Laser holographic digital lens die and manufacturing method thereof

A technology of laser holography and lens molds, which is applied in the field of holographic lenses, can solve the problems of low mold production success rate, complex optical path, and many diffraction elements, and achieve the effect of improving the production success rate and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

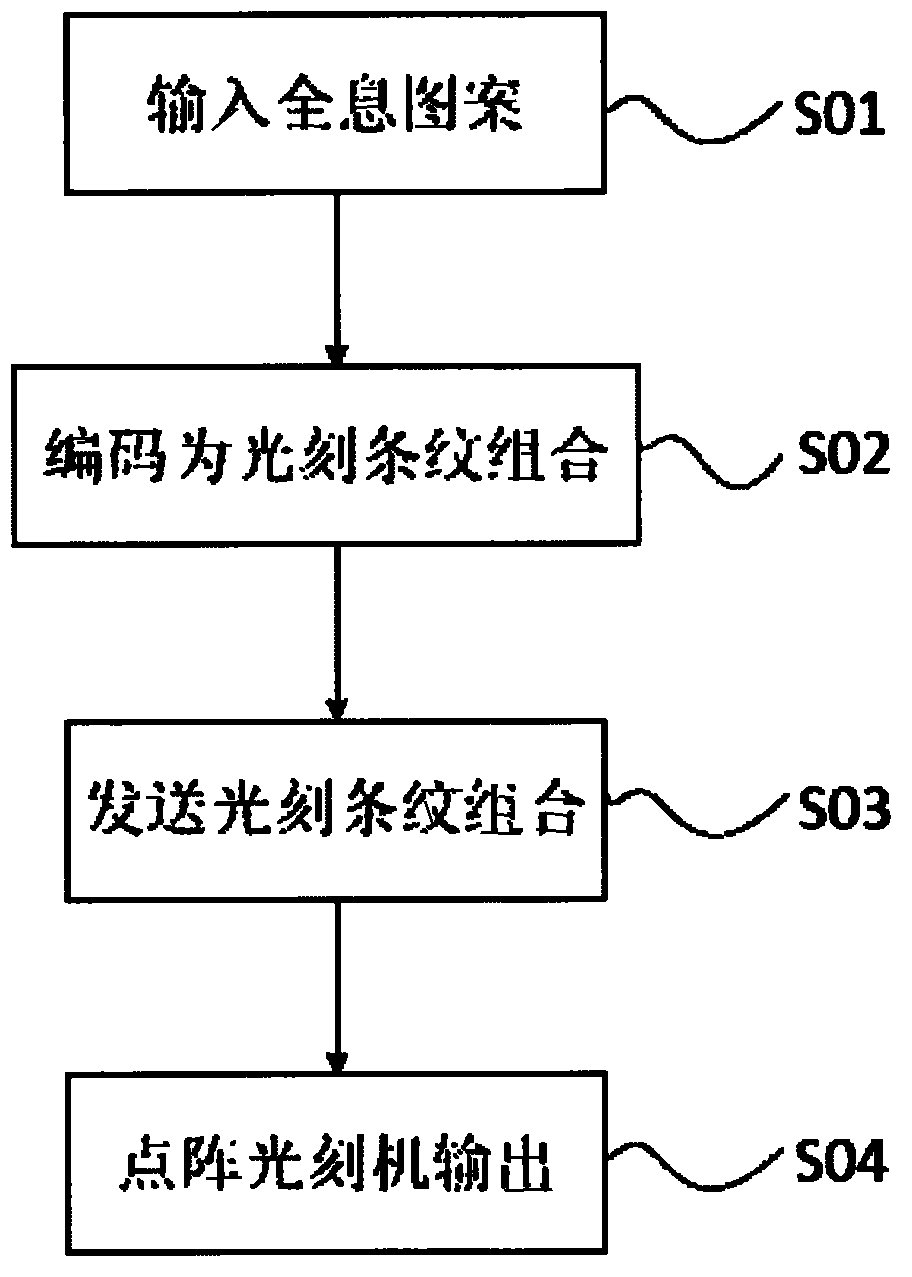

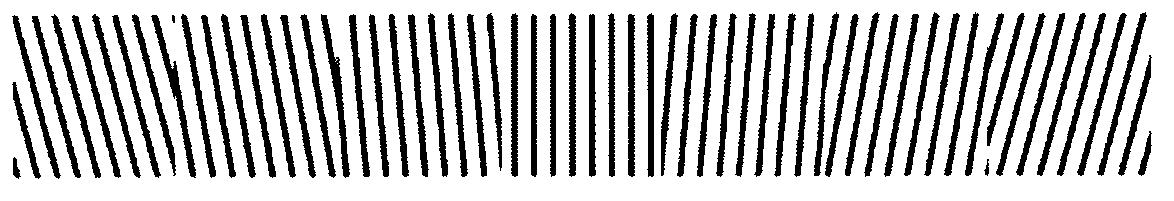

[0027] Such as figure 2 As shown, the stripes of the same frequency are photolithographic stripes of different spatial angles at each pixel point on the horizontal straight track, and the angles change sequentially, and the angle between the photolithographic stripes between adjacent pixel points is 10° that changes continuously in sequence. In this way, pixel points of photolithographic stripes at different angles are realized. Those skilled in the art can understand that, in specific implementation, different lithography stripe angle changes can be adopted according to actual needs, such as 2 degrees, 5 degrees, 20 degrees, etc., the smaller the lithography stripe angle changes, the more The more the optional number of engraved stripe angles, the more detailed and complex the visual effect.

Embodiment 2

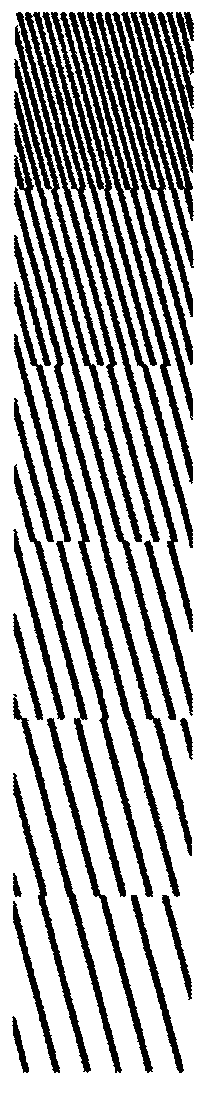

[0029] Such as image 3 As shown, the stripes of the same spatial angle adopt different frequencies of photolithographic stripes for each pixel point on the longitudinal linear trajectory. In the second embodiment, the photolithographic stripes of six different frequencies are used, which are successively reduced, so as to realize different frequency Pixels of photolithographic stripes. The lens texture obtained by using the embodiment is an off-axis convex lens. Those skilled in the art can understand that, in a specific implementation, a plurality of photolithographic stripes with different frequencies, for example, 12, can be used according to actual needs. The more the frequency of the photolithographic stripes, the more detailed and complex the visual effect will be.

Embodiment 3

[0031] Such as Figure 4 As shown, the fringes of the same frequency are photolithographic fringes of different spatial angles at each pixel point on the circular locus, and the angles change sequentially. Using multiple circular trajectories, the frequency change trajectories are scaled with concentric circles, the inner circle has low frequency, and the outer circle has high frequency. The lens texture obtained by using this scheme is a coaxial convex lens.

[0032] other embodiments

[0033] It should be noted that the variation track of spatial angle and frequency in the above embodiment can be designed by those skilled in the art according to needs, for example Figure 5 , the example shown in 6. When the pattern is composed of multi-frequency and multi-angle composite modulation microstructure stripes, the change of angle or frequency is regular at the same time, and those skilled in the art can realize laser holographic digital lens effects with different textures thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com