Unsaturated polyester glass fibre cloth laminated board and preparation method thereof

A technology of polyester glass fiber and glass fiber cloth, which is applied in the field of layered products and its preparation, and can solve the problems of low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

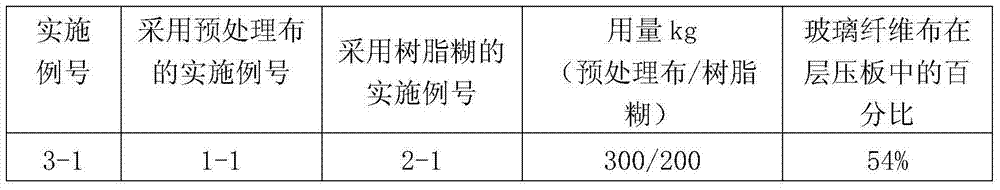

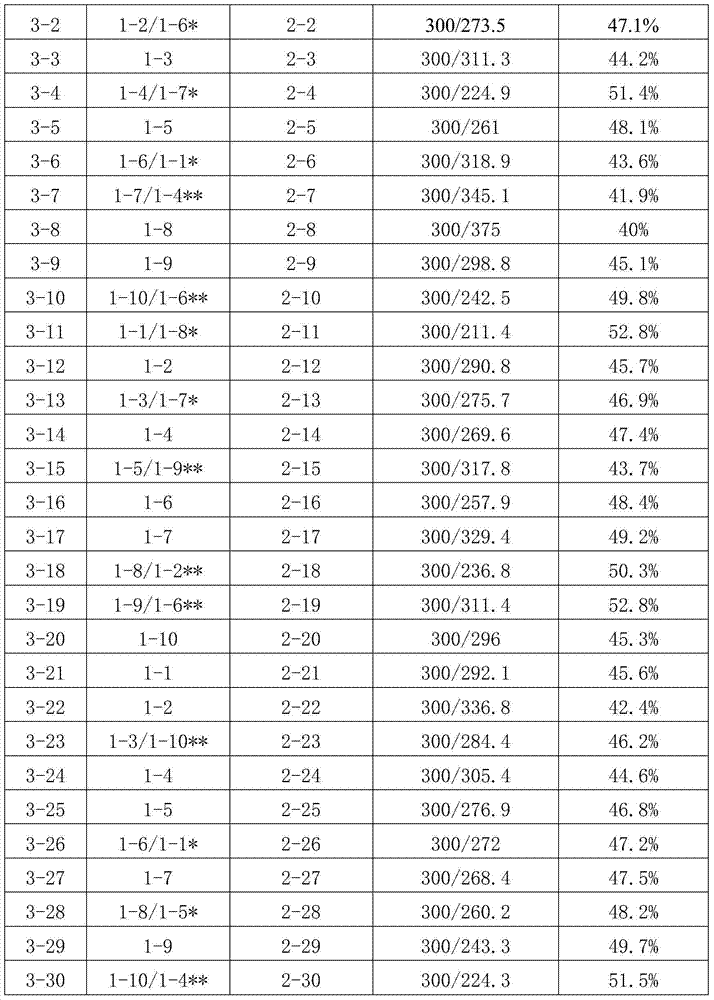

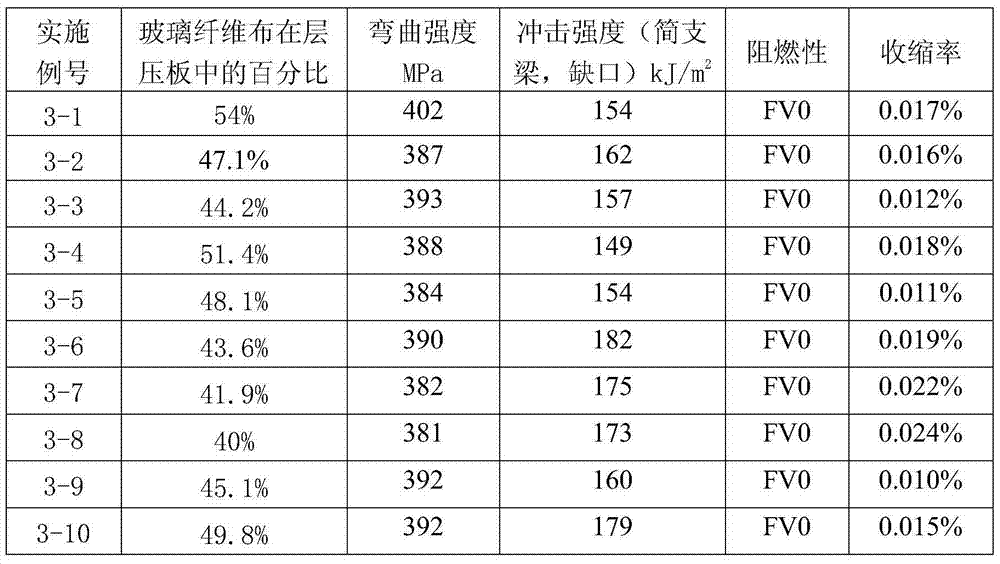

Examples

preparation example Construction

[0054] Preparation of the first part of the pretreatment cloth

[0055] Raw materials used:

[0056] 50%~52% styrene solution of isophthalic or orthophthalic or mixed isophthalic and orthophthalic unsaturated polyester resin with a viscosity of 1300~1600mPa·S, 70% styrene solution of saturated polyester resin , 40% polyvinyl acetate styrene solution, non-alkali plain glass fiber cloth, non-alkali twill glass fiber cloth, and benzopinacol silyl ether are all general-purpose chemical products purchased on the market.

Embodiment 1-1

[0058] 540kg non-alkali plain glass fiber cloth is squeezed and dip-coated from 45kg of styrene solution of 50% o-phthalic unsaturated polyester resin with a viscosity of 1300mPa·S, 8kg of 70% of viscosity of 600-1000mPa·S The styrene solution of saturated polyester resin, the styrene solution of 6kg40% polyvinyl acetate and the glue solution that 1kg benzopinacol silyl ether are formed, make 600kg pretreatment cloth.

Embodiment 1-2

[0060] Squeeze and dip 540kg non-alkali plain glass fiber cloth through the glue solution, from 45kg of styrene solution of 51% isophthalic unsaturated polyester resin with viscosity of 1600mPa·S, 8kg of 70% saturated polyester resin with viscosity of 600~1000mPa·S 600kg of pretreated cloth is made of a styrene solution of type polyester resin, 6kg of 40% polyvinyl acetate styrene solution and 1kg of benzopinacol silyl ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com