A kind of hot-dip galvanized high-strength steel with excellent fe-al alloy layer characteristics and its manufacturing method

A manufacturing method and hot-dip galvanizing technology, which are applied in the plating of superimposed layers, hot-dip plating process, metal material coating process, etc., can solve the problems of unevenness, lack of Fe-Al alloy layer, discontinuity, etc. Increase the content, improve the effective contact, and facilitate the formation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the embodiments and accompanying drawings.

[0035] Table 1 is the composition of the hot-dip galvanized steel sheet according to the present invention. Table 2 shows the annealing process of the hot-dip galvanized steel sheet according to the present invention, and the properties of the hot-dip galvanized steel sheet.

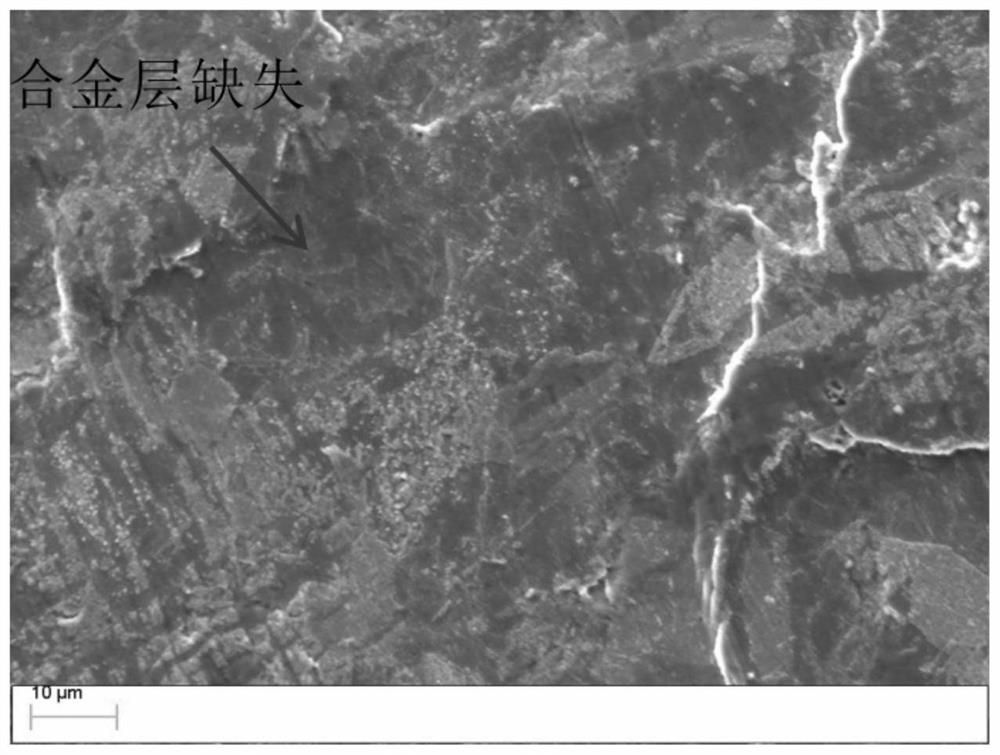

[0036] figure 1 It is a scanning electron microscope image of the surface of the Fe-Al alloy layer at the leakage plating defect of the hot-dip galvanized direct annealing without pre-plating Fe treatment in Comparative Example 1. Depend on figure 1 It can be seen that the Fe-Al alloy layer is discontinuous and missing in a large area.

