Flat pipe and fin structures of parallel flow heat exchanger

An exchanger and flat tube technology, applied in the field of components of parallel flow heat exchangers, can solve the problems of high product defect rate, increased manufacturing cost, unreliable welding, etc., and achieves convenient processing and manufacturing, stable heat exchange efficiency, and improved excellent rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

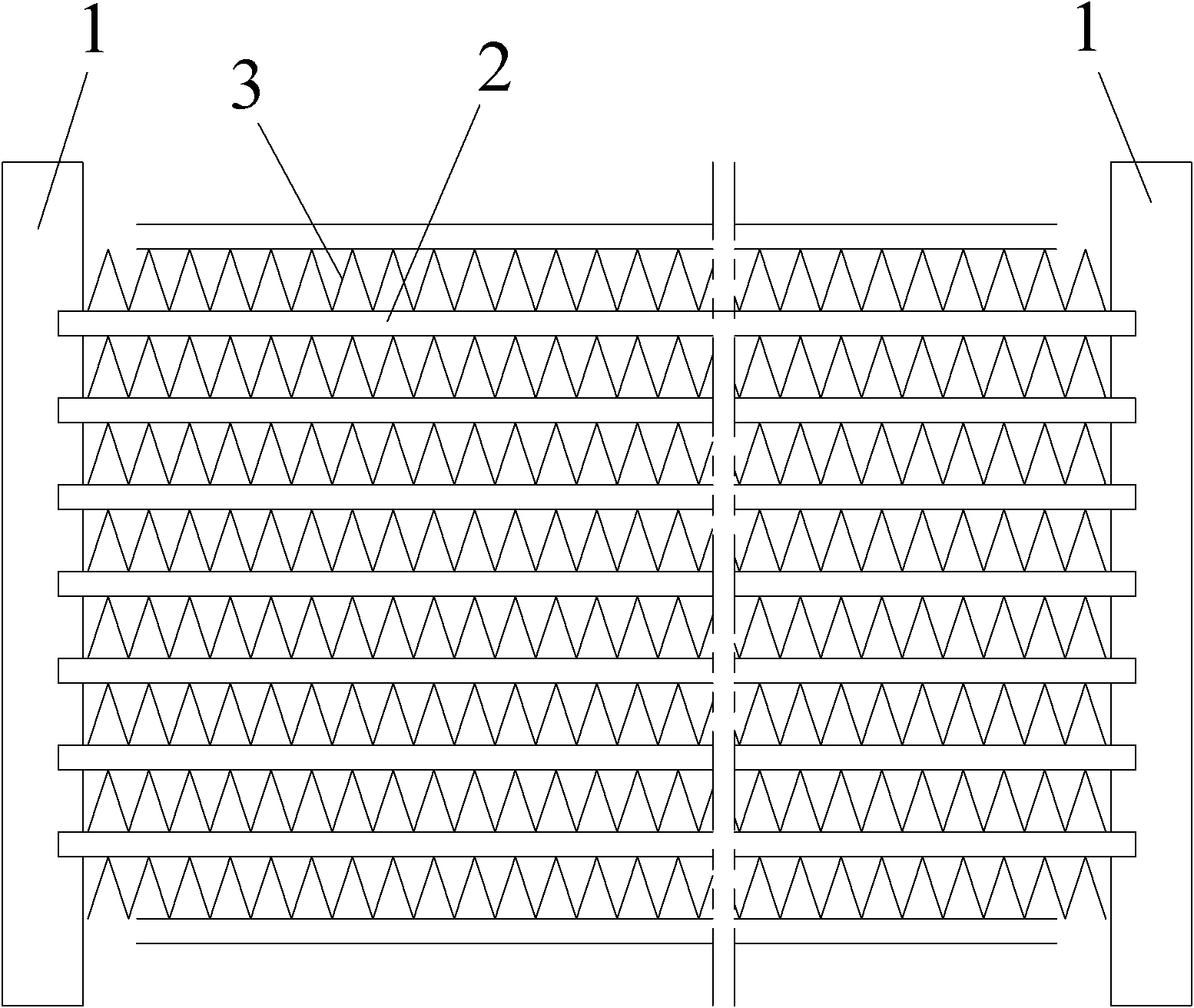

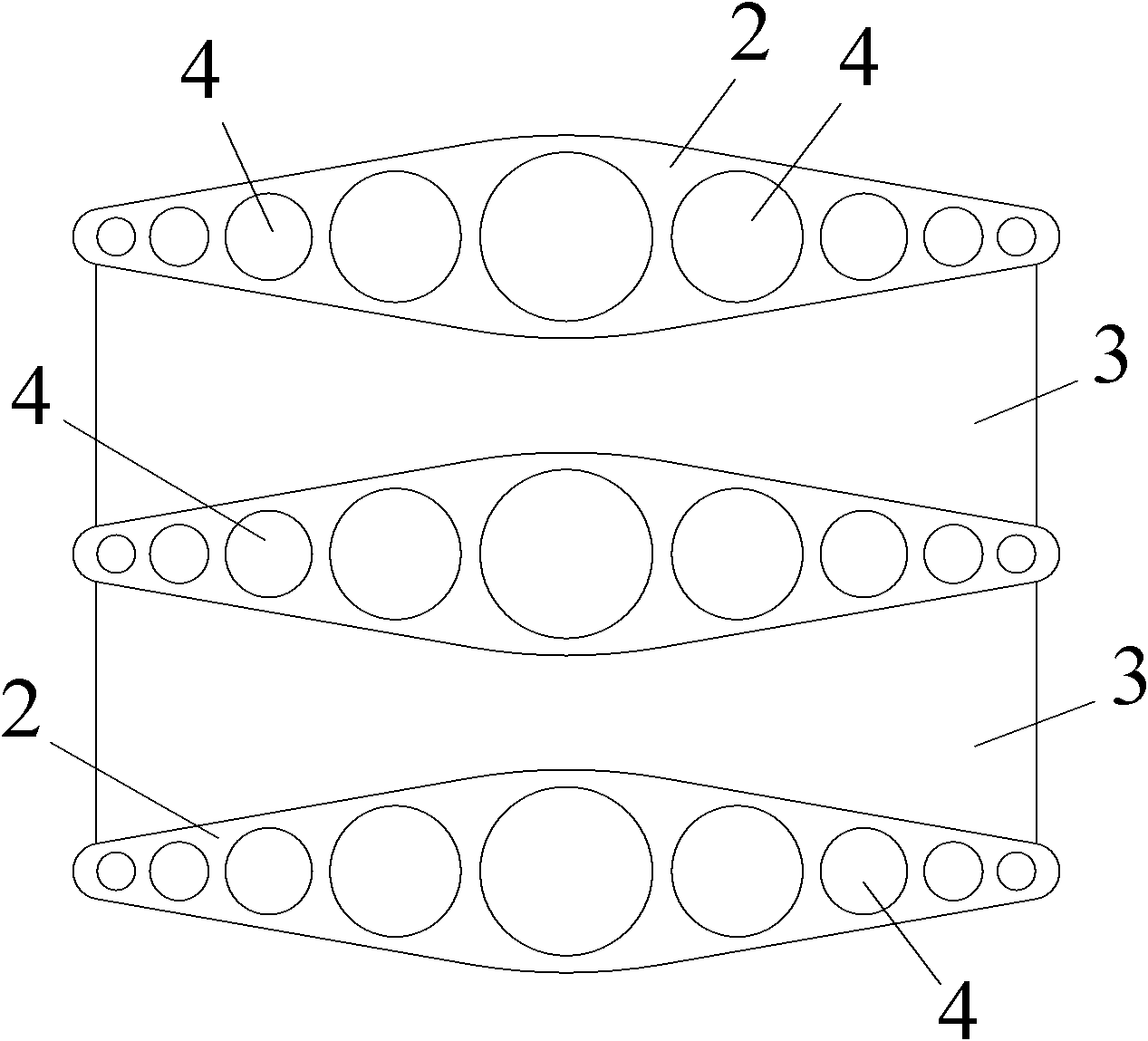

