Preparation method of positive grid

A positive plate and grid technology, which is applied in the field of positive grid preparation, can solve the problems of lead-acid batteries such as short life, battery loss of capacity, and lead dioxide shedding, so as to improve quality and mechanical strength, improve interface bonding, and improve binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

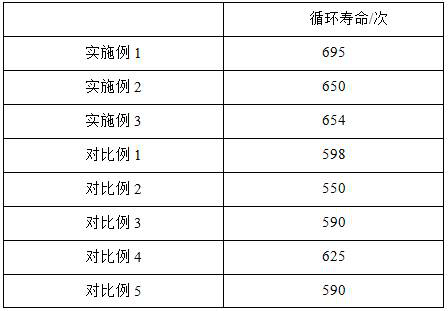

Examples

Embodiment 1

[0027] A method for preparing a positive electrode grid, comprising the following steps:

[0028] S1, configure the alloy liquid;

[0029] S2, heating the grid gravity casting mold, so that the temperature of the grid gravity casting mold upper opening reaches 170°C, the grid gravity casting mold lower opening temperature reaches 170°C, and heats the temperature of the lead pipe to 560°C;

[0030] S3. After removing the surface impurities, spray a mold release agent to the grid transverse rib cavity and the grid vertical rib cavity inside the grid gravity casting mold;

[0031] S4, the alloy liquid is added to the lead spoon through the lead pipe, and the lead spoon is heated to 560 ° C, and the alloy in the lead spoon is poured into the grid gravity casting mold for casting;

[0032] S5. After the casting is completed, the resultant is sprayed with atomized water to cool, and then cut to obtain the positive electrode grid.

[0033] The alloy liquid is made of the following ...

Embodiment 2

[0044] A method for preparing a positive electrode grid, comprising the following steps:

[0045] S1, configure the alloy liquid;

[0046] S2, heating the grid gravity casting mold, so that the temperature of the grid gravity casting mold upper opening reaches 170°C, the grid gravity casting mold lower opening temperature reaches 170°C, and heats the temperature of the lead pipe to 560°C;

[0047] S3. After removing the surface impurities, spray a mold release agent to the grid transverse rib cavity and the grid vertical rib cavity inside the grid gravity casting mold;

[0048] S4, the alloy liquid is added to the lead spoon through the lead pipe, and the lead spoon is heated to 560 ° C, and the alloy in the lead spoon is poured into the grid gravity casting mold for casting;

[0049] S5. After the casting is completed, the resultant is sprayed with atomized water to cool, and then cut to obtain the positive electrode grid.

[0050] The alloy liquid is made of the following ...

Embodiment 3

[0061] A method for preparing a positive electrode grid, comprising the following steps:

[0062] S1, configure the alloy liquid;

[0063] S2, heating the grid gravity casting mold, so that the temperature of the grid gravity casting mold upper opening reaches 170°C, the grid gravity casting mold lower opening temperature reaches 170°C, and heats the temperature of the lead pipe to 560°C;

[0064] S3. After removing the surface impurities, spray a mold release agent to the grid transverse rib cavity and the grid vertical rib cavity inside the grid gravity casting mold;

[0065] S4, the alloy liquid is added to the lead spoon through the lead pipe, and the lead spoon is heated to 560 ° C, and the alloy in the lead spoon is poured into the grid gravity casting mold for casting;

[0066] S5. After the casting is completed, the resultant is sprayed with atomized water to cool, and then cut to obtain the positive electrode grid.

[0067] The alloy liquid is made of the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com