Preparing method of silica-glass-doped evaporation-coating material

A technology of quartz glass and vapor deposition materials, applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problems of low hardness of ceramic particles, easy dusting on the surface of particles, splash points, etc., and achieve the evaporation rate. Uniform and stable, not easy for dust to fall off, and the effect of film quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

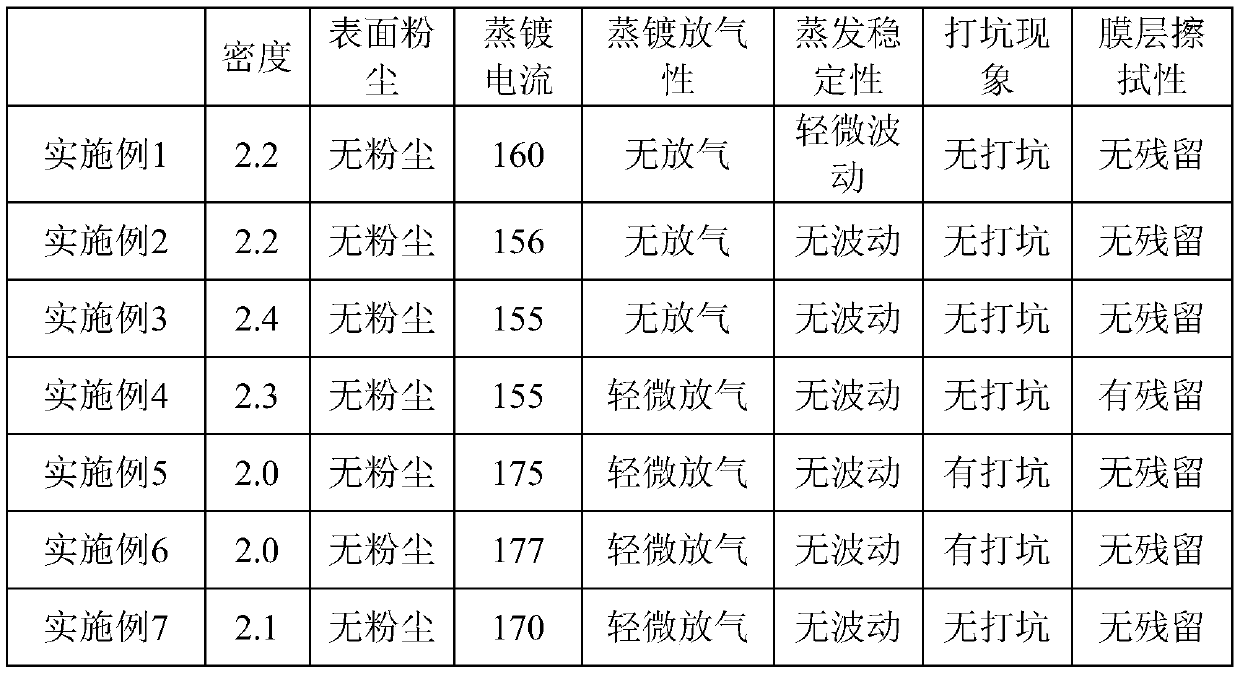

Examples

preparation example Construction

[0031] In order to solve the above problems, the first aspect of the present invention provides a method for preparing a doped quartz glass evaporation material, the steps comprising:

[0032] (1) Preparation of ingredients: the raw material SiO 2 and Al 2 o 3 According to the weight ratio (1-X): X ingredients are mixed, wherein X=1~40wt%; Put the mixed material into the planetary ball mill, add zirconia grinding balls with a diameter of 2 mm and pure water at the same time, and water is the mixing medium in the planetary ball mill Carry out wet ball milling process on the ingredients, the ratio of material to ball is 10:1~20:1, and the ball milling time is 5~10h;

[0033] (2) Slurry spray granulation: put the slurry made after step (1) ball milling into a spray granulator to prepare spherical powder;

[0034] (3) Tablet forming: the composite powder made in step (2) is pressed and formed on a tablet press, and the tablet pressure is controlled at 100-200 MPa to prepare a s...

Embodiment 1

[0085] Embodiment 1 provides a kind of preparation method of doped quartz glass evaporation material, and the steps include:

[0086] (1) Preparation of ingredients: the raw material SiO 2 and Al 2 o 3 According to the weight ratio (1-X): X ingredients are mixed, wherein X=10wt%; the mixed material is put into the planetary ball mill, and zirconia grinding balls with a diameter of two millimeters and pure water are added simultaneously, and water is the mixing medium for the ingredients in the planetary ball mill Carry out the wet ball milling process, the material-ball ratio is 20:1, and the ball milling time is 10h;

[0087] (2) Slurry spray granulation: Put the slurry made after step (1) ball milling into a spray granulator to prepare spherical powder with a diameter of 100 μm;

[0088] (3) Tablet forming: the composite powder made in step (2) is pressed and formed on a tablet press, the tablet pressure is controlled at 200MPa, and a cuboid sheet-shaped green body is pre...

Embodiment 2

[0096] Embodiment 2 provides a kind of preparation method of doped quartz glass evaporation material, and the steps include:

[0097] (1) Preparation of ingredients: the raw material SiO 2 and Al 2 o 3 According to the weight ratio (1-X): X ingredients are mixed, wherein X=1wt%; the mixture is put into the planetary ball mill, and the zirconia grinding balls with a diameter of two millimeters and pure water are added simultaneously, and water is the mixing medium for the ingredients in the planetary ball mill Carry out the wet ball milling process, the ratio of material to ball is 10:1, and the ball milling time is 5h;

[0098] (2) Slurry spray granulation: Put the slurry made after step (1) ball milling into a spray granulator to prepare spherical powder with a diameter of 100 μm;

[0099] (3) Tablet molding: the composite powder made in step (2) is pressed and formed on a tablet machine, the tablet pressure is controlled at 100MPa, and a cuboid sheet-shaped green body is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com