Box opening robot anti-paper-box-falling-off device

A technology of robots and robot bases, applied in packaging, conveyors, conveyor objects, etc., can solve problems such as affecting the normal production of downstream processes, falling off cartons, and affecting product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

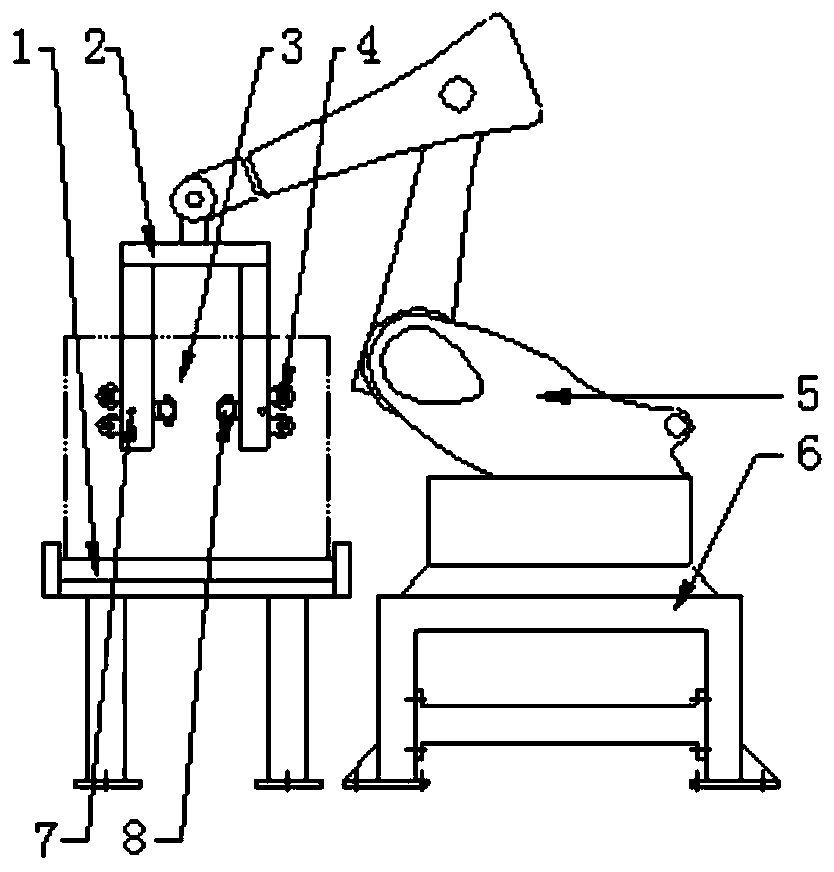

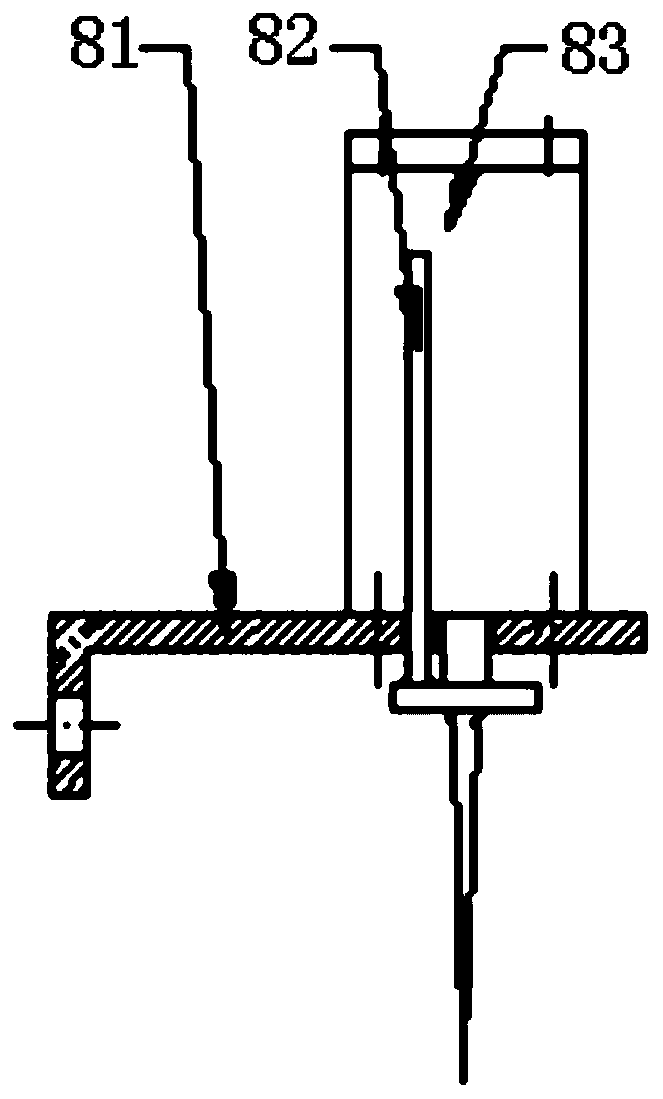

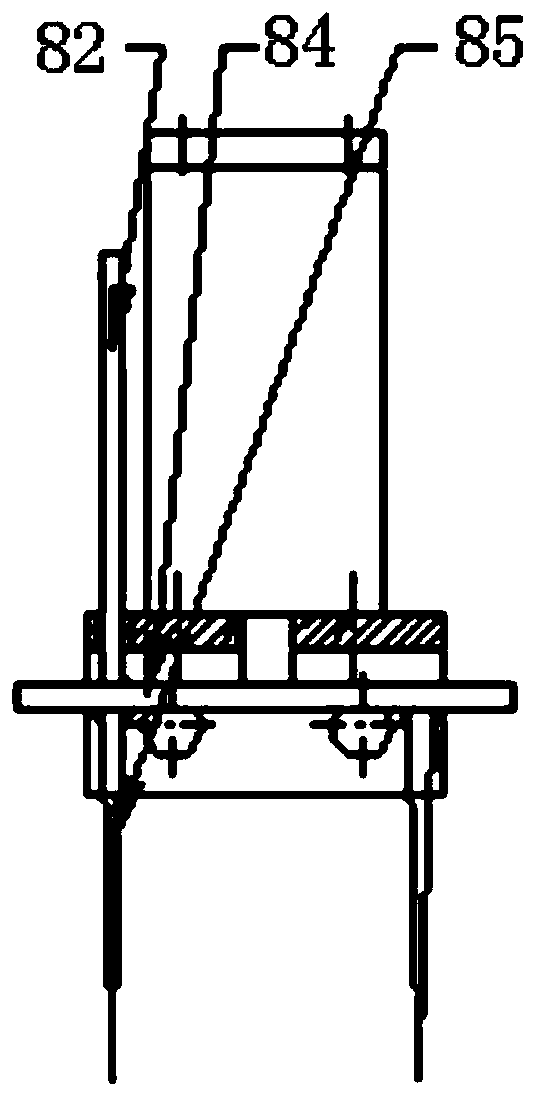

[0026] Such as figure 1 As shown, the application provides an anti-carton drop-off device for an unpacking robot. The robot base 6 is installed on the ground or the reference plane of the production workshop, and the robot 5 for clamping the carton 3 is installed on the robot base 6. Two big jaws 2, when the two big jaws move relatively, are used to realize the clamping of the carton, and through the photoelectric switch 7 arranged on the big jaws, it is realized whether there is a carton between the two big jaws, so as to Start the robot to perform the clamping action. At the same time, when the carton is clamped, the photoelectric sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com