Heat exchanger

A heat exchanger and multi-group heat dissipation technology, applied in the field of heat exchange, can solve problems such as unreliable welding, high welding plugging of products, and increased manufacturing costs, and achieve the effects of stable heat conduction efficiency, convenient manufacturing and processing, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The core of the present invention is to provide a heat exchanger that can effectively fix the heat dissipation flat tubes and fins so that the heat transfer effect of the heat exchanger is relatively stable and reliable, the reliable life is long, and the pass rate of the manufacturing process is improved without increasing the difficulty of manufacturing and processing. .

[0042] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Since the heat exchanger is a well-known technology, the same parts as the prior art will not be repeated here, but only the differences from the prior art will be introduced.

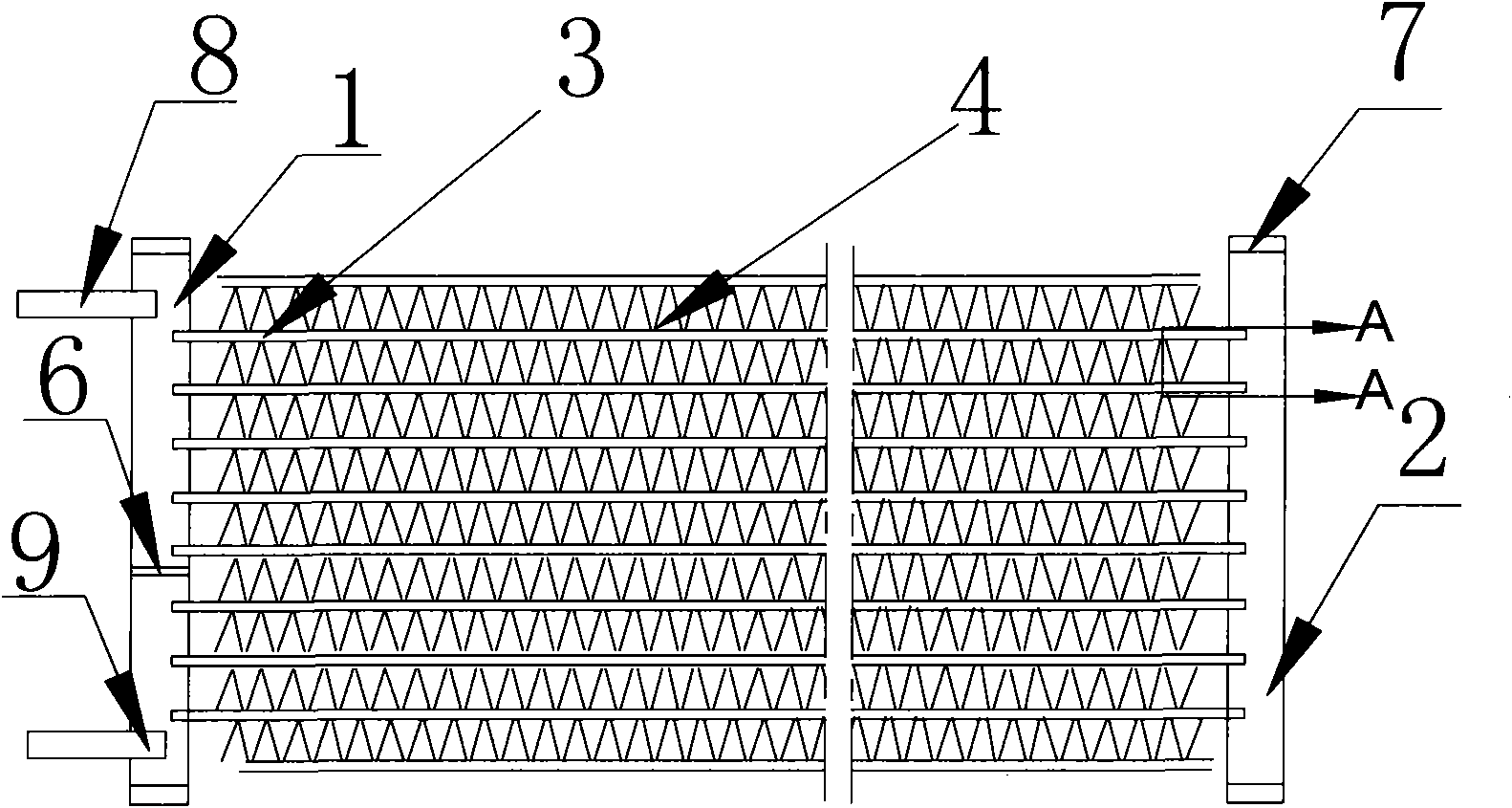

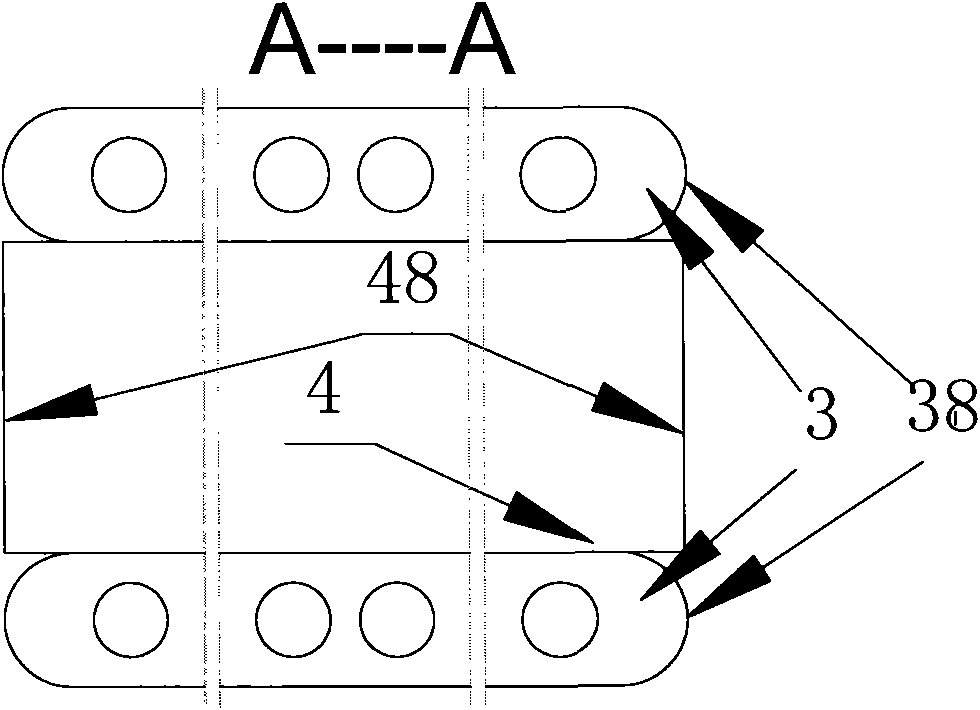

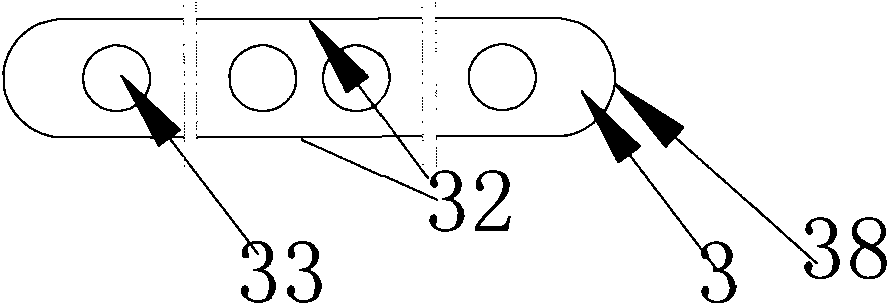

[0043] The heat exchanger generally includes headers 1 and 2 arranged on both sides of the heat exchanger, multiple sets of heat dissipation flat tubes connected to the header through the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com