Touch screen and panel display module integrated combination module and method for producing the same

A flat-panel display and manufacturing method technology, which is applied in the manufacture of semiconductor/solid-state devices, static indicators, electric solid-state devices, etc. The effect of improved light transmittance and thin overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

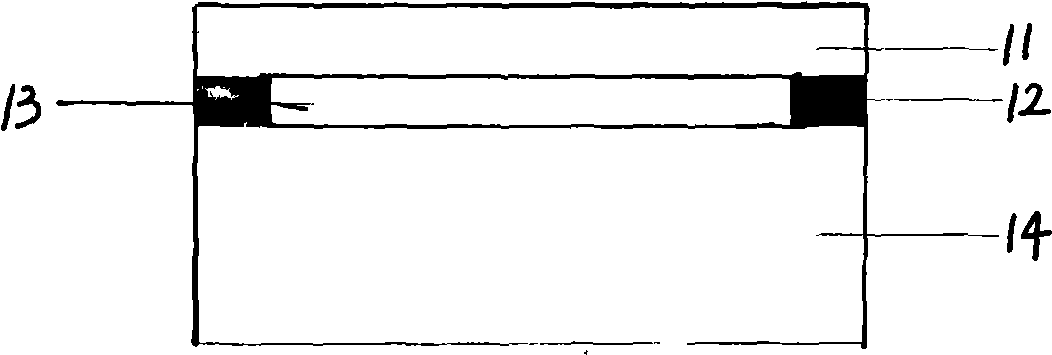

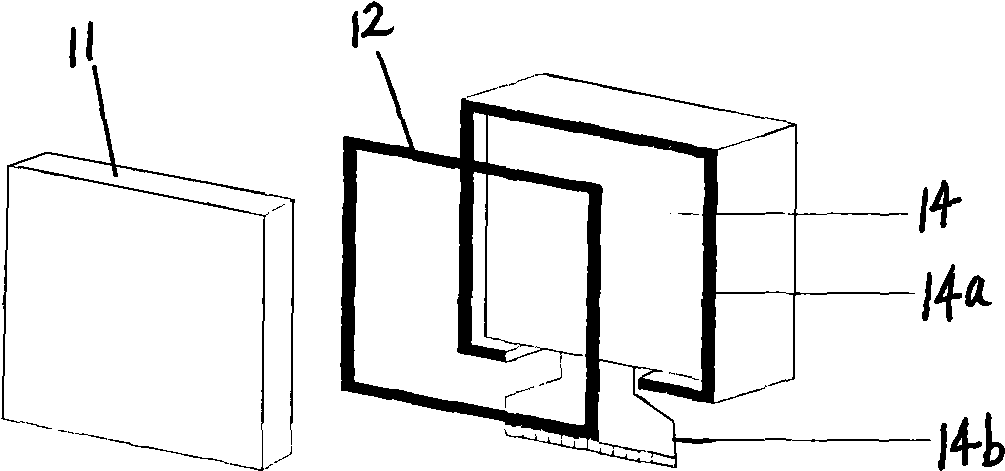

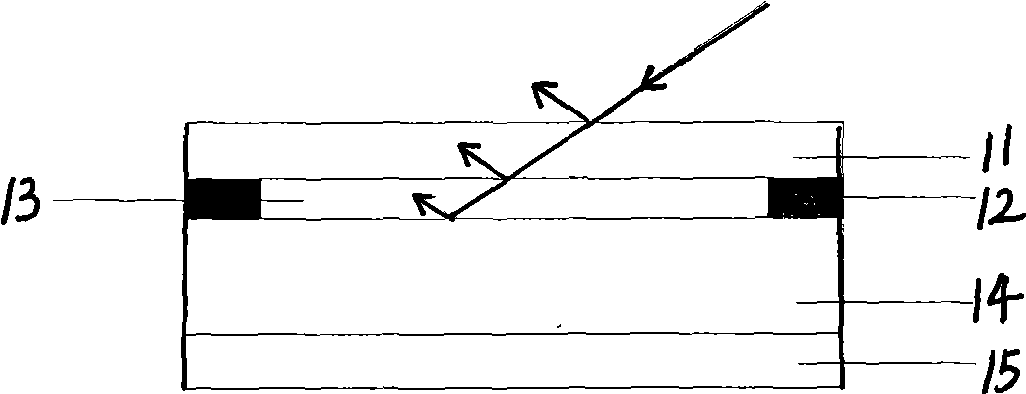

[0037] Such as Figure 5 to Figure 7 The shown touch screen and flat panel display module integrated combination module includes a touch screen 21, a flat panel display module 23 and an intermediate adhesive layer for bonding the touch screen and the flat panel display module. The touch screen 21 adopts a resistive touch screen, and the flat panel display module 23 is Liquid crystal display module, the middle bonding layer is optical adhesive layer 22, and its thickness is 100 microns, and optical adhesive layer 22 completely covers the viewing area of touch screen 21, and is equal to the external dimension of touch screen 21, and the refractive index of optical adhesive layer 22 and touch screen 21 It is the same as the refractive index of the interface of the flat panel display module 23 .

[0038] Such as Figure 5 As shown, when light enters the integrated module from the outside, because the touch screen 21, the optical adhesive layer 22 and the flat panel display modu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com