Preparation of TiO2/graphene/nano silver compound photocatalyst and degradation of formaldehyde thereby

A composite light and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of inability to obtain particle size silver nanoparticles, no silver particles Diameter size, different structure of silver nanoparticles, etc., to achieve good photodegradation effect, improve efficiency, and broaden the absorption range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-5

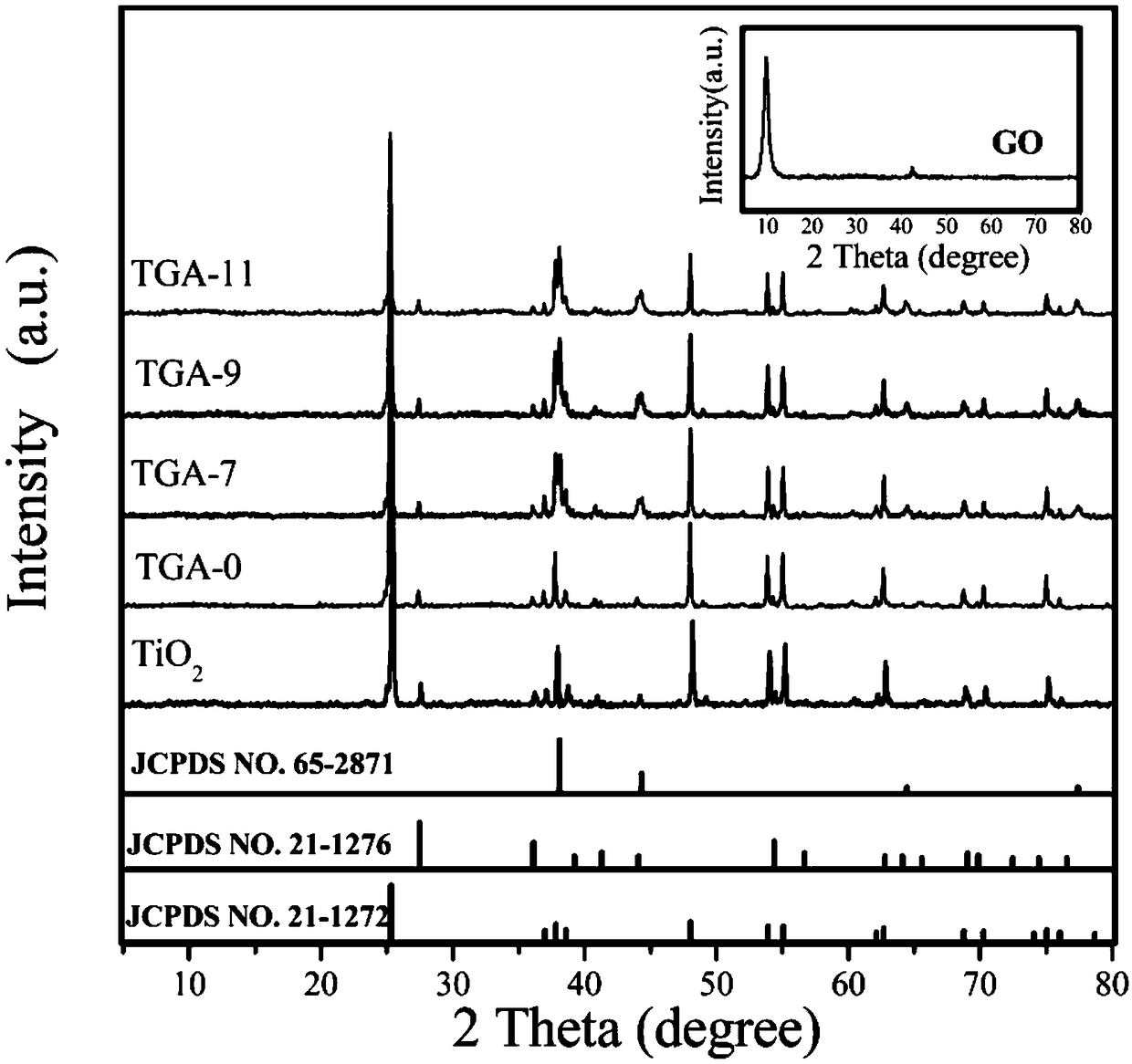

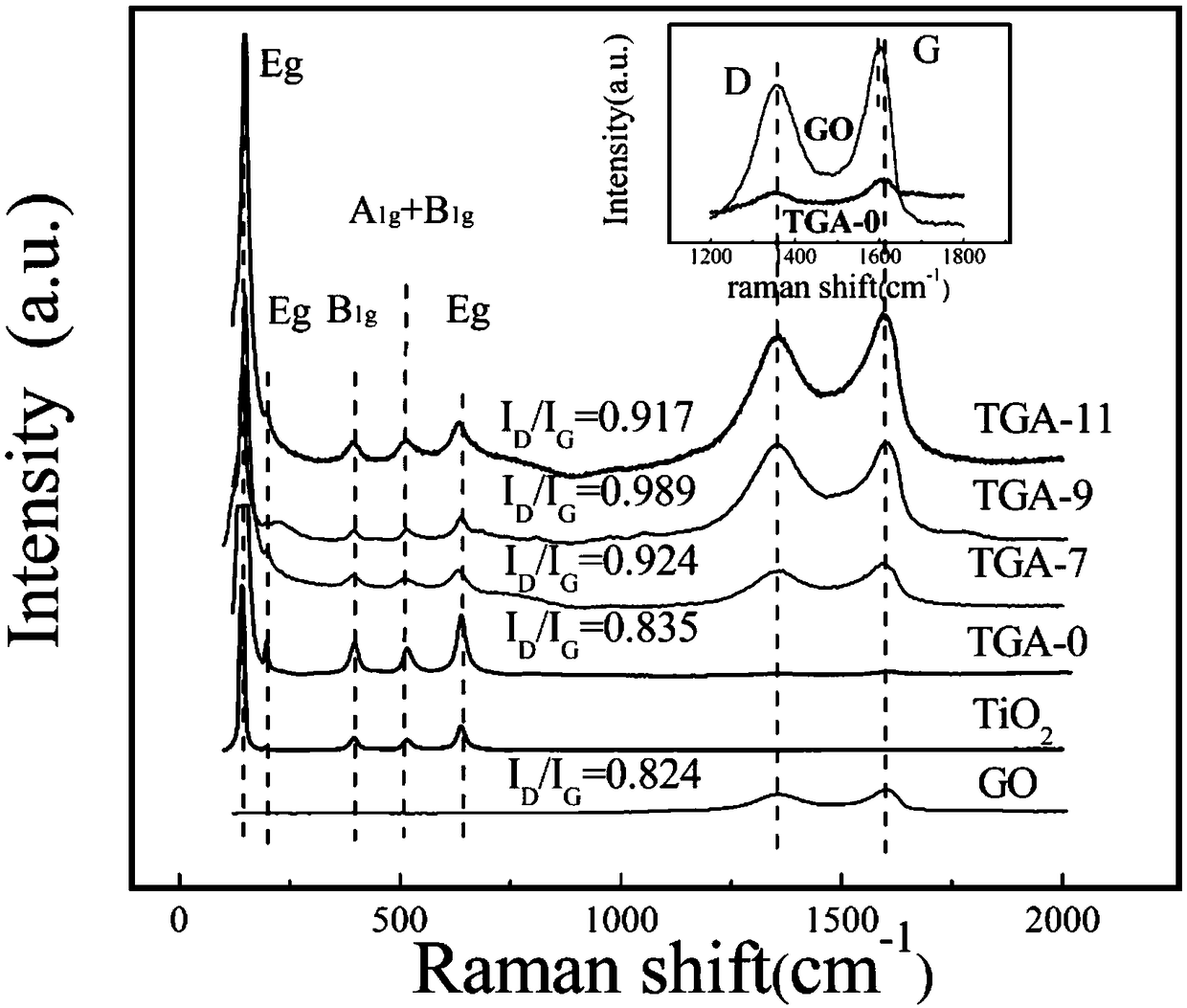

[0044] GO (graphene oxide is added in the deionized water of 20ml, ultrasonically forms GO aqueous dispersion; TiO is added in the GO aqueous dispersion that has been made, magnetic stirring forms homogeneous mixture; Silver nitrate solution (concentration is 0.025mol / L ) and anhydrous sodium citrate are added in the above mixture, fully stirred; then the mixture is transferred to a hydrothermal kettle, sealed, heated to a certain temperature, reacted for several hours, and then cooled to room temperature. Adopt ethanol and water to wash 3 times respectively, Dry at 70°C to obtain a TiO2-GO-Ag catalyst named TGA. The following table lists the specific raw material composition and reaction conditions of Examples 1-5.

[0045]

preparation Embodiment 6

[0047] Prepare TGA as follows:

