A kind of front silver paste for crystalline silicon solar cell

A solar cell and crystalline silicon technology, applied in the field of solar cells, can solve the problems of easy burn-through, increased resistance, and reduced printing performance, and achieves good printability, improved open circuit voltage, and good printing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Metal conductive powder

[0019] Silver powder by physical method is 65%, average particle size D50 is 1.5μm, silver powder prepared by chemical method accounts for 35%, average particle size D50 is 0.8μm.

[0020] 2. Preparation of modified organic binder

[0021] Weigh 60% terpineol, 15% butyl carbitol, 12% butyl carbitol acetate, 2.5% hydrogenated castor oil, 7.5% ethyl cellulose, 1.0% coupling agent (such as KH550), 1.0% lecithin and 1.0% thixotropic agent (polyamide wax), mix evenly, and dissolve at a temperature of 120-130°C while stirring, and the time is 110-120min to obtain a transparent modified Non-toxic organic adhesives.

[0022] 3. Preparation of back silver paste

[0023] By mass percentage 86% silver powder 10.8% modified organic binder, 3.2% silicate glass powder (silicate glass powder, its mass percentage composition is SiO 2 4.3%, Al 2 o 3 0.4%, B 2 o 3 2.0%, Zn 3 (PO 4 ) 2 8.3%, BaCO 3 0.2%, MgO0.4%, TeO 2 20%, P 2 o 5 0.2%, Pb 3 o...

Embodiment 2

[0029] 1. Metal conductive powder

[0030] The silver powder prepared by physical method is 70%, and the average particle size D50 is 2.0μm, and the silver powder prepared by chemical method accounts for 30%, and the average particle size D50 is 0.8μm.

[0031] 2. Preparation of modified organic binder

[0032] Weigh 60% terpineol, 15% butyl carbitol, 12% butyl carbitol acetate, 2.5% hydrogenated castor oil, 7.5% ethyl cellulose, 1.0% coupling agent , 1.0% lecithin and 1.0% thixotropic agent; mix evenly, dissolve at a temperature of 80-100°C while stirring while heating, and the time is 60-80min to obtain a transparent modified organic adhesive.

[0033] 3. Preparation of back silver paste

[0034] According to the mass percentage of 87% silver powder, 9.8% modified organic binder, 3.2% silicate glass powder, after mixing evenly, use a three-roller grinder for 5 times to obtain a fineness ≤ 12μm, viscosity 305kcps Front silver paste.

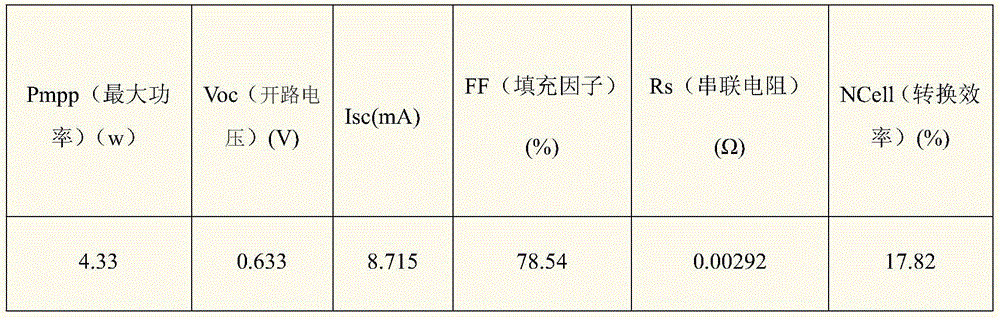

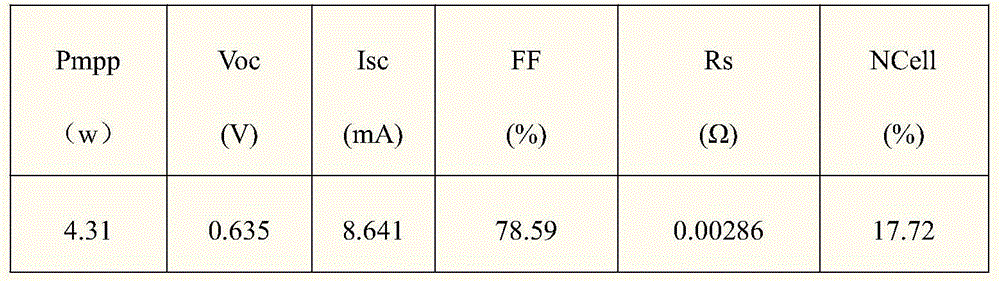

[0035] The above slurry was screen-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com