Double-face welding method preventing big chip from falling off

A double-sided welding, large chip technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve problems such as poor welding, lower production efficiency and output ratio, difficult maintenance, etc., to achieve good welding effect and reliable welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

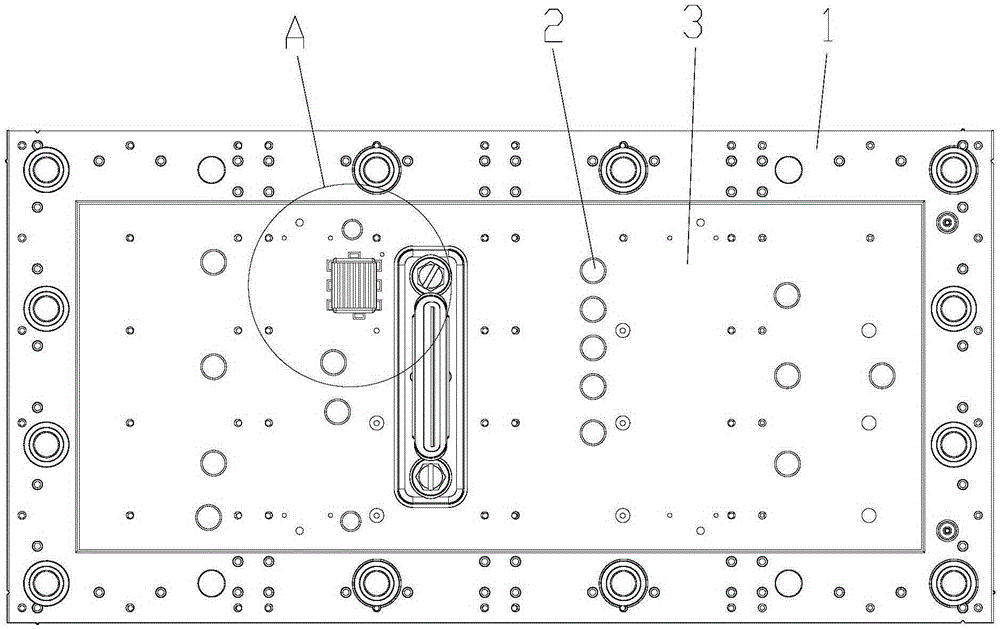

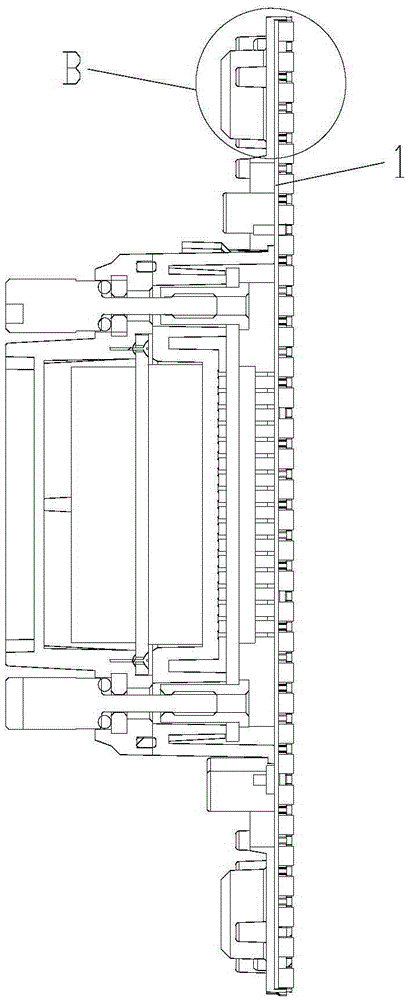

[0021] as attached Figure 1-5 The shown double-sided welding method for preventing large chips from coming off of the present invention comprises the following steps:

[0022] (1) Surface pretreatment: copper plating is carried out on the surface of the printed circuit board 1;

