Semiconductor device, manufacturing method of the semiconductor device, and electronic device

A technology for semiconductors and devices, applied in the fields of electronic devices, semiconductor devices and preparation methods, can solve the problems of low product yield, unfavorable production costs, device failures, etc., to reduce source-drain contact resistance, save production costs, and avoid circuit failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

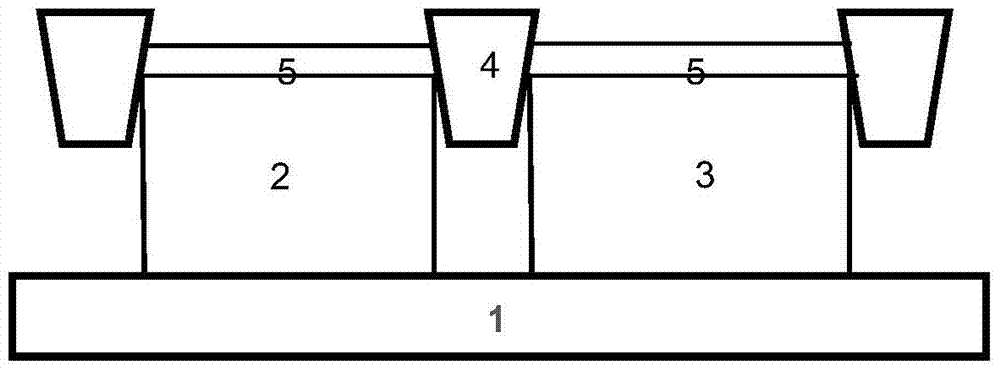

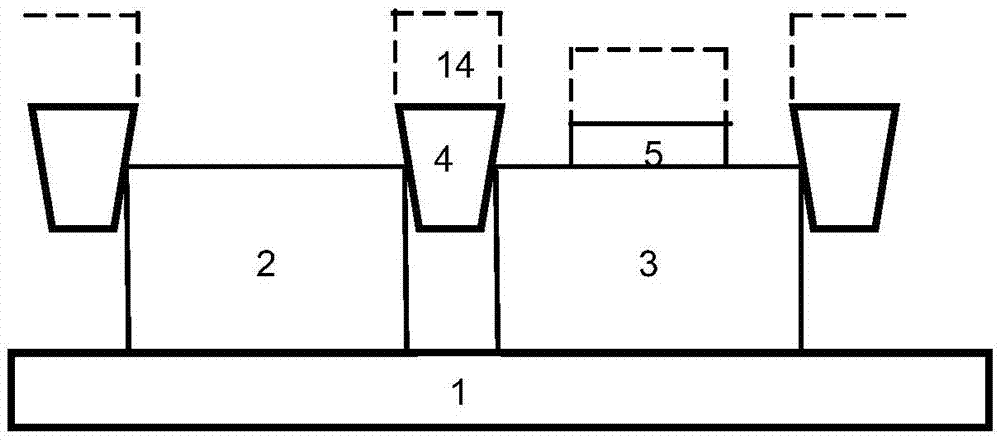

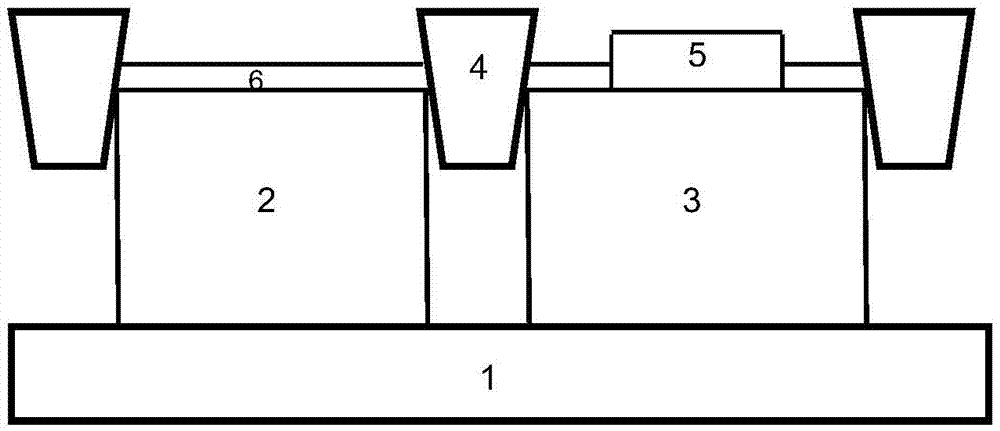

[0045] Attached below Figures 1a-1h The method for preparing the semiconductor device of the present invention is further described.

[0046] First, step 101 is performed to provide a semiconductor substrate 1 , the semiconductor substrate 1 includes a high-voltage device region 3 and a low-voltage device region 2 , and a patterned high-voltage gate oxide layer 5 is formed on the high-voltage device region.

[0047] Specifically, such as Figure 1a Said, in this step, the semiconductor substrate 1 can be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0048] In this embodiment, the material of the semiconductor substrate 1 is preferably silicon.

[0049] The semiconductor substrate 1 includes a high-voltage device region 3 and a low-voltage device region 2, a high-voltage well region and...

Embodiment 2

[0094] The present invention also provides a semiconductor device prepared by the method described in Embodiment 1. The device includes a semiconductor substrate 1, and the semiconductor substrate 1 includes a high-voltage device region 3 and a low-voltage device region 2. In the high-voltage A patterned high voltage gate oxide layer 5 is formed on the device region.

[0095] The semiconductor substrate 1 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), insulator Silicon germanium-on-insulator (SiGeOI) and germanium-on-insulator (GeOI), etc.

[0096] In this embodiment, the material of the semiconductor substrate 1 is preferably silicon.

[0097] The semiconductor substrate 1 includes a high-voltage device region 3 and a low-voltage device region 2, a high-voltage well region and a low-voltage well region are formed in the semiconductor substrate, and isolation is...

Embodiment 3

[0106] An embodiment of the present invention provides an electronic device, which includes the semiconductor device prepared by the method of Embodiment 1.

[0107] The electronic device may be selected from a personal computer, a game machine, a cellular phone, a personal digital assistant, a video camera, a digital camera, etc., but is not limited to the above-listed devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com