Sliding vane switch valve for AB glue volume metering type dispensing

A technology for switching valves and sliding valves, which is applied in the direction of multi-way valves, valve devices, and devices for coating liquid on the surface. The effect of line continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Example.

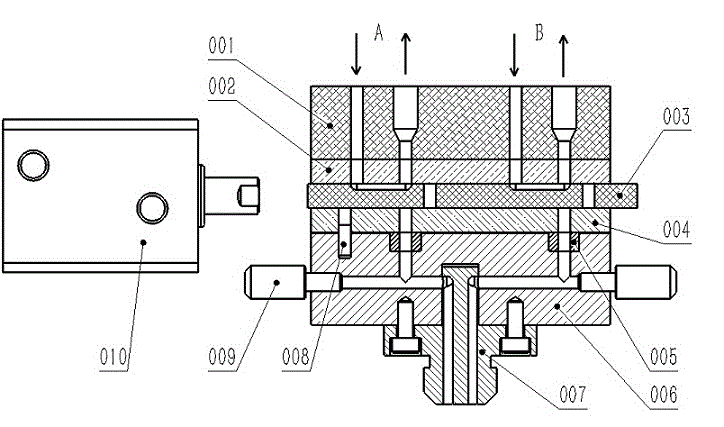

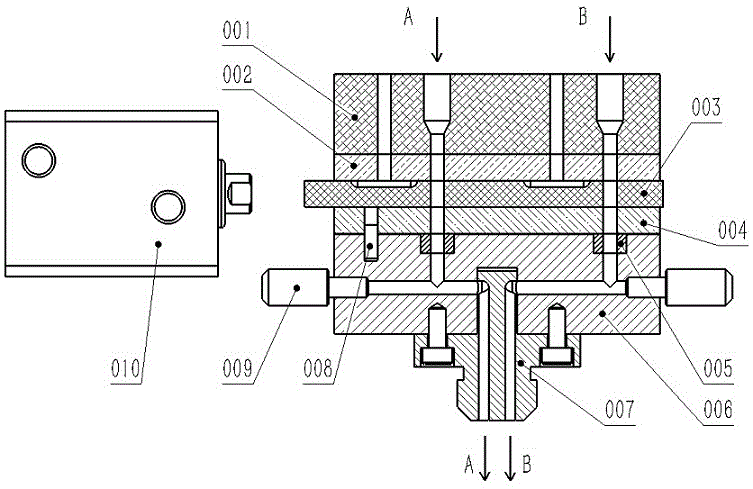

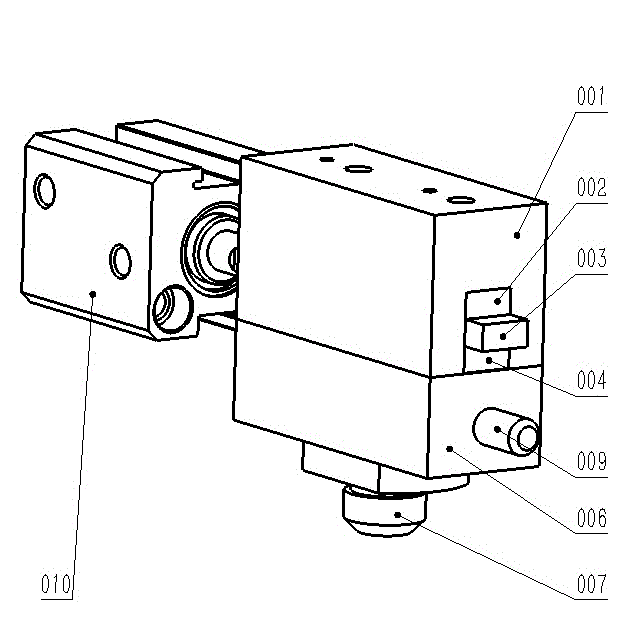

[0014] see figure 1 , figure 2 , image 3 , the valve seat 001 is processed with A glue inlet, A glue cavity, B glue inlet, B glue cavity and the groove for installing the valve plate; the upper valve plate 002 is fixed on the bottom of the valve seat groove with AB glue , so as to eliminate gaps and prevent glue leakage, the four holes on the upper valve plate 002 correspond to the four holes on the valve seat 001 one by one, and the hole diameters are consistent; the switching valve plate 003 has a groove surface and pastes the valve plate 002, and the direction cannot be changed. Wrong; one side of the lower valve plate 004 is attached to the surface of the switching valve plate, and the direction cannot be wrong; two sealing rings 005 are placed in the holes of the slide valve fixing plate 006, and the surface should protrude t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com