Automobile interior decoration substrate

A technology for automotive interiors and substrates, which is applied to vehicle parts, layered products, transportation and packaging, etc., and can solve problems such as bubbles and wrinkles in automotive interior substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

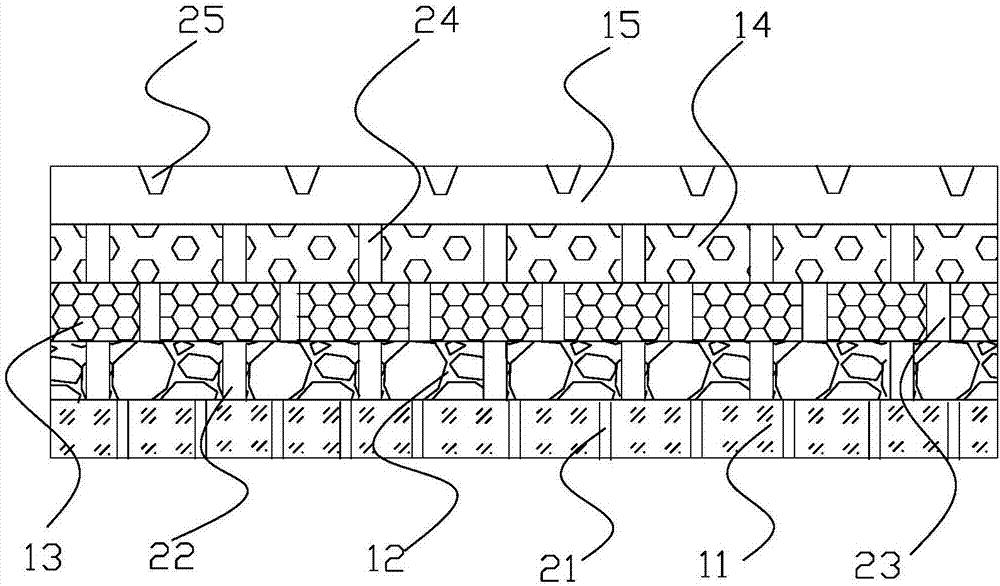

[0015] Please refer to figure 1 and figure 2 As shown, the present embodiment provides an automobile interior trim substrate 10, comprising a fiberboard 11 and a skin 15 located on the fiberboard 11, and a sponge 13 is arranged between the fiberboard 11 and the skin 15, and the fiberboard 11 A membrane body 12 is arranged between the sponge 13, a cloth body 14 is arranged between the sponge 13 and the skin 15, and a plurality of first through holes 21 are arranged on the fiberboard 11, and the membrane body 12 is provided with a plurality of second through holes 21, the sponge 13 is provided with a plurality of third through holes 23, the cloth body 14 is provided with a plurality of fourth through holes 24, and the skin 15 is provided with A plurality of grooves 25, wherein the second through hole 22 is located between the adjacent first through holes 21, the third through hole 23 is located between the adjacent second through holes 22, the The fourth through hole 24 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com