Room-temperature plasma torch array device simultaneously carrying out fiber yarn modification and sewage treatment

A plasma torch and sewage treatment technology, applied in fiber treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of small plasma torch area, easy cracking of the medium layer, and burnt materials, etc., to achieve Avoid medium rupture, accelerate degradation speed, and prolong working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

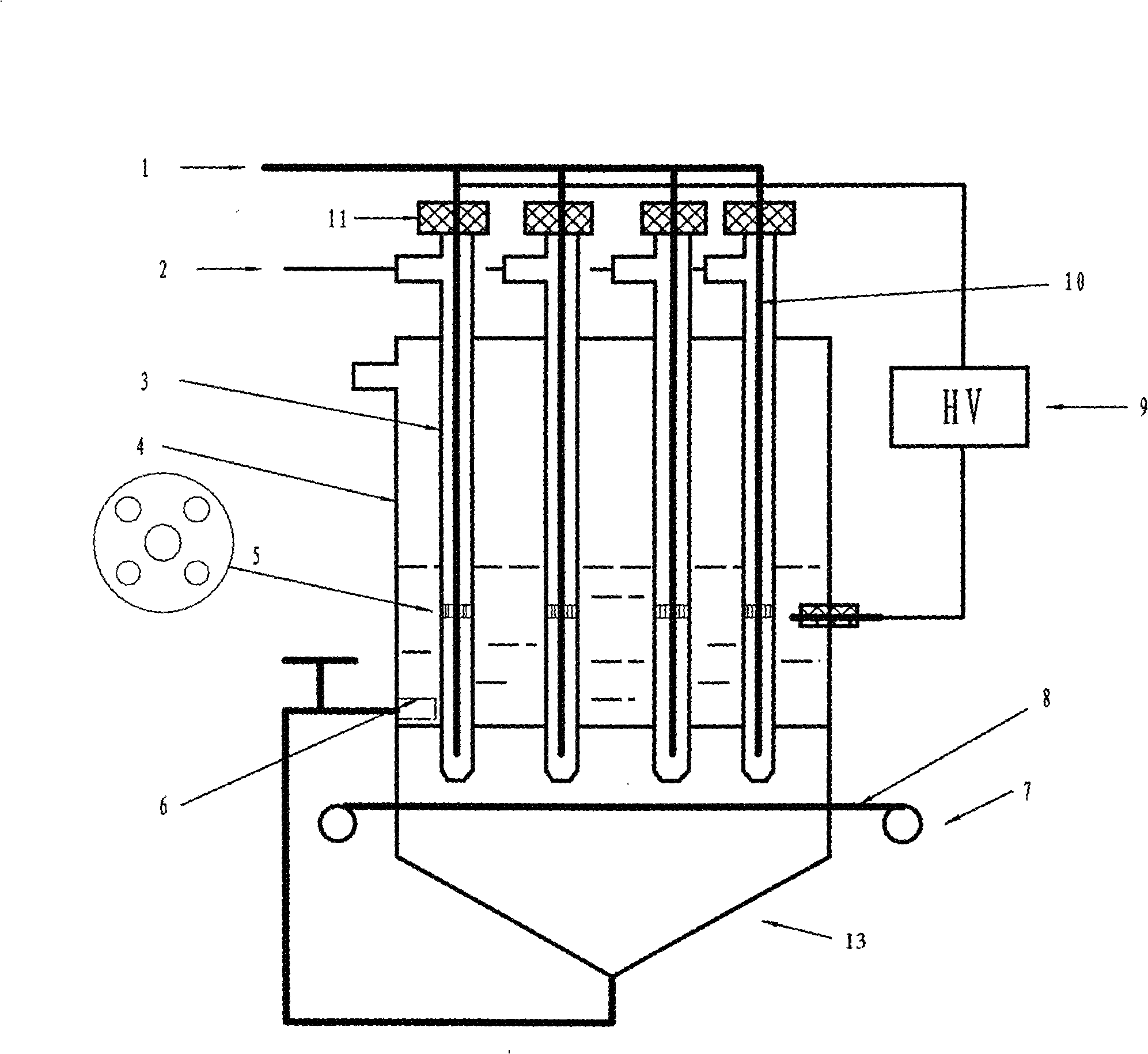

[0014] As shown in the drawings, the present invention contains a conductive aqueous solution electrode 12 in a machine glass water tank 4, and a plurality of rows of quartz tubes 3 with built-in tubular metal electrodes 10 are inserted into the conductive aqueous solution electrode 12, and one end of the quartz tube 3 passes through the machine glass. The bottom of the water tank 4 enters the modification chamber 13, and the other end of the quartz tube 3 is exposed to the organic glass water tank 4, which is sealed with a polytetrafluoroethylene sleeve 11, and the tubular metal electrode 10 passes through the polytetrafluoroethylene sleeve 11 to communicate with the active gas source 1, and the quartz tube 3 is communicated with the inert gas source 2, the bottom of one end of the quartz tube 3 is tapered and has a through hole, and the modification ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com