Patents

Literature

33results about How to "Shedding does not cause" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large-diameter high-speed cutting and high-speed heavy load grinding resin wheel

InactiveCN101695827AHigh thermal conductivityImprove wear resistanceAbrasion apparatusGrinding devicesFilling materialsFilm coating

The invention discloses a large-diameter high-speed cutting and high-speed heavy load grinding resin wheel prepared from the following three components in percentage by weight: 60-72 percent of grinding materials, 18-25 percent of filling materials and 8-18 percent of resin, wherein the grinding materials in the wheel are film-coating calcined brown fused alumina, the filling materials comprise a heat conducting material and an active filling material, and the resin comprises a phenolic resin liquid and phenolic resin powder. The sand is produced by adopting the film-coating calcined brown fused alumina, which has good heat conduction property of metal plating, obviously strengthens the heat radiating effect of the wheel and prolongs the abrasive resistance and the service life of the wheel. In addition, the grinding materials have improved ball-milling flexibility after calcined, which enables the wheel to be durable and the property to be better. The wheel can be used for cutting hot-wire type steel with a diameter of over 100 mm or grinding the steel in a high-speed and heavy load way, and has long service life reaching 100-120min.

Owner:SAINT-GOBAIN ABRASIVES (SHANGHAI) CO LTD +2

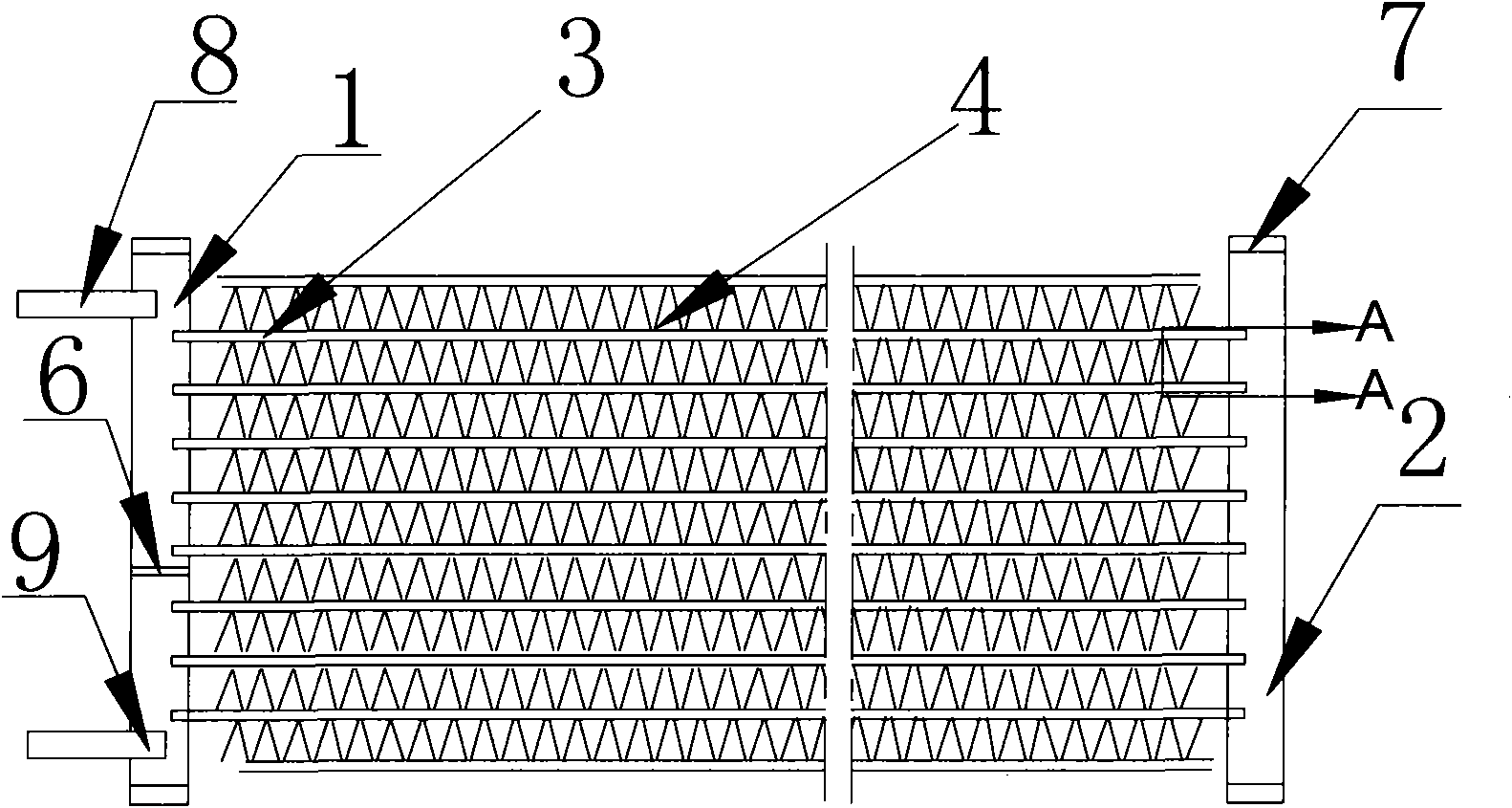

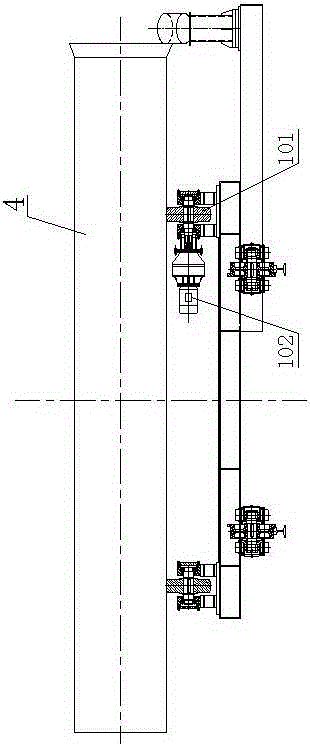

Lining coating technology for spheroidal graphite cast iron tube

ActiveCN103691625AWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

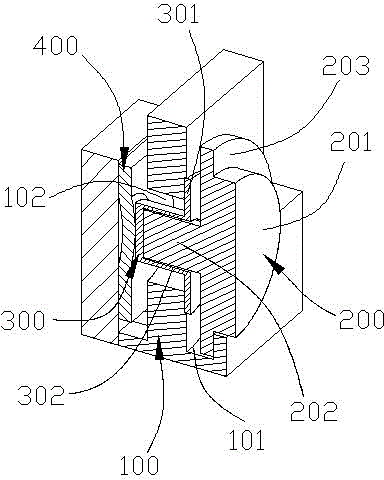

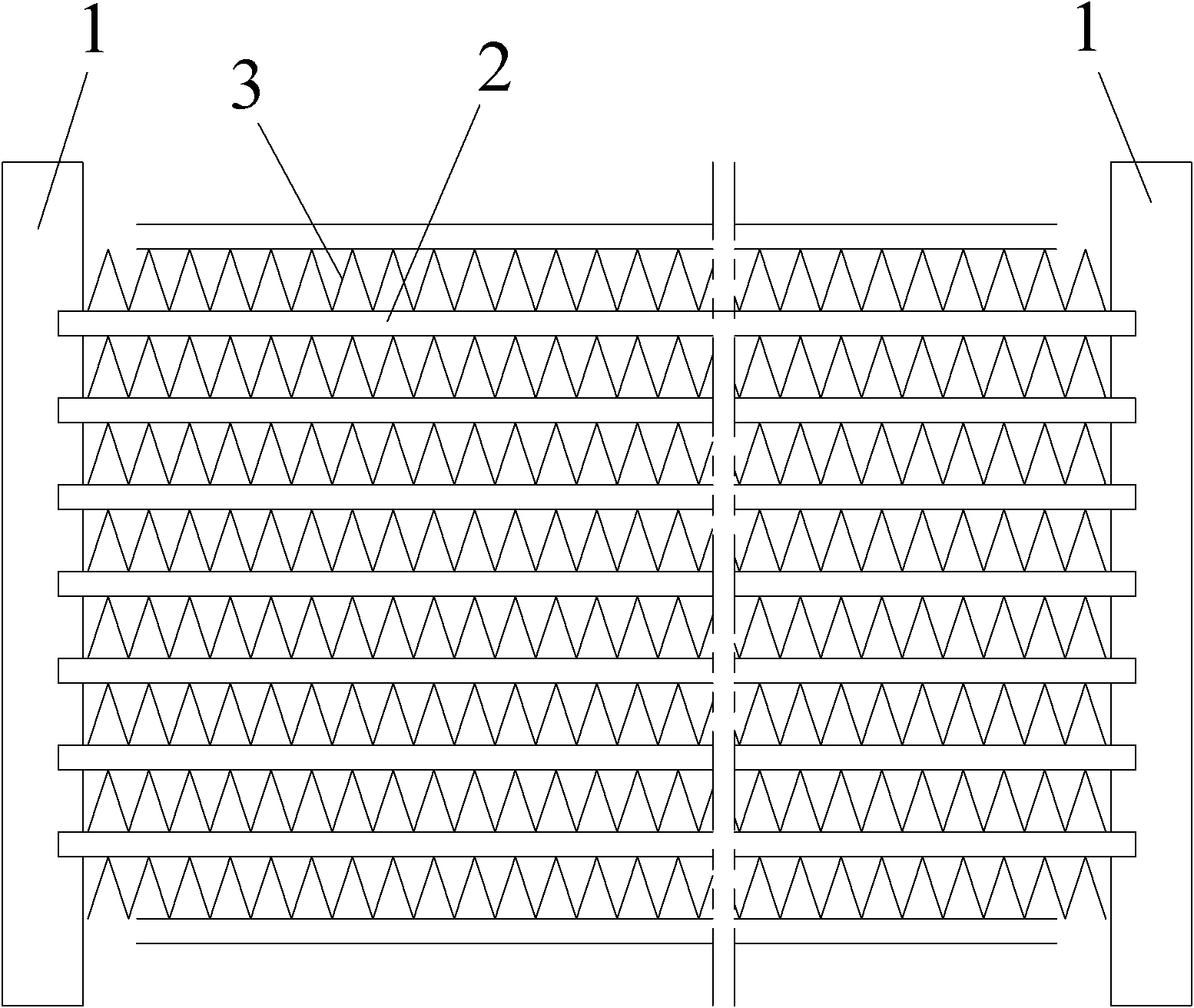

Heat exchanger

ActiveCN101776403APrevent falling offStable heat conduction efficiencyStationary conduit assembliesHeat exchanger casingsRadiationMarine engineering

The invention discloses a heat exchanger comprising a first collecting pipe, a second collecting pipe and a plurality of sets of radiation flat pipes arranged between the first collecting pipe and the second collecting pipe. Ports in which the radiation flat pipes can be inserted are arranged at one sides of the collecting pipes. The radiation flat pipes are inserted into the collecting pipes through the ports. Fins used for heat radiation are arranged between adjacent two sets of radiation flat pipes. Positioning mechanisms for preventing the horizontal movement of the fins are arranged between the radiation flat pipes and the fins. After the use of the positioning mechanisms, the radiation flat pipes and the fins of the heat exchanger can be stably and reliably positioned, and the service life of the heat exchanger can be prolonged. The positioning mechanisms are more suitable for heat exchangers with fins wider than radiation flat pipes. The disconnection caused by the collision of the fins with other components during the assembly, as well as other problems, can be avoided, thereby improving the heat exchange efficiency of the heat exchanger.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

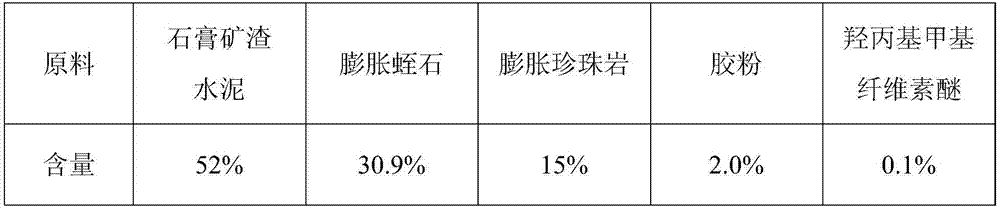

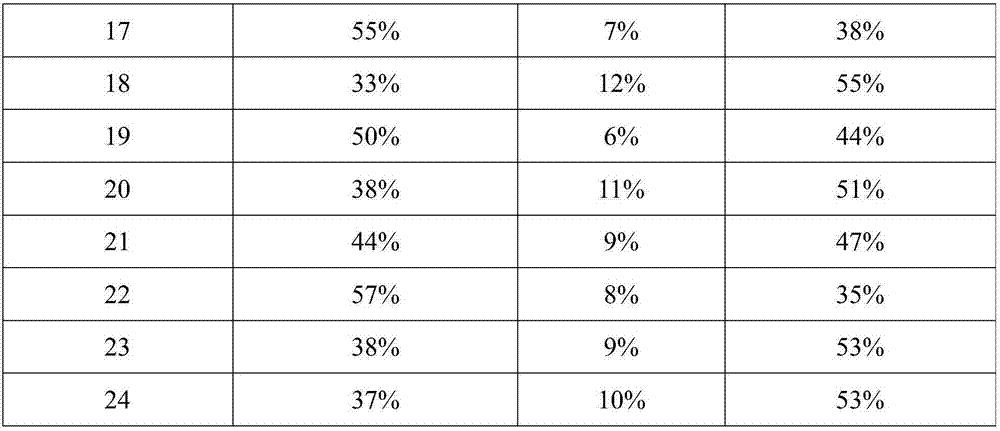

Preparation method of gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating

InactiveCN106867345AHigh strengthHigh bonding strengthFireproof paintsChemical industrySlagThermal insulation

The invention discloses a preparation method of a gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating. According to the preparation method, gypsum mine slag cement is obtained via mixing of gypsum, blast furnace slag, and Portland cement clinker; an ingredient A is obtained via mixing of acrylic acid waterproof elastic emulsion, styrene-acrylic emulsion, vinyl chloride-vinylidene chloride copolymer emulsion, mica powder, titanium dioxide powder, iron red powder, ammoniacal liquor, hydroxyethyl cellulose ether, a dispersant, an antifoaming agent, an antiseptic, a film forming auxiliary agent, and water; a fireproof steel structure anticorrosive primer is composed of the ingredient A and the gypsum mine slag cement; a thick-type steel structure fireproof thermal-insulation coating is obtained via mixing of expanded vermiculite, expanded perlite, rubber powder, hydroxyethyl cellulose ether, and the gypsum mine slag cement; and a finished product is obtained via steel structure surface cleaning treatment, coating of the fireproof steel structure anticorrosive primer, polishing, and coating of the thick-type steel structure fireproof thermal-insulation coating. The comprehensive cost is low; the preparation method is friendly to the environment, can be widely used for fire protection, corrosion protection, thermal insulation, and energy reduction of different kinds of steel structures.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

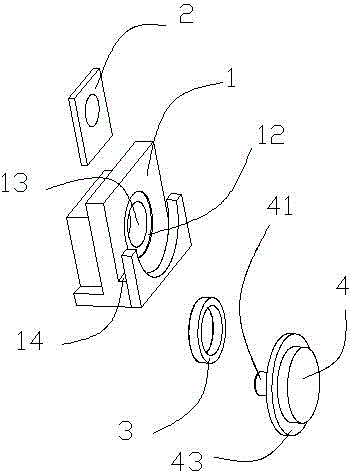

Waterproof key structure and mobile phone using same

ActiveCN104091710AHigh positioning accuracyImprove assembly efficiencyElectric switchesTelephone set constructionsKey pressingEngineering

The invention relates to a waterproof key structure which comprises a shell, a key switch, a flexible material part and a key. The key switch and the key are assembled on the shell in a position corresponding mode. The key is movably assembled on the shell. The flexible material part is installed on the key in a sleeved mode and pasted on the shell. When pressed, the key can abut against the key switch. A rigid supporting layer is arranged on one face of the flexible material part and pasted on the shell. The key extrudes the flexible material part in the pressing direction until the flexible material part deforms to be assembled together with the shell. In the structure, a rigid support is additionally arranged on foam and used for improving the assembling and locating performance; meanwhile, in the key assembling process, the flexible material part is pressed in advance so as to be in a compressed deformation state after being assembled, and therefore the good waterproof performance of the portion between the flexible material part and the shell is achieved; in addition, when the key is pressed, the direction of pressure is perpendicular to the pasting face of the flexible material part, and therefore the flexible material part can be prevented from slipping or falling from the shell, and the problem that the key is out of work can be avoided.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