[0048] (1) Prepare graphite oxide dispersion liquid: disperse 0.08g graphene oxide in 20mL water, ultrasonically disperse for 3h;

[0049] (2) Preparation of AgNO 3 Solution: 0.2165gAgNO 3 Dissolve in 25mL water;

[0050] (3) in 2gTiO 2 Add 0.1838g sodium citrate in, the graphene oxide dispersion liquid in the step (1) and the AgNO in the step (2) 3 The solution was added to the mixture respectively; stirred for 1h;

[0051] (4) Transfer the mixture to an autoclave, heat up to 180°C, and react for 8 hours;

[0052] (5) naturally cool to room temperature. Wash with ethanol and water three times respectively, and dry at a temperature of 70°C.

preparation Embodiment 7

[0054] Prepare TGA as follows:

[0055] (1) Prepare graphite oxide dispersion liquid: disperse 0.12g graphene oxide in 20mL water, ultrasonically disperse for 4h;

[0056] (2) Preparation of AgNO 3 Solution: 0.3188gAgNO 3 Dissolve in 25mL water;

[0057] (3) in 3gTiO 2 Add 0.1838g sodium citrate in, the graphene oxide dispersion liquid in the step (1) and the AgNO in the step (2) 3 The solution was added to the mixture respectively; stirred for 1h;

[0058] (4) Transfer the mixture to an autoclave, heat up to 180°C, and react for 8 hours;

[0059] (5) naturally cool to room temperature. Wash with ethanol and water three times respectively, and dry at a temperature of 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com