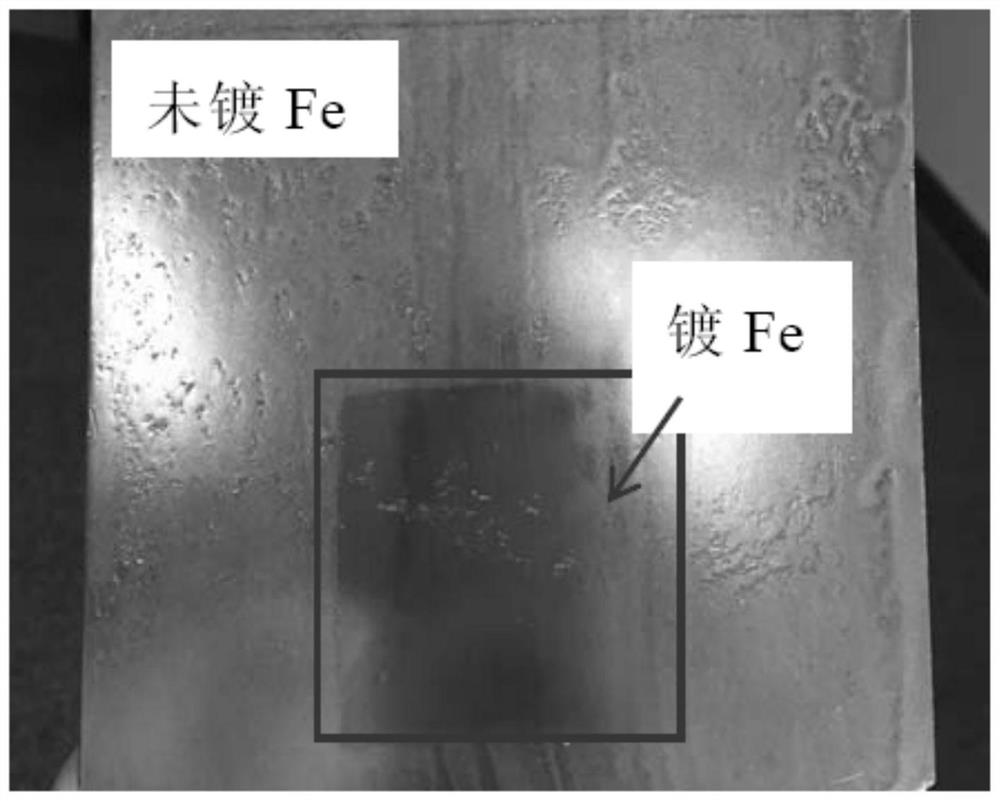

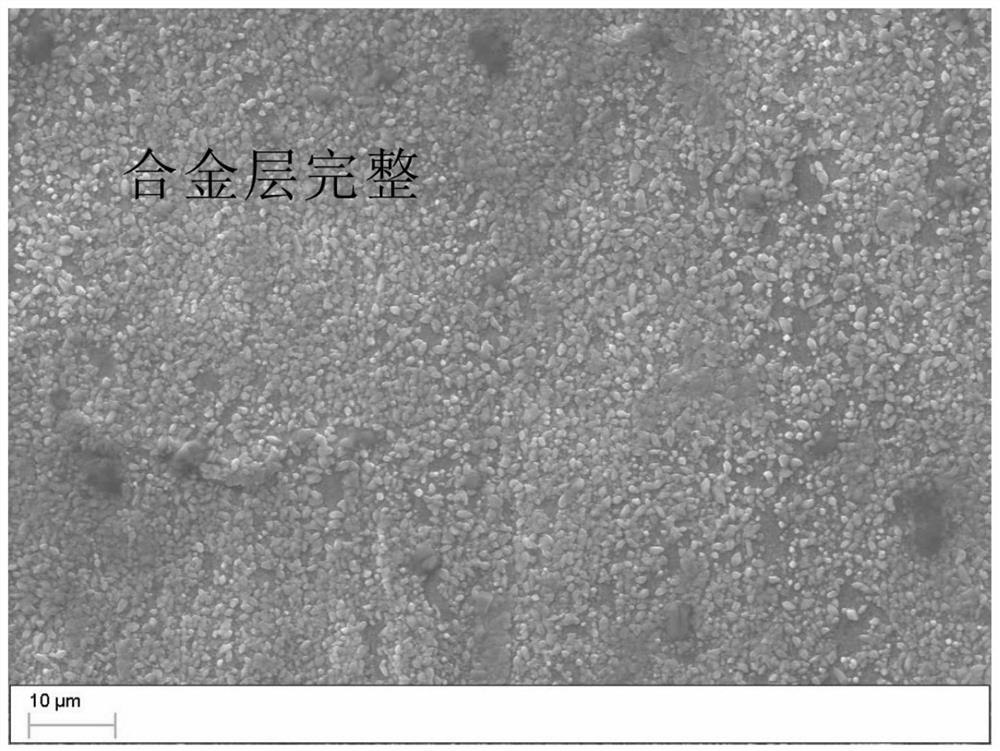

[0037] figure 2It is the appearance of the galvanized sheet after pre-plating Fe treatment in Example 2. Compared with the part without pre-plating Fe treatment, it can be found that the surface quality of hot-dip galvanizing after Fe coating i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com