A kind of preparation method of patterned fine conductive film

A conductive film and patterning technology, applied to the conductive layer on the insulating carrier, etc., can solve the problems of limited application fields, non-green and environmentally friendly etching process, and complicated processing process of the forming layer, so as to simplify the production process and low production efficiency , high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Narrow frame touch screen.

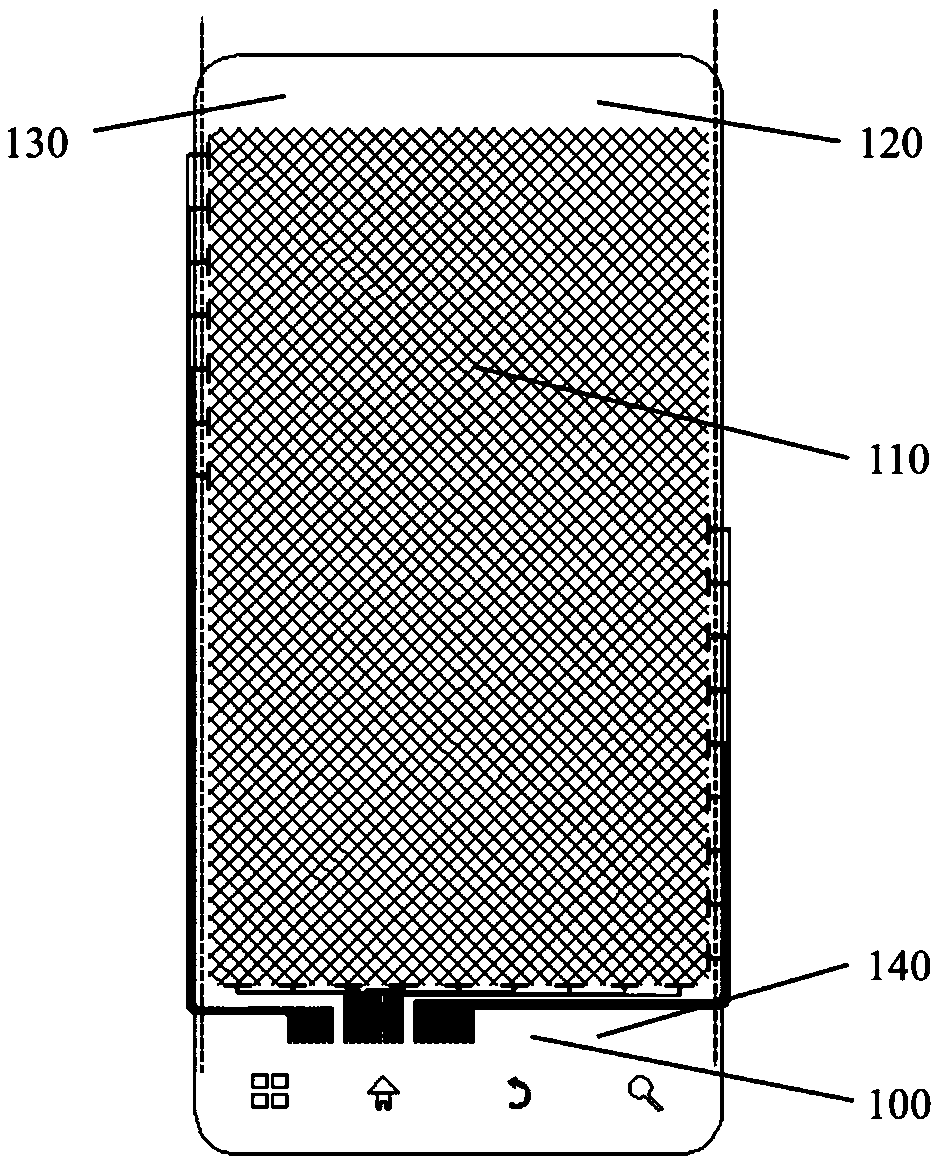

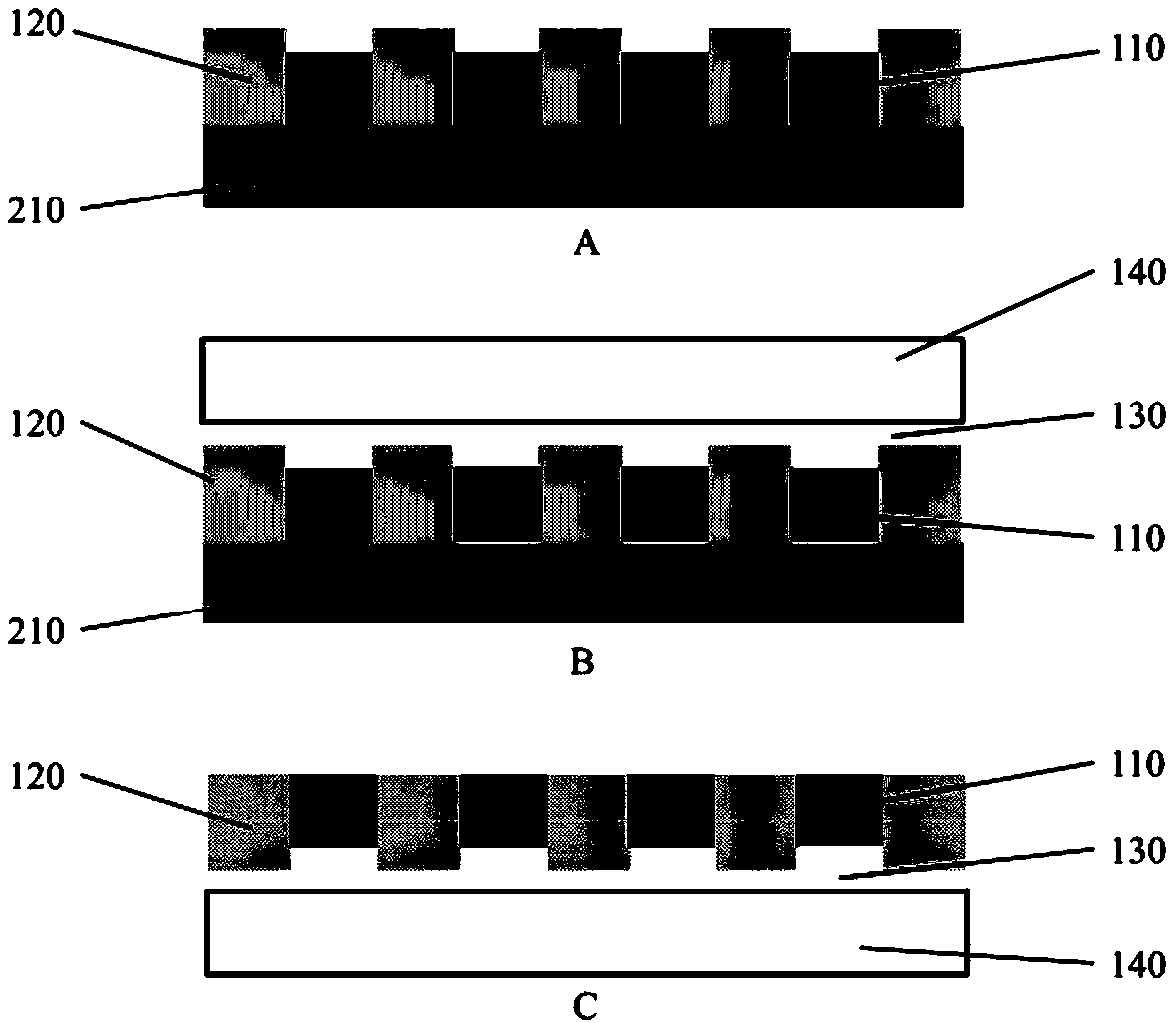

[0063] 1. Structure

[0064] refer to figure 1 , the narrow frame touch screen in the preferred embodiment of the present invention includes a glass panel 100 , a pattern electrode 110 , an adhesive layer 120 , a cured adhesive layer 130 and a substrate layer 140 . The main part of the pattern electrode 110 is composed of a square grid, the thickness h of the grid is 1.5 microns, the line width d is 1.5 microns, and the side length of the grid square is 100 microns, which is composed of electrodeposited nickel wires. The pattern electrode 110 has a half-width of 1.5 microns and can be folded back to form a narrow frame touch screen. The glue layer 120 is an ultraviolet curable glue with a thickness of 1.8 microns. The cured glue layer 130 is a heat-curable or light-curable glue, and the material can be selected to be the same as that of the glue layer 120 . The substrate layer 140 can be a PET film with a light transmittance...

Embodiment 2

[0070] Embodiment 2, TFT array gate and storage capacitor in high-resolution LCD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com