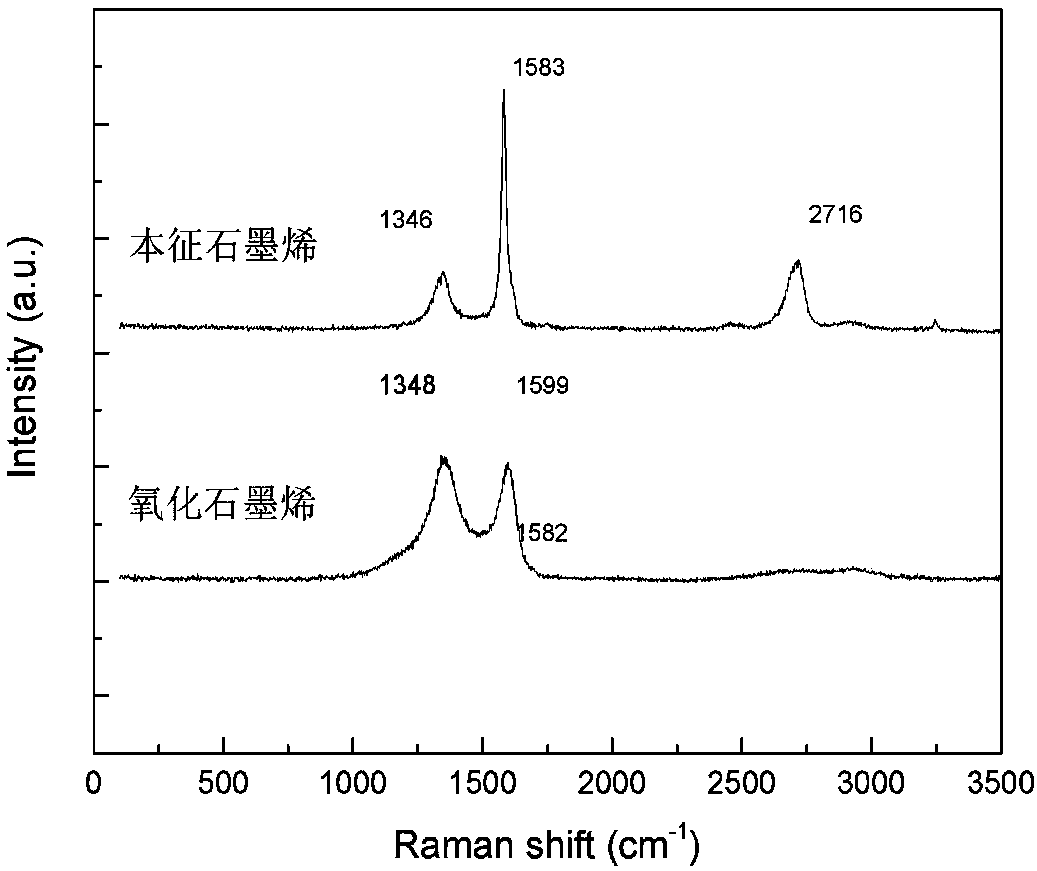

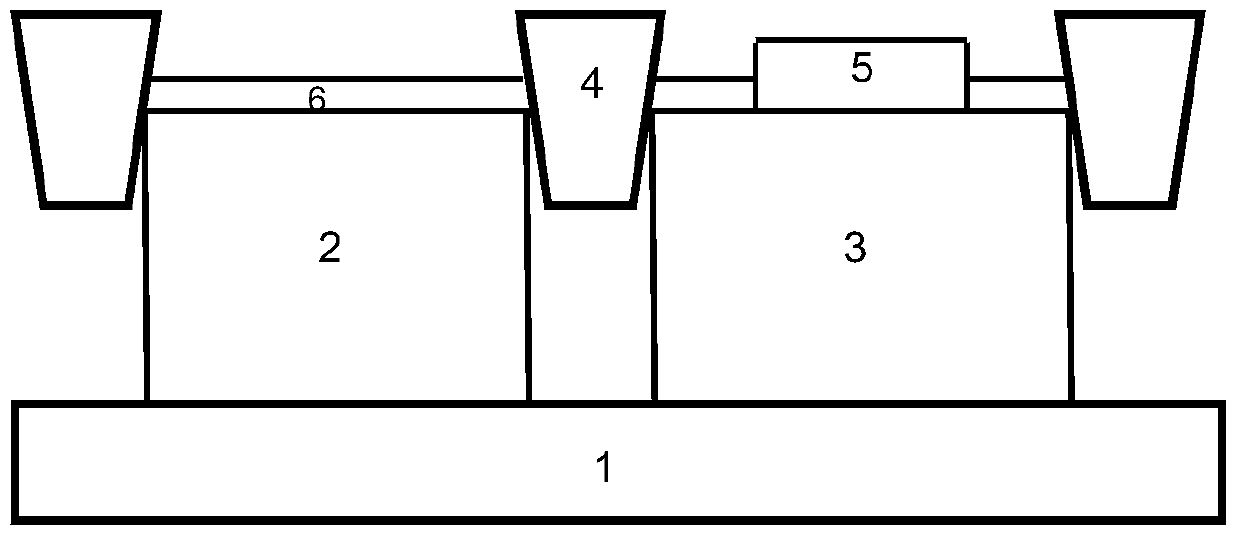

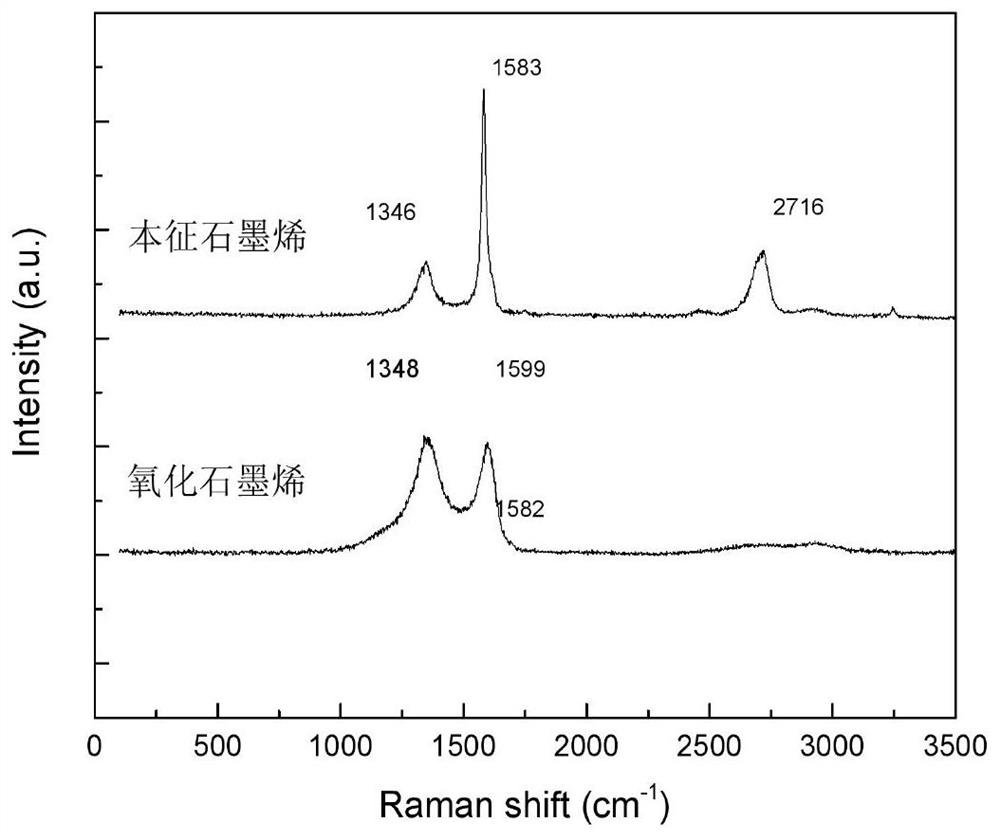

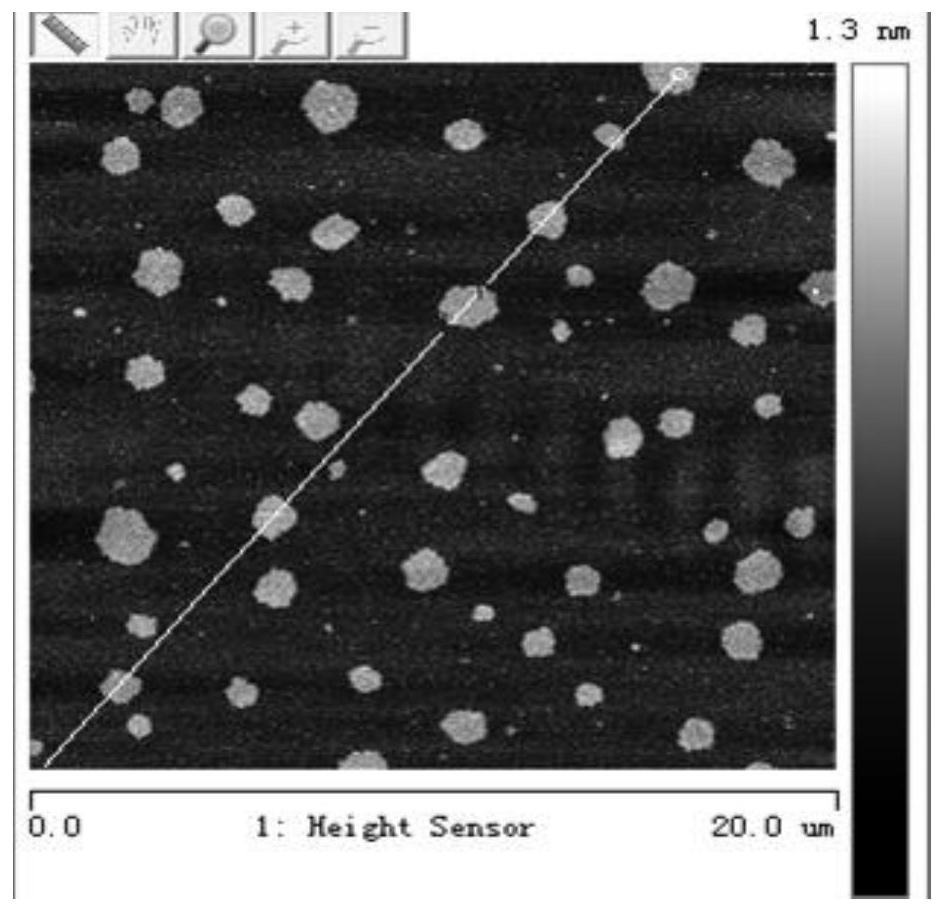

Graphene-based fireproof plastic plate and preparation method thereof

ActiveCN108530669AImprove flame retardant and heat insulation performanceImprove tensile propertiesFireproof paintsPolyurea/polyurethane coatingsCarbon layerIntrinsics

The invention belongs to the field of fireproof materials and provides a graphene-based fireproof plastic plate. The graphene-based fireproof plastic plate comprises a graphene-based fireproof layer and a plastic base material layer, and the graphene-based fireproof layer comprises intrinsic graphene. Flame retardation and heat insulation effects of the fireproof layer can be improved by intrinsicgraphene, the plastic base material layer can be effectively protected in fire accidents, and burning and toxic gas releasing time of the plastic base material layer is delayed to buy time for evacuation and rescue. Further, stretch resistance and flexibility of the fireproof layer can be improved by intrinsic graphene, and the fireproof layer deforms correspondingly in deformation of the plasticbase material layer so as to keep high adhesion to the plastic base material layer; strength of an expansion carbon layer is improved, and less proneness to shedding after heat deformation of the plastic base material layer is realized. Owing to excellent insulation and hydrophobic performances of intrinsic graphene, water resistance of the fireproof layer can be remarkably improved, and the service life of the fireproof plastic plate is prolonged. In addition, the graphene-based fireproof plastic plate is low in density.

