InGaN/GaN multi-quantum-well single-nano-pole LED device and manufacturing method thereof

A technology of LED devices and multiple quantum wells, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems that hinder the development and application of nano-devices, the processing technology cannot be realized, and the cost of preparing a single root is high, so as to weaken the influence and achieve successful production. High efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

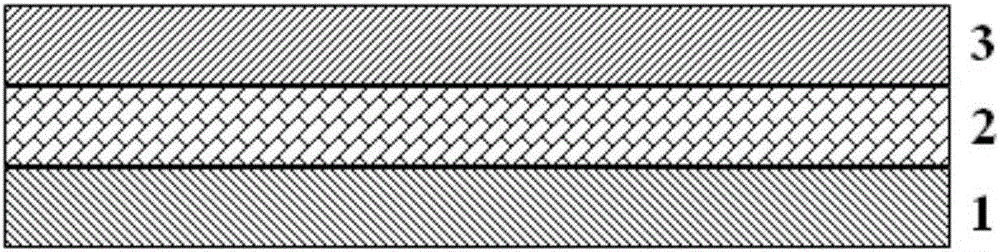

[0056] The InGaN / GaN multi-quantum well single nanocolumn LED device comprises:

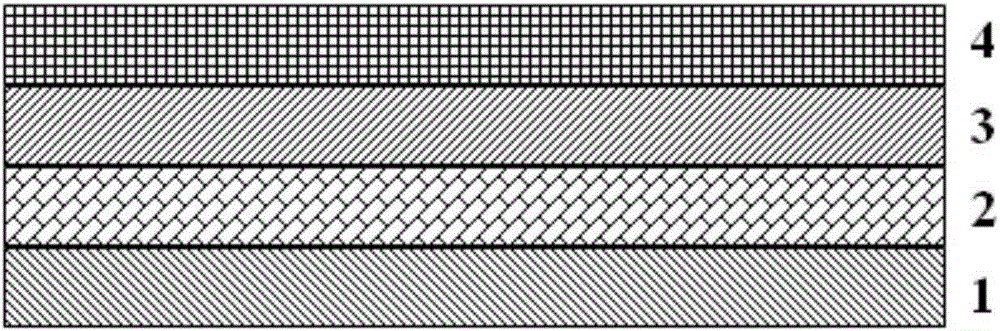

[0057] A1. A 300nm-thick layer of SiO is grown on an InGaN / GaN multi-quantum well LED substrate with an In composition of 0.3, a luminous wavelength of 510nm, and a quantum well period of 10. 2 Insulation layer, 200nm thick PMMA glue and 30nm thick UV curing glue were spin-coated on SiO 2 The surface of the insulating layer; the thickness of the P-type GaN layer of the InGaN / GaN multi-quantum well LED substrate is 500nm, the thickness of the InGaN well layer is 3nm, the thickness of the GaN barrier layer is 12nm, and the thickness of the n-type GaN layer is 2um;

[0058] A2. Using UV soft nano-imprint technology, the soft template prepared in advance and treated with anti-adhesive treatment is in close contact with the surface of the UV-cured adhesive layer of the device, fully exposed to the UV lamp to cure the UV-cured adhesive, and then demoulded, so that The soft template is separated from t...

Embodiment 2

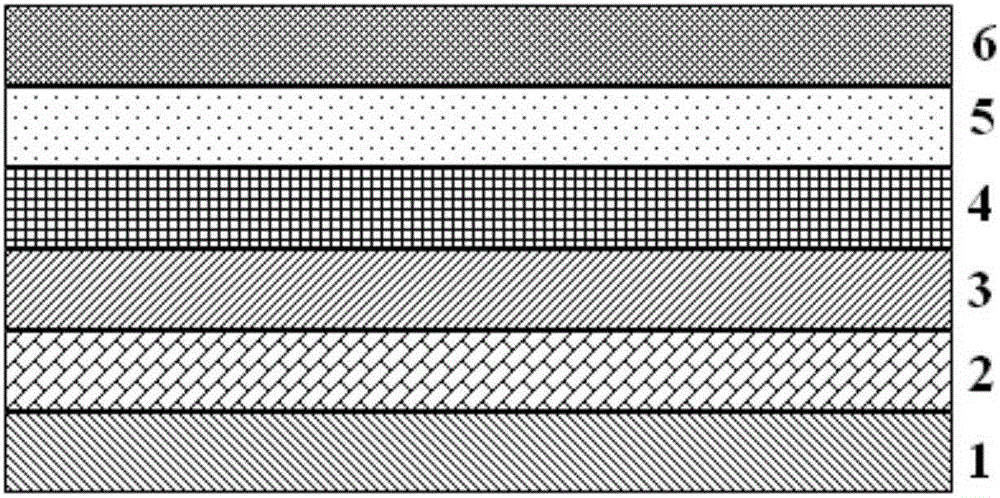

[0073] This InGaN / GaN multi-quantum well single nanocolumn LED device is made by the method of Example 1, the difference is that the device substrate is quartz, and the device insulating layer is SiO 2 layer, the thickness is 50nm, the period number of the InGaN / GaN quantum well active layer is 15, the In composition is 0.35, the emission wavelength is 550nm, the thickness of the p-type GaN layer is 300nm, and the thickness of the n-type GaN layer is 1.5μm , the diameter of the prepared nano-column is 500nm, the length is 3.5μm, the metal electrode film layer is Ni / Au / Ti / Au four-layer metal film obtained by electron evaporation deposition, the thickness is 500nm, the size of the Pt electrode is 400nm×400nm , with a deposition height of 500 nm.

Embodiment 3

[0075] This InGaN / GaN multi-quantum well single nanocolumn LED device is made by the method of embodiment 1, the difference is that the device substrate is PDMS, and the device insulating layer is SiO 2 layer, the thickness is 200nm, the period number of the InGaN / GaN quantum well active layer is 12, the In composition is 0.12, the emission wavelength is 430nm, the thickness of the p-type GaN layer is 400nm, and the thickness of the n-type GaN layer is 3μm, The diameter of the prepared nanocolumn is 70nm, the length is 0.8μm, the metal electrode film layer is a Ti / Au double-layer metal film obtained by electron evaporation deposition, the thickness is 200nm, the size of the Pt electrode is 200nm×200nm, and the deposition height is 200nm .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com