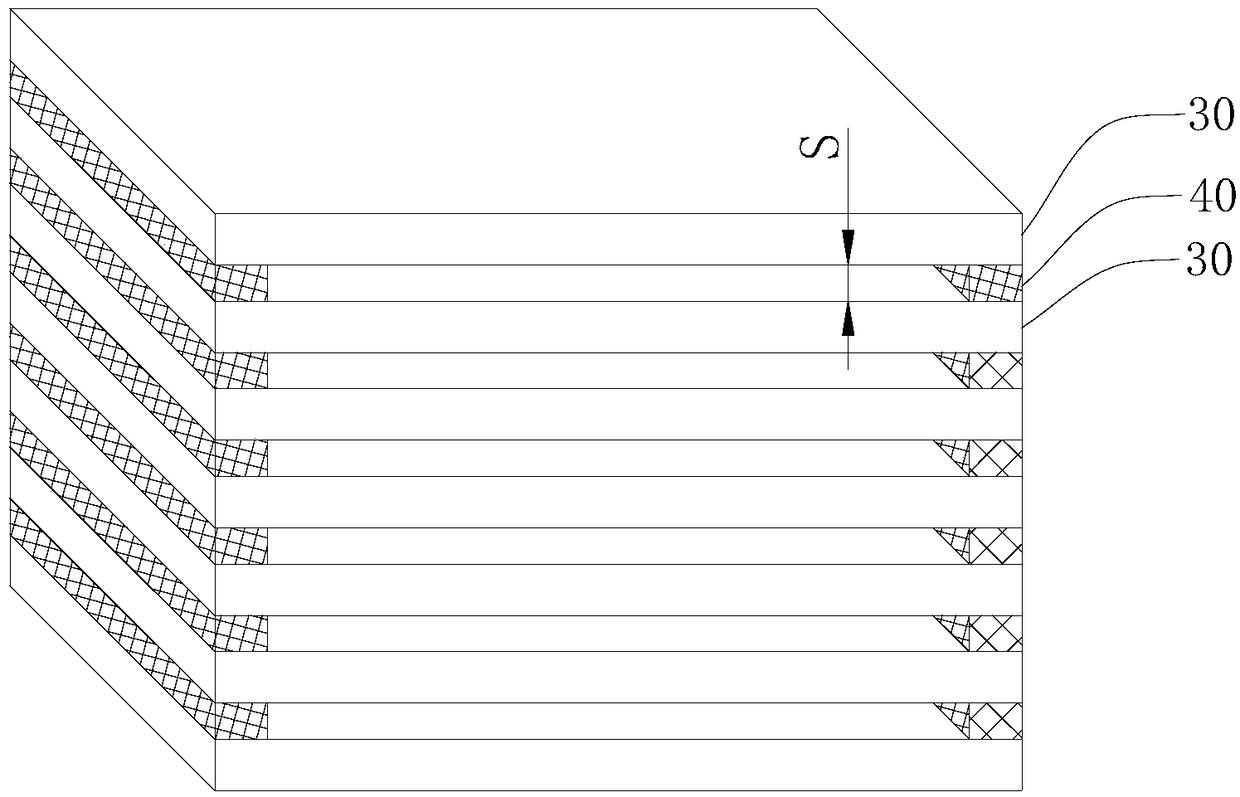

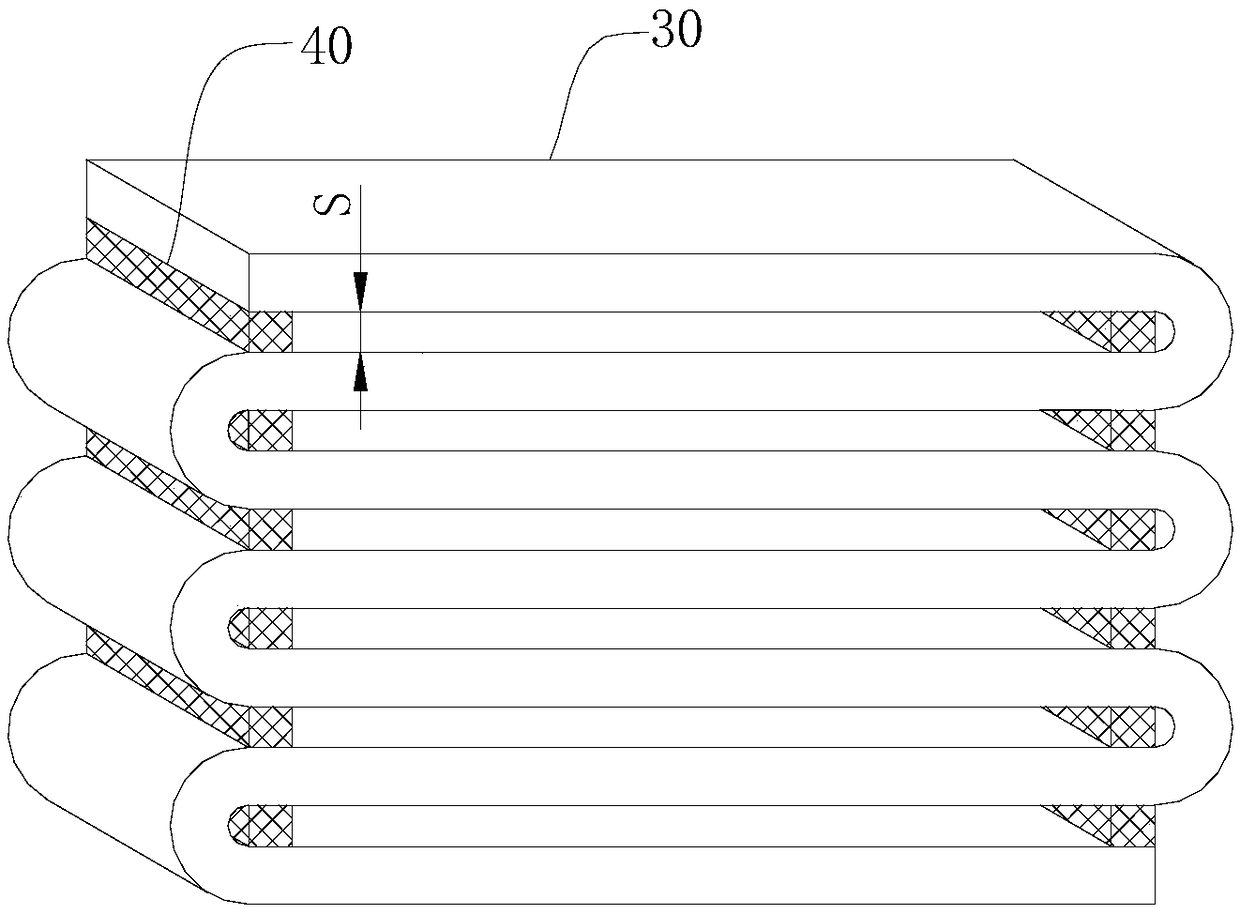

[0040] Please refer to Figure 4  ̄ Figure 6 The difference between this embodiment and Embodiment 1 is that the metal base 30 is spirally formed into multiple layers, and the strip-shaped metal base 30 is wound along the outer surface of the mandrel 50, so that the metal base 30 is in a multi-layer spiral shape. A spacer 40 is provided between the metal bases 30 on adjacent sides, and the spacer 40 is arranged on the curled edge of the metal base 30, that is, when the metal base 30 is not wound, the spacer 40 is set on the edge of the metal base 30 that needs to be curled, and the The metal base 30 provided with the spacers 40 is wound around the mandrel 50 to form a spiral in multiple layers. The axis of the helical metal base 30 is consistent with the connecting direction of the air inlet 11 and the air outlet 12 , so that the precursor can smoothly enter the cavity between the metal bases 30 on adjacent sides.

[0041] The process of preparing two-dimensional material gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com