Owner:东莞市海洲新材料科技有限公司 +1

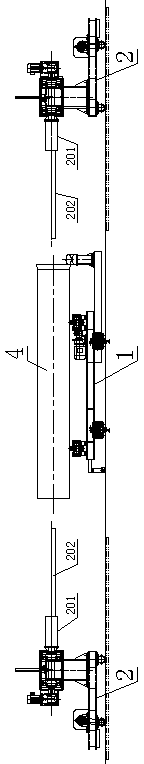

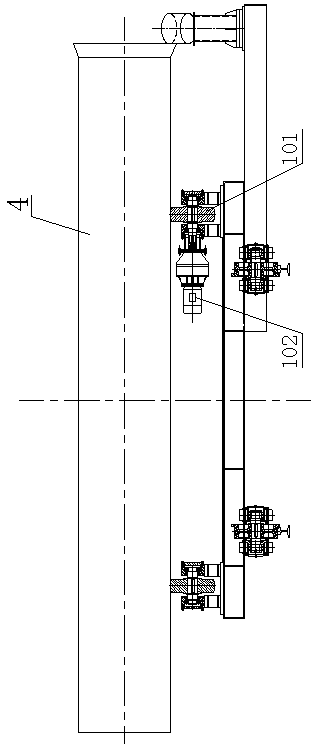

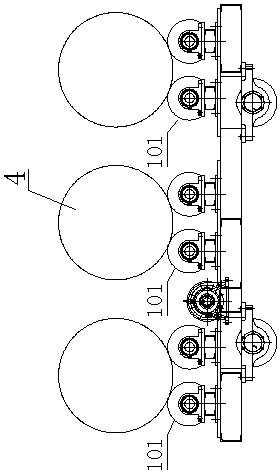

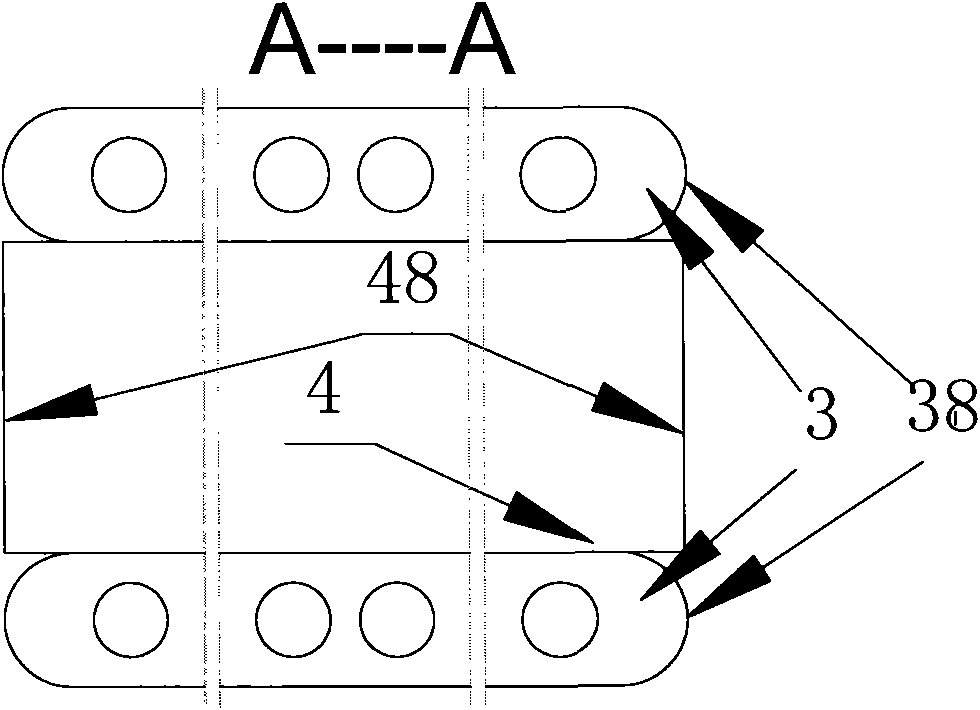

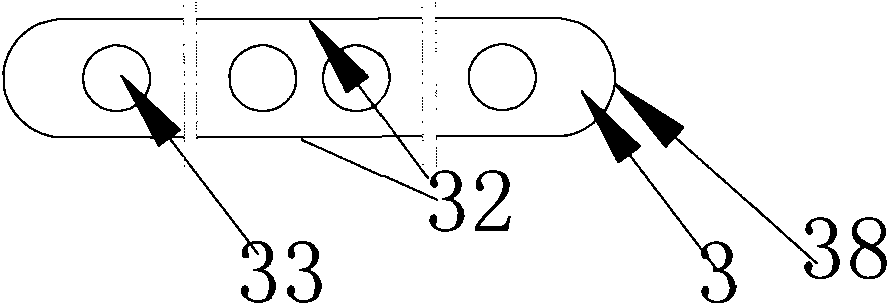

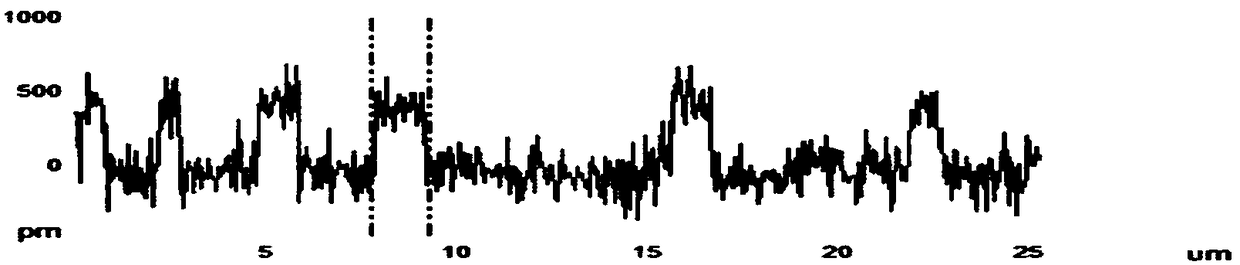

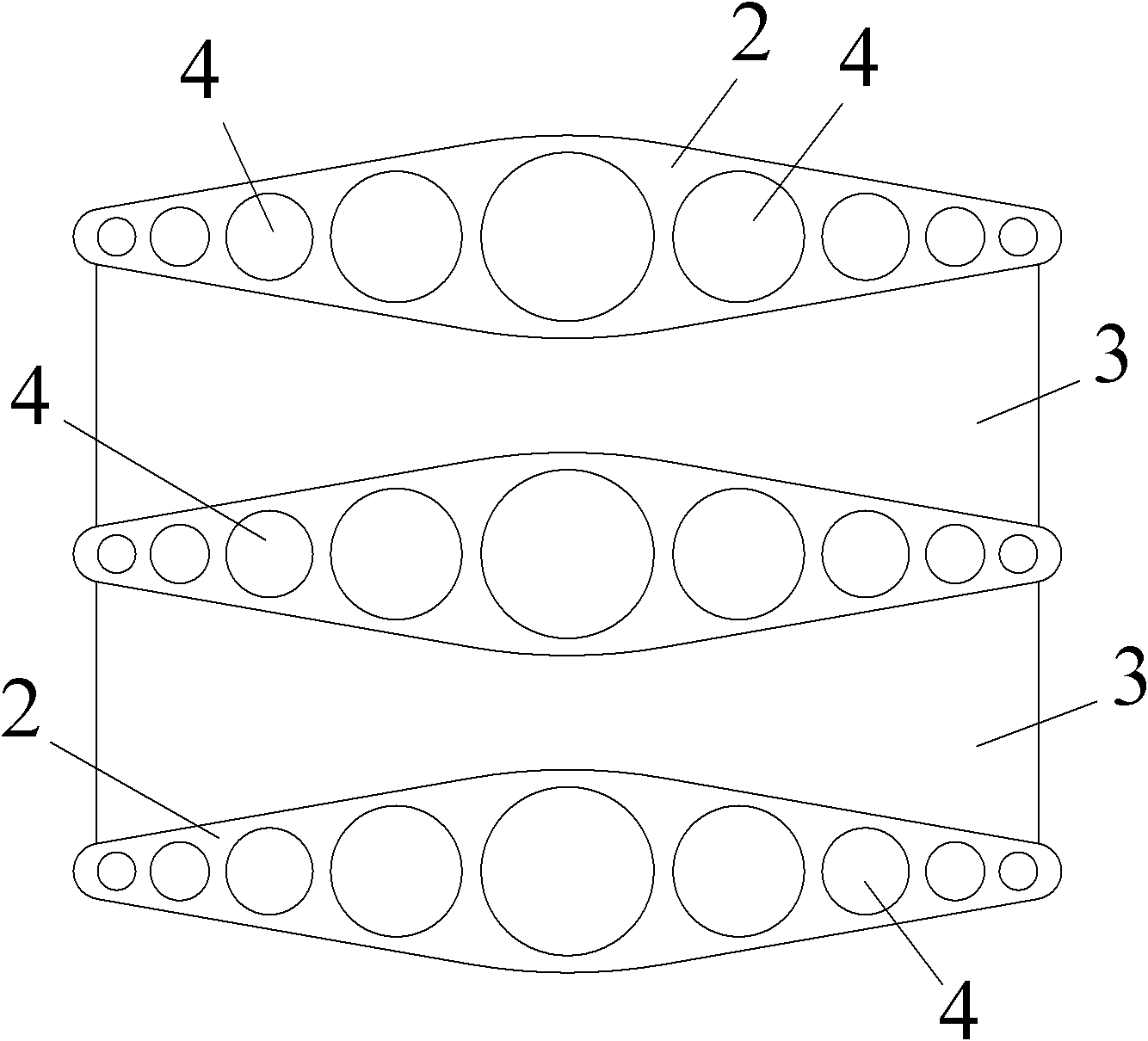

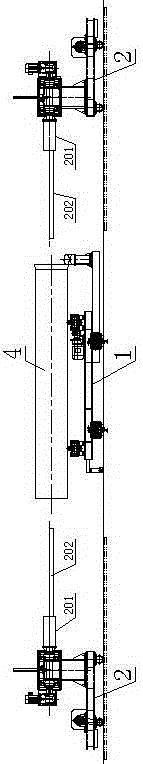

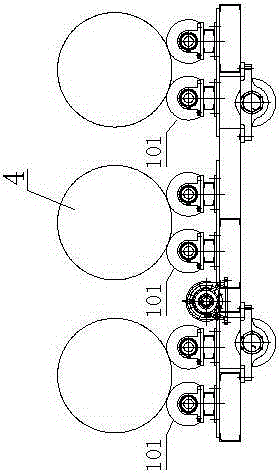

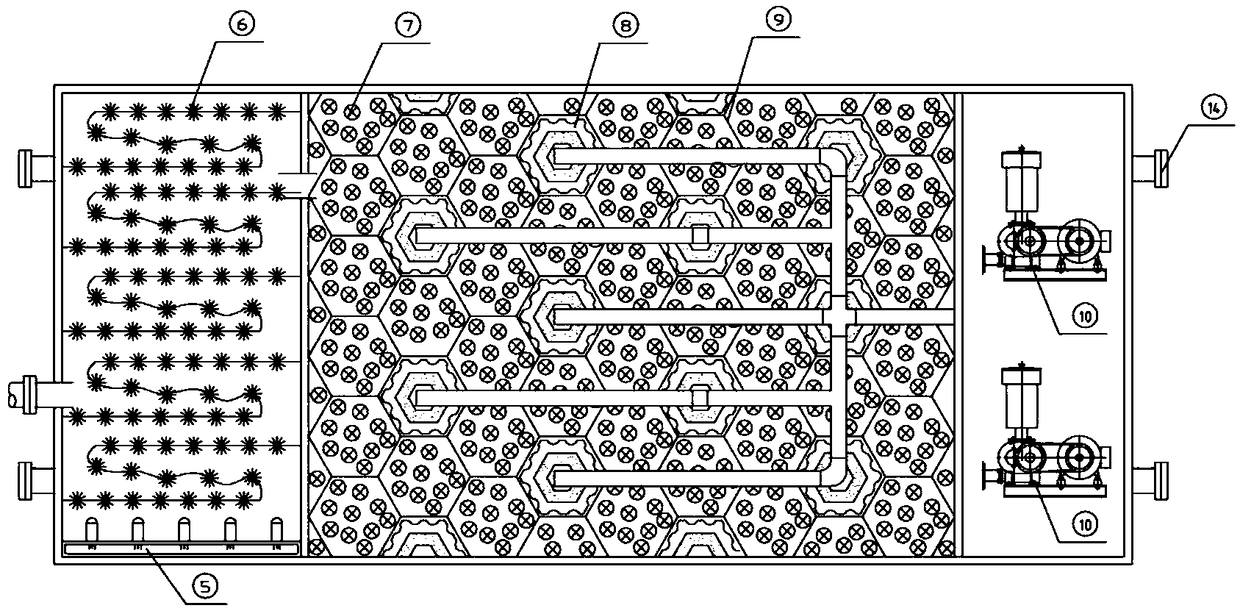

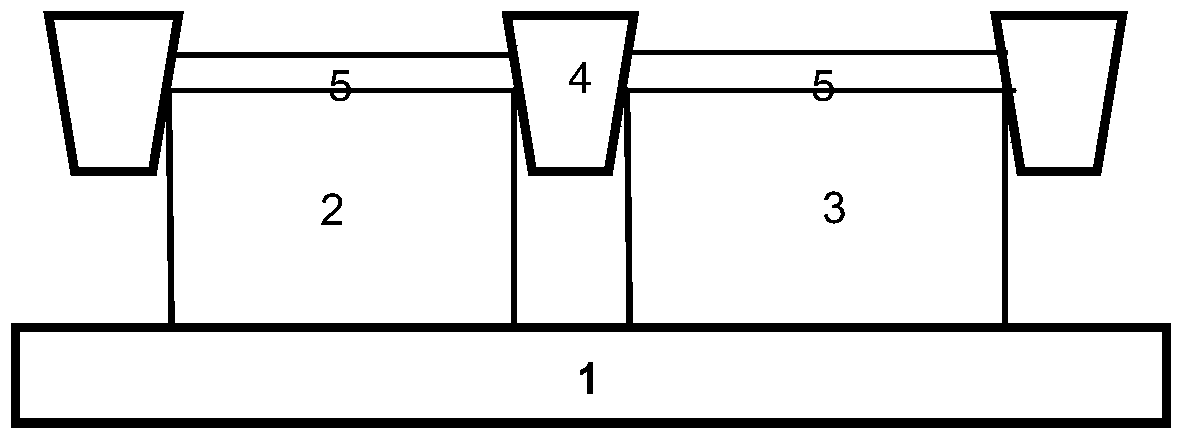

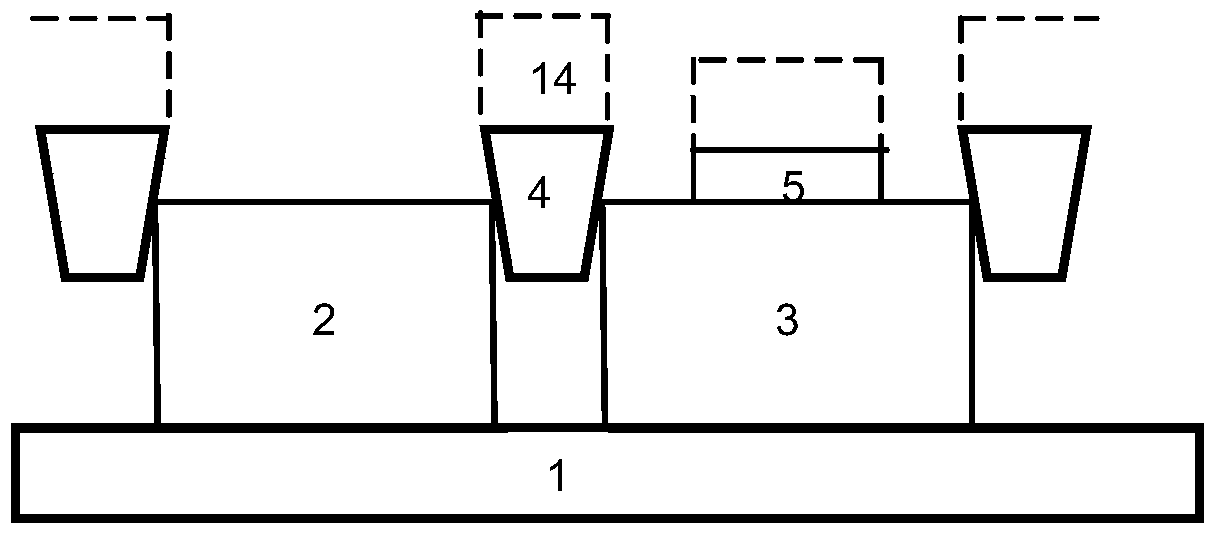

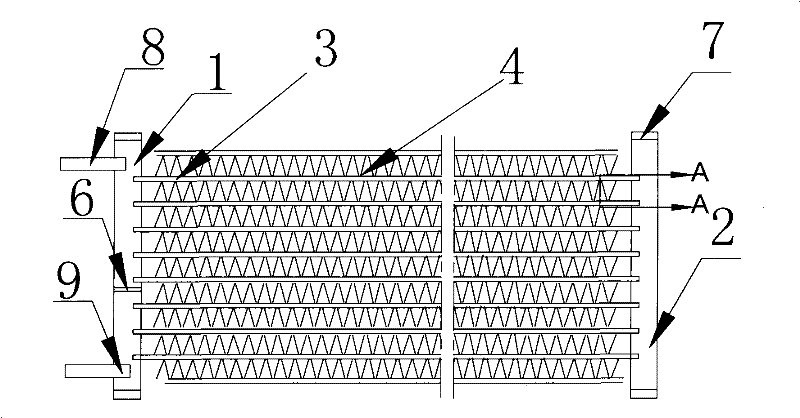

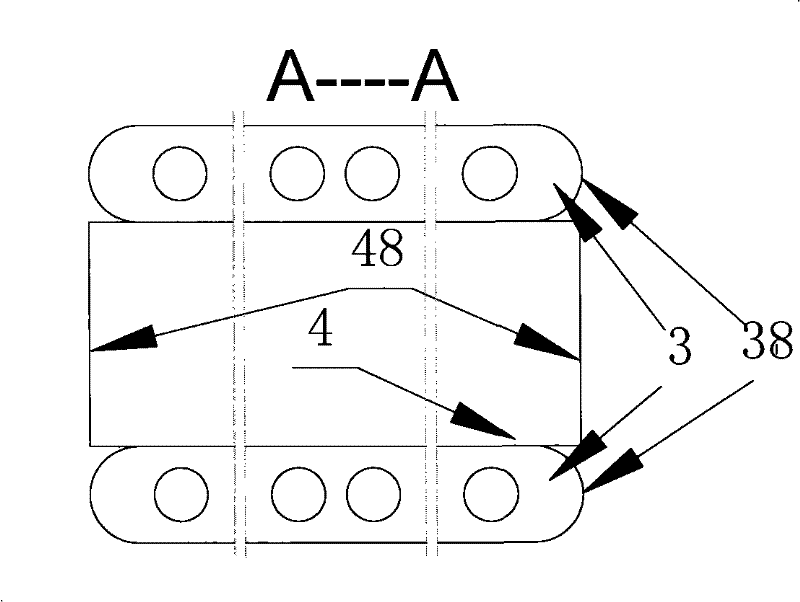

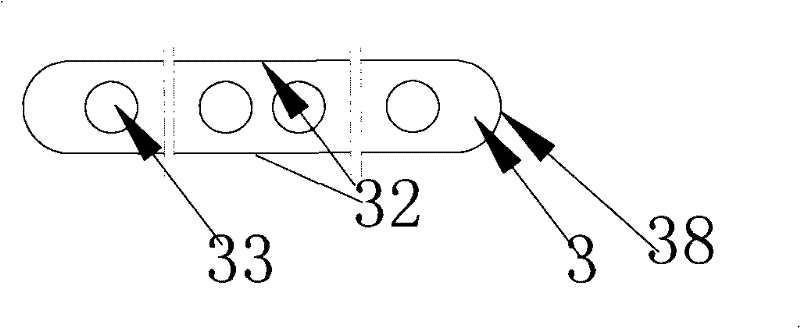

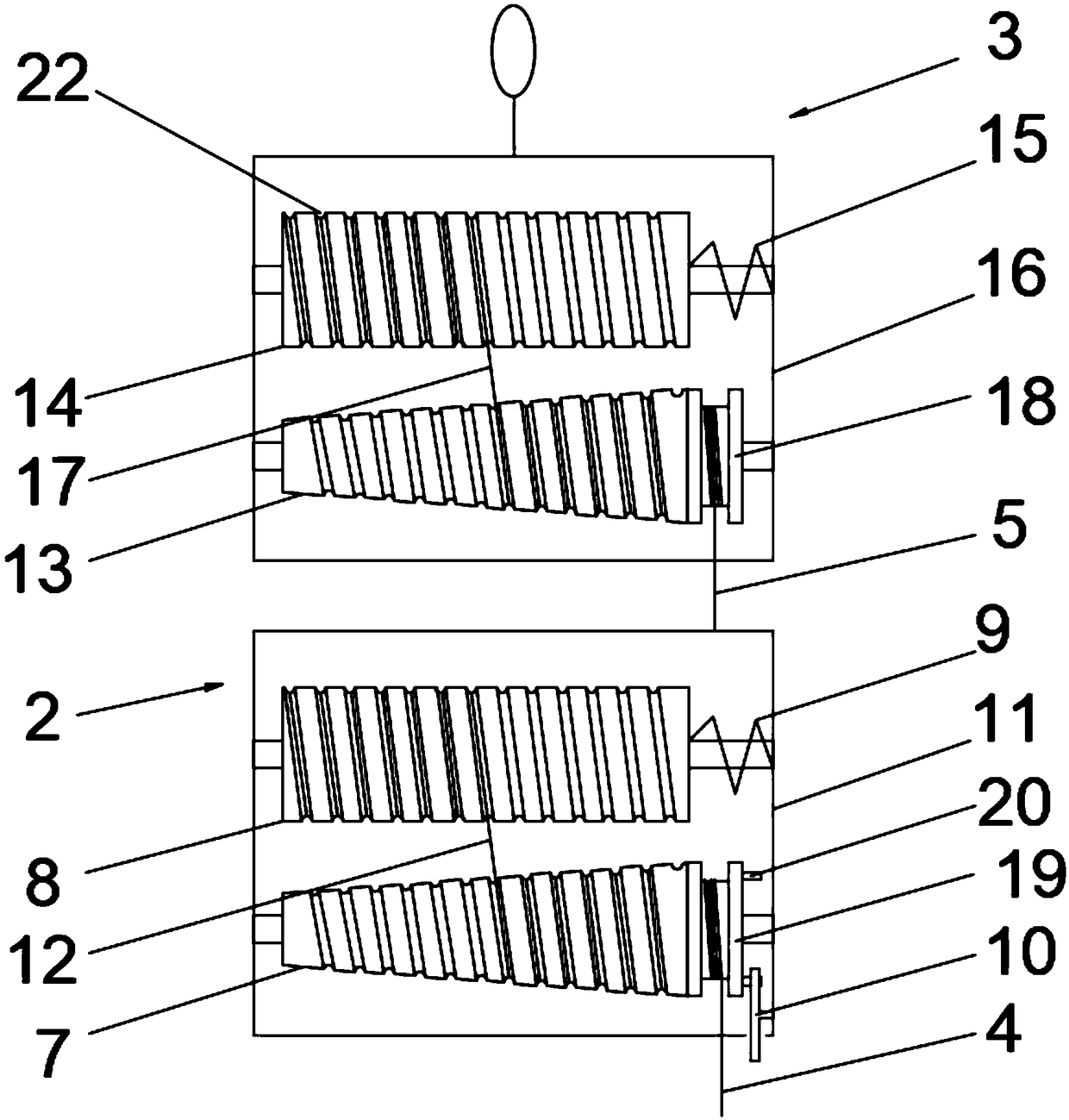

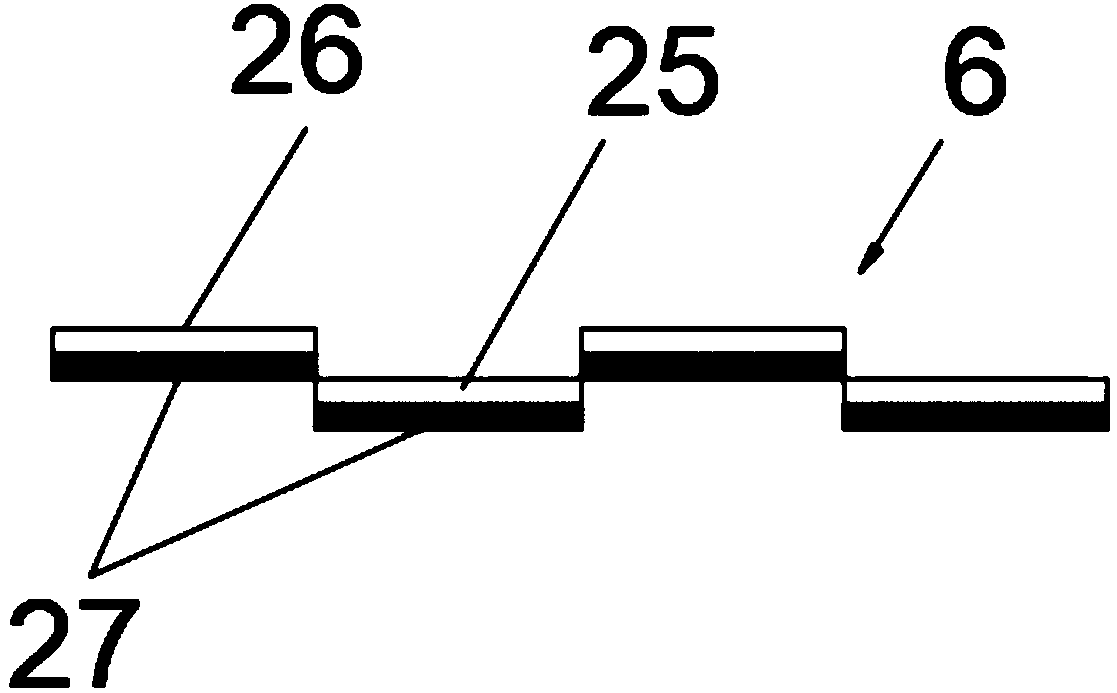

Flat pipe and fin structures of parallel flow heat exchanger

InactiveCN101929820AInhibit sheddingShedding does not causeEvaporators/condensersTubular elementsEngineeringMechanical engineering

The invention discloses flat pipe and fin structures of a parallel flow heat exchanger, which comprise a plurality of flat pipes inserted on header pipes on two ends of the heat exchanger, fins are arranged between adjacent flat pipes, and micro-channels on the flat pipes are communicated with the header pipes on the two ends of the heat exchanger; and longitudinal middle parts at two sides of each flat pipe protrude, and correspondingly each fin is of a structure in which the longitudinal middle parts at two sides are sunken, thus avoiding the fins moving transversely to result in falling-off. Preferably, the protruding parts of the longitudinal middle parts at the two sides of each flat pipe are subjected to smoothing transition, and correspondingly the sunken structure of the longitudinal middle parts at the two sides of each fin is also subjected to smoothing transition, thus facilitating processing and manufacturing of components. After assembly brazing is completed, the fins can remain stationary transversely, thus effectively avoiding the fin moving transversely to result in falling-off; and after long-term service, the fins do not drop even though welding spots between the fins and the flat pipes are corroded or cracked owing to vibration and the like, thus achieving relatively stable heat exchange efficiency of the heat exchanger, facilitating overall processing and manufacturing, and improving excellence rate of assembly processing of the heat exchanger.