[0023] (2) Welding of the driving surface: lead-free soldering is selected, and various components 2 are welded on the driving surface 3 of the printed circuit board 1;

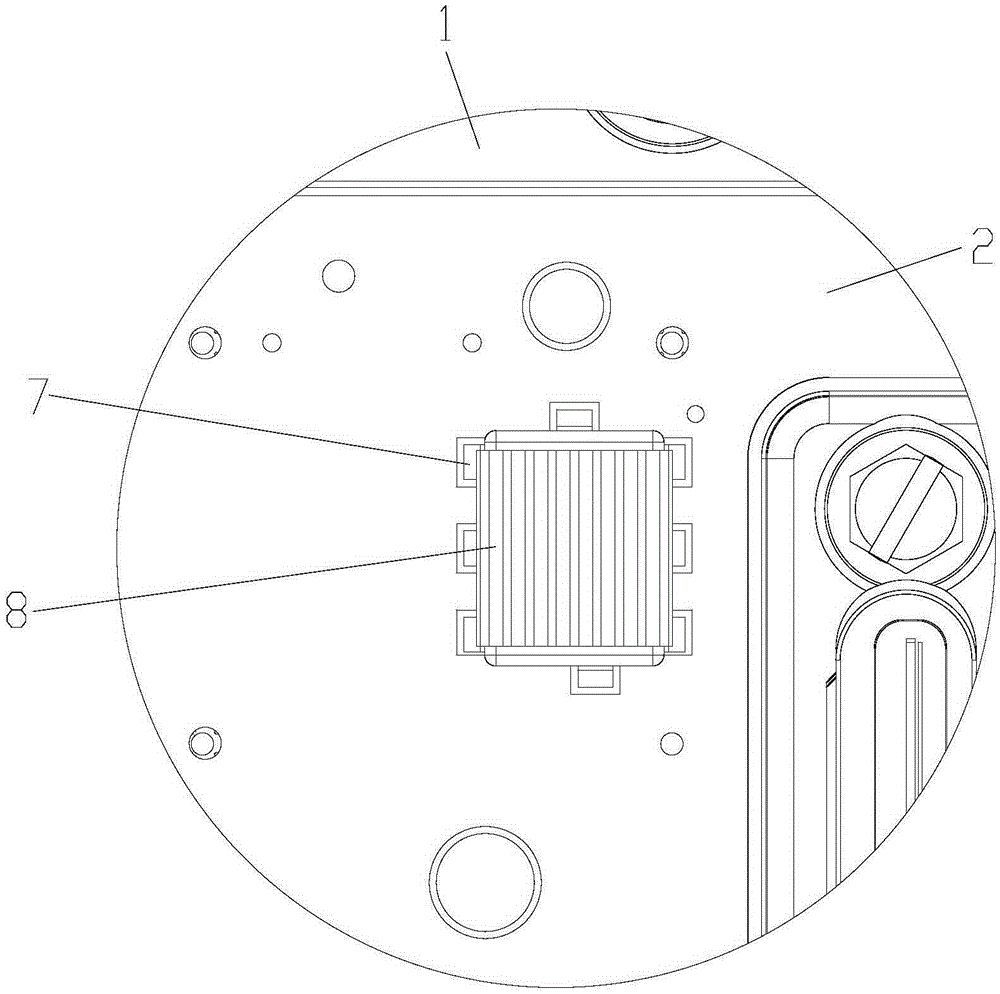

[0024] (3) BGA chip reinforcement: After welding the driving surface 3, dot red glue on the side of the BGA chip 4 for reinforcement;

[0025] (4) Welding of the light-emitting surface: lead welding is selected, and the light-emitting tube 5 is welded on the light-emitting surface 6 of the printed circuit board 1;

[0026] (5) Welding metal shielding case: increase metal shielding case 7 outside BGA chip 4, and metal shielding case 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com