Flame-retardant and heat-insulating epoxy IC packaging carrier plate and preparation method thereof

A technology for encapsulating carrier boards and epoxy-based, applied in surface pretreatment bonding methods, chemical instruments and methods, lamination devices, etc., can solve the problems of poor stability of flame retardant and heat insulation performance, and achieve enhanced flame retardant Heat insulation and smoke suppression performance, improving heat insulation performance and flame retardancy, and improving the effect of flame retardancy and heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a flame-retardant and heat-insulating epoxy-based IC packaging carrier, comprising a cured sheet, an adhesive film and a metal foil, the adhesive film is located between the cured sheet and the metal foil, and the adhesive film is The percentage calculation includes: 22.40% of glass fiber, 14.40% of supplements, and 63.20% of polyamide resin; the supplement includes: 9.10% of aluminum hydroxide, 10.20% of zinc borate, 45.60% of hollow Glass beads, 5.20% butyl titanate, 5.20% glacial acetic acid, 1.20% titanate coupling agent, 8.20% phosphotungstic acid, 15.30% absolute ethanol;

[0028] The metal foil is rolled copper foil; the cured sheet is made of glass fiber cloth impregnated with epoxy resin;

[0029] The present invention also provides a method for preparing a flame-retardant and heat-insulating epoxy-based IC package carrier, the specific processing steps are as follows:

[0030] Step 1: Weigh the glass fiber in the film, polyamide resin a...

Embodiment 2

[0039] Different from Example 1, the adhesive film includes: 23.40% glass fiber, 15.40% supplement, 61.20% polyamide resin by weight percentage; the supplement includes 9.70% by weight Aluminum hydroxide, 10.80% zinc borate, 46.20% hollow glass microspheres, 5.80% butyl titanate, 5.80% glacial acetic acid, 1.80% titanate coupling agent, 8.80% phosphotungstic acid, 11.10 % absolute ethanol.

Embodiment 3

[0041] All different from Examples 1-2, the adhesive film includes: 22.90% glass fibers, 14.90% supplements, and 62.20% polyamide resin by weight percentage; the supplements include: 9.40% aluminum hydroxide, 10.50% zinc borate, 45.90% hollow glass microspheres, 5.50% butyl titanate, 5.50% glacial acetic acid, 1.50% titanate coupling agent, 8.50% phosphotungsten Acid, 13.20% absolute ethanol.

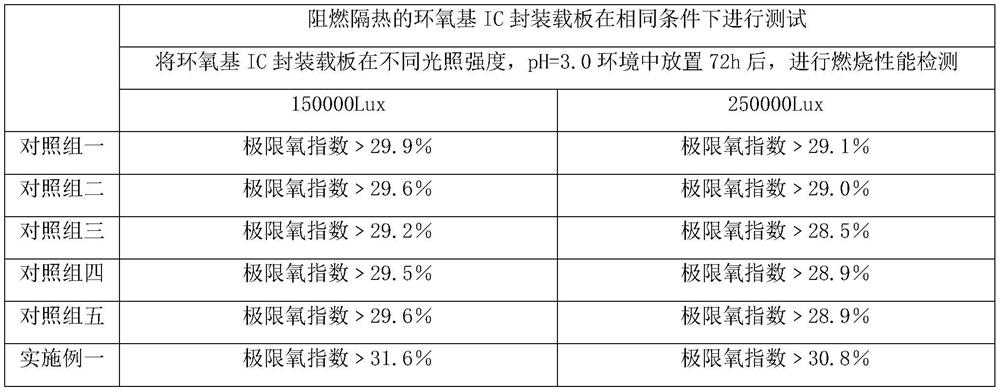

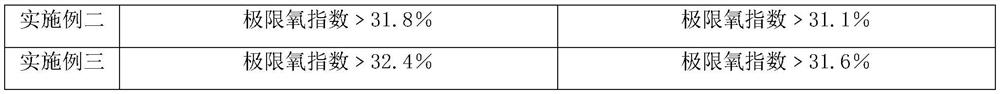

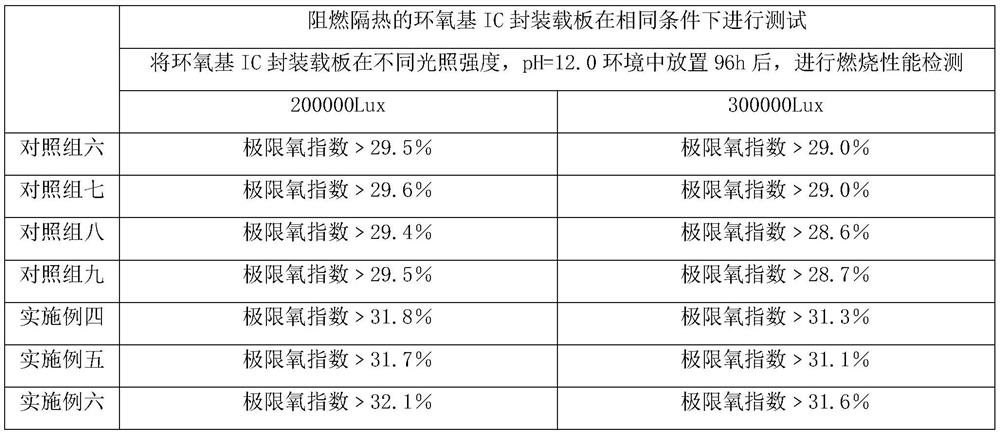

[0042] Take respectively the flame-retardant and heat-insulating epoxy-based IC package carrier of the above-mentioned embodiment 1-3, the flame-retardant and heat-insulated epoxy-based IC package carrier of the control group one, and the flame-retardant and heat-insulated carrier of the control group two. The epoxy-based IC package substrate of the control group three, the flame-retardant and heat-insulated epoxy-based IC package substrate of the control group three, the flame-retardant and heat-insulated epoxy-based IC package substrate of the control group four, and the flame-retarda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com