Owner:浙江金宸三普换热器有限公司

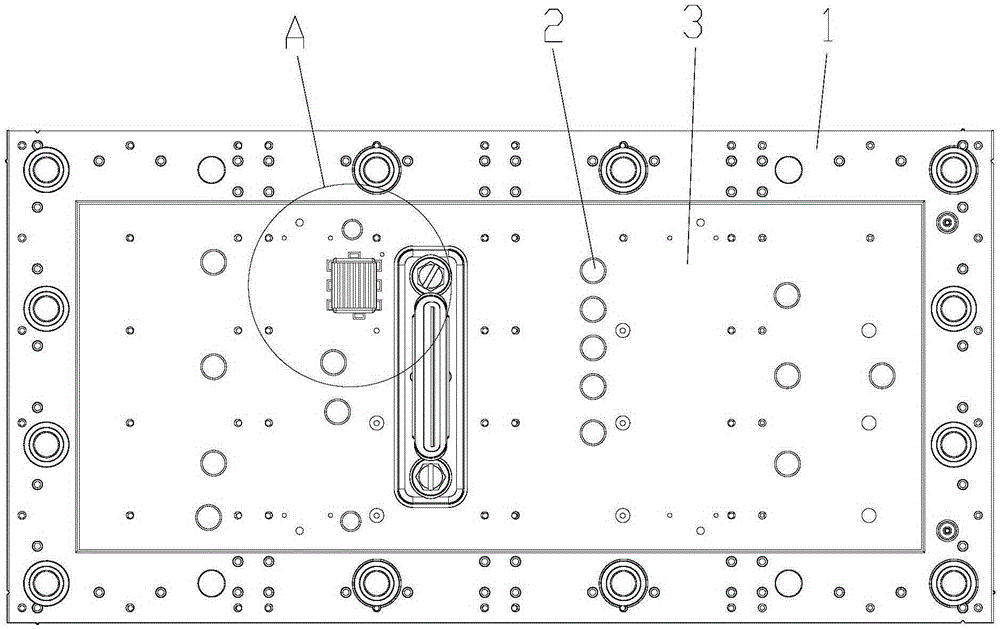

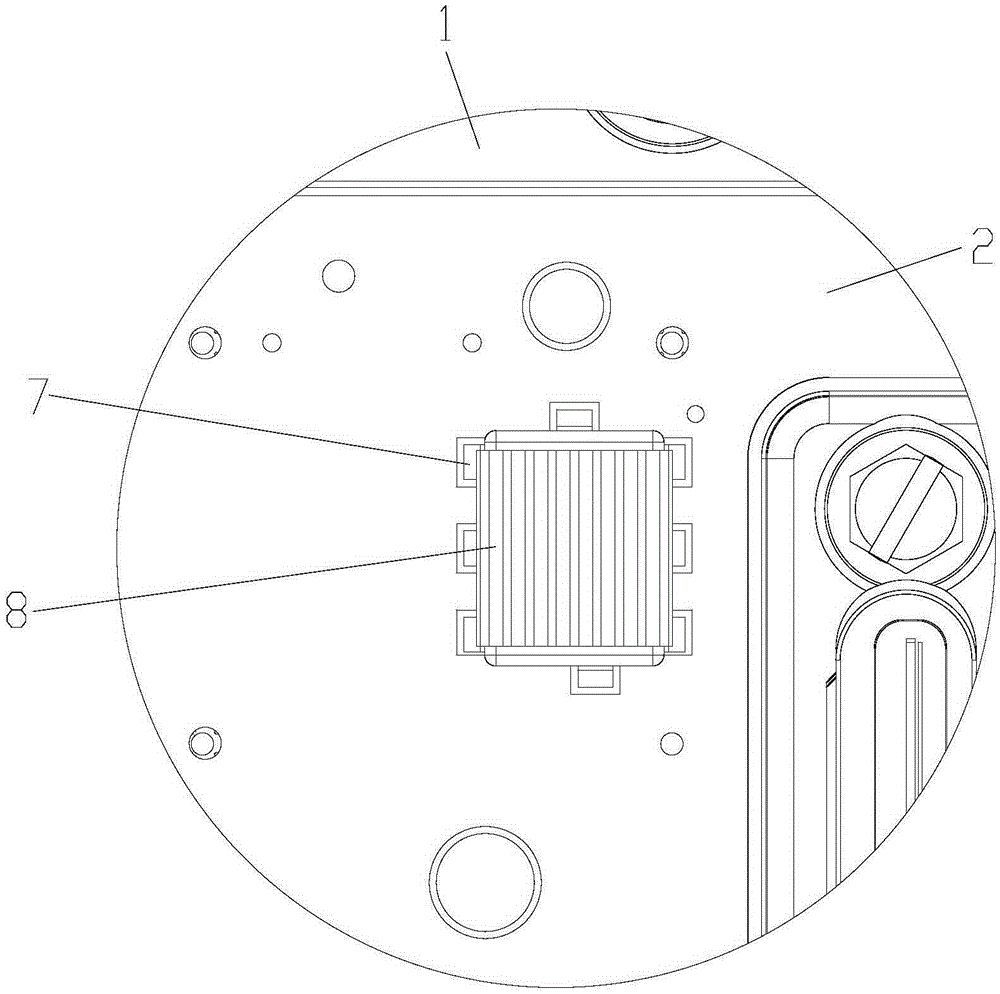

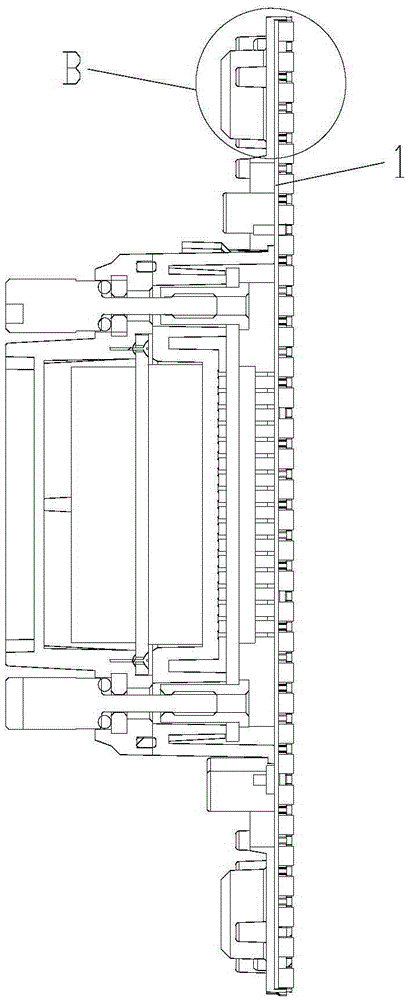

Double-face welding method preventing big chip from falling off

ActiveCN105357899AShedding does not causePrevent fallingPrinted circuit assemblingTemperature differenceEngineering

The invention discloses a double-face welding method preventing a big chip from falling off, belonging to the electronic member welding technology field. The double-face welding method comprises steps of (1) performing surface pre-processing, (2) welding a driving surface, (3) reinforcing a BGA chip, (4) welding a luminescence face, (5) welding a metal shielding housing, and (6) adhering a heat radiation sheet. The double-face welding method disclosed by the invention realizes reliable welding of double faces through welding temperature difference and can effectively prevent the BGA chip from falling off through reinforcing the BGA chip. The invention is good in the effect, and cannot cause BGA chip to fall off even that the shielding housing, the heat radiation sheets are added on the outside of the BGA chip.

Owner:NANJING LUOPU TECH CO LTD

Lining Process of Ductile Iron Pipe

ActiveCN103691625BWill not affect the formationNo shedding phenomenonLiquid surface applicatorsCoatingsPolyvinyl chlorideEngineering plastic

The invention discloses a lining coating technology for a spheroidal graphite cast iron tube. The lining coating technology is characterized by comprising the following steps of 1, polishing the inner wall of a blank tube, and performing shot blasting; 2, putting the treated tube on a riding wheel of lining coating equipment through a transferring tool, and switching on a variable-frequency motor connected with the riding wheel to drive the tube to rotate at the rotating speed of less than or equal to 50rpm; 3, switching on a heating fire gun arranged below the tube to preheat the outer wall of the tube, and controlling the temperature between 140 DEG C and 230 DEG C; 4, after preheating is finished, uniformly distributing polyvinyl chloride or polyethylene or ABS (acrylonitrile butadiene styrene) engineering plastic or polytetrafluoroethylene or polypropylene powdered substances on the inner wall of the tube through a material distribution trolley to form a lining layer, and then cooling the lining layer, wherein in the cooling process, the tube is continuously rotated until the tube is completely cooled. The problem of the influence, which is caused by a fact that the lining layer prepared by an existing lining coating technology for the spheroidal graphite cast iron tube is easy to fall off, on normal mounting, the use of metering equipment, the sanitation of water quality and the like is solved; the manufacturing cost of the lining layer is reduced.

Owner:广西安钢永通铸管管业有限公司

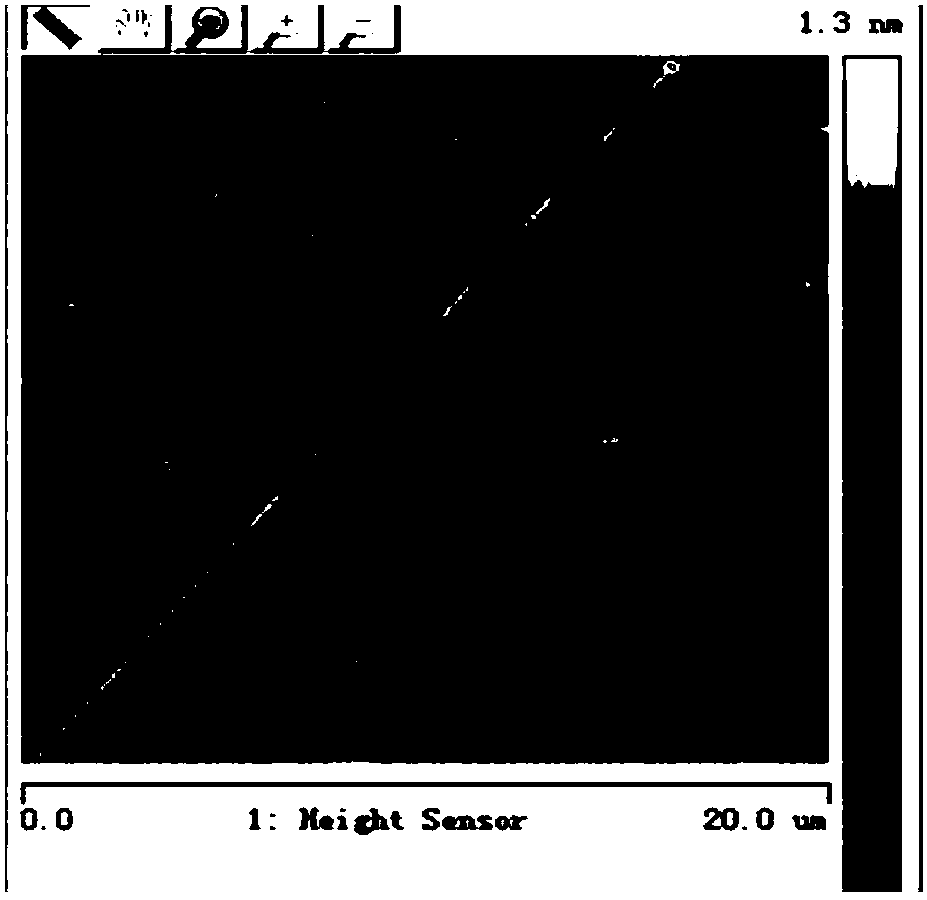

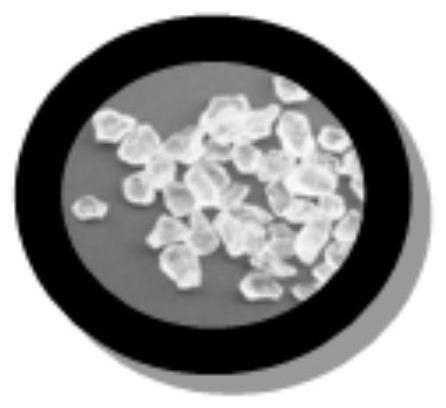

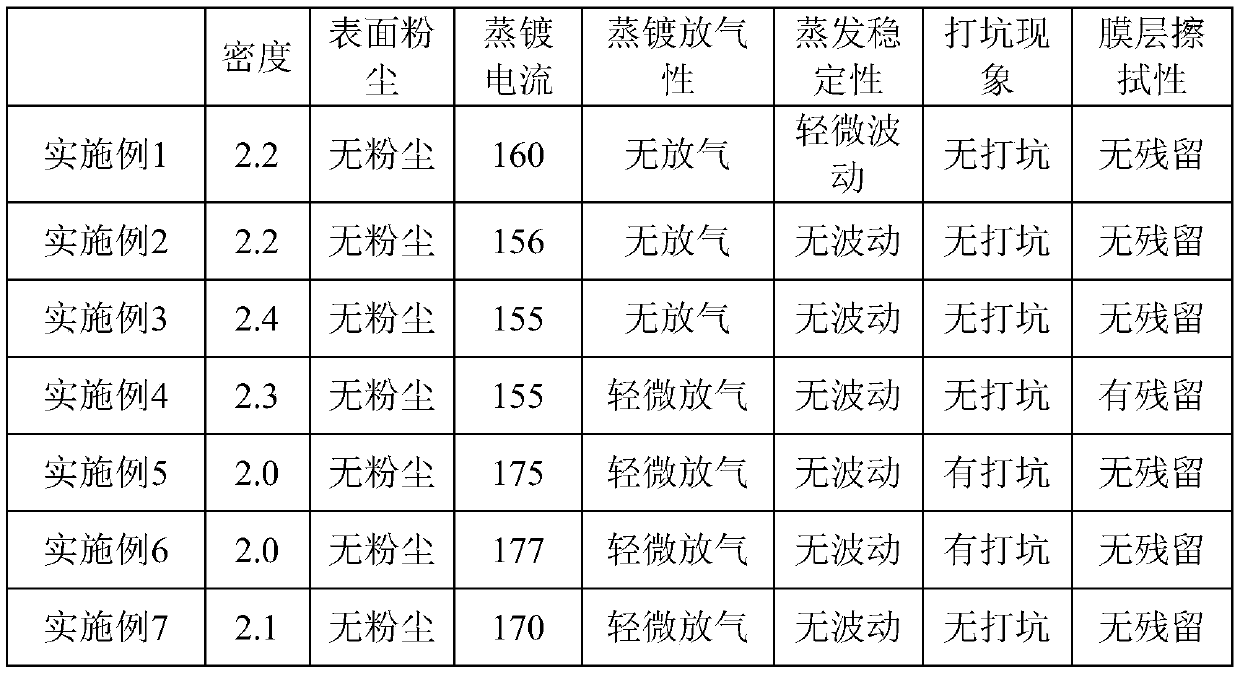

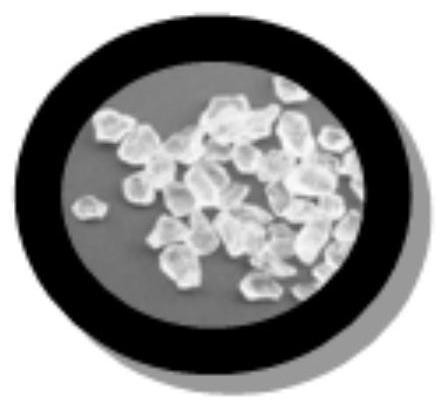

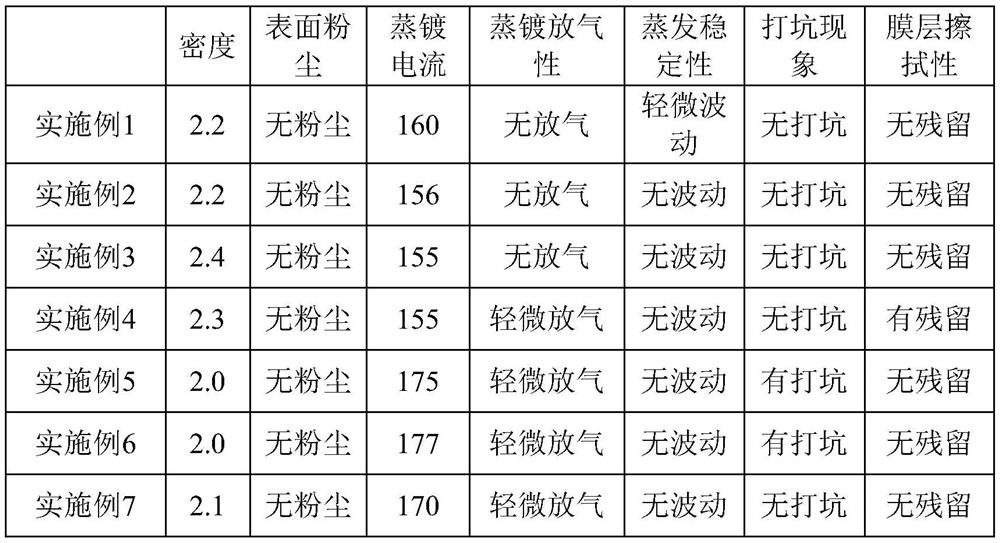

Preparing method of silica-glass-doped evaporation-coating material

ActiveCN110204200AHigh densityFocusGlass furnace apparatusVacuum evaporation coatingSpray GranulationCeramic sintering

The invention relates to the technical field of preparation of evaporation-coating materials, in particular to a preparing method of a silica-glass-doped evaporation-coating material. The preparing method of the silica-glass-doped evaporation-coating material comprises the steps of 1, preparation of ingredients; 2, spray granulation of a sizing agent; 3, tabletting forming; 4, preparation of a sintering body; 5, smashing and pulverizing; 6, founding and heap forming; 6, annealing treatment; 8, smashing into particles; 9, cleaning packaging. According to the preparing method, the steps of firstly, smashing the aluminum silicon ceramic sintering body, then firing and annealing the sintering body, and finally smashing the sintering body again are adopted, the density of the obtained aluminumsilicon glass evaporation-coating material is large, and sputtering phenomena cannot occur due to the light weight of the gun when the electronic gun bombards the evaporation-coating material; few pores exist, the air discharge amount in the coating process is reduced, and the quality of the coating layer is improved accordingly; the evaporation angle is consistent, the evaporation speed is uniform and stable, and focusing of the electronic gun is easy; dust falling is unlikely to occur to the coating material, and sputtering points cannot be generated in the coating process; meanwhile, the evaporation-coating material can be applied to plastic lenses in batch, so that the coating operabiity and the quality of the coating layer after coating are both greatly improved.

Owner:CHANGZHOU PROSRUN PHOTOELECTRIC TECH CO LTD

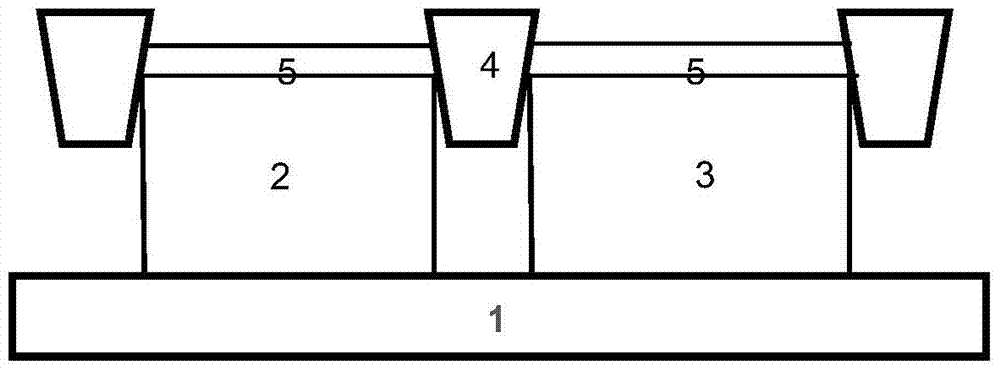

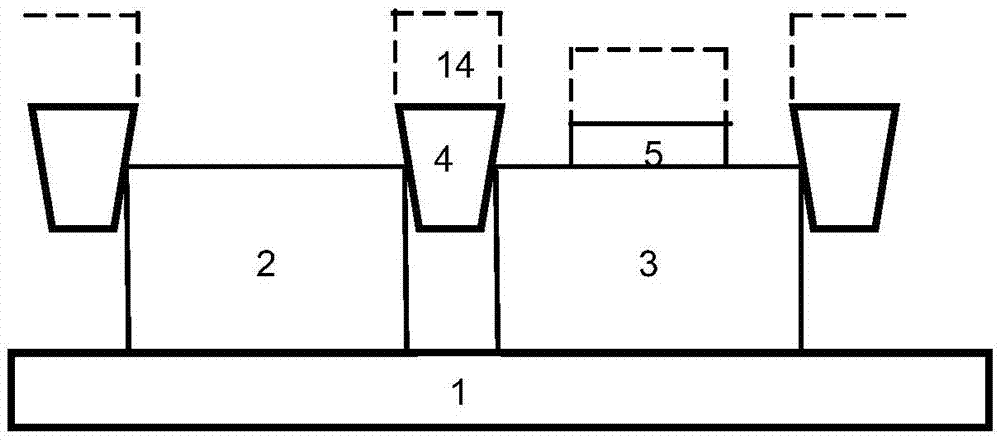

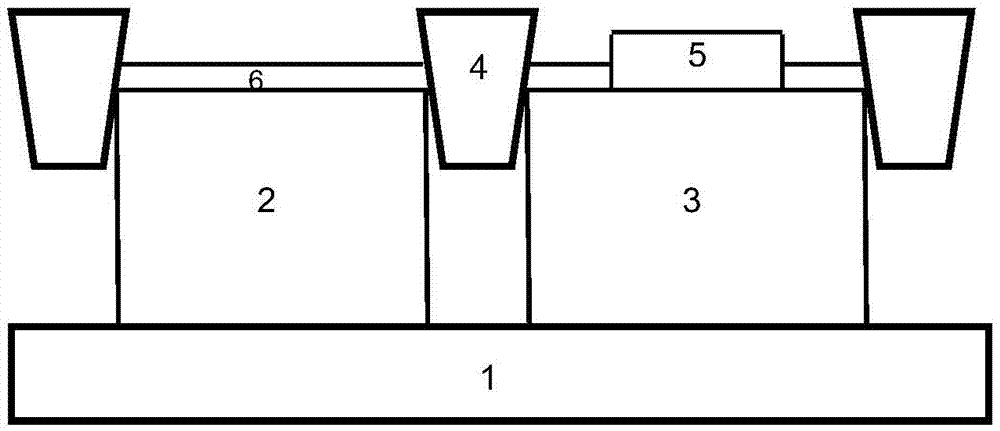

Semiconductor device, manufacturing method of the semiconductor device, and electronic device

