Soft X-ray double-frequency gratings and manufacture method thereof

A dual-frequency grating and X-ray technology, applied in the scientific field, can solve the problems of ensuring consistency, many components, and low control accuracy, and achieve the effect of long service cycle and high production success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

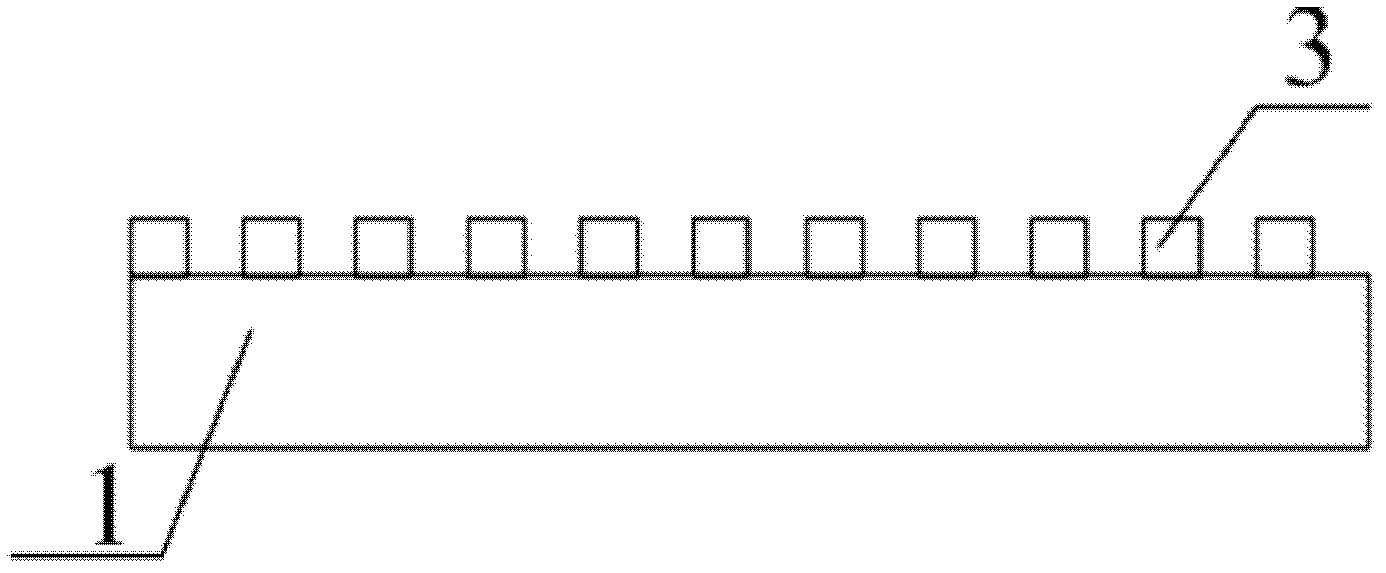

[0045] The cross-sectional view of the X-ray working grating is as follows: figure 2 (i) shown. Its grating groove structure is composed of two groups of rectangular groove gratings etched on the same quartz substrate, and the surface is plated with gold film.

