Fire-resistant glass heat insulation frame positioning structure

A technology of refractory glass and positioning structure, which is applied in the installation of window glass and other directions, can solve the problems of separation of fire-retardant and flame-retardant adhesive strips from refractory glass, reduction of positioning stability of refractory glass, and reduction of stability of profile splicing frame. Water seepage erosion problem, enhance positioning stability, reduce the effect of heat transfer to the interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

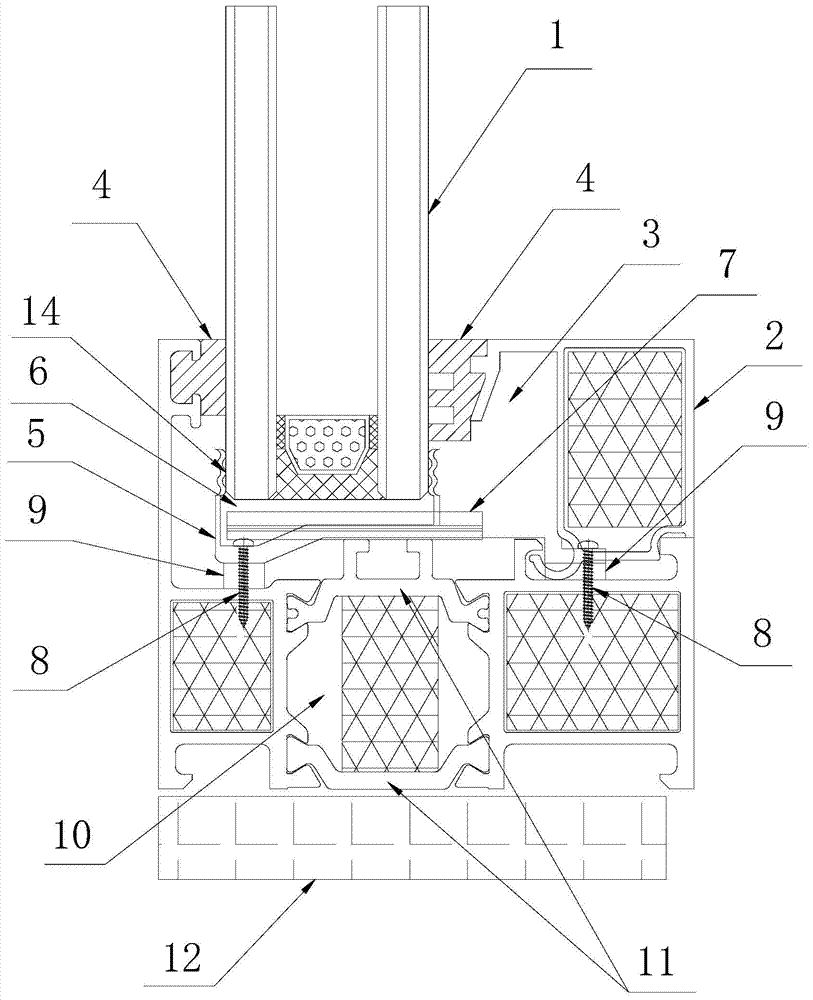

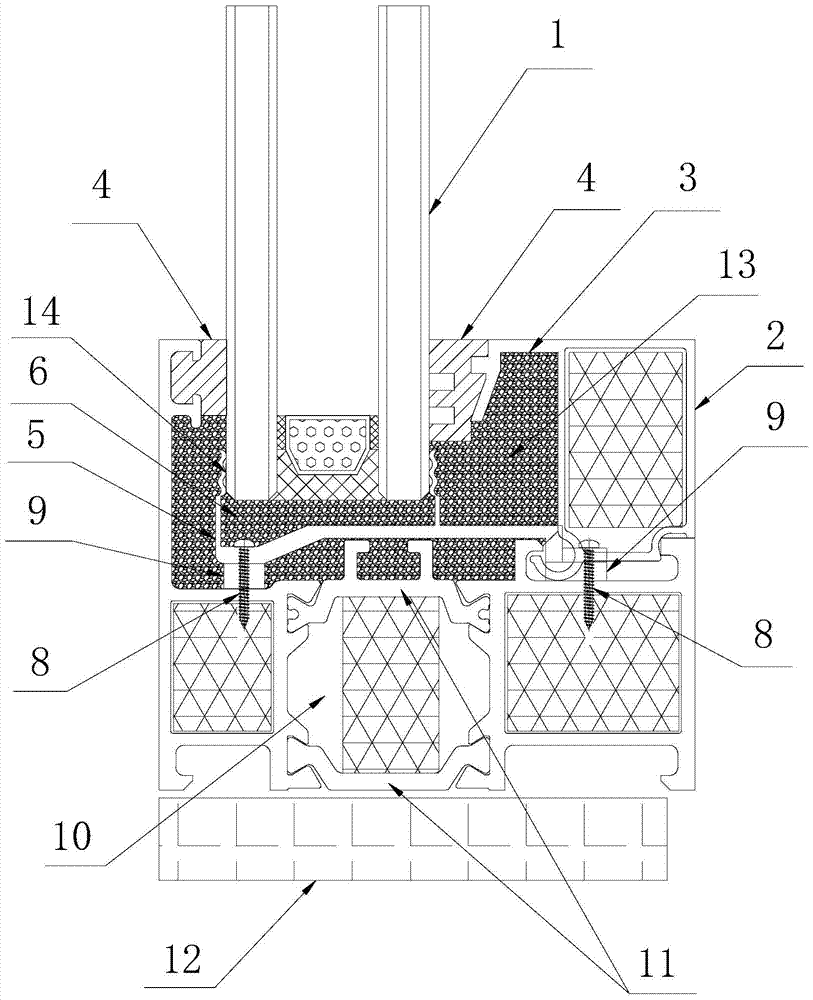

[0023] Example: such as figure 1 As shown, it is a specific embodiment of the fire-resistant glass heat-insulating frame positioning structure of the present invention, which has a profile splicing frame 2 for positioning the side of the fire-resistant glass 1. Into the cavity 3, the profile splicing frame 2 on both sides of the cavity 3 is fixed with fire-resistant and flame-retardant adhesive strips 4 attached to the fire-resistant glass 1; and the profile splicing frame 2 at the bottom of the cavity 3 passes through two The fastener 8 is fixed with a fire-resistant glass side protection frame 5, and the fire-resistant glass side protection frame 5 is provided with a positioning slot 6 for the side of the fire-resistant glass 1 to snap into. In this embodiment, the fasteners 8 are screws, and the position where the two screws are placed on the fire-resistant glass side protection frame 5 and the profile splicing frame 2 are all provided with heat-insulating pads 9. During ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com