ActiveCN106960817AReduce source-drain contact resistanceAvoid circuit failureTransistorSemiconductor/solid-state device manufacturingHigh pressureMetal silicide

The invention relates to a semiconductor device, a manufacturing method of the semiconductor device, and an electronic device. The manufacturing method of the semiconductor device includes the steps: S1, providing a semiconductor substrate which includes a high voltage device region and a low voltage device region, and forming a patterned high voltage gate oxide layer on the high voltage device region; S2, forming a low voltage gate oxide layer at two sides of the low voltage device region and the high voltage gate oxide layer; S3, forming a low voltage gate structure and clearance walls of the low voltage gate structure on the low voltage gate oxide layer, and forming a high voltage gate structure and clearance walls of the high voltage gate structure at the same time, wherein the sum of key sizes of the clearance walls and the high voltage gate structure in the high voltage device region is equal to the key size of the high voltage gate oxide layer; S4, forming a metal silicide barrier layer in the high voltage device region and the low voltage device region and patterning the metal silicide barrier layer; S5, removing the exposed low voltage gate oxide layer; and S6, forming self-aligning silicides on the regions and the high voltage gate structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

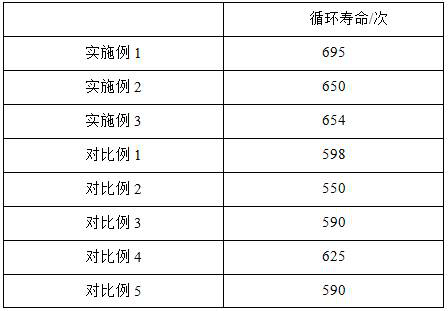

Preparation method of positive grid

ActiveCN112510213AHigh mechanical strengthImprove cycle lifeFinal product manufactureElectrode carriers/collectorsEngineeringCasting mold

The invention discloses a preparation method of a positive grid. The preparation method comprises the following steps: S1, preparing alloy liquid; S2, heating the grid gravity casting mold, and increasing the temperature of the lead conveying pipe to 540-580 DEG C; S3, after surface impurities are removed, spraying a release agent into a grid transverse rib cavity and a grid vertical rib cavity inthe grid gravity casting mold; S4, adding the alloy liquid into a lead spoon through a lead conveying pipe, heating the lead spoon to 540-580 DEG C, and injecting the alloy in the lead spoon into a grid gravity casting mold for casting; and S5, after the casting is finished, spraying atomized water to the obtained product for cooling, and cutting to obtain the positive grid. The positive grid provided by the invention has high mechanical strength, is beneficial to adhesion of active substances, improves the binding force with the active substances, and does not cause softening and falling ofthe active substances, so that the cycle life is remarkably prolonged.

