Manufacturing method of polarization-independent optical isolator, bonding technology and solution of optical components

An optical isolator and manufacturing method technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increasing the O-light and E-light beam walk away, limiting the scope of use and service life, and unable to meet mass production. , to achieve the effect of improving the use range and service life, high parallelism accuracy, and reducing the interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Bonding solution preparation: take an appropriate volume of sodium silicate aqueous solution, the composition of the sodium silicate aqueous solution is 10% NaOH and 25% SiO by weight 2 , and then take 2 parts of deionized water and sodium silicate aqueous solution according to the volume ratio, mix and shake well, and then filter it with a microporous membrane filter smaller than 0.2 microns.

Embodiment 2

[0048] Bonding solution preparation: take an appropriate volume of sodium silicate aqueous solution, the composition of the sodium silicate aqueous solution is 14% NaOH and 30% SiO by weight 2 , and then take 6 parts of deionized water and sodium silicate aqueous solution according to the volume ratio, mix and shake well, and then filter it with a microporous membrane filter smaller than 0.2 microns.

Embodiment 3

[0050] Bonding solution preparation: take an appropriate volume of sodium silicate aqueous solution, the composition of the sodium silicate aqueous solution is 12% NaOH and 28% SiO by weight 2 , and then take 5 parts of deionized water and sodium silicate aqueous solution according to the volume ratio, mix and shake well, and then filter it with a microporous membrane filter smaller than 0.2 microns.

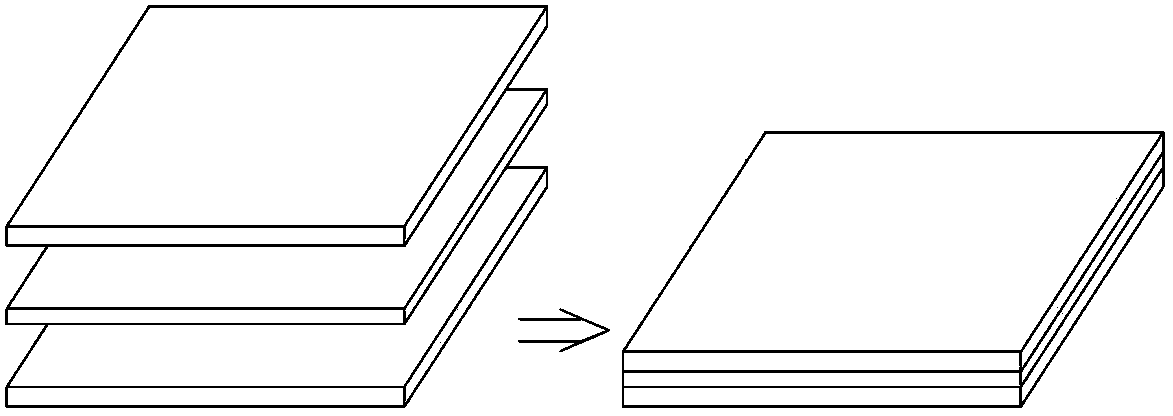

[0051] 2. Bonding process of optical parts

[0052] The process is a hydrogen-oxygen catalytic bonding process, which uses the hydrogen-oxygen catalytic bonding process to bond the various optical components into one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com