Fine-grained high carbide cast iron alloys

a high carbide, cast iron alloy technology, applied in the field of cast iron alloys, can solve problems such as done at the expense of toughness, and achieve the effect of increasing wear resistance and similar toughness levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

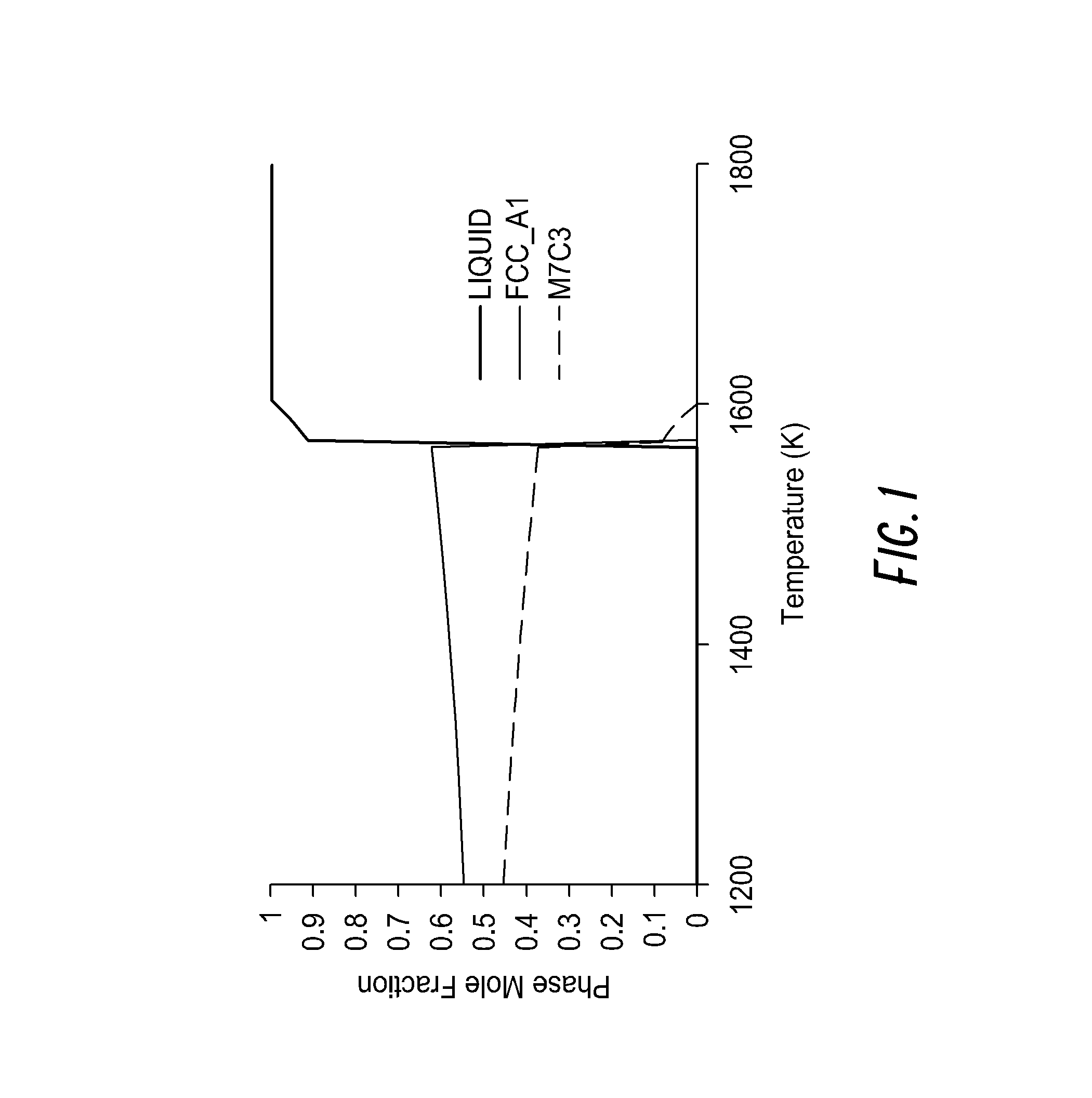

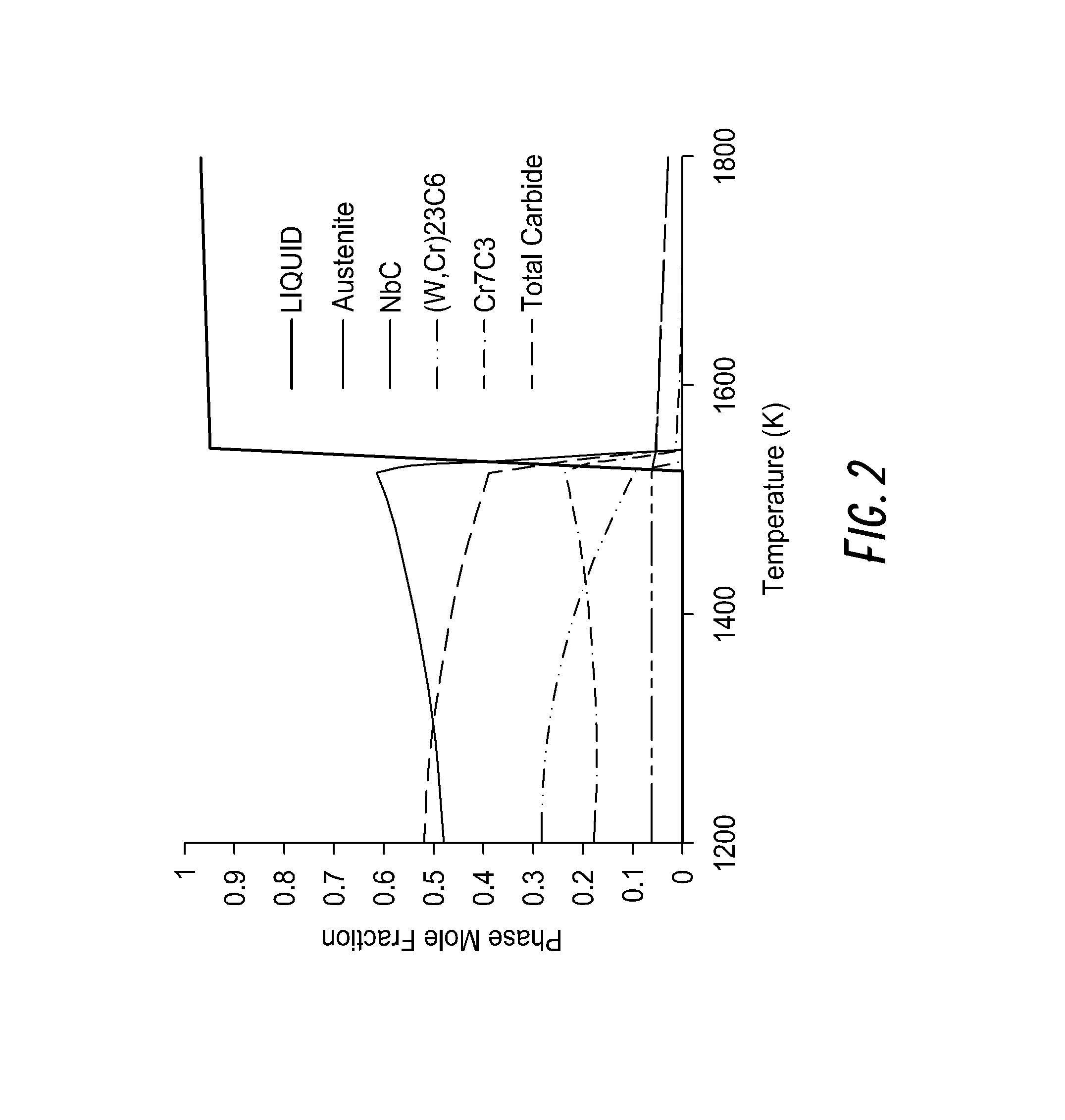

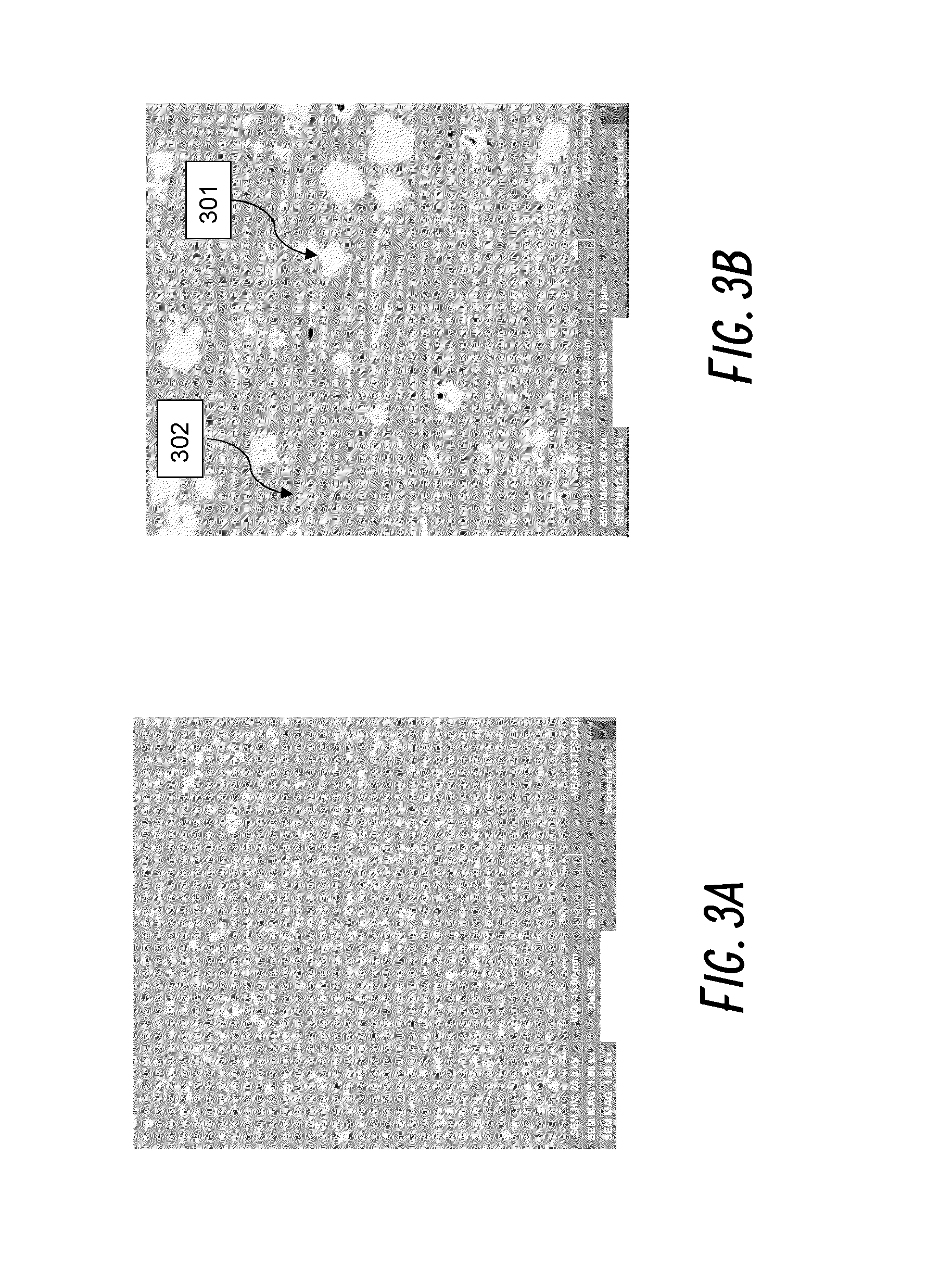

[0056]Disclosed herein is an alloy material, such as an alloy containing Fe, C and Cr, having high carbide contents, as well as a method of increasing carbide content in an alloy. Generally as either Cr or C is increased, the alloy is pushed towards increased amounts of primary, or eutectic, chromium carbide fractions, so embodiments of the disclosed alloys may fall within the group known as chromium white irons. In some embodiments, the disclosed alloys can be “iron based,” indicating that they have a composition that is predominantly iron, e.g., at least 50 wt. % iron. Also disclosed herein are different criteria that can be used for producing a high carbide content alloy. Thermodynamic, microstructural, and compositional criteria could be used to produce such an alloy. In some embodiments, only one of the criterial can be used to form the alloy, and in some embodiments multiple criteria can be used to form the alloy. As disclosed herein, the term alloy can refer to the chemical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt temperature | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com