Owner:广东奥克莱集团有限公司

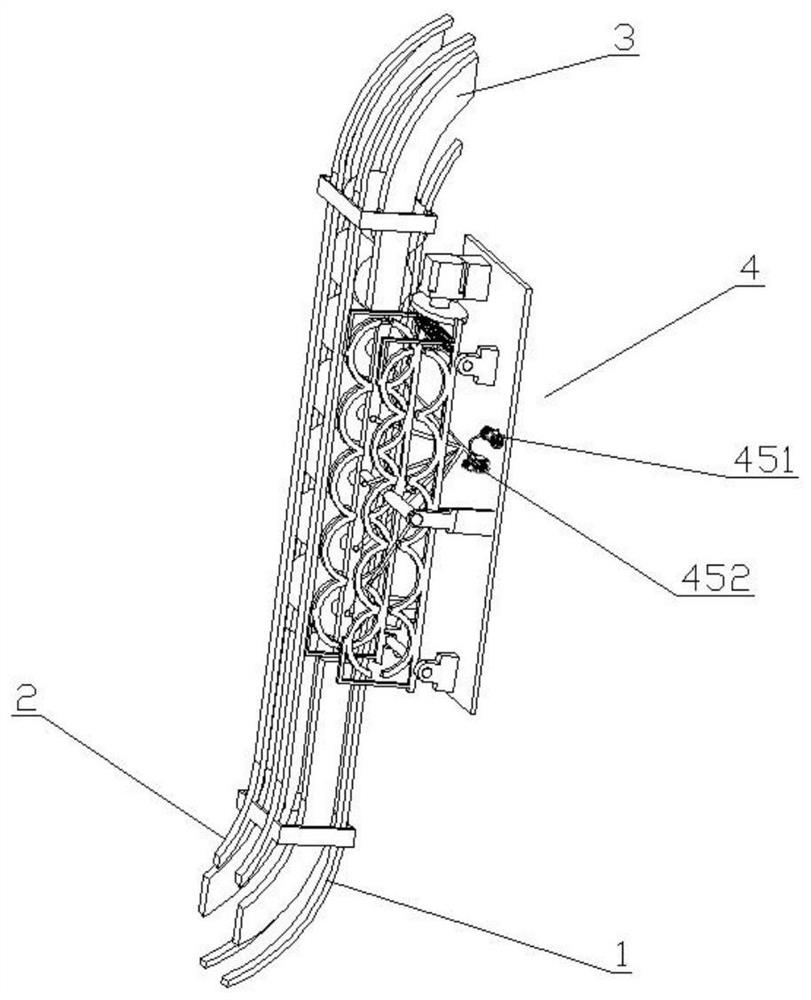

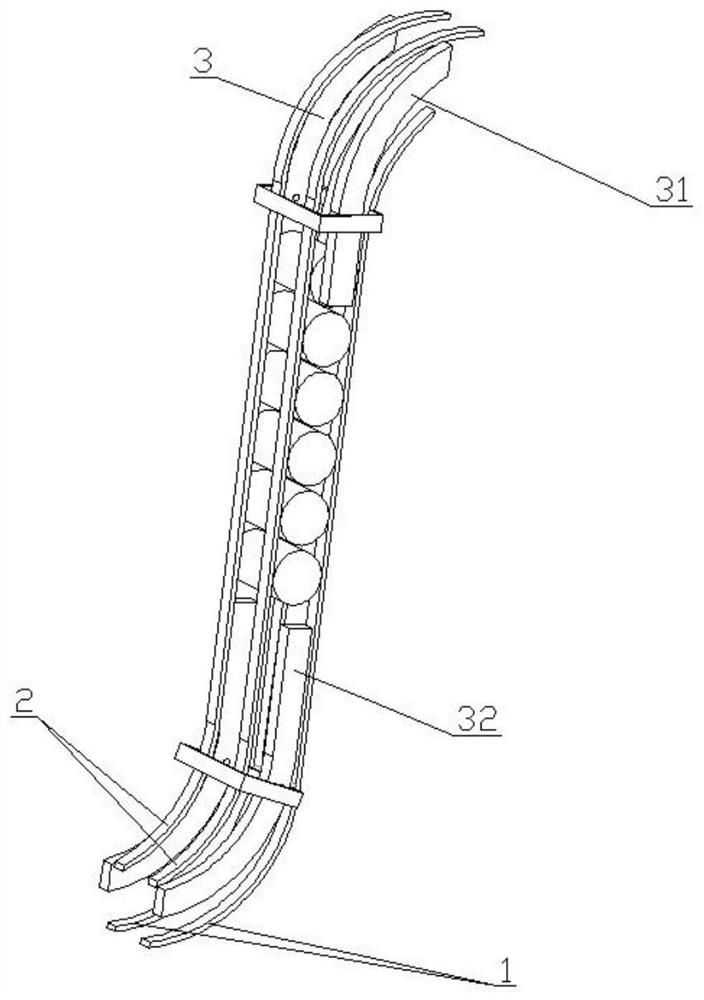

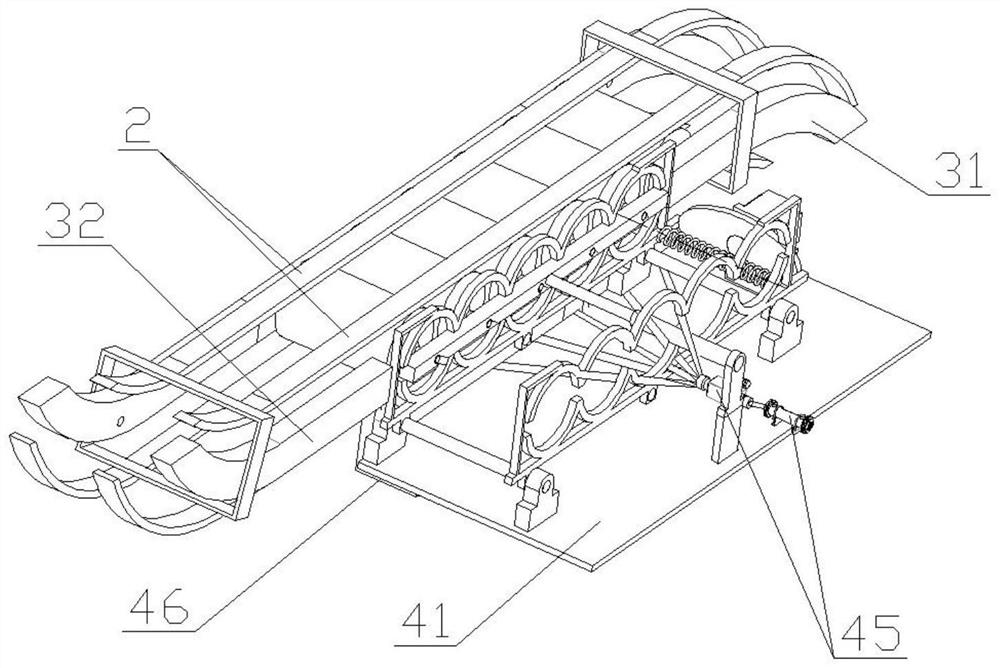

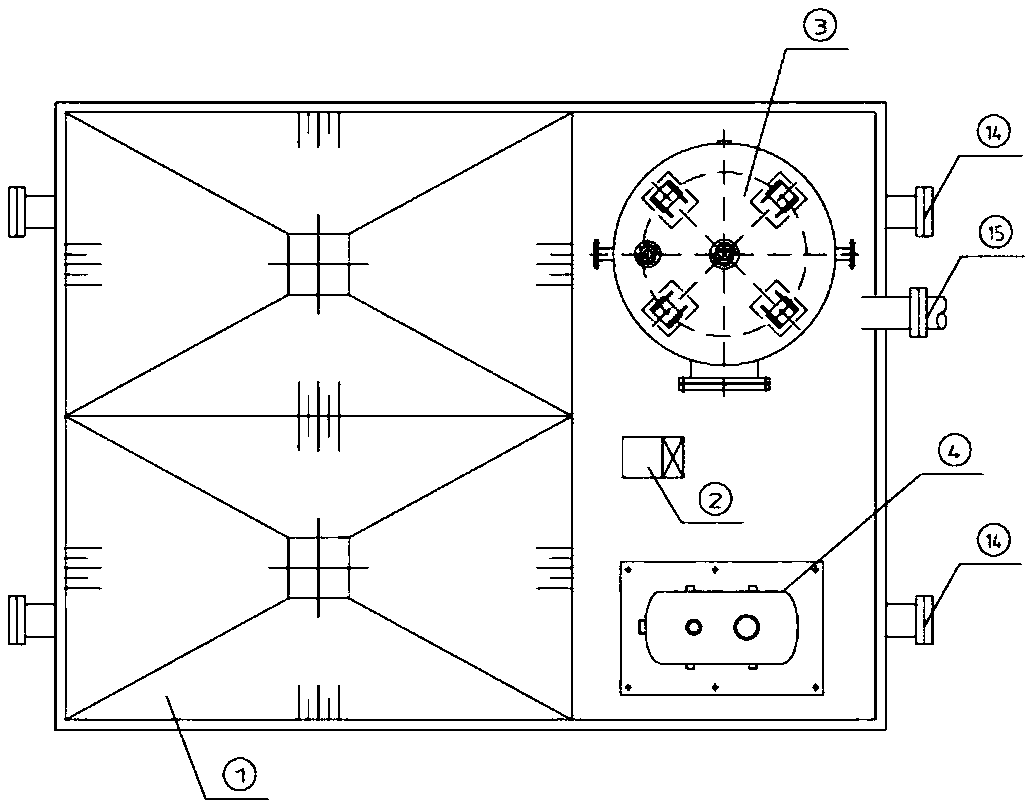

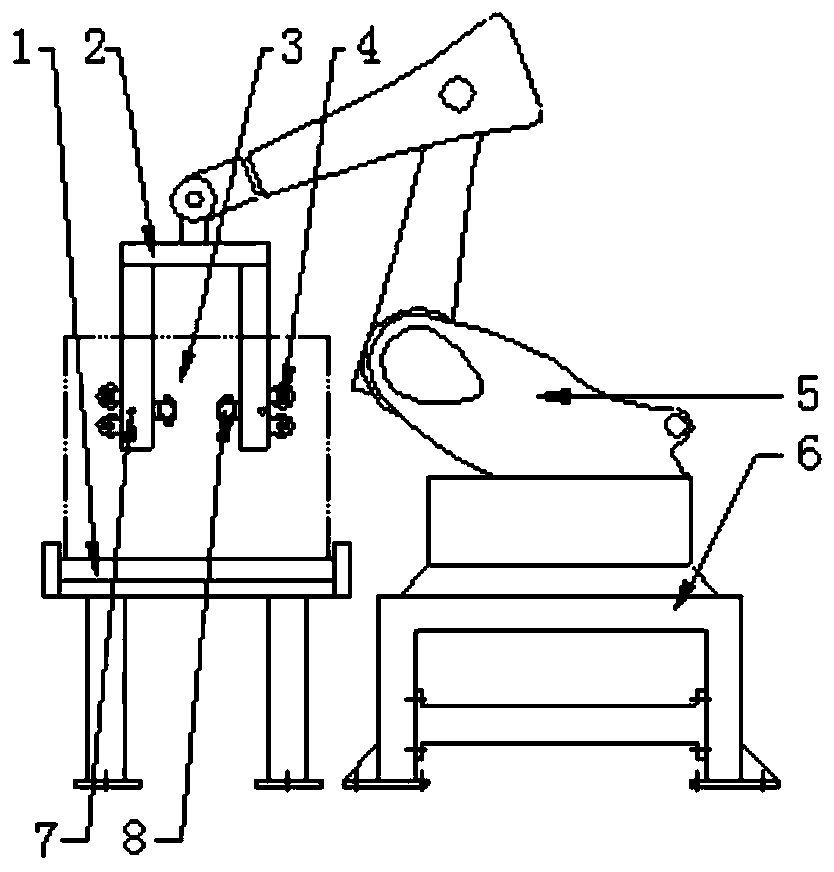

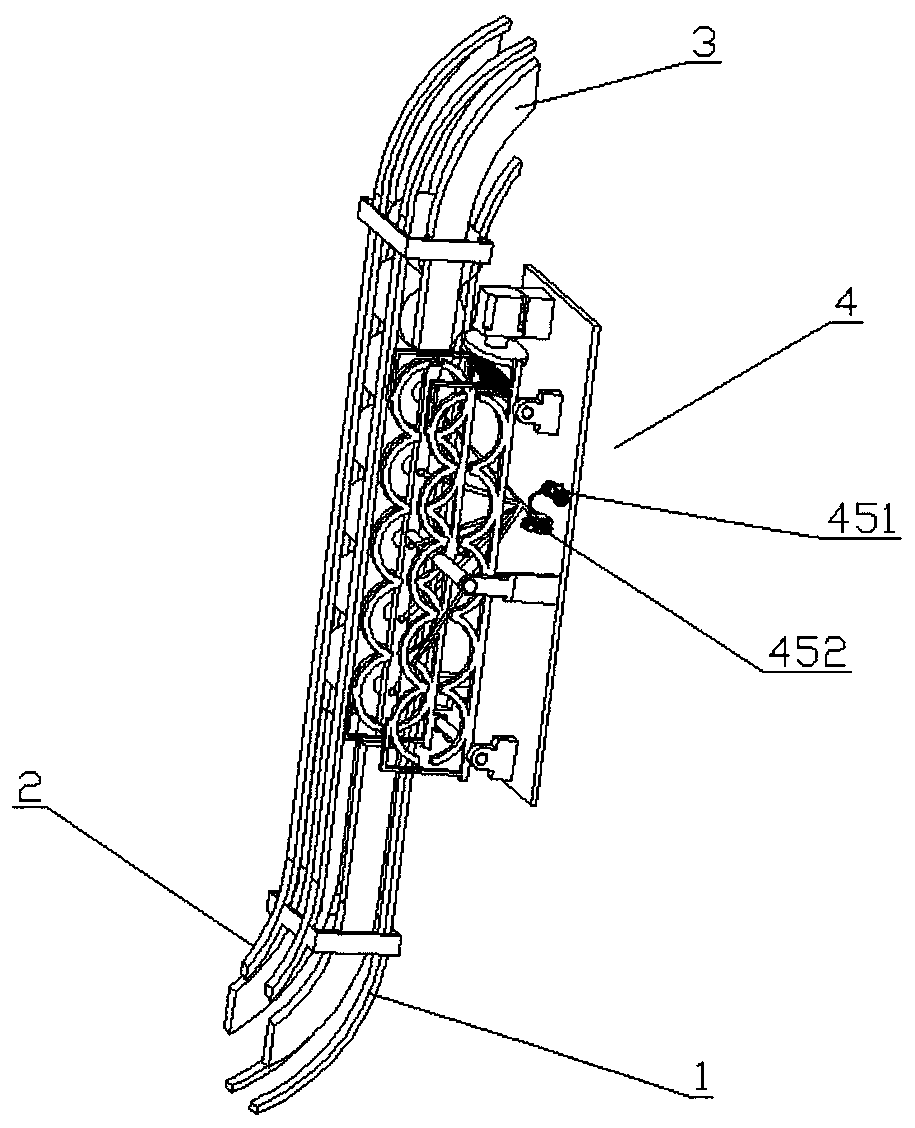

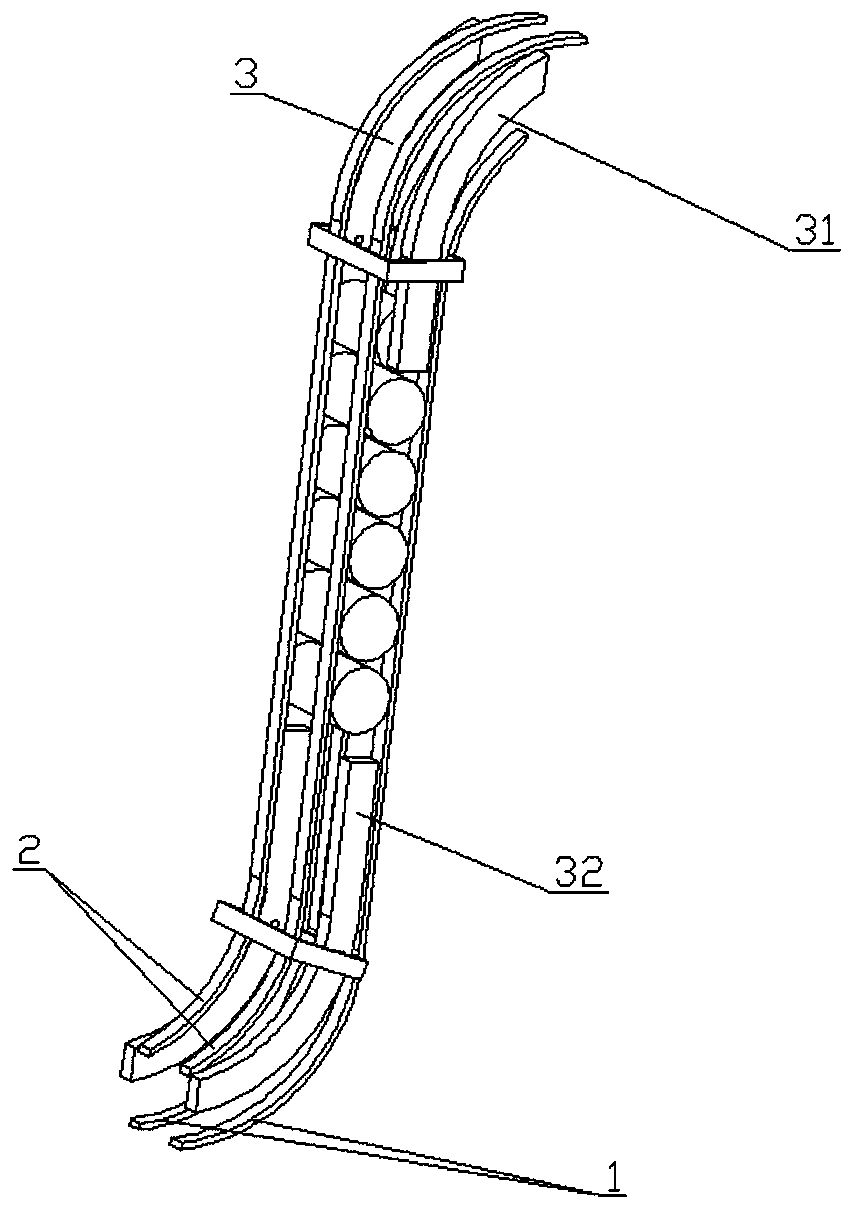

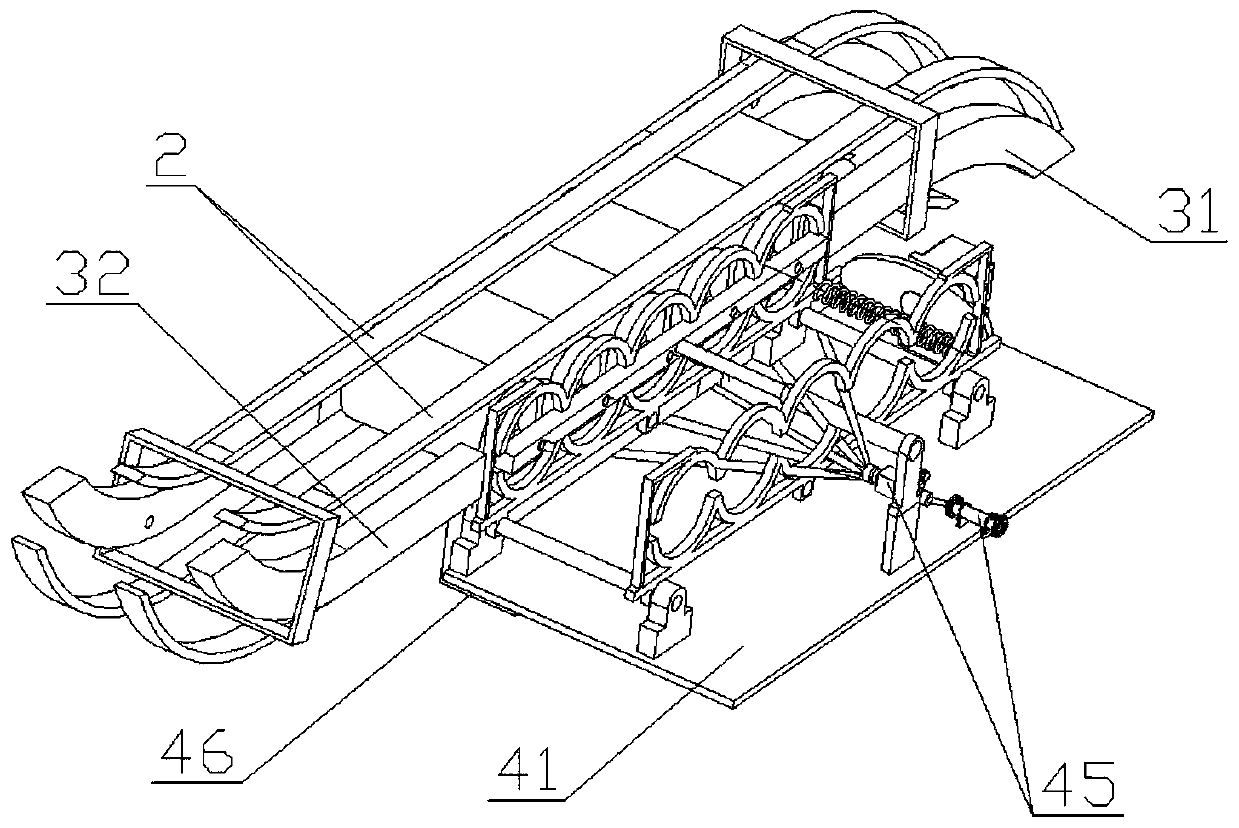

A rejection device applied to the slideway of a can stretching machine

ActiveCN111229913BInhibit sheddingControl sheddingStripping-off devicesHollow articlesMechanical engineeringEngineering

The invention provides a rejecting device applied to a slideway of a pop can stretching machine, belonging to the technical field of pop can production. The technical solution is: including slideway 1 and slideway 2 fixedly connected with slideway 1, a retaining bar is fixed between slideway 2 and slideway 1, and the retaining strips are arranged on both sides of slideway 1 and slideway 2. One side of the retaining bar includes an upper half and a lower half, an interval is provided between the upper half and the lower half, and a rejecting mechanism is provided at the interval, and the rejecting mechanism includes a bottom plate, a bracket one and a bracket two, and An opening and closing mechanism is arranged between the second and the support one, and the opening and closing mechanism drives the support two and the support one to move in the opposite direction, and a suction cup mechanism is also arranged on the bottom plate, and the suction cup mechanism translates the can to the support one and the support two. The beneficial effects of the present invention are: the present invention removes the unqualified pop cans on the slideway at the same time through the suction cup, the work efficiency is fast, and the pop cans will not collide with the subsequent pop cans when they are removed, effectively ensuring the quality of the subsequent pop cans.

Owner:济南联合制罐有限公司

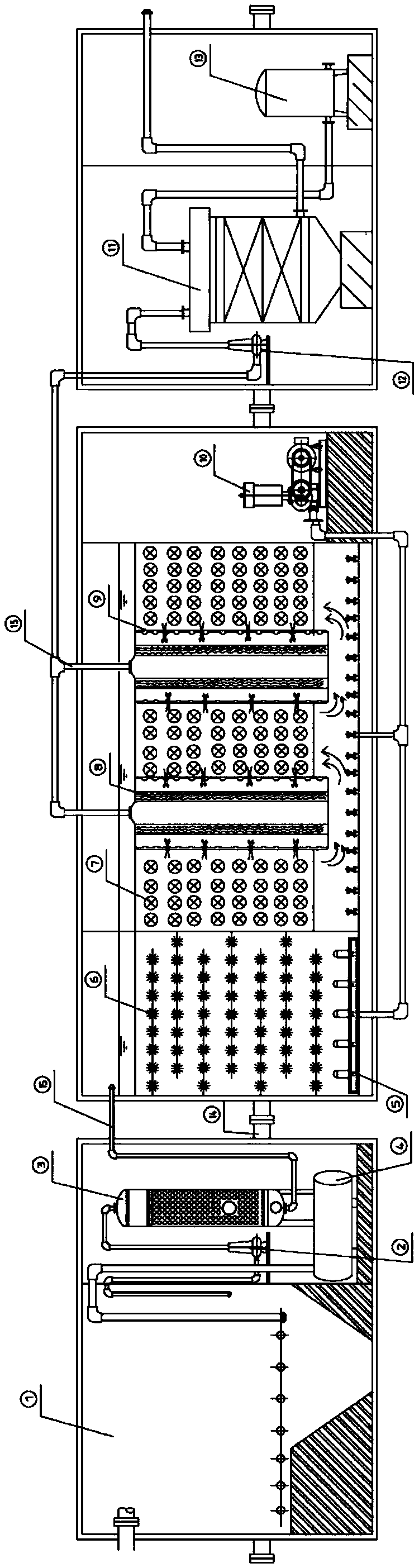

Zero-emission medical wastewater treatment equipment and method

PendingCN108706838ARemove CODEliminate ChromaSpecific water treatment objectivesTreatment involving filtrationActivated sludgeEnvironmental resistance

The invention relates to environmental-friendly special wastewater treatment equipment and in particular relates to zero-emission medical wastewater treatment equipment and method. The treatment equipment comprises a strong pretreatment mechanism, a biochemical mechanism and an advanced treatment mechanism connected in sequence, wherein the biochemical mechanism comprises a first treatment area and a second treatment area communicated with each other; a plurality of elastic packing layers are arranged in the first treatment area from top to bottom; each elastic packing layer is composed of a plurality of elastic packing chains; each elastic packing chain is formed by connecting a plurality of pieces of elastic packing in sequence; at least one bend is arranged on the elastic packing chain;and impellers are arranged at the bottom and side faces of the first treatment area. Compared with the prior art, the environmental-friendly special wastewater treatment equipment disclosed by the invention has the advantages that the packing is wholly stacked and sways along an S-shaped curve, the packing is orderly slowly impelled in a circular curve in the process, problems of violent wire fracture, drop and the like are solved, the sludge can be uniformly stirred and dispersed, biogas can be effectively dispersed, and rapid reproduction growth of novel activated sludge is promoted.

Owner:上海亚威环保科技有限公司

Large-diameter high-speed cutting and high-speed heavy load grinding resin wheel

InactiveCN101695827BLow wear resistanceReduced service lifeAbrasion apparatusGrinding devicesFilling materialsWear resistance

The invention discloses a large-diameter high-speed cutting and high-speed heavy load grinding resin wheel prepared from the following three components in percentage by weight: 60-72 percent of grinding materials, 18-25 percent of filling materials and 8-18 percent of resin, wherein the grinding materials in the wheel are film-coating calcined brown fused alumina, the filling materials comprise aheat conducting material and an active filling material, and the resin comprises a phenolic resin liquid and phenolic resin powder. The sand is produced by adopting the film-coating calcined brown fused alumina, which has good heat conduction property of metal plating, obviously strengthens the heat radiating effect of the wheel and prolongs the abrasive resistance and the service life of the wheel. In addition, the grinding materials have improved ball-milling flexibility after calcined, which enables the wheel to be durable and the property to be better. The wheel can be used for cutting hot-wire type steel with a diameter of over 100 mm or grinding the steel in a high-speed and heavy load way, and has long service life reaching 100-120min.

Owner:SAINT-GOBAIN ABRASIVES (SHANGHAI) CO LTD +2

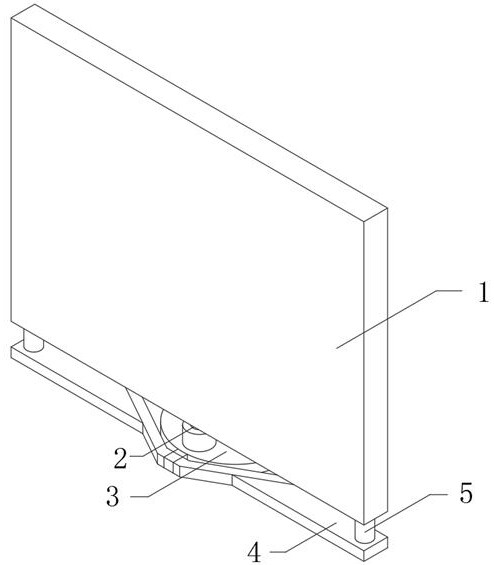

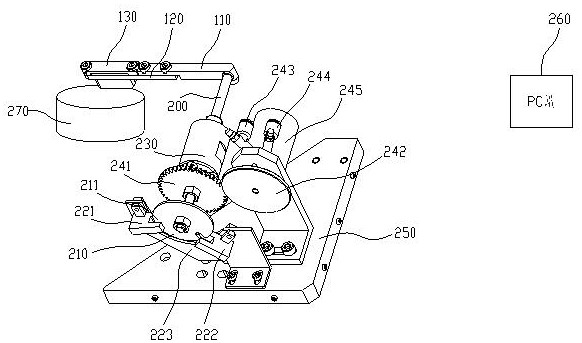

Industrial display screen connecting wire winding mechanism

InactiveCN112198932AAnti-sheddingShedding does not causeDigital data processing detailsMechanical engineeringElectrical and Electronics engineering

The invention discloses an industrial display screen connecting wire winding mechanism which comprises a display screen body, a fixing block is fixedly arranged on one side of the display screen body,a first rotating disc is rotatably arranged on one side of the fixing block, a second rotating disc is rotatably arranged on one side of the first rotating disc through a rotating shaft, and a connecting rod is hinged to one side of the outer wall of the first rotating disc. According to the connecting wire winding mechanism of the industrial display screen, through fixing of the second rotary disc, the connecting wire is fixed to the outer side of the rotary shaft, and the handle is rotated, so that redundant connecting wires are wound tightly; the connecting rod is clamped into the clampinggroove of the fixing ring on the outer wall of the second rotary disc to prevent the connecting line from falling off, the connecting line of the display screen is stably placed, the end of the connecting line is stably connected with the display screen body, falling off is avoided, and files are prevented from being lost.