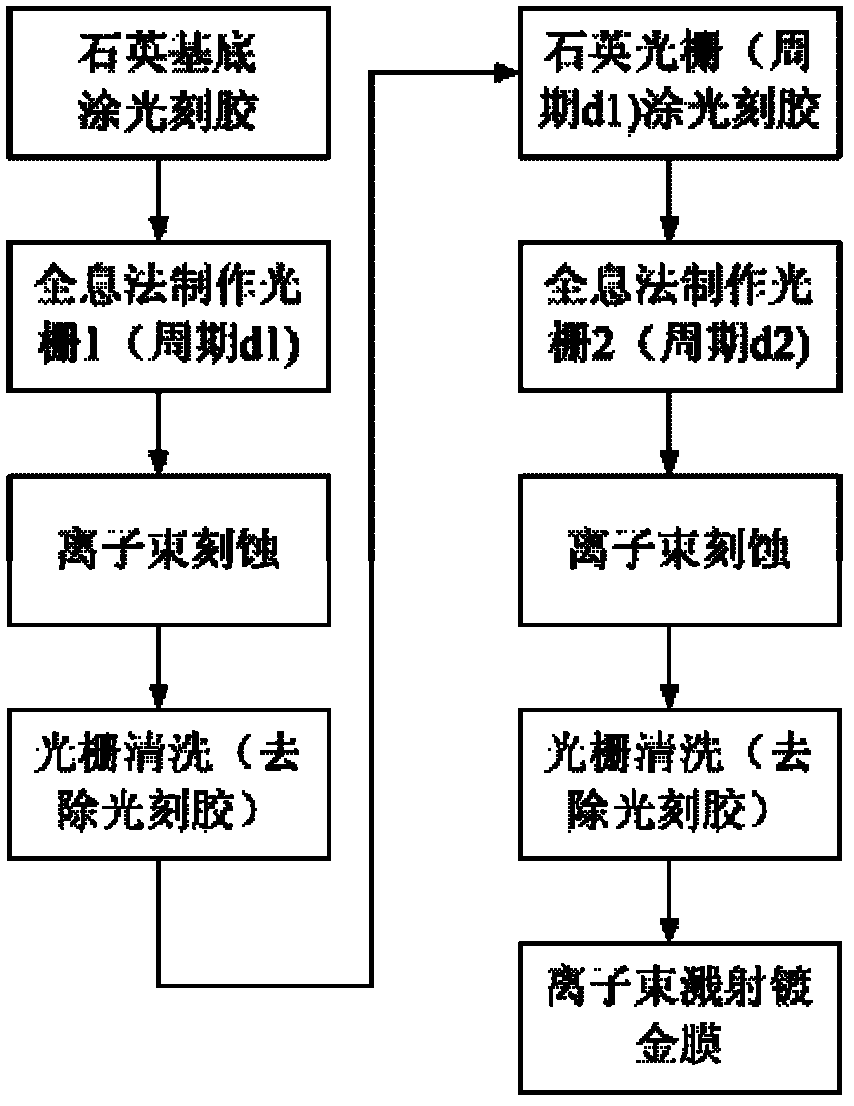

[0046] In order to realize the above-mentioned dual-frequency grating structure, the present invention proposes a preparation method of the dual-frequency grating, including holographic exposure, ion beam etching, cleaning, further holographic exposure, ion beam etching, cleaning and coating processes. The specific production process is as figure 1 shown.

[0047] Its production steps are as follows:

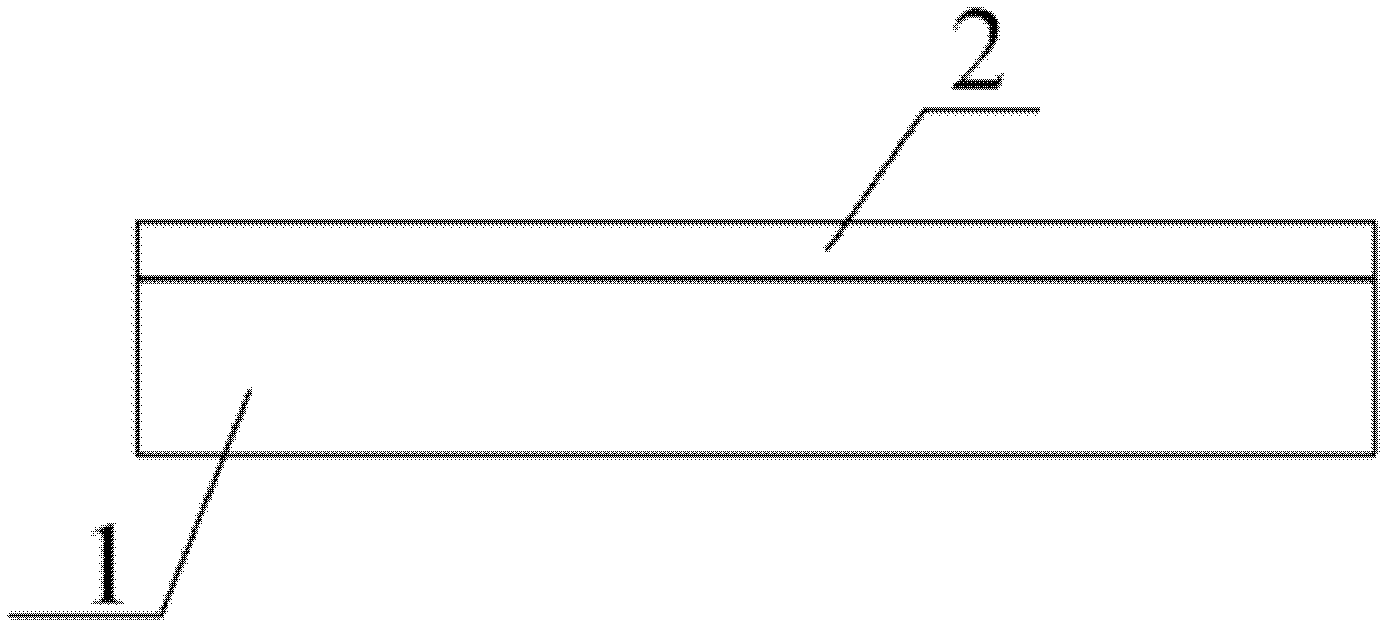

[0048] Step 1. Coat photoresist on a quartz substrate whose surface shape is better than 1 / 10 wavelength and whose optical surface roughness is better than 0.5nm. figure 2 (a).

[0049] Step 2. Use a Kr ion laser with a wavelength of 0.4131 μm to perform holographic exposure method with a period of 1 μm, develop w...

Embodiment 2

[0060] Such as figure 1 , figure 2 As shown: (a) Coat photoresist 2 on a quartz substrate 1 with a size of 60mm×60mm×10mm and a surface shape better than 1 / 10 of the wavelength (wavelength is 632.8nm), with a thickness of 200nm, bake the glue, and temperature 85°C for 30 minutes. (b) Carry out the holographic exposure method to make a photoresist grating mask 3 with a period of 1 μm. After developing with a photoresist developer, dry it in an oven at a temperature of 110° C. for 30 minutes to obtain a double-frequency grating Photoresist relief pattern of the first set of gratings. (c) Etching the grating mask with an etching depth of 14 nm by using an ion beam etching machine. (d) Utilize acetone to clean the etched quartz substrate, and then use a volume ratio of 2:1 concentrated sulfuric acid: hydrogen peroxide (30%) to clean the quartz substrate to obtain a relief with a period of 1 μm and a depth of 14 nm Structured Quartz Grating Graphics. (e) Coating photoresist 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com