An intelligent flow-type molding system for shoe soles

A flow-through, cabinet technology, applied in home appliances, other home appliances, household components, etc., can solve problems such as low production efficiency, improper operation of employees, and operational errors, so as to shorten the time of transfer, improve production efficiency, and ensure customer service safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

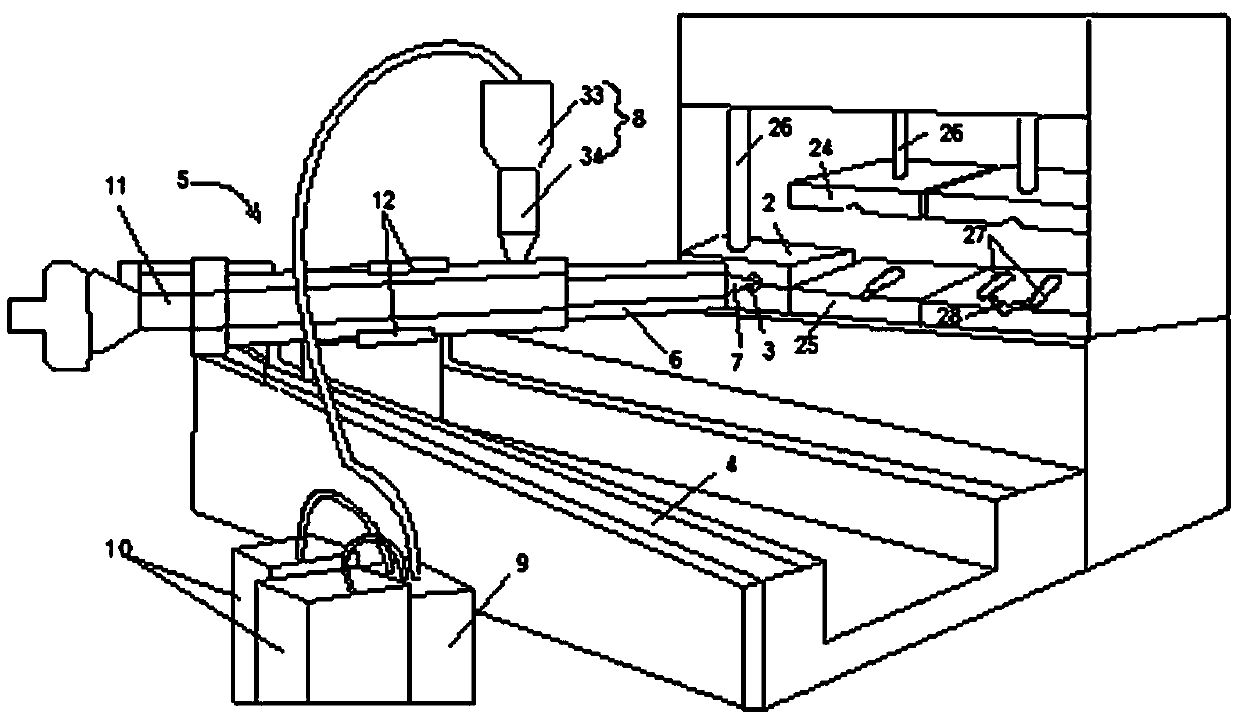

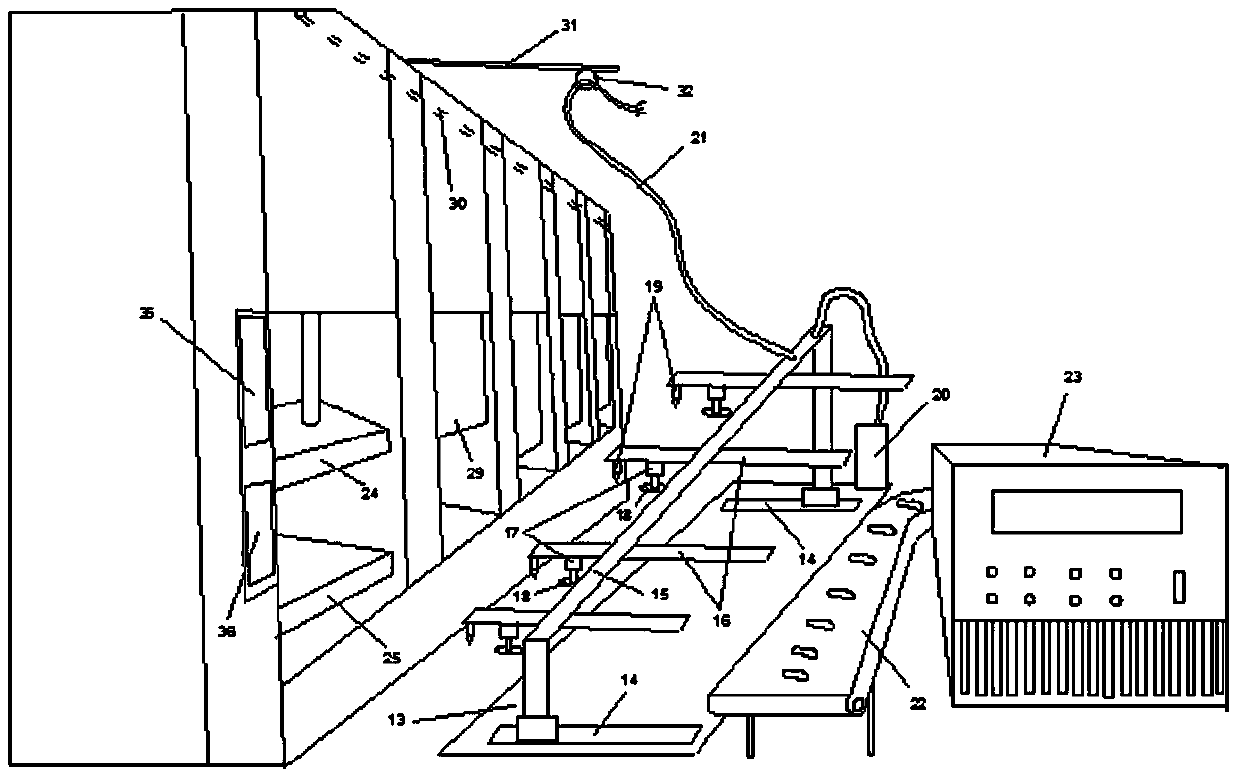

[0024] See figure 1 and figure 2 , the present embodiment provides an intelligent flow-type molding system for shoe soles, which is characterized in that: it includes a shoe sole extrusion cabinet 1, and a shoe sole extrusion mold 2 driven by a cylinder is arranged inside the shoe sole extrusion cabinet 1; The pressing die is provided with a rubber extrusion hole 3; the front side of the sole extrusion cabinet is provided with a concave track bed 4, and the concave track bed 4 is provided with an extrusion device that moves left and right relative to the sole extrusion cabinet 1 5. The extrusion device includes a heating unit 6, the discharge end of the heating unit is a tapered extrusion head 7, which is used to insert the rubber into the extrusion hole 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com