Owner:西安德创自动化工程有限公司

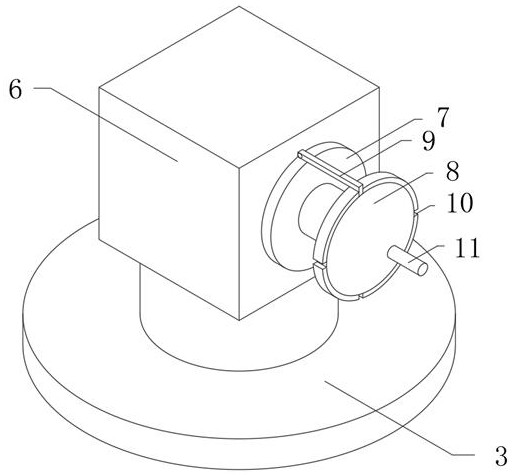

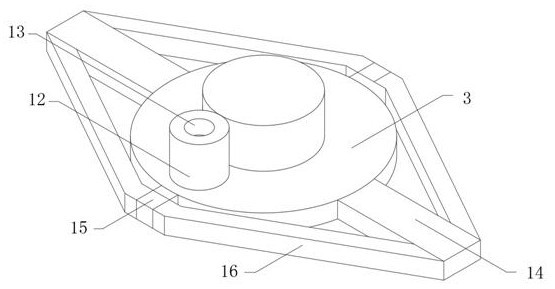

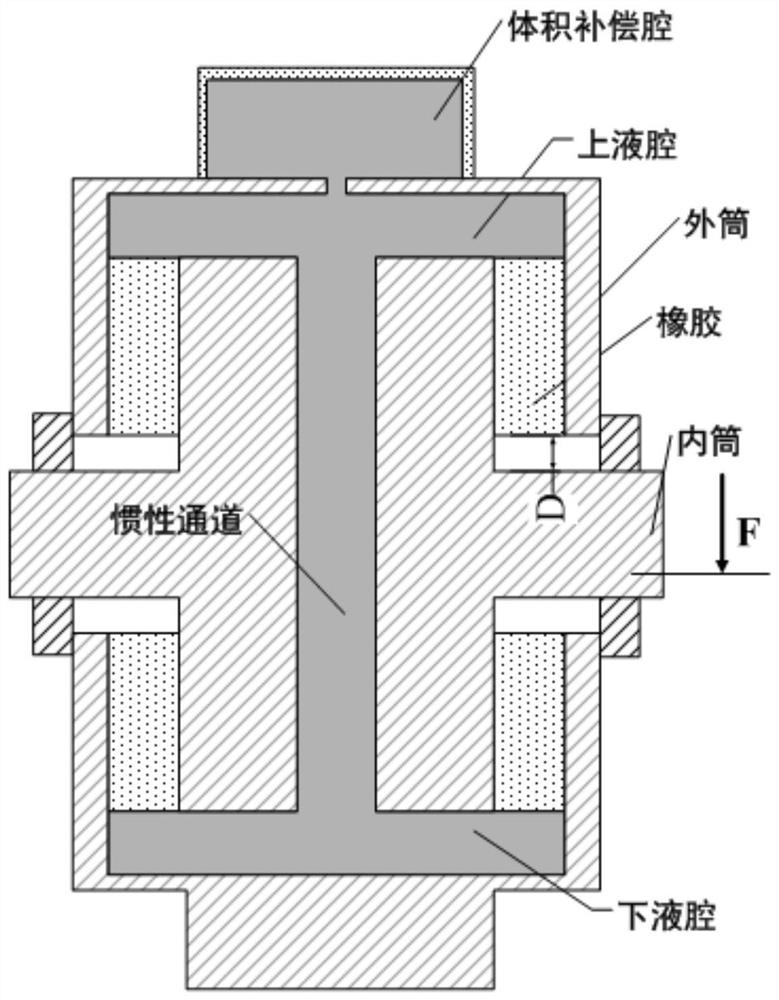

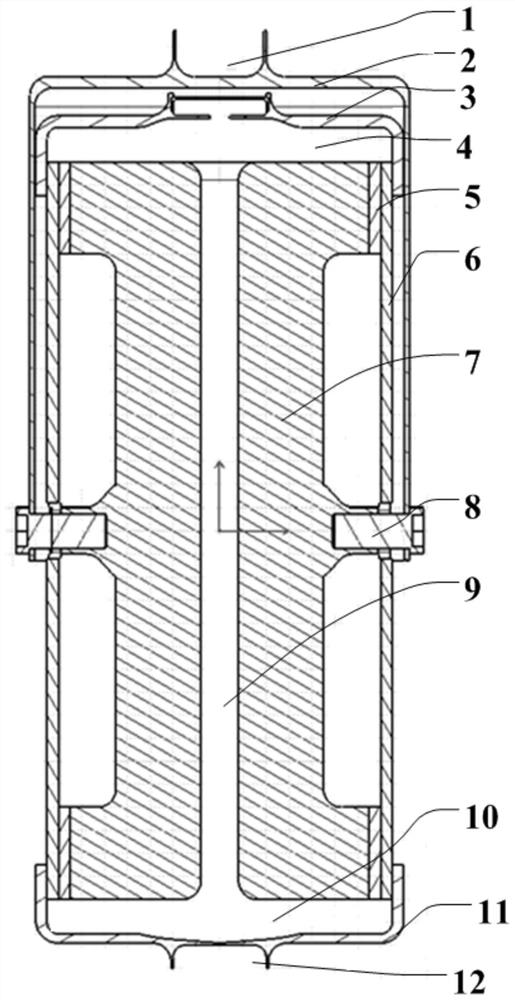

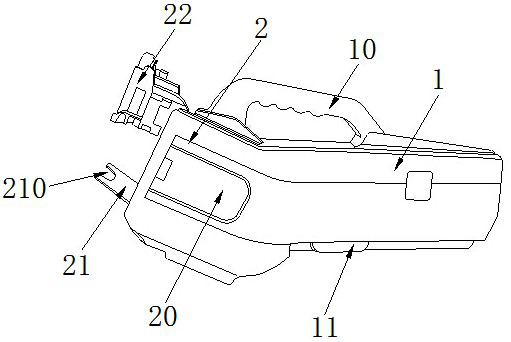

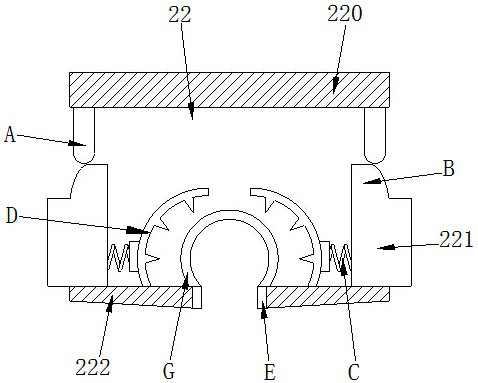

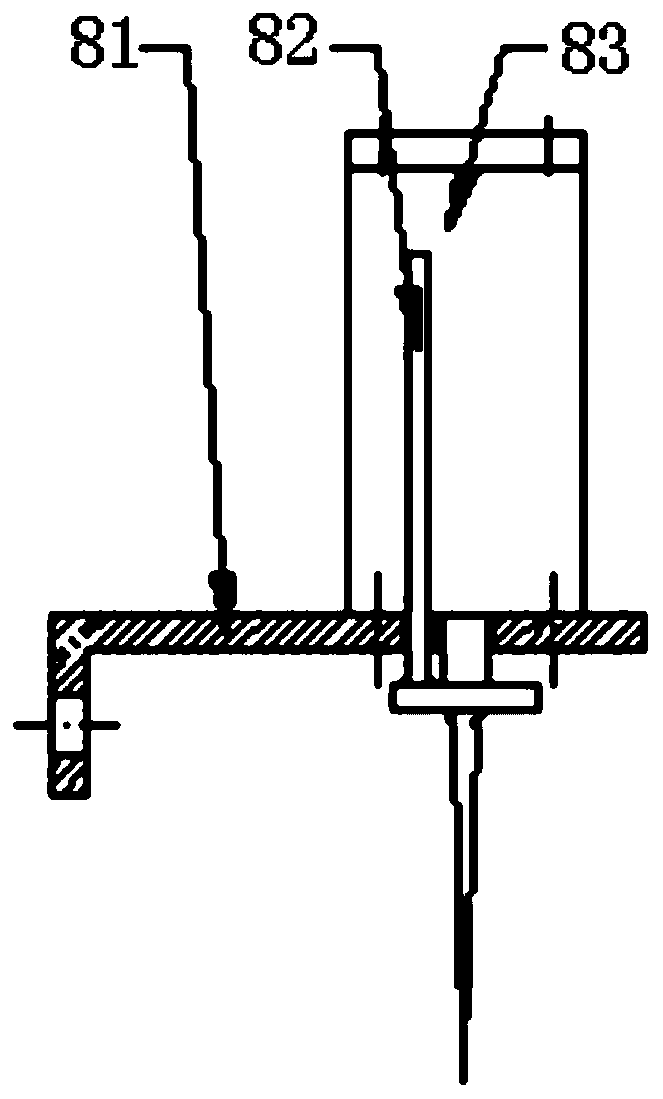

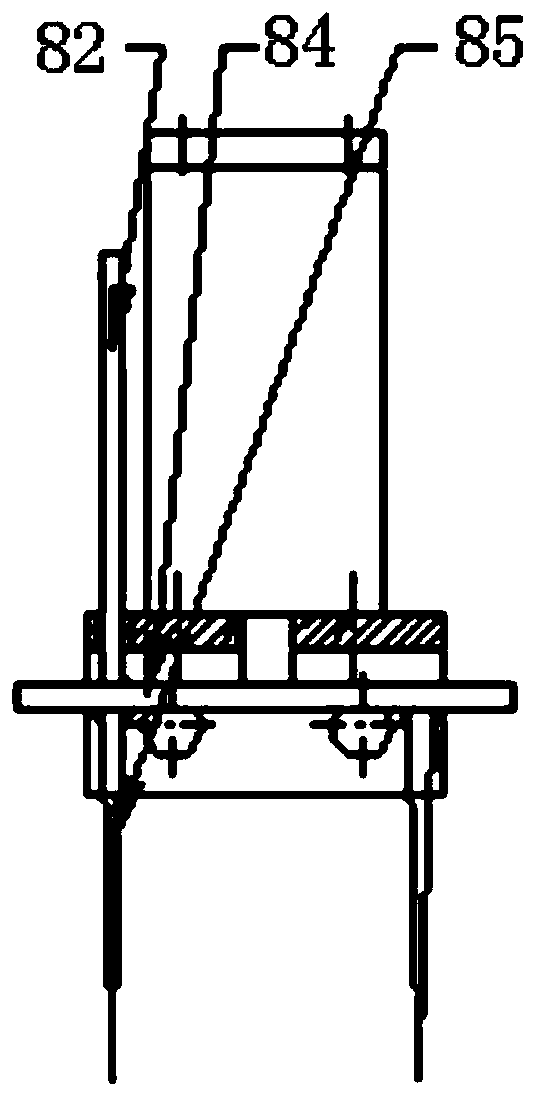

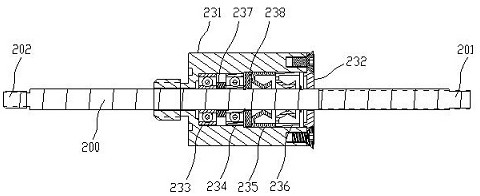

Liquid elastic vibration isolator with embedded inner cylinder

InactiveCN112178111APlay a bearing roleEnsure safetySpringsShock absorbersVibration controlVulcanization

The invention belongs to the technical field of helicopter vibration control, and discloses a liquid elastic vibration isolator with an embedded inner cylinder. The liquid elastic vibration isolator comprises an outer cover 3, an upper outer cylinder cover 4, rubber 6, an outer cylinder 7, the inner cylinder 8, a connecting bolt 9 and a lower outer cylinder cover 12, wherein the inner cylinder 8 is connected with the outer cover 3 through the connecting bolt 9; and the connecting bolt 9 penetrates through the outer cover 3 and the inner cylinder 8 when the outer cover 3 and the inner cylinder8 are connected, an up-down movement gap with a preset distance is formed between the outer cylinder 7 and the connecting bolt 9, and the inner cylinder 8 and the outer cylinder 7 are vulcanized together through the rubber 6. The liquid elastic vibration isolator with the embedded inner cylinder can isolate dynamic loads transmitted by a helicopter rotor wing, and a force bearing structure does not fail after the rubber fails.

Owner:CHINA HELICOPTER RES & DEV INST

A kind of bagging device for young fruit

ActiveCN110521468BEasy squeezeNot easy to dropPlant protective coveringsTabletingMechanical engineering

The invention discloses a bagging device for young fruit. Its structure includes a body and a machine head. The body is provided with a handle and a bagging box. The beneficial effect is that the extruder can be pushed through the cover plate, so that the bead on the pinch plate presses the buckle ring, so that the buckle ring forms a zigzag ring-shaped buckle head, and drives the bag to be buckled on the branch on the apple to cover the apple , because of the zigzag structure formed by the bead, the bag can be firmly held on the apple, so that the bag will not fall easily. At the same time, when the bag is disassembled, the bag can be disassembled by gently pulling the bag. tools, so that the apples will not fall off when the bag is disassembled, and it will not be difficult to disassemble. It can improve the work efficiency of unpacking while ensuring the safety and appearance of the apples.

Owner:安徽荣光农业科技有限公司

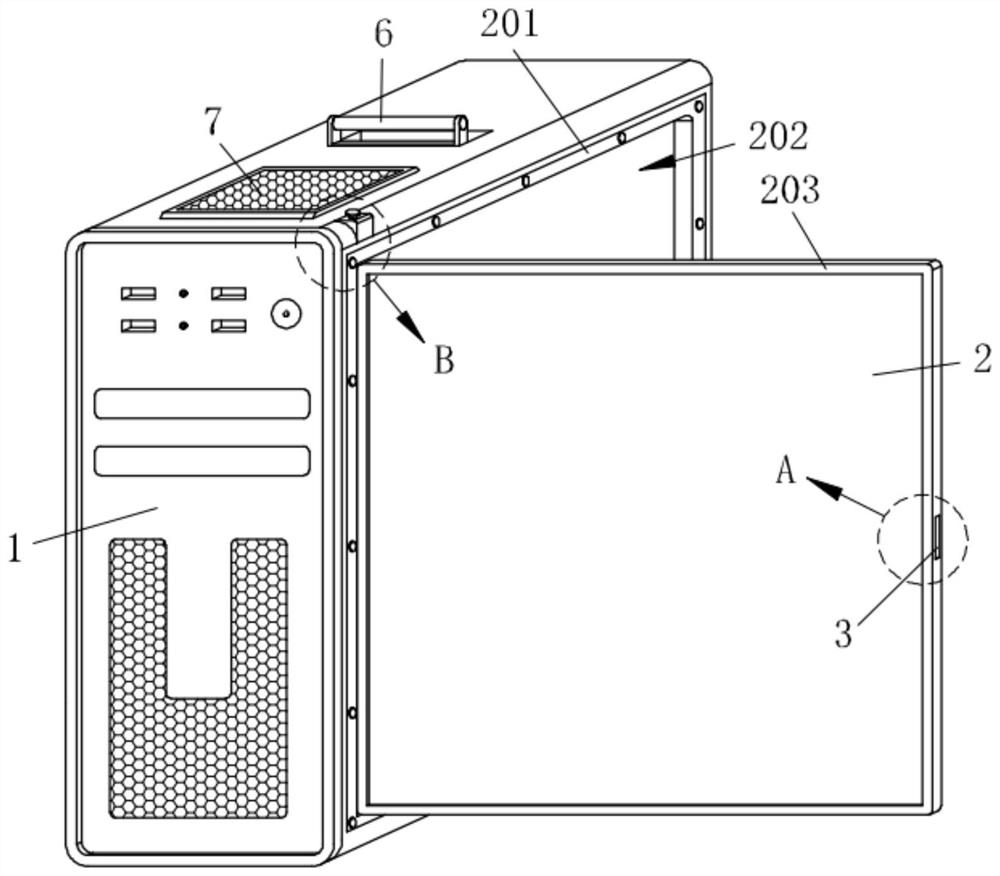

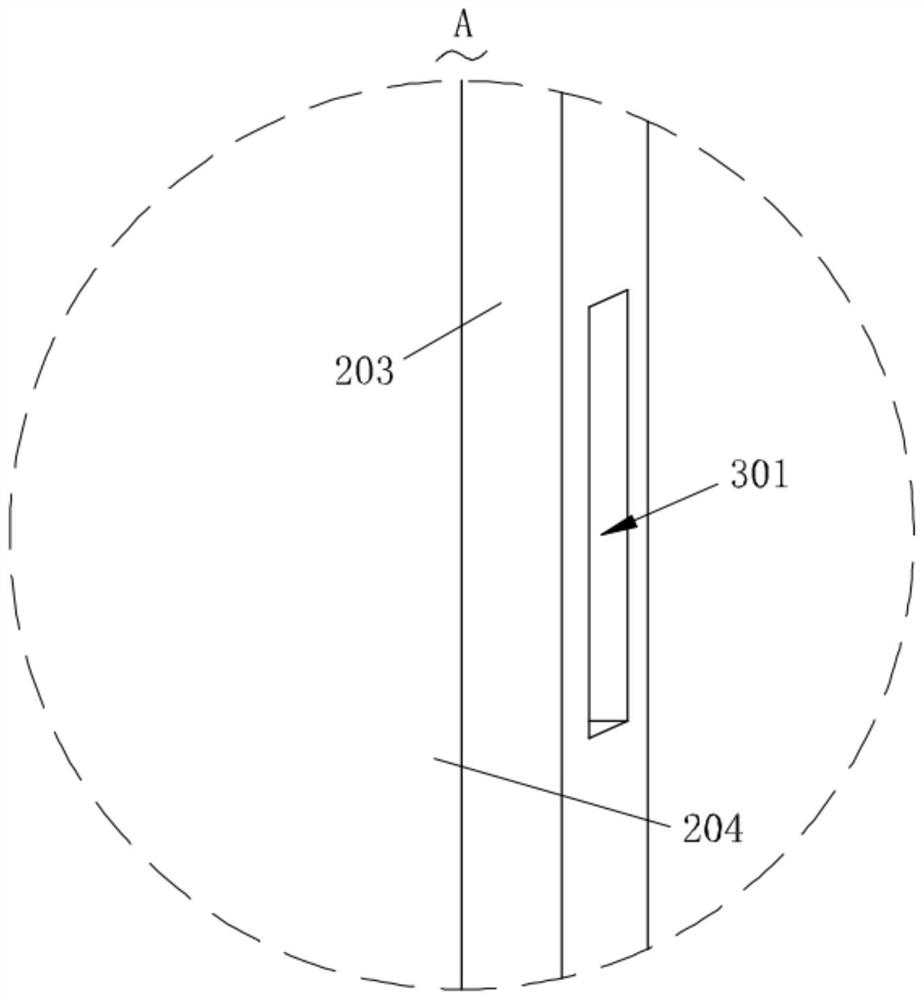

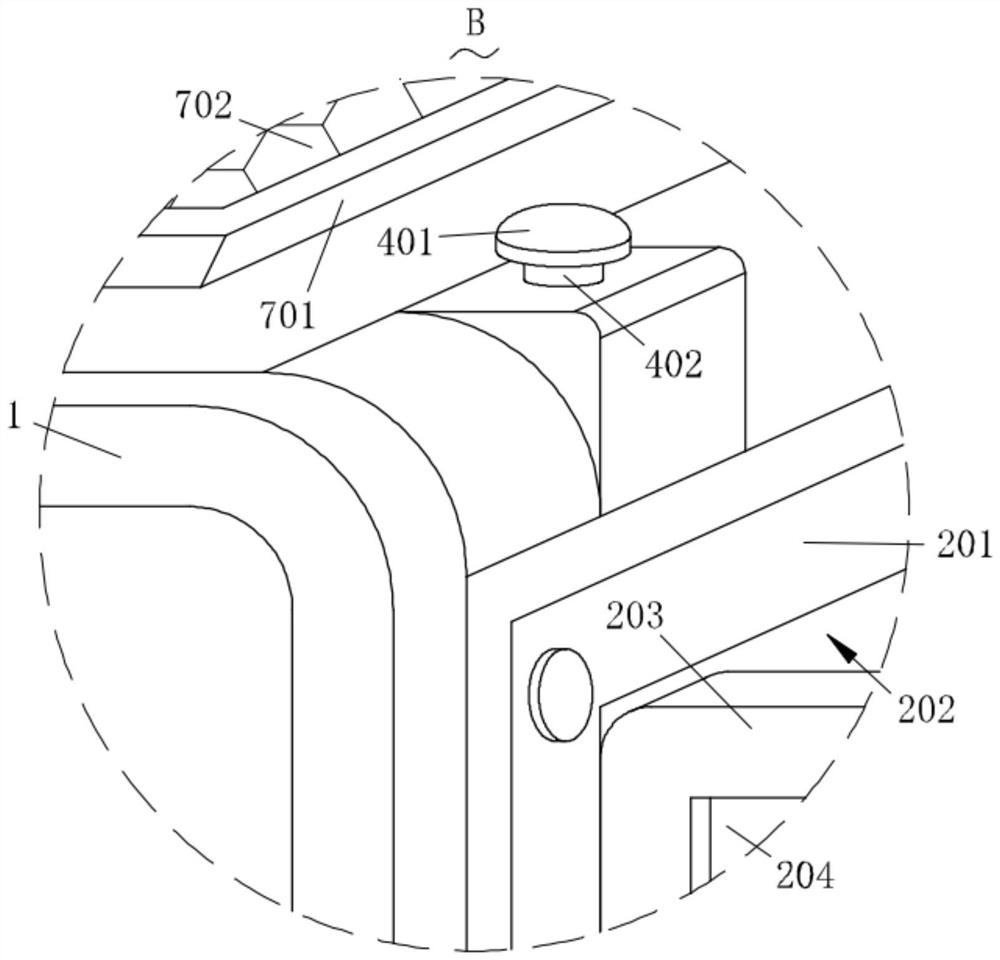

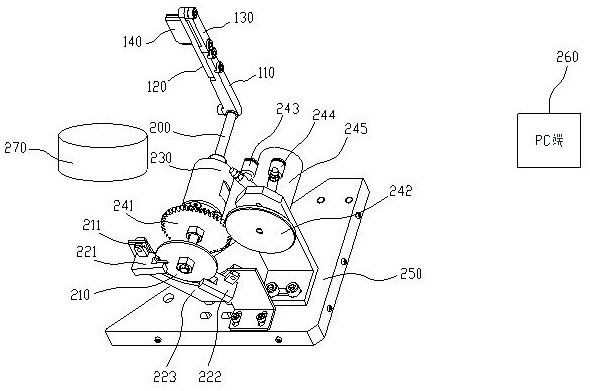

Testing device for testing crawler acquisition technology

ActiveCN114020116AEasy to storeEasy to expandSoftware testing/debuggingDigital processing power distributionLocking mechanismProtection mechanism

The invention relates to the technical field of software testing devices, in particular to a testing device for testing a crawler acquisition technology. The device comprises: a host body, wherein a display mechanism is mounted on the host body, a locking mechanism is mounted on the host body, a rotating mechanism is mounted on the display mechanism, a limiting mechanism is mounted on the display mechanism, a holding mechanism is mounted on the host body, a ventilation mechanism is mounted on the host body, and a protection mechanism is internally mounted in the host body. Through cooperation of the display mechanism, the rotating mechanism, and the locking mechanism, the display mechanism and one side of the host body are folded and unfolded, and limiting control is facilitated when the display mechanism and the host body rotate are under the action of the limiting mechanism, so that the display mechanism is stable after being adjusted, the host body is convenient to hold through the holding mechanism, the dust-proof and heat dissipation effects are achieved through the ventilation mechanism, and protection of the ventilation mechanism is facilitated through the cooperation of the holding mechanism and the protection mechanism.

Owner:SHANDONG WANLIHONG INFORMATION TECH

A preparation method of doped quartz glass evaporation material

ActiveCN110204200BHigh densityFocusGlass furnace apparatusVacuum evaporation coatingSpray GranulationEvaporation (deposition)

The invention relates to the technical field of preparation of vapor deposition materials, in particular to a preparation method of doped quartz glass vapor deposition materials. A method for preparing a doped quartz glass evaporation material, the steps comprising: (1) preparing ingredients; (2) slurry spray granulation; (3) tablet molding; (4) sintered body preparation; (5) crushing (6) melting into lumps; (7) annealing treatment; (8) crushing into granules; (9) cleaning and packaging. The present invention adopts the steps of pulverizing the sintered body of silicon-aluminum ceramics, firing and annealing, and crushing again, so that the obtained silicon-alumina glass evaporation material has a high density, and the electron gun bombards the coating material without splashing due to its light weight; there are few pores, Reduce the amount of outgassing during the coating process, thereby improving the quality of the film layer; the evaporation angle is consistent, the evaporation rate is uniform and stable, and the electron gun is easy to focus; the coating material is not easy to have dust falling off, and the coating process will not cause sputtering points, and can be applied in batches to plastics On the lens, the operability of the coating and the quality of the coating layer after coating have been greatly improved.

