Graphene-based fireproof plastic plate and preparation method thereof

A graphene-based, fire-resistant plastic technology, applied in the direction of fire-resistant coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of reducing the mechanical properties of plastics, plastics are flammable, and the flame-retardant effect is poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides the preparation method of graphene-based fireproof plastic board described in above-mentioned technical scheme, comprises the following steps:

[0042] (1) carrying out surface treatment to plastic base material layer, obtains pretreatment plastic base material layer;

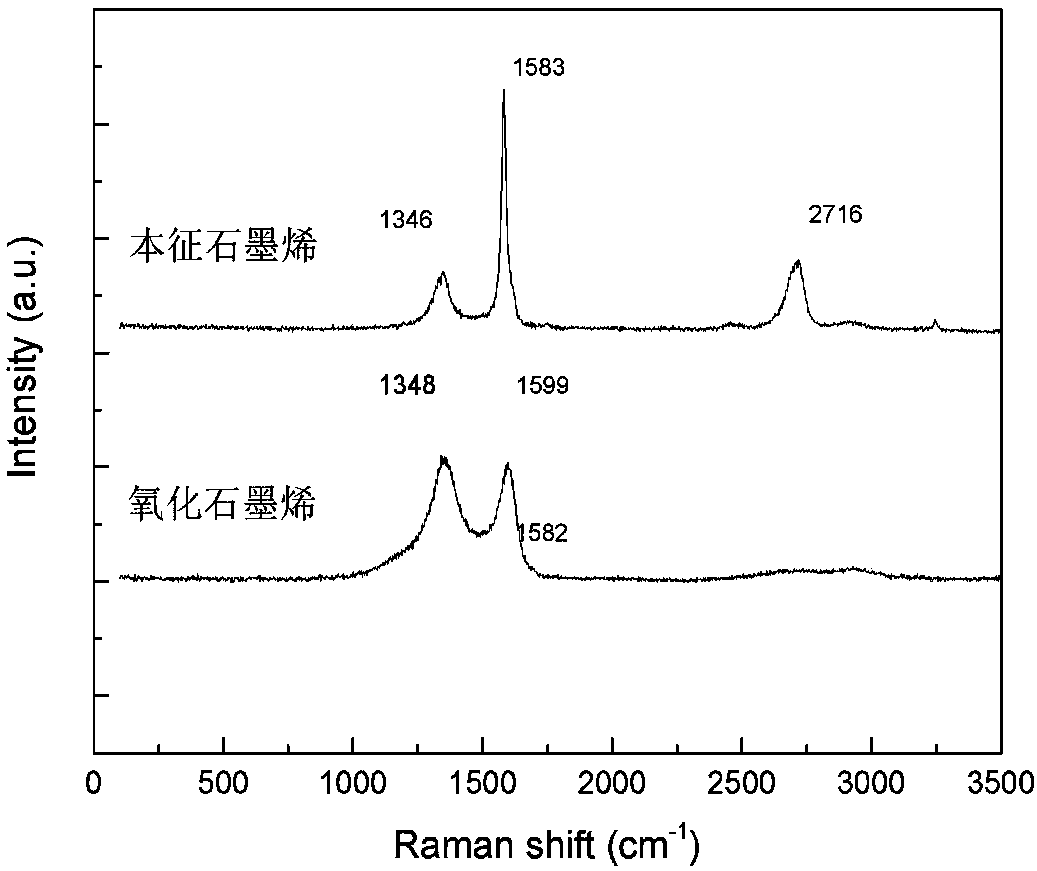

[0043] (2) coating graphene-based fireproof paint on the surface of the pretreated plastic substrate layer obtained in the step (1), forming a graphene-based fireproof layer, obtaining a graphene-based fireproof plastic plate, in the graphene-based fireproof layer Contains intrinsic graphene.

[0044] The invention carries out surface treatment on the plastic base material layer to obtain the pretreated plastic base material layer. In the present invention, the surface treatment is preferably plasma surface treatment or chemical surface treatment. In the present invention, the surface treatment can improve the coating adhesion of the graphene-based fireproof layer. ...

Embodiment 1

[0054] Weigh 30 parts of epoxy resin E51, 2 parts of intrinsic graphene powder, 0.1 part of defoamer BYK-052N, 0.25 parts of leveling agent BYK-3550, 15 parts of dibutyl phthalate and mix with a mechanical stirrer Evenly, the graphene is evenly dispersed; Weigh 20 parts of ammonium polyphosphate, 2 parts of chlorinated paraffin, 6 parts of dicyandiamide, 6 parts of dipentaerythritol, 5 parts of triphenyl phosphate, and 15 parts of barium sulfate, and add them to the obtained slurry in sequence , and stir while adding. After stirring evenly, transfer the slurry to a ball mill, disperse by ball milling, and stop until the slurry fineness is <90 μm, and take it out for later use.

[0055] Weigh 7 parts of T31 curing agent and 5 parts of acetone, and mix them uniformly to obtain component B.

[0056] Choose ABS plastic base material with a thickness of 2.5mm to remove dust and oil.

[0057] Mix A and B components evenly according to the mass ratio of A:B=100:12, and then coat on...

Embodiment 2

[0059] Weigh 30 parts of acrylic resin, 2 parts of intrinsic graphene powder, 0.1 part of defoamer BYK-066N, 0.25 parts of leveling agent BYK-32015 parts of ethyl acetate, and use a mechanical stirrer to mix evenly to disperse the graphene evenly Weigh 20 parts of melamine phosphate, 2 parts of chlorinated paraffin, 6 parts of dicyandiamide, 6 parts of dipentaerythritol, 5 parts of triphenyl phosphate, and 15 parts of talcum powder, and add them to the obtained slurry in turn, stirring while adding. After stirring evenly, transfer the slurry to a ball mill, disperse by ball milling, and stop until the slurry fineness is <90 μm, and take it out for later use.

[0060] Choose ABS plastic base material with a thickness of 2.5mm to remove dust and oil.

[0061] The graphene-based fireproof layer slurry is coated on ABS plastic, one-side coating, one coating 100-250 μm; multiple coatings until the thickness of the fireproof layer is 500 μm and then dried to obtain a graphene-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com