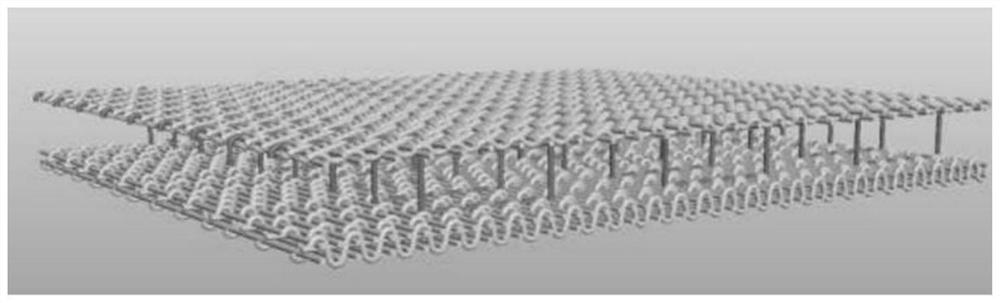

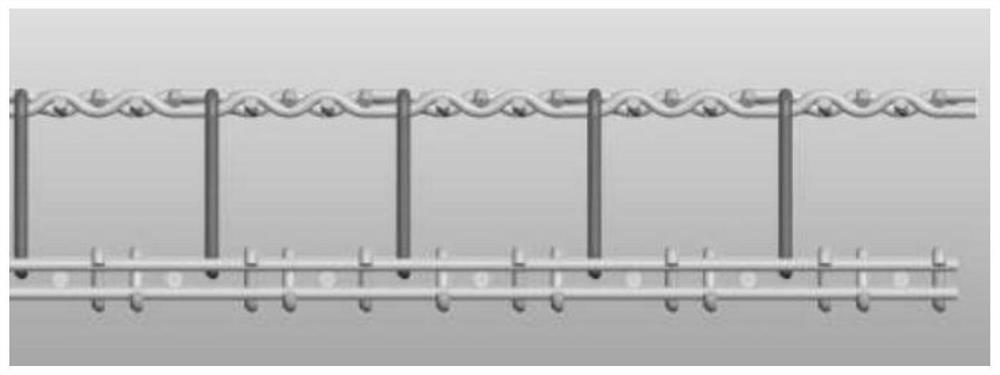

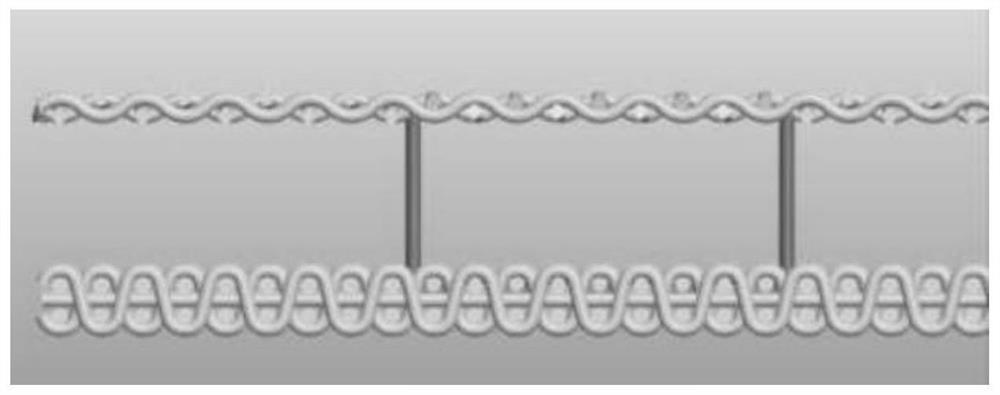

Flame-retardant and heat-insulating basalt-flame-retardant fiber three-dimensional spaced woven fabric and manufacturing method thereof

A technology of flame-retardant fiber and basalt, which is applied in the field of flame-retardant and heat-insulating basalt-fire-retardant fiber three-dimensional spacer woven fabric and its manufacturing field, and can solve the problems that the flame-retardant and heat-insulating properties of flame-retardant and heat-insulating fabrics need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Specifications and sources of raw materials used in this example: basalt fiber yarn, 240D, Shanxi Jintou Basalt Development Co., Ltd.; flame-retardant acrylic-cotton fiber blended yarn, 40S, Hengfeng Textile Co., Ltd.;

[0047] Machine used: SGA598 automatic rapier loom, working air pressure is 0.5MPa;

[0048] Weaving method and process:

[0049] (1) Treatment of flame retardant acrylic fiber-cotton fiber blended yarn: Combine four flame retardant acrylic fiber / cotton fiber blended yarns into one on the Dstw-01 digital sample cascading twister, and twister parameters: twisted yarn The number is 30.00Tex, the twist is 18.26 twist / 10cm, the spindle speed is 1771 rev / min, and the sliver speed is 10.00 m / min, and the flame-retardant acrylic-cotton fiber blended yarn after twisting is wound on the bobbin for a total of 96 barrels of yarn need to be wound, to be drawn in;

[0050] (2) Treatment of basalt fiber yarn: Wind 20m long basalt fiber yarn on the bobbin of the cree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com