Owner:CHANGZHOU PROSRUN PHOTOELECTRIC TECH CO LTD

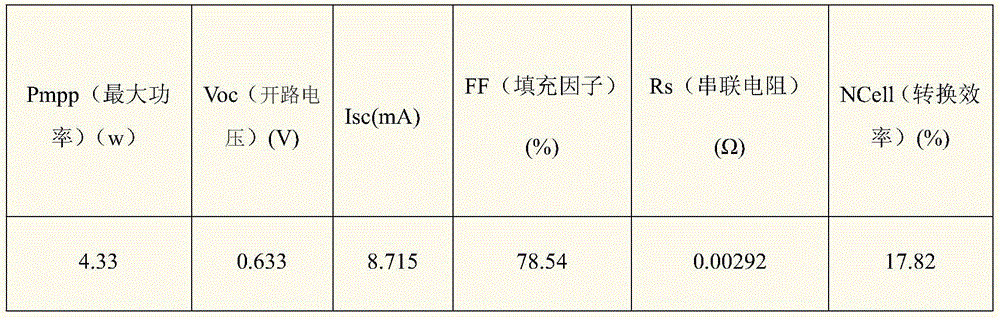

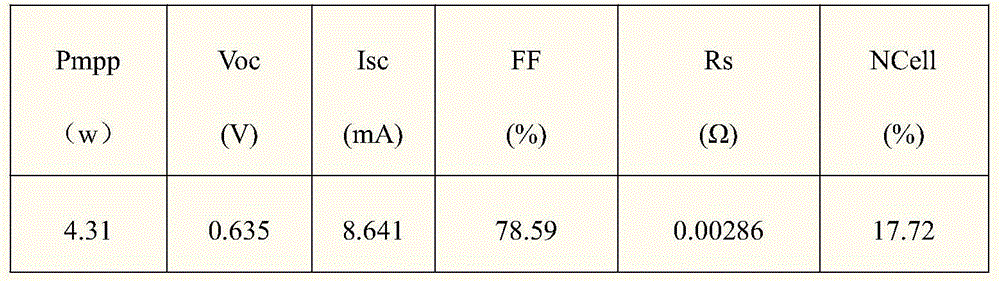

A kind of front silver paste for crystalline silicon solar cell

InactiveCN103956198BGood dispersionHigh degree of sphericityNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteCrystalline silicon

The invention discloses front silver paste for crystalline silicon solar cells. The front silver paste is characterized by comprising, by mass, 85%-90% of silver powder, 5%-12% of modified organic binder and 1%-3.5% of inorganic binder, wherein the sum of the mass percents of all the components is 100%. The front silver paste prepared from the silver powder prepared through both a physical method and a chemical method, the modified organic binder and glass power has the advantages that the printing performance is excellent, and the aspect ratio of a thin grid line is large; meanwhile, the requirement for sintering temperature is low, a pn junction is not prone to being burnt through, and therefore Isc and Uoc are effectively improved.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

Lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings

InactiveCN110605225AWill not affect the formationNo shedding phenomenonChemical industryPretreated surfacesEpoxyMetallurgy

The invention discloses a lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings. The technology comprises the following steps of carrying out shot blasting treatment on a spiral steel pipe product to be subjected to lining coating formation to make the inner wall and the outer wall of the spiral steel pipe product clean and expose theground color of the inner wall and the ground color of the outer wall of the pipe product; placing the pipe product subjected to shot blasting onto a riding wheel of a lining coating forming device,starting up a variable-frequency motor connected with the riding wheel to drive the pipe product to rotate, controlling the rotating speed of the pipe product to range from 30 revolutions per minute to 60 revolutions per minute, igniting a heating fire gun below the pipe product to preheat the pipe product, heating the pipe product to 50 DEG C to 70 DEG C, and shutting off the fire gun after heating; arranging one spraying trolley at one end of the inner wall of the pipe product and one spraying trolley at one end of the outer wall of the pipe product, using the spraying trolleys to spray solvent-free epoxy ceramic paint onto the inner wall and the outer wall of the pipe product at the same time, controlling the advancing frequency of the spraying trolleys to be within the range from 15 HZto 30 HZ, and forming the solvent-free epoxy ceramic linings on the inner wall and the outer wall of the pipe product; and placing the pipe product onto the riding wheel for rotation again till the pipe product cools and solidifies. With the lining coating forming technology for spiral steel pipe inner wall and outer wall solvent-free epoxy ceramic coatings, the manufacturing cost of inner linings and outer linings can be reduced, and the service life of spiral steel pipes can be prolonged.

Owner:广西安钢永通铸管管业有限公司

A kind of semiconductor device and preparation method, electronic device

ActiveCN106960817BAvoid failureElectrical influenceTransistorSemiconductor/solid-state device manufacturingDevice materialLow voltage

The invention relates to a semiconductor device, a manufacturing method of the semiconductor device, and an electronic device. The manufacturing method of the semiconductor device includes the steps: S1, providing a semiconductor substrate which includes a high voltage device region and a low voltage device region, and forming a patterned high voltage gate oxide layer on the high voltage device region; S2, forming a low voltage gate oxide layer at two sides of the low voltage device region and the high voltage gate oxide layer; S3, forming a low voltage gate structure and clearance walls of the low voltage gate structure on the low voltage gate oxide layer, and forming a high voltage gate structure and clearance walls of the high voltage gate structure at the same time, wherein the sum of key sizes of the clearance walls and the high voltage gate structure in the high voltage device region is equal to the key size of the high voltage gate oxide layer; S4, forming a metal silicide barrier layer in the high voltage device region and the low voltage device region and patterning the metal silicide barrier layer; S5, removing the exposed low voltage gate oxide layer; and S6, forming self-aligning silicides on the regions and the high voltage gate structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A kind of graphene-based fireproof plastic board and preparation method thereof

ActiveCN108530669BImprove flame retardant and heat insulation performanceImprove tensile propertiesFireproof paintsPolyurea/polyurethane coatingsToxic gasCarbon layer

The invention belongs to the field of fireproof materials and provides a graphene-based fireproof plastic plate. The graphene-based fireproof plastic plate comprises a graphene-based fireproof layer and a plastic base material layer, and the graphene-based fireproof layer comprises intrinsic graphene. Flame retardation and heat insulation effects of the fireproof layer can be improved by intrinsicgraphene, the plastic base material layer can be effectively protected in fire accidents, and burning and toxic gas releasing time of the plastic base material layer is delayed to buy time for evacuation and rescue. Further, stretch resistance and flexibility of the fireproof layer can be improved by intrinsic graphene, and the fireproof layer deforms correspondingly in deformation of the plasticbase material layer so as to keep high adhesion to the plastic base material layer; strength of an expansion carbon layer is improved, and less proneness to shedding after heat deformation of the plastic base material layer is realized. Owing to excellent insulation and hydrophobic performances of intrinsic graphene, water resistance of the fireproof layer can be remarkably improved, and the service life of the fireproof plastic plate is prolonged. In addition, the graphene-based fireproof plastic plate is low in density.

Owner:合肥市海洲新材料科技有限公司 +1

Box opening robot anti-paper-box-falling-off device

The invention relates to a box opening robot anti-paper-box-falling-off device. The device comprises a robot, wherein two opposite large clamping jaws are arranged at the end part of the robot, and are used for clamping a paper box, a corresponding sucker is arranged on each large clamping jaw and is used for adsorbing the paper box, photoelectric switches are arranged on the large clamping jaws and are used for detecting contact signals of the large clamping jaws and the paper box to the robot, and a corresponding anti-paper-box-falling-off device body is arranged on each large clamping jaw.According to the technical scheme, the anti-paper-box-falling-off device bodies are arranged on the two large clamping jaws of the robot, when the large clamping jaws clamp boxes of cigarette blocks,due to the fact that the length of penetrating nails exceeds the end faces of the suckers and the nails can be inserted into the paper box, the large clamping jaws cannot cause the falling of the paper box in the clamping process.

Owner:CHINA TOBACCO HENAN IND

Removal device applied to ring-pull can stretcher slideway

ActiveCN111229913AInhibit sheddingControl adsorptionStripping-off devicesHollow articlesStructural engineeringMechanical engineering

The invention provides a removal device applied to a ring-pull can stretcher slideway, and belongs to the technical field of ring-pull can production. The technical scheme of the invention is that theremoval device comprises first slideways and second slideways fixedly connected with the first slideways, wherein blocking bars are fixedly arranged between the first slideways and the second slideways; the blocking bars are arranged on two sides of the first slideways and the second slideways; the blocking bar on one side comprises an upper half part and a lower half part, wherein an interval isarranged between the upper half part and the lower half part and is provided with a removal mechanism; the removal mechanism comprises a bottom plate, wherein the bottom plate is provided with a first bracket and a second bracket, and an opening and closing mechanism is arranged between the second bracket and the first bracket and drives the second bracket and the first bracket to carry out inverse movement; the bottom plate is also provided with a sucking disk mechanism; and the sucking disk mechanism can carry out translation on the ring-pull can to the first bracket and the second bracket.The removal device has the beneficial effects that unqualified ring-pull cans are simultaneously removed on the slideways through the sucking disk, working efficiency is high, when the ring-pull cansare removed, the removed ring-pull cans do not collide and rub with subsequent ring-pull cans, and the quality of the subsequent ring-pull cans is effectively guaranteed.

Owner:济南联合制罐有限公司

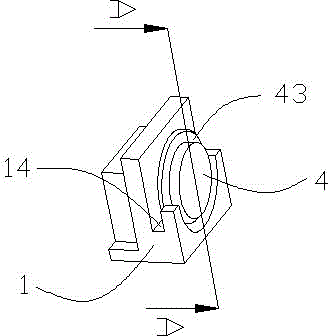

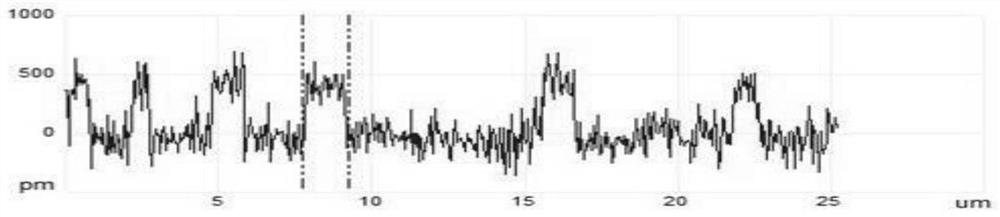

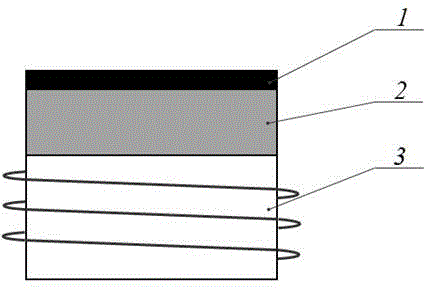

Laser shock peening absorbing layer and clamping device thereof

The invention discloses a laser shock peening absorbing layer and a clamping device of the laser shock peening absorbing layer. The laser shock peening absorbing layer mainly comprises main components of ferroferric oxide powder, an adhesion agent and carbon powder, wherein the ferroferric oxide is black, and has a good absorbing function for laser adopted by the invention, and also has magnetism; the clamping device of the absorbing layer is an electromagnet arranged on the back surface of a workpiece, the absorbing layer adopts a coating mode, is directly covered on the surface of the workpiece, and is aired in air, with the coating thickness of 80-150 micrometers; and after the laser shock peening is finished, the electromagnet is enabled to be in a power failure sate, and is capable of automatically enabling the absorbing layer to drop from the surface of the workpiece. By adopting the special absorbing layer and the clamping device of the special absorbing layer disclosed by the invention, the energy loss of laser shock waves can be remarkably reduced, the absorbing layer can be enabled to be automatically drop, and the surface subjected to laser shock does not need to be cleaned for the second time, thus the laser shock peening absorbing layer can be applied to laser shock peening of the surface of a metal workpiece.

Owner:东台城东科技创业园管理有限公司

Heat exchanger

ActiveCN101776403BStable heat conduction efficiencyImprove pass rateStationary conduit assembliesHeat exchanger casingsPlate heat exchangerMarine engineering

The invention discloses a heat exchanger comprising a first collecting pipe, a second collecting pipe and a plurality of sets of radiation flat pipes arranged between the first collecting pipe and the second collecting pipe. Ports in which the radiation flat pipes can be inserted are arranged at one sides of the collecting pipes. The radiation flat pipes are inserted into the collecting pipes through the ports. Fins used for heat radiation are arranged between adjacent two sets of radiation flat pipes. Positioning mechanisms for preventing the horizontal movement of the fins are arranged between the radiation flat pipes and the fins. After the use of the positioning mechanisms, the radiation flat pipes and the fins of the heat exchanger can be stably and reliably positioned, and the service life of the heat exchanger can be prolonged. The positioning mechanisms are more suitable for heat exchangers with fins wider than radiation flat pipes. The disconnection caused by the collision ofthe fins with other components during the assembly, as well as other problems, can be avoided, thereby improving the heat exchange efficiency of the heat exchanger.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

Knocking rod device for PIC coating equipment

ActiveCN113403589ASolve looseWill not cause loosening by knockingVacuum evaporation coatingSputtering coatingStructural engineeringMechanical engineering

The invention relates to a knocking rod device for PIC coating equipment, the knocking rod device comprises a knocking rod, one end of the knocking rod is provided with a trigger head for arc striking, the other end of the knocking rod is assembled at one end of a rotating rod, the knocking rod and the rotating rod are arranged in an included angle shape, and the rotating rod is rotatably mounted on a knocking mounting seat through a bearing seat. A rotation adjusting assembly used for adjusting the rotating rod to rotate is arranged on the knocking mounting seat. According to the scheme provided by the invention, the problems of loosening, improper knocking and target sticking of the knocking rod in the knocking process can be effectively solved, the trigger head is not liable to fall off, so that the trigger head is prevented from being quickly worn, the failure rate is reduced, and stable coating is effectively ensured.

Owner:ANHUI CHUNYUAN COATING TECH CO LTD

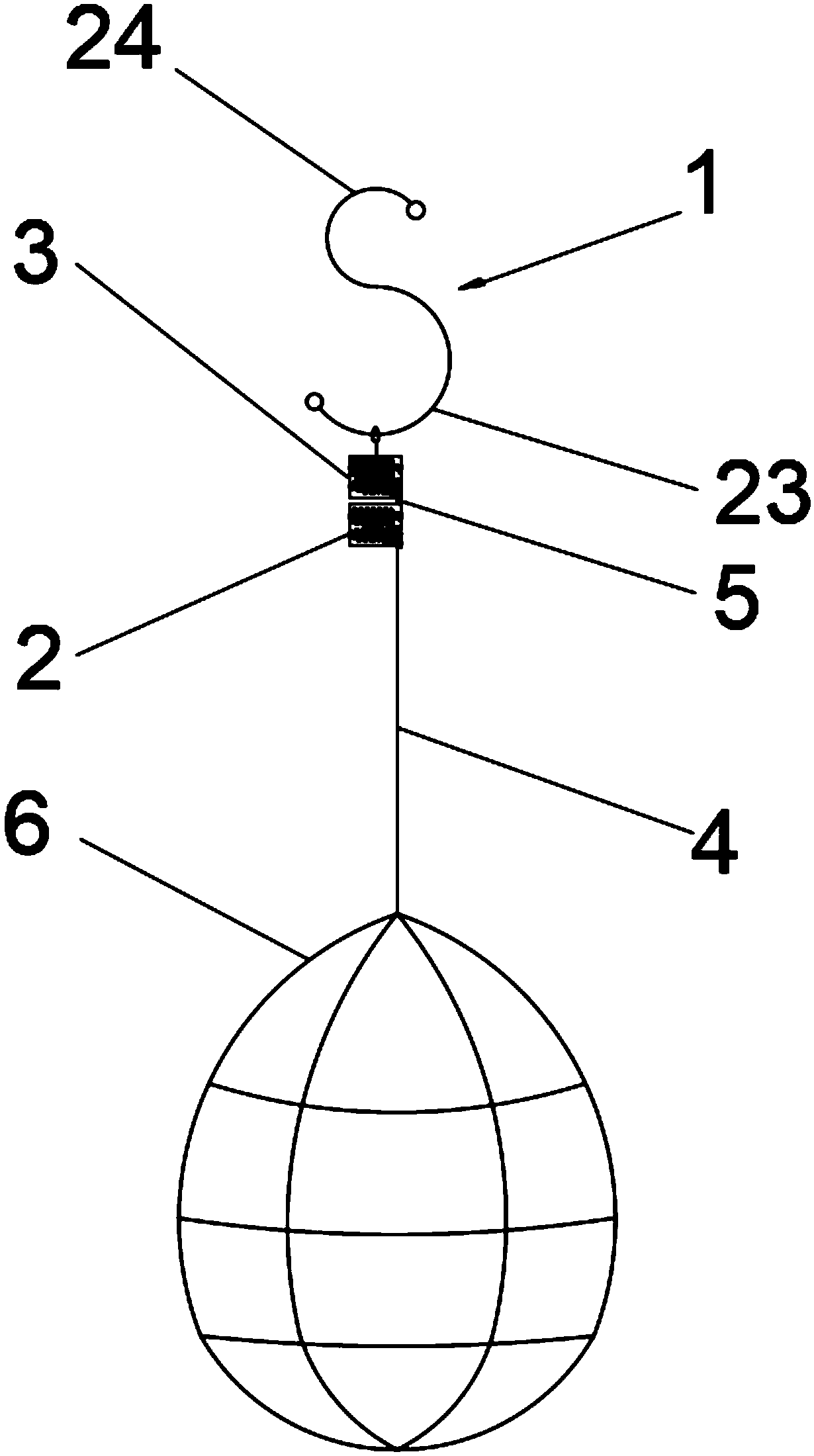

Fruit setting device and method suitable for small melons cultivated in way of stereoscopic cultivation

The invention discloses a fruit setting device and method suitable for small melons cultivated in the way of stereoscopic cultivation. The device comprises a hook, a first movable device, a second movable device, a first pulling rope, a second pulling rope and a net pocket. The distance between the hook and the net pocket is adjusted by the first movable device and the second movable device, so that the height of a hanging fruit is conveniently adjusted. When the fruit position is higher, the net pocket is adjusted to rise, the operation is convenient, and no re-knotting is needed to adjust the height of the net pocket. When the fruit position is lower and the fruit grows up, the weight of the fruit is increased, and the excess weight is transferred to the vine of the plant, avoiding forming dents on the surface caused by too much pulling force and affecting the appearance. When melons and fruits are picked, the fruit stem of the melon and fruit is cut off, and under the support of thepulling ropes, the support of a worker for the melon and fruit is reduced, and the hook is placed in a basket and then the net pocket is removed to prevent the fruit from falling and being damaged. Heavyweight melons and fruits are carried as easily and conveniently as lightweight melons.

Owner:HAINAN RUNDA MODERN AGRI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com