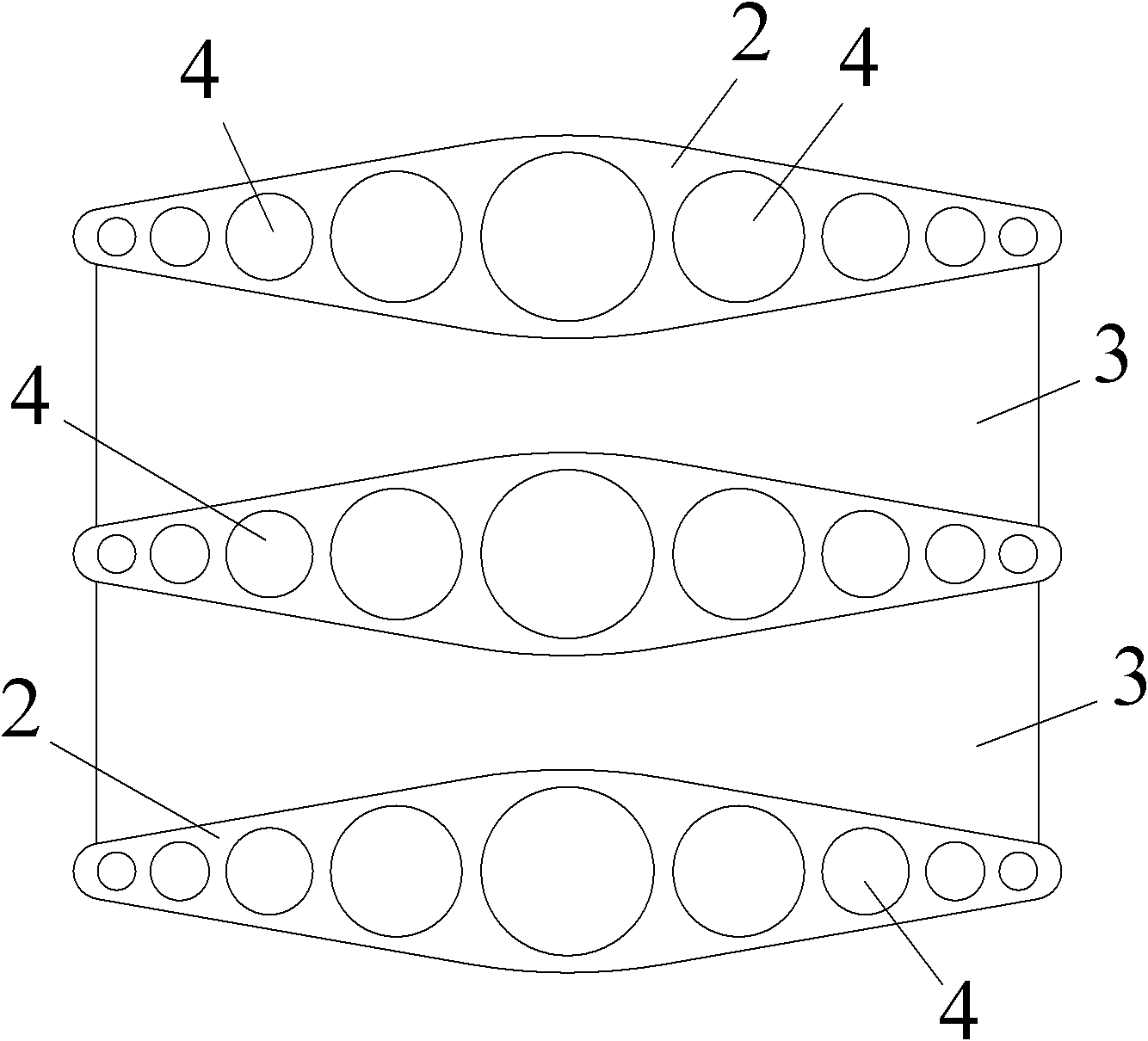

[0010] Example: see figure 1 and figure 2 , the heat exchanger of the present invention includes several flat tubes 2 inserted on the headers 1 at both ends, fins 3 are arranged between adjacent flat tubes 2, and the microchannels 4 on the flat tubes 2 communicate with the headers 1 at both ends. . Wherein, both sides of the flat tube 2 are raised in the longitudinal middle, and correspondingly, the fins 3 are concave in the longitudinal middle of both sides, which can prevent the fins from falling off due to lateral movement. Preferably, the raised parts in the longitudinal middle of both sides of the flat tube 2 have a smooth transition, and correspondingly the concave structures in the longitudinal middle of both sides of the fin 3 also have a smooth transition, which facilitates the processing and manufacturing of components.

[0011] In the present invention, the flat tube is designed as a raised structure in the longitudinal middle of both sides, and the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com